Showing 21 items matching "textile design textile production"

-

National Wool Museum

National Wool MuseumBook, Instruction Paper No.513: Pile Weaves, 1st Ed

... Textile Design Textile Production Textile Industry - education... Textile Industry - history Textile Design Textile Production ..."Instruction Paper No.513: Pile Weaves, 1st Ed." - International Correspondence Schools Ltd."Instruction Paper No.513: Pile Weaves, 1st Ed." - International Correspondence Schools Ltd.weaving textile machinery textile industry - history textile design textile production textile industry - education, international correspondence schools ltd, corduroy, carpet, velvet, weaving, textile machinery, textile industry - history, textile design, textile production, textile industry - education -

National Wool Museum

National Wool MuseumLabel, Blanket, Physician Chillproof Blanket

... Textile Design Textile Production... by Collins Bros Pty Ltd. Textile Design Textile Production Collins ...Woven labels for 'Physician' blankets produced by Collins Bros Pty Ltd.Woven labels for 'Physician' blankets produced by Collins Bros Pty Ltd.Physician CHILLPROOF BLANKET EXTRA SUPER FINE PURE MERINO WOOL MOTHPROOFED MADE IN AUSTRALIAtextile design textile production, collins bros mill pty ltd, textile design, textile production -

National Wool Museum

National Wool MuseumClothing - Jacket, Mrs Jean Inglis, 1988

... Weaving Textile Design Textile Production Shibori Kumo Shibori ...This jacket is by the prolific spinner and weaver Jean Inglis. It has been woven with a warp of commercially brought wool & a weft of hand spun Corriedale. It is completed in a Swedish lace style of weaving. The highlight of the jacket is the blue section of fabric on the top left shoulder of the wearer, which works down to the bottom right hip. This pattern looks like long thin individual separate sections of fabric stitched to the jacket; however, only one section of fabric has been added. A dying technique has been utilised to give the appearance of multiple sections. This Japanese dyeing technique is called Shibori, “to wring, squeeze or press". It is a manual tie-dyeing technique, which produces several different patterns on fabric. The specific pattern on this fabric is known as Kumo Shibori. It utilises bound resistance. This technique involves folding sections of the cloth very finely and evenly. Then the cloth is bound in very close sections. The result is a very specific spider-like design. This design requires very precise technique. Specific to this jacket, the fabric for the dyed section was made with the same fabric as the rest of the jacket. A section of the excess fabric was concertina wrapped around a 100mm pipe and tied up before dying. This gives the consistent straight blue lines, with no bleed from the dye. The sections were then sewed into the jacket with the occasional sequin added for additional decoration and glamour. The jacket won 1st prize at the 1988 Geelong Show. Jean was assisted by the dress maker Ruth Randell with some of the design and sewing. Jean always found sewing “a bit of a bore”. The jacket also has an attached swing tag. It was added to provide information to the judges at the Melbourne Show on how the jacket was created. It comes complete with Jean’s self-proclaimed terrible handwriting. It was donated to the National Wool Museum in 2021.Cream singled breasted jacket with no overlap. The jacket has no column of buttons for fastening, or lapels. It is designed to be plain, to not draw attention. The jacket is highlighted by the Shibori dyed waves on the top left shoulder of the wearer, which works down to the bottom right hip. This blue dyed section of fabric is dotted with the occasional blue sequin. Internally, the jacket features a white silk lining for comfort. The jacket ends in a straight cut hem, including at the cuffs. The jacket has an attached swing tag. The swing tag is cream with a printed thin black boarder. Within the boarder, handwriting in black ink is found. It has a hole punch in the top left corner of the swing tag for attaching to the jacket.hand spun, hand weaving, textile design, textile production, shibori, kumo shibori -

National Wool Museum

National Wool MuseumBook, Cloth Sample

... designs, they did not necessarily go into production.. Textile ...One of four tarpaper covered sample books. These samples were made up at mills (often R S & S) to Alexander Lau designs, they did not necessarily go into production..LADIES' MATERIALtextile design fashion textile industry - history, alexander lau pty ltd, lau, mr alexander - alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample

