Showing 51 items matching "textile industry knitting"

-

National Wool Museum

National Wool MuseumSocks

... textile industry knitting... by Scallywags. textile industry knitting scallywags industries textile ...Pair of grey woollen socks, green and white diamond pattern, c1930's and 1940's, possibly manufactured by Scallywags.Pair of grey woollen socks, green and white diamond pattern, c1930's and 1940's, possibly manufactured by Scallywags.textile industry knitting, scallywags industries, textile industry, knitting -

National Wool Museum

National Wool MuseumSock

... Textile Industry Knitting... . Textile Industry Knitting Scallywags Industries Textile Industry ...Grey woollen sock, green red ,white and blue decoration, c1930's and 1940's, possibly manufactured by Scallywags .Grey woollen sock, green red ,white and blue decoration, c1930's and 1940's, possibly manufactured by Scallywags.textile industry knitting, scallywags industries, textile industry, knitting -

National Wool Museum

National Wool MuseumSock

... Textile Industry Knitting... manufactured by Scallywags . Textile Industry Knitting Scallywags ...A men's fine woollen sock, plain navy blue, woven with fine ribbing, c1930's and 1940's, possibly manufactured by Scallywags .A men's fine woollen sock, plain navy blue, woven with fine ribbing, c1930's and 1940's, possibly manufactured by Scallywags.textile industry knitting, scallywags industries, textile industry, knitting -

Clunes Museum

Clunes MuseumTextile - KNITTED SAMPLE, INTERKNIT

INTERKNIT WAS INDUSTRY STARTED IN CLUNES AFTER THE GOLDMINING HAD CLOSEDSAMPLE SHOWING 6 DIFFERENT PATTERNS OF KNITTING WITH KNITTED BAND. MOUNTED ON CARDBOARD WITH INTERKNIT HANDWITTEN SIGN.interknit, sample, knitted, wool -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

... Weaving Textile Industry - history Textile Production... Industry - history Textile Production Machine Knitting Textile ..."Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

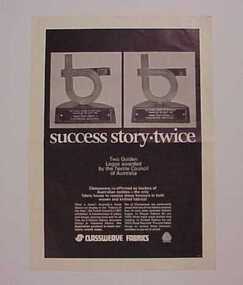

National Wool MuseumAdvertising Sheet, success story twice

... Textile Industry Textile Design Weaving Knitting... down. Textile Industry Textile Design Weaving Knitting Federal ...Acquired when "Classweave Industries" closed down.textile industry textile design weaving knitting, federal woollen mills ltd classweave industries pty ltd textile council of australia, textile industry, textile design, weaving, knitting -

National Wool Museum

National Wool MuseumAdvertising Sheet, success story twice

... Textile Industry Textile Design Weaving Knitting... down. Textile Industry Textile Design Weaving Knitting Federal ...Acquired when "Classweave Industries" closed down.textile industry textile design weaving knitting, federal woollen mills ltd classweave industries pty ltd textile council of australia, textile industry, textile design, weaving, knitting -

National Wool Museum

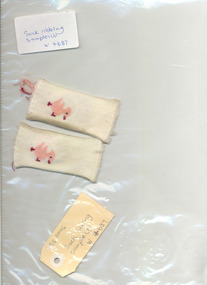

National Wool MuseumSample, Textile

... of childs socks. Machine Knitting Scallywags Industries Sample ...From the Scallywags Mill (unconfirmed). Samples of childs socks.machine knitting, scallywags industries -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

... Weaving Textile Industry - history Textile Production... Industry - history Textile Production Machine Knitting Textile ..."Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

