Showing 18 items matching "textile machine maker"

-

National Wool Museum

National Wool MuseumBook, Finishing Machinery

... Textile Machine Maker..."Finishing Machinery" - James Bailey, Textile Machine Maker..., textile machine maker, Huddersfield, c.1926.... Finishing James Bailey Textile Machine Maker Milling Scouring ..."Finishing Machinery" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Catalogue of machinery for fulling, scouring, carbonising, dyeing and finishing woollen and worsted and other types of textiles.Catalogue of textile finishing machinery from James Bailey, textile machine maker, Huddersfield, c.1926.textile machinery textile finishing, james bailey, textile machine maker, milling, scouring, carbonising, dyeing, raising, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumBooklet, Why Not...?

... Textile Machine Maker..., Textile Machine Maker, Huddersfield, c. 1926. Promotes... ?" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926 ..."Why Not Help the Country in its Economy Campaign by Economising Yourself and thus Increase Your Profits ?" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Promotes the advantages of buying a new scouring machine.Booklet, c.1926. Produced by James Bailey, textile machinery manufacturer, Huddersfield, to promote a new scouring machine.textile machinery textile finishing, james bailey, textile machine maker, scouring, textile machinery, textile finishing -

Federation University Historical Collection

Federation University Historical CollectionCostume, Perhaps made internally at Alfred Hospital, Nurses Apron, Cap and Collar, 1960s

This nurse's collar, cap and apron would have been worn by student nurses at the Alfred Hospital in Melbourne in the 1960's. Although the style did not change much from earlier years the length of the skirt had shortened. The white semi circular collar has a single row of drawn thread work 1.5 centimeters from the outer edge and is made of starched cotton fabric. The cap is made of a half circle of fine white cotton lawn with a turn back front edge bearing the Alfred Hospital emblem. It has a tape casing about 1.5 centimeters from the edge which contains a thin tape for gathering up the edge of the cap. The white cotton apron has a 5 panel skirt, a waistband with four covered buttons and a bib front which went over the shoulders and buttoned at the back of the waistband.The collar has written in black marker - D.L.Ross E.37; Also written in black marker - E980; A tape printed and machine stitched on - L.A. Holberton The cap has a printed emblem - Alfred Hospital Incorp. Melbourne, Service and Care The apron has written in black maker - M Taylor; E877; J. Williamsalfred hospital, nursing, nurse uniform, student nurse uniform, nurse apron, nurse cap, nurse collar, apron, costume, textiles -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumTextile - Quilt, Domestic Wagga, 1950s

Part of the Running Stitch collection, possibly made in BallaratDomestic wagga, unfilled, consisting of two machine sewn layers of woollen garment pieces both knitted and woven. The front pieces are predominantly red, blue and yellow, the back is mostly brown red and blue.WAGGA/ Maker unknown 154cm long X 90cm wide/ Made of parts of wool garments, knitted and woven.....handicrafts quilting quilting - history, running stitch collection, running stitch group, handicrafts, quilting, quilting - history -

National Wool Museum

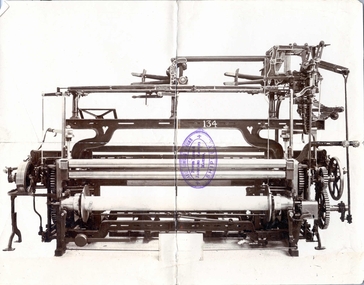

National Wool MuseumPhotograph

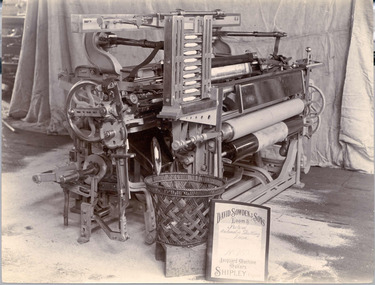

Photograph probably for promotional purposes, of a "David Sowden & Sons" loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls MillPhotograph. black and white, of a "David Sowden & Sons" loom.DAVIS SOWDEN & SONS SHIPLEY/Power loom and jacquard machine makerstextile machinery weaving textile mills textile mills, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving, textile mills -