... into production.. Textile Design Fashion Textile Industry - history ...One of four tarpaper covered sample books. These samples were made up at mills (often R S & S) to Alexander Lau designs and specifications, they did not necessarily go into production..LADIES' MATERIALtextile design fashion textile industry - history, alexander lau pty ltd, lau, mr alexander - alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample

... into production.. Textile Design Fashion Textile Industry - history ...One of four tarpaper covered sample books. These samples were made up at mills (often R S & S) to Alexander Lau designs and specifications, they did not necessarily go into production..LADIES' MATERIAL/ Spring 57, Winter 57-58 Messres S G SAVIGEtextile design fashion textile industry - history, alexander lau pty ltd, lau, mr alexander - alexander lau pty ltd savige, s g - returned soldiers and sailors mill, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample

... into production.. Textile Design Fashion Textile Industry - history ...One of five tarpaper covered sample books. These samples were made up at mills (often R S & S) to Alexander Lau designs and specifications, they did not necessarily go into production..LADIES' MATERIALtextile design fashion textile industry - history, alexander lau pty ltd, lau, mr alexander - alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample

... into production.. Textile Design Fashion Textile Industry - history ...One of five tarpaper covered sample books. These samples were made up at mills (often R S & S) to Alexander Lau designs and specifications, they did not necessarily go into production..LADIES' MATERIALtextile design fashion textile industry - history, alexander lau pty ltd, lau, mr alexander - alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample

Production samples from Alexander Lau Pty Ltd. 1967 - 1970.ALEXANDER LAU PTY LTDtextile design fashion textile industry - history, alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

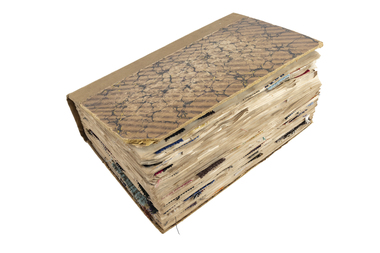

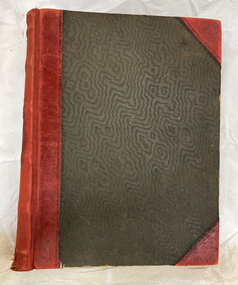

National Wool MuseumBook, Cloth Sample, 1928

Production samples from Returned Soldiers and Sailors Mill, given to Mr Alexander Lau before the mill closure.Sample book: textile sample book, cardboard cover, cloth bound. The cover is in a mottled brown pattern, the spine has "1928" handwritten at the top. Inside , small textile sampples are glued and later stapled, to paper pages. The pages have numerous handwritten inscriptions and are headed by dates, beginning 1958-1959.1958-1959 varioustextile design fashion textile industry - history, alexander lau pty ltd returned soldiers and sailors mill, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample, 1928

Production samples from Returned Soldiers and Sailors Mill, given to Mr Alexander Lau before the mill closure.varioustextile design fashion textile industry - history, alexander lau pty ltd returned soldiers and sailors mill, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample, 1931

Production samples from Returned Soldiers and Sailors Mill, given to Mr Alexander Lau before the mill closure.1958-59 varioustextile design fashion textile industry - history, alexander lau pty ltd returned soldiers and sailors mill, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumProduction sheets

Season 1951-1952textile design fashion textile industry - history, alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumTextile - Yarn Display

Samples of woollen yarn mounted on a board. From the Collins Bros' Mill, used by textile designs for creating patterns and design for sale to the publicSample display. Numbered cards of woollen yarn mounted on a wood display board. The woollen yarn is multi-coloured. yarn production, collins bros mill pty ltd -

