Showing 12 items

matching thread cutter

-

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Thread cutter

... Thread cutter...thread cutter...Metal thread cutter with two handles and an adjustable... island tool thread cutter V [punched] 7/16 V Metal thread cutter ...Metal thread cutter with two handles and an adjustable screw inside the jaw.V [punched] 7/16 Vchurchill island, tool, thread cutter -

Vision Australia

Vision AustraliaFunctional object - Object, Automatic needle threader with thread cutter

... Automatic needle threader with thread cutter... with thread cutter Functional object Object ...This device allows easy threading of needles with ease. Place the needle in the casing then wrap the thread across the groove. Press the button down gently but firmly and pull the thread that appears on the other side slowly until the shorter end appears, and the needle is threaded.Red plastic rectangle with one insert tubes and one white push tabs, a leaflet of instructions and a white stand to place the threader on"Needle threader" in red on one side and an image of a female holding a needle threader on the reverseassistive devices, hong kong -

Queenscliffe Historical Museum

Queenscliffe Historical MuseumFour silver thumbles

... 1. Made in USA, Mt Patd. Thread cutter on side. 2... Gilbert, Illinois, USA. 1. Made in USA, Mt Patd. Thread cutter ...Belonged to two grandmothers of donor - Emma Quimby, Maryland, USA and Anna Katherine Smailes Gilbert, Illinois, USA.1. Made in USA, Mt Patd. Thread cutter on side. 2. Handmade Victorian thimble, silver mark, fancy edge. 3. Silver thimble, floral edge. O for name. 4. Silver thimble size 8. -

Cheese World Museum

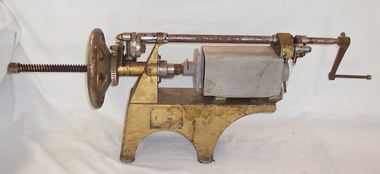

Cheese World MuseumButter cutter

No known provenance.Gold-coloured metal butter cutter on 4 legs with winding handle, a box for butter and a wheel on a threaded spindle. The metal handle is connected to a geared cog and when turned pushes a metal plate in the butter box which forces the butter through a star-shaped hole and the wire drops to cut the shaped slice of butter to the determined size.BUT AP ATTAbutter manufacture, butter cutters, warrnambool cheese and butter factory company ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Taps and Dies set, Wiley and Russell Mfg. Co, C. 1884

This set of taps and dies tools was owned by Frederick William McDowell (Fred) (1880 to 15-6-1967). He was a wheelwright by trade. He made and repaired vehicles such gigs, buggies, jinkers, sulkeys, spring carts and farm wagons. His workshop was on the corner of Cramer Street and Raglan Parade in Warrnambool., previously the site of Fotheringhams, and after McDowell's, and still in 2023, occupied by Reece Plumbing Fred's workplace prior to retiring was at Bryant & Waterson's in Kepler Street, opposite the Criterian Hotel, making rubber tyred horse-driven farm wagons. This Wiley and Russell hand operated, thread cutting Die and Stock, or Die and Tap, set’s patent carries the description “The taper-headed screws adjust the size; the four side screws hold the cutters firmly in the holder. Marketed as the Wiley & Russell LIGHTNING SCREW PLATE. The taper-headed screws are carried over from the J.J. Grant October 21, 1871 patent (no. 120,266). This patent was improved by Smart's Oct. 21, 1884 patent (no. 306,783).” Dies are used to cut external screw thread, stocks are the tools that hold the dies in place with countersunk adjustable screws, and taps are the tools that make the internal threads. The tools would be used by farriers, blacksmiths, wheelwrights sailing and steam ship engineers for making new, or repairing old, threads in metal. WILEY AND RUSSELL Manufacturing Company The company Wiley and Russell was established in 1872 by Solon Wiley and Charles P Russell, whose uncle founded the J. Russell Cutlery Co. The company began with the purpose of manufacturing thread cutting tools in Green River U.S. This tap and die set is an example of tools used by blacksmiths, farriers, wheelwrights and engineers on sailing and steam ships. It is also an example of early U.S. made engineering tools.Tap, Die, Die Stock set of industrial tools, fitted inside original timber box with three instruction labels attached inside lid. The set is the “Wiley and Russell LIGHTNING SCREW PLATE Pat. Aug. 5, 1884”. The lid has three metal hinges and is secured by two metal hook and eye fittings. This set of Whitworth standard threads has metal die and stocks (seven), and taps (three - the case has provision for four more die). The manufacturer’s details and the sizes of the threads are impressed into the tools. The paper labels have instructions and a diagram for the use and care of the tools. Tools have a protective oil coating. Made by Wiley and Russell Manufacturing Co. of Greenfield, Massachusetts, U.S., c. 1884; the tools were patented in August 1884, U.S. Patent 303,060. “Wiley & Russell MFG.CO, Greenfield, Mass, Pat Aug 5 1884.” “WHIT. STD.”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tap and die set, 1884 engineering tools, wiley and russell mfg co, lightning tap and die set, tap, die and stock set, screw thread cutting tools, taps and dies, stocks and dies, lightning screw plate, cutters, j.j. grant, patent no. 120266, solon wiley and charles p russell, wiley and russell, j. russell cutlery co, green river u.s, whitworth thread, fred mcdowell, frederick mcdowell, wheelwright, gig, buggy, jinker, sulkey, spring cart, farm wagon, 2-wheeled cart, horse cart, horse cart parts, jinker buggy, transport, vehicle, horse drawn, horse jinker, bryant & waterson -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Auger bits X 13