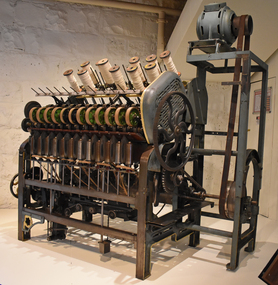

National Wool MuseumMachine - Cap Spinner, 1925

This cap spinner squeezes the thread under the stationary cap and winds them onto the bobbin. Spinning transforms tops into yarns. The tops are pulled out into fine strands known as rovings. They are then twisted to bind the thread together to give the yarn greater strength. The yarns are wound into differently shaped tools. They are then sent off for weaving and knitting.Cap spinning machine.weaving, knitting, cap spinning, cap spinner, machine, textile industry, factory -

National Wool Museum

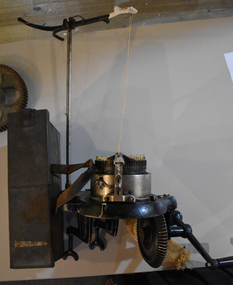

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

... into seamless clothing. Sock Knitting Machine Textile Industry Wool ...Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

National Wool Museum

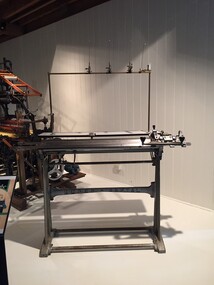

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

Stawell Historical Society Inc

Stawell Historical Society IncBook - Laboratory Reference Book, Knitting, Pitman's Common Commodities and Industries by Harry Wignall

Textbook. Lab Reference - Norwellan & AUNDE North Western Woollen Mills became Norwellan Textiles then AUNDERed hardcover with Red and Cream DustcoverJohn T Bennett, Lyddon Hall Leeds 8/10/1969manufacturing -

National Wool Museum

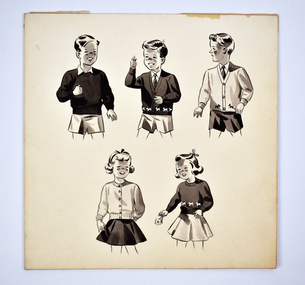

National Wool MuseumDrawing - Illustration, Kathryn Knitwear, c.1961-1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Original illustration artwork on cream matboard/card inked in shades of grey and black. Used for marketing. Depicts Five figures of children in iconic Kathryn knitwear styles. The boy on the top left wears a dark crew neck jumper over a pale collared short with shorts. The two other boys on the top row (at centre and right) are depicted in very similar outfits, though the shades of their clothing differ. They are both shown in v-neck cardigans with three buttons and a colourwork animal motif at the hem over a pale suit with a dark tie. The figure at the centre has a dark cardigan and pale shorts, while the figure at the right has a light cardigan and dark shorts. The two figures on the bottom row are both girls wearing flared skirts with bows in their hair. They both wear crewnecks, the figure on the left wears a pale cardigan with six buttons down the front, while the right wears a dark jumper with two buttons on the shoulder and an animal motif at the hem. The jumper on the girl on the right is the same style as NWM-08893. There is tape still affixed to the back of the boardbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry -

National Wool Museum

National Wool MuseumSlide - Marketing Portraits, c.1970-1980

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.A strip of three medium format colour transparencies. Images are from of a promotional shoot for Kathryn knitwear and feature two children wearing patterned jumpers with an orange and pink kite. Figure on left wears a red turtleneck jumper with a geometric Nordic pattern of diamonds, primarily in white with a dark accent colour. Figure on right wears a cardigan with a shirt-style collar, which is predominantly navy and has a white yoke and geometric Nordic print in red, navy and white. There is a staple in the bottom left-hand corner, and damage along the bottom edge where a staple was removed.business, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

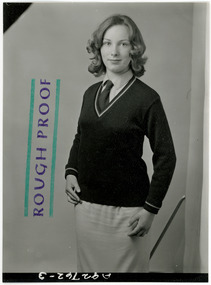

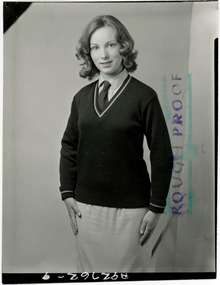

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

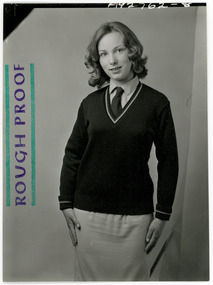

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of a young woman with chin-length curly hair, wearing a dark v-neck jumper with a pale stripe at the neck and sleeve cuffs over a collared shirt and tie. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the bottom edge with white ink is an index code A92762-3 From a promotional shoot for Kathryn Knitwear Collegewear[Obverse (stamped in blue ink with green ink lines above and below)] ROUGH PROOF (upside down) A92762-3 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of a young woman with chin-length curly hair, wearing a dark v-neck jumper with a pale stripe at the neck and sleeve cuffs over a collared shirt and tie. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the top edge with white ink is an index code A92762-8 From a promotional shoot for Kathryn Knitwear Collegewear[Obverse] A92762-8 (stamped in blue ink with green ink lines above and below)] ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

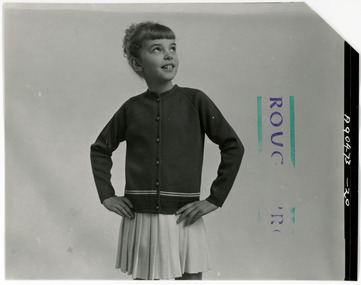

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of a child wearing a pale pleated skirt and dark crew-neck cardigan with two stripes above the hem that closes to the neck with six buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-20 From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below ROUGH PROOF (in white ink along right edge) A90473-20 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

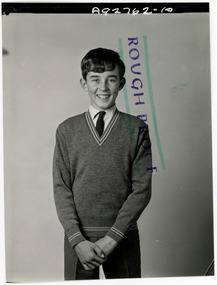

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of an adolescent boy wearing a grey V-neck jumper with a pale stripe at the neck and sleeve cuffs over a collared shirt and tie. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the top edge with white ink is an index code A92762-10 From a promotional shoot for Kathryn Knitwear Collegewear[Obverse] A92762-10 ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

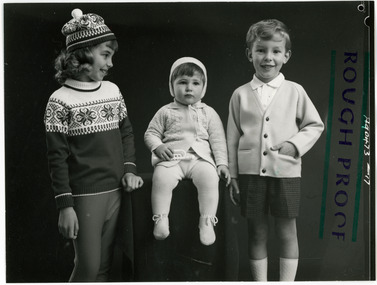

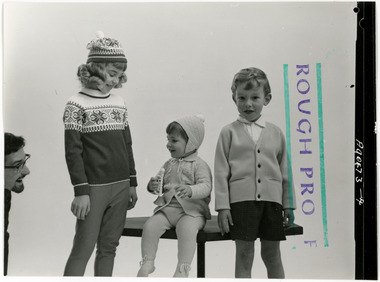

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set od a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Photograph is stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-14 From a promotional shoot for Kathryn Knitwear[Obverse (stamped in blue ink with green ink lines above and below)] ROUGH PROOF A90473-14 [Reverse] LATROBE STUDIOS Advertising Photographers 152 LITTLE LONSDALE St. C.l TELEPHONE 324623 – 4 LINESbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-17 From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink) A90473-17 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the left edge with white ink is an index code A90473-23 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-23 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-28[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink)business, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of a young woman with chin-length curly hair, wearing a dark v-neck jumper with a pale stripe at the neck and sleeve cuffs over a collared shirt and tie. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the top edge with white ink is an index code A92762-9 From a promotional shoot for Kathryn Knitwear Collegewear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink) A92762-9 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of two children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-16 From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink) A90473-16 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle holds a toy trumpet and wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. The face and arm of a man with glasses and a goatee is visible on the left side of the image, smiling widely to encourage the toddler to smile for the camera. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-4 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-4 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of two children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-30 From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink) A90473-30 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972