Showing 12 items matching "textile fibres textile production"

-

National Wool Museum

National Wool MuseumBook, Textiles for Modern Living

... Textile Fibres Textile Production... for secondary school students. Textile Fibres Textile Production Textile ..."Textiles for Modern Living" - E.P.G. Gohl & L.D. Vilensky, Longman Cheshire, 3rd ed., 1987. Reference book for secondary school students.textile fibres textile production, textile fibres, textile production -

National Wool Museum

National Wool MuseumJournal, Wool Record

... Wool Processing Wool Marketing Textile Fibres Textile... Textile Fibres Textile Industry Textile Production Wool Record ..."Wool Record" Vol. 100, No. 2745, Bradford, Fri. Dec. 22, 1961.wool processing wool marketing textile fibres textile industry textile production, wool processing, wool marketing, textile fibres, textile industry, textile production -

National Wool Museum

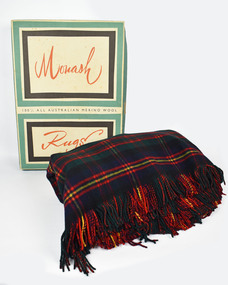

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumBook, Industrial Fibres: a review

... Textile Fibres Textiles - industrial Textile Industry... Textile Production Industrial Fibres: a review Book ..."Industrial Fibres: a review of production, trade and consumption relating to wool, cotton, silk, flax, jute, sisal and other hemps, mohair, coir, kapok, rayon and other man-made fibres" - Commonwealth Economic Committee - Intelligence Branch, London, 1960.textile fibres textiles - industrial textile industry textile production, commonwealth economic committee, textile fibres, textiles - industrial, textile industry, textile production -

National Wool Museum

National Wool MuseumReport, Commercial textiles in Australia: a growth market, but will wool benefit?

... Textiles - upholstery Textile Fibres... Production Wool Marketing Textiles - upholstery Textile Fibres ..."Commercial textiles in Australia: a growth market, but will wool benefit? " A G Pinches, Head of Marketing, International Wool Secretariat, April 1981L E WARDtextiles - industrial textile production wool marketing textiles - upholstery textile fibres, international wool secretariat australian wool corporation, carpet, textiles - industrial, textile production, wool marketing, textiles - upholstery, textile fibres -

National Wool Museum

National Wool MuseumBook, Introductory Textile Science

... Textile Fibres Yarn production Weaving Textile Production... L. Joseph, 1972. Textile Fibres Yarn production Weaving ..."Introductory Textile Science" 2nd ed. - Marjory L. Joseph, 1972.textile fibres yarn production weaving textile production textile finishing, felting, textile fibres, yarn production, weaving, textile production, textile finishing -

National Wool Museum

National Wool MuseumBook, How to Know Textiles

... Textile Fibres Weaving Machine Knitting Yarn production..., 1932. Textile Fibres Weaving Machine Knitting Yarn production ..."How to Know Textiles" - Cassie Paine Small, 1932.textile fibres weaving machine knitting yarn production cotton silk, lace, dyeing, cloth - woollen, cloth - worsted, rayon, textile fibres, weaving, machine knitting, yarn production, cotton, silk -

National Wool Museum

National Wool MuseumBook, Wool: the fashion fibre

... Production Australian Wool Corporation Fashion Textile Production ..."Wool: the fashion fibre" - Australian Wool Corporation, c.1985. Examines the use of wool for womens garments and includes descriptions of processes and styles.fashion textile production, australian wool corporation, fashion, textile production -

National Wool Museum

National Wool MuseumBook, Wool: eminently suitable

"Wool: the fashion fibre" - Australian Wool Corporation, c.1985. Examines the use of wool for mens garments and includes descriptions of processes and styles.fashion textile production, australian wool corporation, fashion, textile production -

National Wool Museum

National Wool MuseumBook, Lanificio Ing. Loro Piana & C. spa Italia

... Textile Production Wool - superfine Textile Fibres Merino... and superfine wool. Textile Production Wool - superfine Textile Fibres ..."Lanificio Ing. Loro Piana & C. spa Italia" 1988. History of the Italian textile manufacturing company Lanificio Ing. Loro Piana & C. Includes photos of processes and products. They make use of vicuna and cashmere, as well as Tasmanian merino and superfine wool.textile production wool - superfine textile fibres merino sheep, lanificio ing. loro piana & c., textile production, wool - superfine, textile fibres, merino sheep -

National Wool Museum

National Wool MuseumBook, Principles of worsted spinning

... Textile Fibres Yarn production... Priestman, 1921 Textile Fibres Yarn production Yarn - worsted ..."Principles of worsted spinning 2nd ed" - Howard Priestman, 1921textile fibres yarn production, yarn - worsted, spinning, textile fibres, yarn production -

National Wool Museum

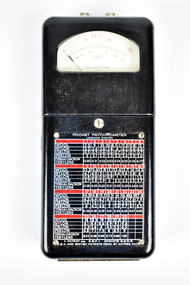

National Wool MuseumInstrument - Psychrometer, Electronova S.A, c.1965

Kathryn Knitwear Collection A Psychrometer is an instrument used to measure humidity using two thermometers, one of which is wet and one is dry. A similar example is housed at laboratoire d'histoire des sciences et des techniques (LHST). Inventory number 603.0509 Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black metal measuring instrument with clear window to view gauge for displaying humidity. Reference table listing values for different fibres is printed in red and white on a black metal plate that is screwed onto the front of the psychrometer. The instrument is housed in brown leather case with zip. It includes a printed paper instruction book with black text and greyscale figures.psychrometer, measuring instrument, humidity, textile manufacturing, fashion textile production