Auger bits fit into the jaws of a hand brace (brace and bit), which is used to bore holes into wood. The tapered end, or tapered shank, fits into the brace, while the twisted shank and twisted point draw the bit into the wood. The twisted shank guides the bit into the wood, helping to remove chips produced by the cutters and enabling the user to bore deep straight holes. The collection pictured here includes two common patterns of twist bits: the ‘Jennings’ double twist pattern; and the ‘Irwin’ single twist pattern. Their finely pitched threaded points are typically used to cut hardwood timber.Set of thirteen auger bits, with tapered proximal ends and corkscrew spiraled distal ends. Some with tight and loose spiral patterns. Paint spots and surface rust.[size of each bit stamped on]churchill island, tool, auger bits -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Video recordings: Instructional NMCOT and NMIT 1980s

U-Matic Video recordings (Master tapes) mostly dated in the 1980s. Alphabetically: A house of all trades [No date] (14 min). An Introduction to floor managing An introduction to floor managing. Architrave: running the mould. Solid plastering. [No date] (17 min). Boom spray calibration (turf management). [No date] (6 min). Drafting. Module C51 Step no 4.(footwear) (1987) [No time] (Edit master) Fibrous plastering (1988) (Duration 11.00) Firm foundations: presenting a case for finance (21 min) Flux cored arc welding. Roof plumbing: fitting outlet. Friction in engineering (20 min). Grafting and budding techniques. (1986) (Duration 10.00) Horticultural courses at Collingwood College of TAFE. [No date] (10 min). Making a hand made thread. [No date] [No time] Making a hand-made thread Manual metal arc welding [No date] (24 min). Master saddlery; stitching: 1 saddle, 2 back. Microphones and their use in location sound recording [No date] [No time] Microphones and their uses in location sound recording Mold cutting [No date] [No time] Plain sailing: a film about business planning (20 min). Potentiometers, Part 1. (1983)(16 min). Preparation of artwork for video tape production (1977)(162 min). Preparation of instructional video tapes (1977)(12 min). Roof plumbing: fixing eaves cutters: Part 1 – fixing methods. [no time] Saddlery: hand stitching Safe saddle making. (1985) [No time] Solid plastering/Setting in Plaster and lime (1987) (Duration 10.00) (Edit master) Special electronic effects in video production. [No date] [No time] Splitting a stone using plugs and feathers [No date, possibly 1987] (Duration 9.40) (Master edit) The necessary art; videotape lighting: practical tips. (1974)(15 min). Tiling a staircase (1987) (Duration 25.00) (master edit) Water resistant board (W.R. Board): What is a word processor (26 min). WR Board northern metropolitan college of tafe, handbooks, nmit -

NMIT (Northern Melbourne Institute of TAFE)

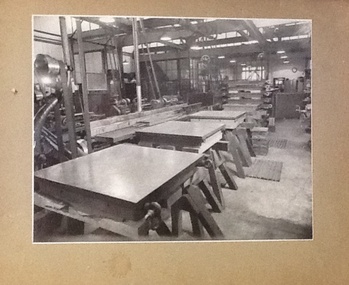

NMIT (Northern Melbourne Institute of TAFE)Photographs - CTS 1940-1943, Collingwood Technical School. Defence Training Scheme, 1940-1943

Collingwood Technical School trained apprentices in many trades. CTS was also invlved in Training Schemes during the late 1930s and during World War II. These photographs depict some of the machines and machine parts built in class. These are high quality professional photographs taken circa 1940-1943. At this time , CTS was part of the Defence Training scheme. These photographs are a visual record of this scheme.6 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work undertaken during the Defence Training Scheme, 1940-43. Also a smaller photograph of a Moultar Thread Milling Machine 1941.Each photograph has a hand written caption on the back. Captions: 1. Finished surface plates for R.A.A.F. / standing on trestle after scraping. Stack of / others in background waiting for scraping. 2. Lathe bodies in foreground, with machined / parts of lathes in middle distance, and milling / cutters, gauges and bearings in background. 3. Frames of glass splitting machines, thread / rectifying machines, and two types of milling / machine vises made in technical schools. 4.View of engineering machine shop. Carbon dioxide / freezing box in foreground, and stack of / surface plates for RAAF in middle / distance. 5.Fan geared lathes, 6 inch centres, with / self-contained motor drives, made for / cartridge factory. To be used for making / this 6.Freezing of cast iron surface plates / in layers of solid carbon dioxide / blocks. Smaller photograph has a handwritten note on the reverse: 'this photograph shows how, with the aid of a 3ft. extension mounted in front of the tool box, on which Mr. Grubb sen. is seated, these large milling machine bases ... machinists at Collingwood Technical School. A Strang, Principal 21.4.1941'. collingwood technical school, cts, apprentices, students, defence training scheme, lathes, machinery, machine parts, nmit, -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBag, Wire cutters bag

Japanese army bag for holding wire cuttersCanvas bag for storing wire cutters. 1 large section for mechanism and 2 small sections to store handles. Fasten with a strap and buckle and a tap to thread onto a belt.8 Japanese inscriptions on the outside, small Japanese inscriptions on inside.japanese, bag, tatura -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools