Showing 8321 items matching "this england"

-

Friends of Ballarat Botanical Gardens History Group

Friends of Ballarat Botanical Gardens History GroupWork on paper - Different Kinds of Conifers, extract from THIS ENGLAND Magazine undated, Unknown. Information given: THIS ENGLAND, Winter? p.38

... extract from THIS ENGLAND Magazine undated....THIS ENGLAND...Unknown. Information given: THIS ENGLAND, Winter? p.38. ...There are fine examples of some Conifers in the Ballarat Botanical Gardens. Conifers in the Ballarat Botanical gardens are an important and longstanding part of the Garden's original design which called to mind trees in the British Isles, from where some of Ballarat's early settlers had come.1 white sheet with Conifers as the heading with trees shown in colour. Cones and vegetation shown below each tree featured. Noneconifers, this england, ballarat botanical gardens, john garner, doctor, john garner collection, friends of ballarat botanical gardens, george longley, gardens, ballarat -

Friends of Ballarat Botanical Gardens History Group

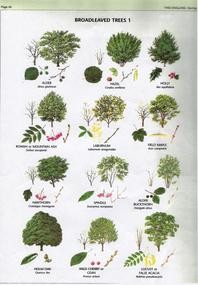

Friends of Ballarat Botanical Gardens History GroupWork on paper - Broadleaved Trees, This England, Spring 2009, Spring, 2009

... This England, Spring 2009...This England ...These 4 pages give a detailed list of broadleaved trees, useful for identification.These illustrations of broadleaved trees relate to trees in the Ballarat Botanical Gardens.4 pages in colour of the trees, leaves and fruit.Nonejohn garner, doctor, john garner collection, ballarat botanical gardens, this england, braodleaved trees, friends of ballarat botanical gardens, gardens, ballarat -

Bendigo Military Museum

Bendigo Military MuseumBook - BOOK, GEORGE CROSS, The Register of the George Cross, 1985

... This England Books ...Hard cover, dark blue buckram. Gold print front & spine. Dust cover dark blue striped background with the George Cross with ribbon over black band in foreground. Rear view of George Cross on back section of dust cover. 151 pages, cut, plain, white. Illustrated, black & white photos, portraits of recipients.On front fly leaf handwritten inscription & two RSL stamps: "M R Birks 3 Timbertop Avenue Carlingford NSW, 2118 Australia" Handwritten in black ink on front fly leaf: "To Ray Birks from Leon Goldsworthy" books - reference, military history - army, george cross -

Lilydale RSL Sub Branch

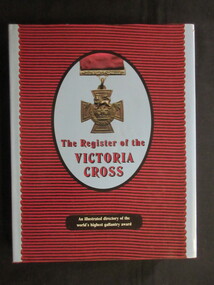

Lilydale RSL Sub BranchBook, This England Books, The Register of the Victoria Cross, 1997

... This England Books ...An Illustrated directory of the world's highest gallantry awardBook - Mainly red cover with an Illustration of the Victoria Cross and Titlenon-fictionAn Illustrated directory of the world's highest gallantry award -

Melbourne Athenaeum Archives

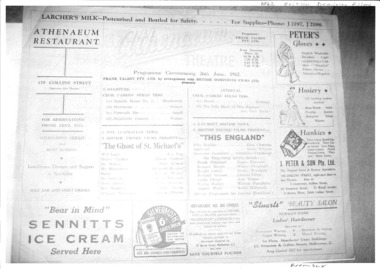

Melbourne Athenaeum ArchivesReproduction of theatre program, The Ghost of St. Michael's (Film 1941) plus This England (Film 1941) screened at Athenaeum Theatre 26 June 1942

... The Ghost of St. Michael's (Film 1941) plus This England ... -

Bendigo Military Museum

Bendigo Military MuseumPoster - POSTCARDS, PHOTOGRAPHIC WW1, 1), .2), .3), .5), .8), .10) & .11) Brighton Palace Series, c.1916-1919

Photographic postcards of Brighton & Folkestone, England sent home in WWI.Postcards B & W of Southern England.Descriptions of tourist sites in Southern England, some with handwriting.photography-photographs, military history -

Chelsea & District Historical Society Inc

Chelsea & District Historical Society IncPhotograph - St Chad's Church of England, Chelsea, Masquerade Ball in Kismet Hall, c 1920's

St Chad's Church of England congregation and friends attend a ball at Kismet Hall Kismet Hall was built by Mr Walker on his property adjoining the "Kismet" tea rooms in 1914, in the Strand, Chelsea.Sepia photo of members and friend of Chad's Church of England attending a Masquerade ball at Kismet Hall, in the Strand, Chelsea. Church of England, Chelseachurch of england, anglican, religion, building, church, chelsea, kismet hall, masquerade ball -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Archbishop Frank Woods (left) and Sir Rohan Delacombe (right) pictured at Ringwood's Yarra Valley Church of England School dedication - October, 1965. The inscription on the plaque reads, "Yarra Valley Church of England School. This plaque commemorating the founding of the school was unveiled by His Excellency Major General Sir Rohan Delacombe, Governor of Victoria on October 2nd 1965 and was dedicated on that date by the Most Reverend Frank Woods, M.A., D.D., Archbishop of Melbourne"

... reads, "Yarra Valley Church of England School. This plaque ...The inscription on the plaque reads, "Yarra Valley Church of England School. This plaque commemorating the founding of the school was unveiled by His Excellency Major General Sir Rohan Delacombe ... Governor of Victoria on October 2nd 1965 and was dedicated on that date by the Most Reverend Frank Woods, M.A., D.D., Archbishop of Melbourne". -

Orbost & District Historical Society

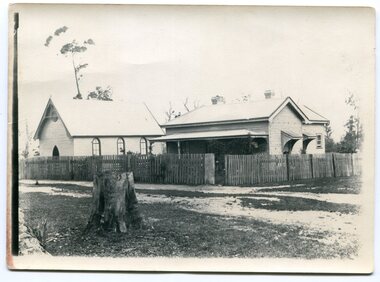

Orbost & District Historical Societyblack and white photograph, C1900

This photograph is of the first Church of England in Orbost, dedicated on Sunday, 6th March, 1892 by the Rt. Rev. T. Geo, Bishop of Melbourne, The church was later used in the `1970s by the Orbost State School as a music, physical education room until it was moved. The rectory was later moved so the new church could fit.This item is reminiscent of the late 19th - mid 20th centuries when church-going was more common.Three copies of the first Orbost Church of England with the small rectory adjacent.on back - "Mary Gilbert - Church of England"church-orbost church of england-orbost -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - Three Silver thimbles

It is believed the word thimble evolved from "thumb bell". They were first produced in 1695 by a dutch metalworker. The small thimble, size 7 is 15 mm at the rim and was made in Germany. The medium thimble (Size 8) was made in England. The largest thimble is a size 13 3 silver thimbles each of varying sizes. Large thimble has England stamped on it and the number 1. Each thimble has indentations covering 2/3 of the thimble areaEngland 1thimbles, sewing aid -

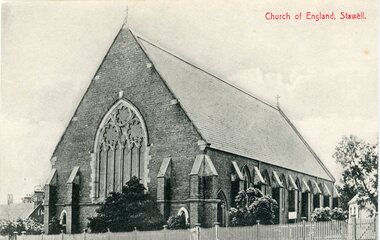

Stawell Historical Society Inc

Stawell Historical Society IncPostcard, Church of England in Main Street Stawell c1907. Two photo's

Second copy donated 9/5/2024 by Meryl BowersFront of Church of England with wooden picket fence. Red writing Church of England Stawell on top right on one copy Church of England Stawell printed on bottom of second copy but same photoChurch of England Stawellstawell -

Robin Boyd Foundation

Robin Boyd FoundationSlide, Robin Boyd, 1950

Penleigh Boyd, Robin and Patricia Boyd's son, writes “Prior to 1950 Robin, like most other amateur or hobby photographers, took black and white printed photographs. The oldest slides date from 1950 when Robin and Patricia travelled to Europe on Robin’s Robert Haddon Travelling Scholarship.” In 1948 Robin Boyd was awarded ‘joint first place’ in the Robert Haddon competition for his design of Mildura art gallery. The scholarship helped fund their first overseas trip. Robin and Patricia were passengers on the Greek ship “Cyrenia” departing in May 1950, passing through the Suez Canal and landing in Genoa five weeks later. For six months, they travelled extensively throughout Europe (predominantly driving themselves) - France, Italy, United Kingdom, Sweden, Denmark, Germany, Austria, Switzerland and Spain.Colour slide in a mount. Unknown location in EnglandMade in Englandhaddon travelling scholarship, haddon, robin boyd, slide -

Robin Boyd Foundation

Robin Boyd FoundationSlide, Robin Boyd, 1950

Penleigh Boyd, Robin and Patricia Boyd's son, writes “Prior to 1950 Robin, like most other amateur or hobby photographers, took black and white printed photographs. The oldest slides date from 1950 when Robin and Patricia travelled to Europe on Robin’s Robert Haddon Travelling Scholarship.” In 1948 Robin Boyd was awarded ‘joint first place’ in the Robert Haddon competition for his design of Mildura art gallery. The scholarship helped fund their first overseas trip. Robin and Patricia were passengers on the Greek ship “Cyrenia” departing in May 1950, passing through the Suez Canal and landing in Genoa five weeks later. For six months, they travelled extensively throughout Europe (predominantly driving themselves) - France, Italy, United Kingdom, Sweden, Denmark, Germany, Austria, Switzerland and Spain.Colour slide in a mount. Unknown Cottage, EnglandEngland Cottage (Handwritten)haddon travelling scholarship, haddon, robin boyd, slide -

Robin Boyd Foundation

Robin Boyd FoundationSlide, Robin Boyd, 1950

Penleigh Boyd, Robin and Patricia Boyd's son, writes “Prior to 1950 Robin, like most other amateur or hobby photographers, took black and white printed photographs. The oldest slides date from 1950 when Robin and Patricia travelled to Europe on Robin’s Robert Haddon Travelling Scholarship.” In 1948 Robin Boyd was awarded ‘joint first place’ in the Robert Haddon competition for his design of Mildura art gallery. The scholarship helped fund their first overseas trip. Robin and Patricia were passengers on the Greek ship “Cyrenia” departing in May 1950, passing through the Suez Canal and landing in Genoa five weeks later. For six months, they travelled extensively throughout Europe (predominantly driving themselves) - France, Italy, United Kingdom, Sweden, Denmark, Germany, Austria, Switzerland and Spain.Colour slide in a mount. York, EnglandEngland (Handwritten) / York (Handwritten)haddon travelling scholarship, haddon, robin boyd, slide -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Parish Church of St. Peter and St. Paul in Ringwood, Hampshire, England

Church in Ringwood, EnglandWritten below photograph, "Church Ringwood England" -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Footprint tool

Small footprint tool with "The Footprint" and "Made in England" on handle.The Footprint, Made in England.tool, footprint -

Chelsea & District Historical Society Inc

Chelsea & District Historical Society IncPhotograph - St Chad's Church of England, Chelsea, Original Church Building, 1915

The foundation stone for St Chad's was laid on the 20th June 1914 and the church was completed and opened in August. The building was a wooden structure capable of seating about 150 people. The Church was built in Thames Promenade, Chelsea.Black and white photo of Chad's Church of England, ChelseaChurch of England, Chelseachurch of england, anglican, religion, building, church, chelsea -

Chelsea & District Historical Society Inc

Chelsea & District Historical Society IncPhotograph - St Chad's Church of England, Chelsea, Original Church Building, c 1950's

The foundation stone for St Chad's was laid on the 20th June 1914 and the church was completed and opened in August. The building was a wooden structure capable of seating about 150 people. The Church was built in Thames Promenade, Chelsea.Black and white photo of Chad's Church of England, ChelseaChurch of England, Chelseachurch of england, anglican, religion, building, church, chelsea -

Robin Boyd Foundation

Robin Boyd FoundationSlide, Robin Boyd, 1950

Penleigh Boyd, Robin and Patricia Boyd's son, writes “Prior to 1950 Robin, like most other amateur or hobby photographers, took black and white printed photographs. The oldest slides date from 1950 when Robin and Patricia travelled to Europe on Robin’s Robert Haddon Travelling Scholarship.” In 1948 Robin Boyd was awarded ‘joint first place’ in the Robert Haddon competition for his design of Mildura art gallery. The scholarship helped fund their first overseas trip. Robin and Patricia were passengers on the Greek ship “Cyrenia” departing in May 1950, passing through the Suez Canal and landing in Genoa five weeks later. For six months, they travelled extensively throughout Europe (predominantly driving themselves) - France, Italy, United Kingdom, Sweden, Denmark, Germany, Austria, Switzerland and Spain.Colour slide in a mount. York Minster, York, EnglandEngland (Handwritten) / York (Handwritten)haddon travelling scholarship, haddon, robin boyd, slide -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchFramed Object, 1940

Silk scarf Rising Sun England 1940Silk scarf Rising Sun England 1940 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CRUCIBLE

Clay crucible marked Battersea Round F Morgan England commonly used for melting gold.Morgan Englandmining, equipment, crucible -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CRUCIBLE

Clay crucible marked Battersea Round F Morgan England commonly used for melting gold.Morgan Englandmining, equipment, crucible -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CRUCIBLE

Clay crucible marked Battersea Round D Morgan England commonly used for melting gold.Morgan Englandmining, equipment, crucible -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CRUCIBLE

Clay crucible marked Battersea Round G Morgan England commonly used for melting gold.Morgan Englandmining, equipment, crucible -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CRUCIBLE

Clay crucible marked Battersea Round G Morgan England commonly used for melting gold.Morgan Englandmining, equipment, crucible -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CRUCIBLE

Clay crucible marked Battersea Round E Morgan England commonly used for melting gold.Morgan Englandmining, equipment, crucible -

National Wool Museum

National Wool MuseumShearing Hand piece

Shearing handpiece inscribed "MUNRO / 4134/ MADE IN ENGLAND", "MUNRO/ PAT. APPLIED FOR/ OIL", "REGISTERED DESIGN". Munro manufacturers in Ballarat, created by George Munro c.1927. Handpeice manufactured in England by Burgon and Ball (Sheffield) for Austrlaian market. Handpiece contains Wolseley start spindle similar to Burgon, missing a 'bush' in tension nut.Metal, leather and plastic shearing handpiece inscribed "MUNRO / 4134/ MADE IN ENGLAND", "MUNRO/ PAT. APPLIED FOR/ OIL", "REGISTERED DESIGN". Plastic hand piece with leather casing attached with wire, covering swivel joint."MUNRO/ PAT. APPLIED FOR/ OIL" Munro 4134 made in england Registered designshearing -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Shallow Vegetable Serving bowl, Johnson Brothers England, 1913 - 1942

Johnson Bros. was founded by two brothers named Alfred and Frederick who purchased a pottery factory in Hanley, England, in 1883. They were grandsons of a renowned English potter, Alfred Meakin. They were later joined in the business by their brothers Henry and Robert. Their business grew rapidly, as they were one of the world's largest pottery factories by the turn of the 20th century. By 1970, Johnson Bros. obtained the Royal Charter to become the official provider of china for Her Majesty Queen Elizabeth II. More than 1,300 patterns have been created throughout Johnson Brothers' history. Due to their growing success, manufacturing plants were established overseas including the establishment of a tableware factory, Johnson Brothers Australia in 1957 in Croydon, Victoria operated through a company known as Sovereign Pottery Ltd. Due to rising competition, Johnson Brothers became part of the Wedgewood Group in 1968. In 2015, following the acquisition of Wedgewood by Finnish company Fiskars, the Johnson Brothers branding was discontinued. The trademark on this bowl was used by Johnson Brothers between 1913 and 1942. An item which reflects the changing market for tableware that was reasonably priced and serviceable. Their innovation of the pottery line called semi-porcelain changed the industry. This development allowed potteries to produce fashionable pottery items that were affordable to all social classes of the time. Their use became widespread in Australia, especially following their establishment of a tableware factory in Melbourne, Victoria. A shallow white bowl with gold trim, probably used for serving vegetables at the table. The underside of the bowl bears the mark of Johnson Bros England. The mark is composed of a green crown above the words "Johnson Bros England" also in green.On under side of bowl, beneath a green crown "Johnson Bros/England"johnson brothers ceramics, domestic utensils, kitchenware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Kew Historical Society Inc

Kew Historical Society IncHeadwear - Iridescent Feather Casque, 1920s

The Kew Historical Society’s fashion and design collection is comprised of costumes, hats, shoes and personal accessories. Many of these items were purchased or handmade in Victoria; some locally in Kew. The extensive hat collection comprises items dating from the 1860s to the 1970s. Most of the hats in the collection were created by milliners for women. There are however a number of early and important men’s hats in the collection. The headwear collection is particularly significant in that it includes the work of notable Australian and international milliners.Woman’s hat covered in iridescent feathers. The hat was made in and imported from England by the retailer.Label: Made in Englandwomen's clothing -- hats, headwear, feather casques