National Wool Museum

National Wool MuseumPhotograph

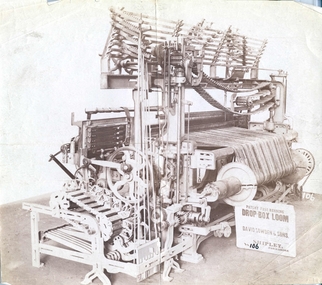

Photograph probably for promotional purposes, of a ""Patent Fast Running Drop Box Loom", David Sowden and Sons, Shipley , Yorkshire No106" loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls Mill.Photograph.sepia, of a "David Sowden & Sons" loom. "Patent Fast Running Drop Box Loom", David Sowden and Sons, Shipley , Yorkshire No106.106 DAVIS SOWDEN & SONS SHIPLEY/Power loom and jacquard machine makerstextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumPhotograph

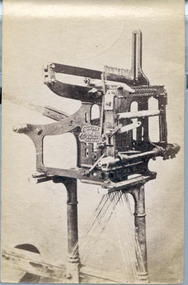

Photograph probably for promotional purposes, of part of a "David Sowden and Sons" loom attachment. Photograph was with other photographs in an envelope printed "David Sowden & Sons", among items from Yarra Falls Mill.Photograph, sepia, of a "David Sowden & Sons" loom attachment, which has been threaded with yarn.DAVID SOWDEN & SONS/ BRADFORD/ POWER LOOM AND JACQUARD MACHINE MAKERStextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumPhotograph, Patent Automatic Shuttling Loom

Photograph probably for promotional purposes, of a ""David Sowden & Sons Patent Automatic Shuttling Loom", No 162. Photograph was among items from Yarra Falls Mill.Photograph, black and white, of a "David Sowden & Sons Patent Automatic Shuttling Loom", No 162."David Sowden & Sons/Looms/ Patent /Automatic Shuttling/ Loom"/ No 162/Jacquard Machine Makers/ SHIPLEYtextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumMachine - Wrap Reel

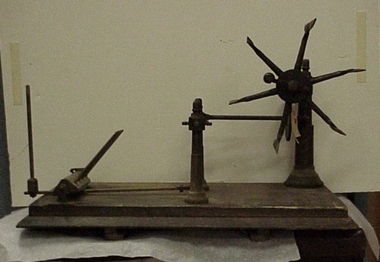

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

National Wool Museum

National Wool MuseumBook, John Haigh and Sons Ltd, Machine Makers and Iron Founders

"John Haigh and Sons Ltd, Machine Makers and Iron Founders", c.1925.Book: catalogue of machinery produced by John Haigh and Sons Ltd, Machine Makers and Iron Founders, c.1925.textile machinery, john haigh and sons ltd, scribbling, carding -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumBook, Textile Machines

This book provides a brief history and overview of English textile machinery, machinery makers and factories.SHIRE / ALBUM / 103 / Textile Machines / ANNA P. BENSONtextile machinery -

National Wool Museum

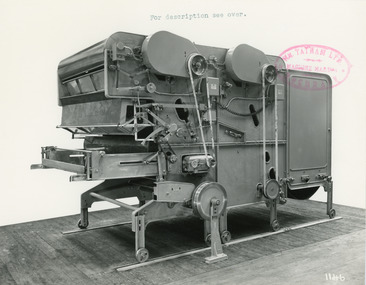

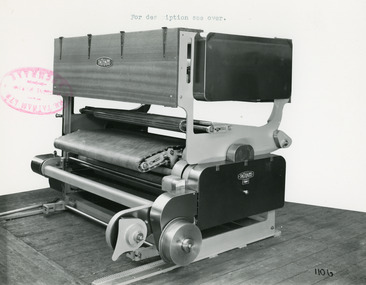

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

National Wool Museum

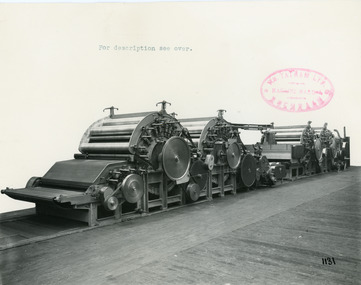

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

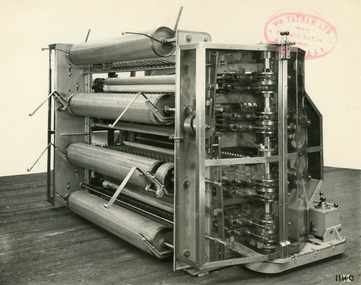

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

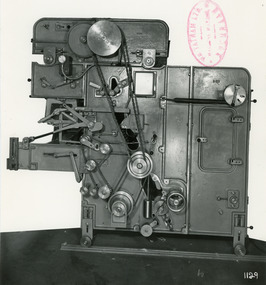

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool