Showing 436 items matching "textile machines"

-

National Wool Museum

National Wool MuseumBook, Textile Machines

... Textile Machines...SHIRE / ALBUM / 103 / Textile Machines / ANNA P. BENSON... Machinery SHIRE / ALBUM / 103 / Textile Machines / ANNA P. BENSON ...This book provides a brief history and overview of English textile machinery, machinery makers and factories.SHIRE / ALBUM / 103 / Textile Machines / ANNA P. BENSONtextile machinery -

National Wool Museum

National Wool MuseumPamphlet, Poland - Well Known Exporter of Textile Machines

... Poland - Well Known Exporter of Textile Machines..."Poland - Well Known Exporter of Textile Machines" - Jerzy... Machines" - Jerzy Boniecki, c.1958. Textile Machinery Bielsko ..."Poland - Well Known Exporter of Textile Machines" - Jerzy Boniecki, c.1958.textile machinery, bielsko textile machinery works polmatex falubaz carding engine works metalexport -

National Wool Museum

National Wool MuseumBook, Finishing Machinery

... Textile Machine Maker..."Finishing Machinery" - James Bailey, Textile Machine Maker..., textile machine maker, Huddersfield, c.1926.... Finishing James Bailey Textile Machine Maker Milling Scouring ..."Finishing Machinery" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Catalogue of machinery for fulling, scouring, carbonising, dyeing and finishing woollen and worsted and other types of textiles.Catalogue of textile finishing machinery from James Bailey, textile machine maker, Huddersfield, c.1926.textile machinery textile finishing, james bailey, textile machine maker, milling, scouring, carbonising, dyeing, raising, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumMachine, Textile Parts

... Machine, Textile Parts...Parts for grey textile machine manufactured by Scott...-and-the-bellarine-peninsula Parts for grey textile machine manufactured ...Parts for grey textile machine manufactured by Scott Testers Inc, Builders, Providence R.I., USA. -

National Wool Museum

National Wool MuseumGill Box

... Textile machine - Gill box. Combs and brushes driven...-and-the-bellarine-peninsula Textile machine - Gill box. Combs and brushes ...Textile machine - Gill box. Combs and brushes driven by electric motor. Name plate of machine is missing. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, late 19th or early 20th century

... textile machines...-village textile machines sailmaker's machine maritime sewing ...This Eclipse model, treadle operated sewing machine was made by the Oldham Sewing Machine Company in Greater Manchester U.K.. It was used by sailmakers for sewing sails with box shape top and slim neck. Sewing machine, foot treadle, for sewing sails with box shape top and slim neck. Brand is Eclipse. Cast iron base is bolted to square wooden table-top with drawer under table. Drawer has 3 partitions and wood fitting with 5 drilled holes for needle storage, lock has diamond shaped, decorative metal surrounds; half of inside drawer is painted black. Decorative metal stand, painted green, with 2 foot pedals; 1 foot pedal drives the wheel wheel. Padals both have "ECLIPSE" cast into the iron.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, textile machines, sailmaker's machine, maritime sewing machine -

National Wool Museum

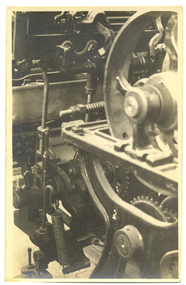

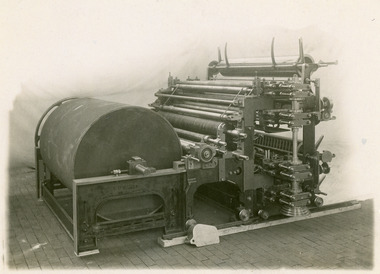

National Wool MuseumPhotograph - Textile Machinery, Fred Murgatroyd, c.1920s

... Black and white photograph of part of a textile machine... Black and white photograph of part of a textile machine ...Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Black and white photograph of part of a textile machine, possibly a Hattersley loom at Federal Woollen Mill. The photograph has postcard formatting on back of card.Back: [printed] F Murgatroydtextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill federal woollen mills ltd, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, photography -

National Wool Museum

National Wool MuseumReel

... Wooden roving bobbin used on textile machines....-and-the-bellarine-peninsula Wooden roving bobbin used on textile machines ...Wooden roving bobbin used on textile machines.W 89.0095spinning machinery -

National Wool Museum

National Wool MuseumReel

... Wooden roving bobbin used on textile machines....-and-the-bellarine-peninsula Wooden roving bobbin used on textile machines ...Wooden roving bobbin used on textile machines.89.0095spinning machinery -

National Wool Museum

National Wool MuseumReel

... Wooden roving bobbin used on textile machines....-and-the-bellarine-peninsula Wooden roving bobbin used on textile machines ...Wooden roving bobbin used on textile machines.spinning machinery -

National Wool Museum

National Wool MuseumFunctional object - Roving Bobbin

... Wooden roving bobbin used on textile machines....Wooden roving bobbin used on textile machines. Spinning ...Wooden roving bobbin used on textile machines.Large wooden reel, light coloured wood, hollow, with round end pieces and dark rings around centre circle. spinning machinery, textile industry, bobbin, reel, roving bobbin, spinning, wool -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - SINGER SEWING MACHINE ACCESSORIES BOX

... TEXTILE MACHINERY Sewing machines accessories Singer Sewing ...Cardboard box with red lettering reading the Singer manufacturing Co accessories for 66K machines.Singer Sewing Machines Singer logo of large S over a lady at sewing machine.textile machinery, sewing machines, accessories -

National Wool Museum

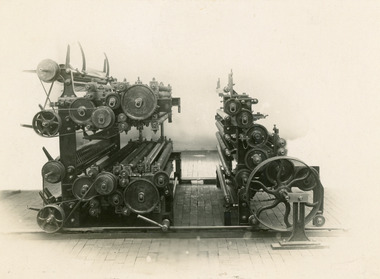

National Wool MuseumPhotograph, Carding Machine, Unknown

... Co Ltd, a British textile machine company established in 1899.... by Chadwick Machine Co Ltd, a British textile machine company ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Black and white photograph of a carding machine.Rear handwritten top edge - Chadwickstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph, Carding Machine, Unknown

... Co Ltd, a British textile machine company established in 1899.... by Chadwick Machine Co Ltd, a British textile machine company ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Two black and white photographs of a carding machine. The first photo is of the rear of the machine, the second the front.8054.1 - rear handwritten top edge - Chadwicks left edge - unknown 8054.2 - a calculation of numberstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

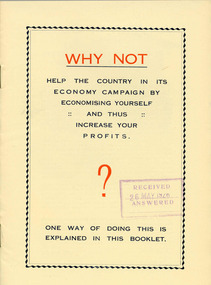

National Wool MuseumBooklet, Why Not...?

... Textile Machine Maker..., Textile Machine Maker, Huddersfield, c. 1926. Promotes... ?" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926 ..."Why Not Help the Country in its Economy Campaign by Economising Yourself and thus Increase Your Profits ?" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Promotes the advantages of buying a new scouring machine.Booklet, c.1926. Produced by James Bailey, textile machinery manufacturer, Huddersfield, to promote a new scouring machine.textile machinery textile finishing, james bailey, textile machine maker, scouring, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumPhotocopy, Melbourne School of Textiles - Shearing machine experting

... Melbourne School of Textiles - Shearing machine experting...-and-the-bellarine-peninsula Melbourne School of Textiles - Shearing machine ...Melbourne School of Textiles - Shearing machine experting certificate awarded to K Galloway, 1969shearing shearing machinery, melbourne college of textiles, galloway, mr ken, shearing, shearing machinery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - TABLECLOTH WITH EMBROIDERED NAMES

... Textiles. Machine made rectangular cream coloured linen... TEXTILES Domestic tablecloth with embroidered names Textiles ...Textiles. Machine made rectangular cream coloured linen tablecloth. 3.5cm turned over hem with decorative stitching around top of hem. 2.5cm diameter machine embroidered wreath in centre of blue flowers and brown and yellow leaves. 326 names (blue) hand embroidered around the edge at right angles to the hem and 44 names scattered in central area. (several colours)., tag in one corner ''SEMCO''. Old box 75,yellow label 183.textiles, domestic, tablecloth with embroidered names -

National Wool Museum

National Wool MuseumTool - Finishing machine

... Textile finishing machine. Horizontal, made from grey... at Collins Bros Mill. textile machinery collins bros mill pty ltd ...Variable speed cloth puller, used for tightening and smoothing blanket edges, prior to them being sewn or bound. Used at Collins Bros Mill.Textile finishing machine. Horizontal, made from grey steel with a small encased gear box and two attached rollers. Separate belt drive and nine other rollers. Enclosed in original brown cardboard box, used for shipping.SUISIE / VARIABLE SPEED / VERSATILE CLOTH PULLERtextile machinery, collins bros mill pty ltd, blankets -