National Wool Museum

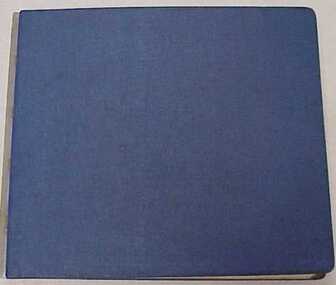

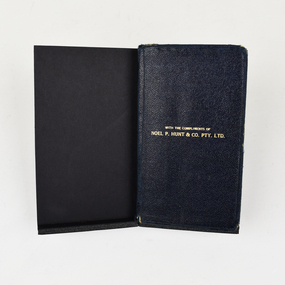

National Wool MuseumBook - Notebook, Collins Textile Diary - 1958, 1958

... the stories of Australian Textile design. This notebook contains ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. This notebook contains information on how to calculate and enlarge a small sample pattern into a larger textile. The equations would provide answers to the required length of thread (often measured in weight as opposed to distance) of a selected textile. The sample and appropriate thread would be needed for mass production at a commercial mill.Blue textured vinyl forms the covers of this notebook. On the front of the inscription is visible in gold text. Internally, small font black writing on yellowing pages forms most of this notebook. Pp.128 published pages with calendar and spare pages for notes forming the second half of this notebook. Front Cover. Words, printed. WITH THE COMPLIMENTS OF / NOEL P. HUNT & CO. PTY. LTD.textile design, textile calculations -

National Wool Museum

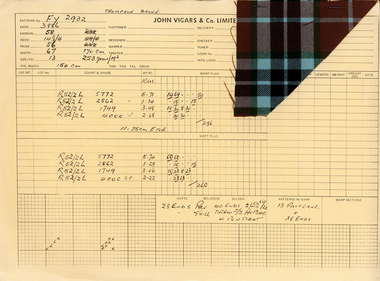

National Wool MuseumDocument - Mastercard, 1970-1975

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. Once a pattern has been selected for mass production, a master card is produced. A mastercard shows exactly how to replicate the designs and colours depicted on the sample attached. “Ends” is the technical word to describe a vertical band and “picks” describes a horizontal band.Brown card with fabric sample stapled to the top right. Writing is present on the left and bottom of the card detailing the information applicable to the design of attached fabric. 14 individual Masetercards in collectiontextile calculations, textile design -

National Wool Museum

National Wool MuseumBook - Cloth Sample Book, Yarra Falls Mills, 10 March 1927

... Textile Production Textile Design Textile Mills..., Melbourne. Textile Production Textile Design Textile Mills Forrest ...Book of fabric samples produced by Yarra Falls Pty Ltd, Melbourne.Large cloth and leather bound book of fabric samples, text and figures. Spine and corners of red leather and rest of cover dark green. Book manufacturers label past on inside cover. Two small white labels with numbers pasted on spine.Arbuckle Waddell Pty. Ltd. Printerstextile production textile design textile mills, forrest, mr craig - yarra falls pty ltd, melbourne, victoria, textile production, textile design, textile mills -

National Wool Museum

National Wool MuseumTextile - Children's Lace Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream short sleeved jumper with overall open lace design, front yoke with accent lacework and applied lace ruffle edging .2 is a retail tag with style code and size, reverse has washing instructions for acrylic and cotton.1) [white tag back neck, printed blue letters] KATHRYN REGD POLYESTER/VISCOSE MADE IN AUSTRALIA .2 [retail swing tag, numbers handwritten in blue ink] KATHRYN Children’s Knitwear STYLE [handwritten] 363 PRICE SIZE [handwritten] 6children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, machine lace -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White lacework baby romper suit with long sleeves and legs, and enclosed feet. Closes at centre back with two plastic buttons. Zips open around leg inseam. Size 00 .2 is a retail tag marked with the price and size, and refers to the label sewn into the garment for washing instructions..2 [Retail Swing Tag] [Obverse] KATHRYN Children’s Knitwear STYLE PRICE [handwritten] $18 SIZE [handwritten] 00 [Reverse] WASHING INSTRUCTIONS Refer to label sewn in Garment Designed and manufactured by ROBERT BLAKE PTY. LTD., Melb., Aust.children's knitwear, children's clothing, baby clothing, baby knitwear, clothing, knitwear, romper, jumpsuit, manufacturing, fashion textile production, machine knitting, machine lace, baby clothes -