National Wool Museum

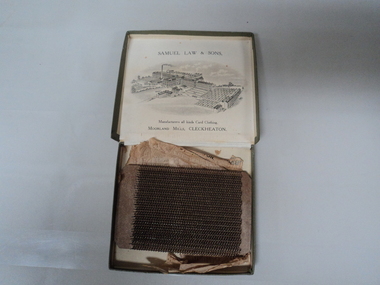

National Wool MuseumSample, Card Clothing

... on the fibres.' This fits into a carding machine ("The Textile... operated on the fibres.' This fits into a carding machine ...Card clothing sample manufactured by Samuel Law and Sons, Cleckheaton and probably sent to the Collins Bros Mill at the same time as W621. Card clothing is defined as 'the leather or other stiff material which holds the wire staples, the points of which project outwardly and form the carding teeth which operated on the fibres.' This fits into a carding machine ("The Textile Industries" vol. 8 - William S. Murphy, 1911).Card clothing sample, comprising rows of bent wires mounted on a thick rectangular leather base. Wrapped in tissue printed with an engraving of the factory where it was made and housed in an olive green lidded cardboard box, the interior of which is printed with an image of the manufacturer's factory.SAMUEL LAW & SONS, / Manufacturers all kinds Card Clothing. / Moorland Mills. / CLECKHEATON, England. SAMPLE OF CARD CLOTHING / FROM / SAMUEL LAW & SONS, / (branch of the English Card Clothing Company, Limited). / CLECKEATON. / MOORLAND MILLSsamuel law and sons collins bros mill pty ltd, carding, card clothing -

National Wool Museum

National Wool MuseumPicker

... Wool picking machine designed to separate locks of wool... is collected with this machine. Wool Picking Textile manufacturing wool ...Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

... -village sewing machine hand operated dressmaking textile machinery ...In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Bendigo Military Museum

Bendigo Military MuseumTextile - BLANKET, WOOL, WAGGA, Unknown

Derych Victor Lawes VX22625 enlisted 30 May 1940, age 25 years 3 mths. Embarked 14 Sept 1940 for Middle East. Rose through the ranks to S/Sgt Weapons Instructor Palestine. Disembarked Aust 29.4.1942. From 19.1.1945 Acting WO1 at HQ Small Arms School Bonegilla. Discharged 18 Dec 1945. Blanket - wool, machine stitched patches of brown toned wool blankets. Yellow numbers have been stitched by hand (no reason given for the numbers.)White label - handwritten in biro on white tape ""D. LAWES 473092"on one corner. Yellow wool handstitched numbers in various positions on the blanket. "8926, 10830, 10752, 107, 6". craft, blanket, wagga blanket, d lawes -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile, Dress, promenade, 1880s

There is no information available on this dress which has been in the Historical Society’s collection for many years. It may have been a wedding dress. This is an interesting item as an example of a woman’s dress worn about the 1880s. It is a wonderful display item. This is a claret-coloured dress with a full length skirt with bustle. It is made of good quality heavy satin mounted on organza with a back fastening. There is a rosette in the same fabric with two pendant panels. There is a matching fitted jacket with hooks and eyes to fasten and full length narrow sleeves edged with claret lace (much tattered). The jacket is faded and torn in parts. Machine and handsewn. claret-coloured dress, warrnambool, 1860's ladies dress -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings "Holeproof', mid 20thC

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. A unused pair of lady's silk stockings in original box. 'Holeproof' 'Truly Yours' Candlelight, size 10Box Cover: Truly Yours / by / Holeproof Side Holeproof 'Candlelight' Size 10clothing, stockings, nylons, holeproof hosiery pty ltd, lingerie, melbourne, bentleigh, cheltenham moorabbin, brunswick milwaukee usa, wisconsin -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. An unused pair of lady's nylon stockings in original box. 'Holeproof' 'For you', 'Precious' size 91/2Box Cover : For You / HOLEPROOF/ SUPERFINE EXQUISITE SHEERS Side : Precious 9 1/2 Package : 60 GUAGE / SHEER NYLON / BY / HOLEPROOF / 9 1/2 Card : Especially / For You / fromclothing, stockings, nylons, holeproof pty ltd, milwaukee usa, hosiery, fashion, melbourne, bentleigh, cheltenham moorabbin, brunswick, lingerie -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific BrandsAn unused pair of lady's stockings, in original box, 'Holeproof', 'Beauty Fit', ' Nocturn' Size 81/2 - 9 Box Cover : HOLEPROOF / Beauty Fit / LADDERPROOF MESH SHEERS STRETCH Inside Wrapper ; HOLEPROOF / Beauty Fit / LADDERPROOF STRETCH NYLONS 8 1/2 - 9clothing, stockings, nylons, hosiery, melbourne, bentleigh, cheltenham moorabbin, brunswick, holeproof pty ltd, lingerie, fashion -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Work Apron, 1883-1899

The personal 'carry-all', a cloth apron like article was utilised by Thomas Hamilton Osborne in his work with the Warrnambool Steamship Navigation Company. He was Company manager in 1883 until its dissolution in 1899. Osborne wrote many articles on early Warrnambool, particularly maritime material under the name of " Sliding Gunter". When he died he was buried at sea off the breakwater.His sister Mrs Annabella Kell is thought to have made this article.This is a significant item as T.H.Osborne was a key figure in 19th Century Warrnambool history, particularly in maritime affairs. Six sided, scalloped edges, four pockets, two metal hooks, purple woven fabric with yellow and gold embroidery, lifebuoy outline with W.S.N.Co and THO initials embroidered and two flags. Machine sewing of pockets and tab to base apron.W.S.N.Co THO initials on top of each other Two metal hookswork apron, warrnambool steamship navigation company, wsnc, thomas hamilton tracey osborne, annabella kell, sliding gunter -

Orbost & District Historical Society

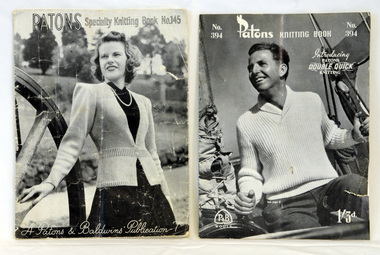

Orbost & District Historical Societypattern books, Patons Specialty Knitting Book, 1940-1950

These knitting pattern leaflets were published by Patons and Baldwins and contain knitting patterns for women's and men's garments. Patons & Baldwin began as two separate companies: J & J Baldwin and Partners, founded in the late 1770s by James Baldwin of Halifax, West Yorkshire, England, and John Paton Son and Co., founded in 1814 by John Paton of Alloa, Scotland. Both men had formed their businesses using the spinning mule developed by Samuel Crompton. They mainly produced yarns for commercial knitting machines. Patons established itself in Australia with its first mill built in Tasmania in 1923. For decades, Patons was the leading hand knitting yarn brand but due to the market conditions in the mid 1980's, Patons felt the decline and eventually amalgamated with Alliance Textiles, New Zealand in 1996. Patons Australia was acquired by Australian Country Spinners in 2000. Knitting has always had a great appeal to women, as it needs few tools. Companies which manufactured yarn often produced instruction guides and patterns. These pattern books are typical of the knitting pattern books commonly used in the mid 20th century. The patterns contained are for garments commonly worn at that time.Two knitting pattern books. Both are black / white and contain knitting patterns. 821.1 cost 7d, is titled "Patons Specialty Knitting Book No. 145" and has on the front cover a lady standing near a buggy wheel. 821.2 cost 1/3, is titled " Patons Knitting Book No. 394 (introducing Patons Double Quick Knitting)" and has has on the front cover a photograph of a man on a boat.knitting-patterns needlecraft patons-baldwin -

Orbost & District Historical Society

Orbost & District Historical Societypleating machine, late 19th century - early 20th century

... textile-machinery sewing pleating-machine... used today. textile-machinery sewing pleating-machine Metal ...Pleated ruffles were a fashionable trimming for ladies’ clothing in the late 19th century - early 20th century. Dressmakers and classy laundries offering “fancy” ironing services both had plenty of use for a pleating machine. Pleating machines were sold for home use too.This item is an example of a machine not commonly used today.Metal and wood pleating machine, still in working order. Handles are carved wood.textile-machinery sewing pleating-machine -

Orbost & District Historical Society

Orbost & District Historical Societypattern book, Patons Knitting Book, mid 20th century

This knitting pattern leaflet was published by Patons and Baldwins and contains knitting patterns for women's garments. Patons & Baldwin began as two separate companies: J & J Baldwin and Partners, founded in the late 1770s by James Baldwin of Halifax, West Yorkshire, England, and John Paton Son and Co., founded in 1814 by John Paton of Alloa, Scotland. Both men had formed their businesses using the spinning mule developed by Samuel Crompton. They mainly produced yarns for commercial knitting machines. Patons established itself in Australia with its first mill built in Tasmania in 1923. For decades, Patons was the leading hand knitting yarn brand but due to the market conditions in the mid 1980's, Patons felt the decline and eventually amalgamated with Alliance Textiles, New Zealand in 1996. Patons Australia was acquired by Australian Country Spinners in 2000.Knitting has always had a great appeal to women, as it needs few tools. Companies which manufactured yarn often produced instruction guides and patterns. This pattern book is typical of the knitting pattern books commonly used in the mid 20th century. The patterns contained are for garments worn at that time.A seven page stapled booklet of knitting patterns. It is titled Patons Knitting Book No. 444, Ladies' and Girls' Gloves and Hats. It has a price 1/3.On the front cover are photos of the garments for which the patterns are provided.knitting handicrafts patons-and-baldwins