National Wool Museum

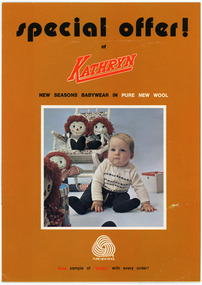

National Wool MuseumPamphlet - Mail Order Pamphlet, Kathryn Knitwear et al, 1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. They also established ‘Woolknit Distributors’, a mail-order service that sold ‘Kathryn’ quality garments at a lower price point. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Advertising pamphlet for Kathryn Knitwear’s direct-to-consumer subsidiary ‘Woolknit Distributors’. Consists of four pages, printed in colour. Front cover is orange and features an image of a baby sitting up on the floor with a toy box and rocking chair behind. There are four rag dolls on the left hand side of the image; two sitting on the seat of the rocking chair, one at the base, and one in the foreground. Below the image is the woolmark logo. The internal pages are laid out as a double page spread, with the left hand side detailing instructions for ordering and a description of the offered garments, and the right hand side featuring drawings of babies wearing the garments available for purchase. The back page is a full-page advertisement for ‘Softly’ detergent, and features a blonde woman wearing a blue jumper with matching blue eyeshadow with a blonde baby wrapped in a white blanket. The bottom of the page has a coupon for 40c off a purchase of ‘Softly’.[obverse] special offer! of KATHRYN NEW SEASONS BABYWEAR IN PURE NEW WOOL (woolmark logo) PURE NEW WOOL Free sample of “Softly” with every order! [internal] 8 EXQUISITE STYLES AT PRICES YOU CAN’T AFFORD TO MISS … ! Woolknit distributors* brings you an exciting range of new seasons pure wool baby clothes made by leading children’s wear manufacturer “Kathryn” mailed direct to you at no extra cost. - STYLED IN A DELIGHTFUL RANGE OF COLOURS… - DESIGNED EXCLUSIVELY IN WOOL FOR SAFETY, WARMTH, COMFORT AND LONG LIFE… - ALL HAND WASHABLE FOR EASY CARE… - A MONEY BACK GUARANTEE FROM WOOLKNIT DISTRIBUTORS IF YOU ARE NOT COMPLETELY SATISFIED… Just select your style number from the list below: Fill in details of colour, size and quantity required on the enclosed card. Mail it in the reply paid envelope and print your name and address clearly. Send only cheque, postal order or money order. Do not enclose stamps, coins or bank notes. [left column] 15/MJ Matinee jacket with collar in Warm white; blue; lemon; pink. Size 16” only $3.50 16/MJ Pop your little bundle into this lacy matinee jacket. Warm white; blue; lemon; pink. Size 16” only $3.30 117/CSW All winter warmth in this com- bination suit with smart ‘fair- isle’ pattern and zip front. Red/ Warm white; Empire blue/Warm white; Sky blue/Warm white. Sizes 16” and 18”. $6.50 625/3 Beautifully styled pram set, keeps baby cosy from top to toe. Jacket, cap and breech- ettes. Warm white; blue; lemon; Pink. Sizes 16” and 18” and 20”. $9.30 681/CW Delightful baby cardigan in purl knit. Warm white; blue; lemon; pink. Sizes 18”, 20” and 22”. $4.30 [right column] 629/3 Three-piece pram set, including Frock, bonnet and breechettes. Warm white; lemon; pink. Sizes 16” and 18”. $10.00 Each item available individu- ally :- 629/B – Breechettes. Warm white; lemon; pink. Sizes 16” and 18” $3.00 629/C – Bonnet. Warm white; lemon; pink. Sizes 16” and 18” $1.60 629/F – Frock, hand embroidered. Warm white; lemon; pink. Sizes 16” and 18” $5.40 721/PW Cuddly pullover in purl knit keeps out winter winds. Warm white; blue; lemon; pink. Sizes 18”, 20” and 22”. $4.30 Shawl. Exquisitely knitted, super-fine shawl. Warm white only. $9.50 SIZE CHART Baby’s age / 0-6mths / 6mths. to 1 year / 1 to 2 years / 2 to 3 years Size of garment to order / 16 / 18 / 20 / 22 *WOOLKNIT DISTRIBUTORS PTY. LTD. 30 HALL STREET, MOONEE PONDS, VICTORIA, 3039 [reverse] Softly care keeps woollens soft as new Softly is safe for all kinds of woollens From the delicate things baby wears to the heavy winter blankets you wash in your machine. Softly gently cleans and protects. Leaving them soft as new. Try Softly yourself by taking advantage of the offer below. Do it now – for your woollens’ sake.business, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, mail order