Showing 19 items matching "throttle"

-

Moorabbin Air Museum

Moorabbin Air MuseumPlan (item) - Bristol Aeroplane 170 schematic drawings, Throttle Control Lever Wheel (Complete) In Board

Bristol Aeroplane Company Ltd -

Moorabbin Air Museum

Moorabbin Air MuseumPlan (item) - Bristol Aeroplane 170 schematic drawings, Throttle Control Lever Wheel (Complete) Outboard

Bristol Aeroplane Company Ltd -

Moorabbin Air Museum

Moorabbin Air MuseumBook (item) - CAC Collection - Instructions For The Repair Of Lucas Throttle Valves - Type TVA3 And TVB1

-

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - ARINC - Air Transport Automatic Throttle System (ATS)

ARINC Characteristic No.558 -

Nhill Aviation Heritage Centre

Nhill Aviation Heritage CentreMemorabilia - Aircraft engine hand control unit

Hand slide control for throttle, mixture and propeller Assy 16-1131-001 -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumMachine - Outboard Motor

Twin cylinder water cooled 2 stroke Mercury outboard motor 25 HP. Features twist grip combination throttle/gearshift.Serial No 1495870 -

Federation University Historical Collection

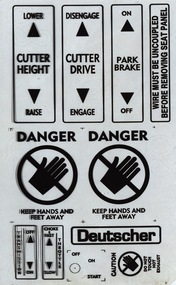

Federation University Historical CollectionArtwork, other - Artwork - Decals, ZILLES COLLECTION: Deutscher Transparencies of Decal Designs and Stickers for Large Mower - Ride-on

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Designs for Duetscher machinery. 27114.2 are Safety Instructions for a large lawn mower (ride-on). 27114.1 decals are for sections of the mower such the cutter section - height drive and park brake, Transmission and Choke/Throttle.Ten sheets of transparencies for Deutscher machineszilles printers, duetscher, decals, lawn mower, ride-on, cutter, cutter height, cutter drive, park brake, transmission, throttle, off/on -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VS model commodore, April 1995

The extent of exterior changes veered not much further than a redesigned Holden logo and wheel trims. An updated Ecotec (Emissions and Consumption Optimisation through TEChnology) version of the Buick V6 engine coincided with the changes to the engine in the United States. The Ecotec engine packed 13 percent more power, an increase of 17 kilowatts (23 hp) over the VR, cut fuel consumption by 5 percent, and increased the compression ratio from 9.0:1 to 9.4:1. Holden mated the new engine with a modified version of the GM 4L60-E automatic transmission, bringing improved throttle response and smoother changes between gearsThe VS Commodore was the last of which to be sold as Toyota Lexcens, as Holden and Toyota ended their model-sharing scheme The last Lexcens were built during 1997This model was also sold between 1995 and 1997 in small numbers to Malaysia and Singapore as the Opel Calais.4 door sedan VS Commodore sedanLion and stone badge on Bonnet and on Boot centre, Commore on both mudguards Holden badge on Rear under tail lightsvehicle, vs commodore, car -

Federation University Historical Collection

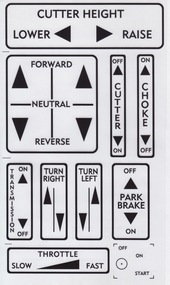

Federation University Historical CollectionArticle - Article - Decal designs for machinery, ZILLES COLLECTION: Decal stencils for parts of a cutting machine

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Stencil has sections relating to various parts and functions of a cutting machine. These labels / decals would be placed at appropriate parts for the safe operation of the machine.Frosted sheet with black labelled sectionszilles printers, ballarat, machine, labels, decals, cutter height, choke, cutter, park brake, transmission, throttle, turn right, turn left -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - EH Holden special sedan, August 1963 - February 1965

It was the first Holden to incorporate the new "Red" engine, with a 7 main bearing crankshaft instead of the 4 main bearing crankshaft used in the "Grey" engine. The larger capacity 149 ci (2400cc) engine was first only sold attached to a three-speed manual gear box or the "Hydramatic" three-speed automatic transmission with a (column shift). Although the Controlled Coupling Hydramatic used in the EH was actually a four speed, it effectively worked as a three speed unit except at full throttle. The 179 ci (2900cc) engine was initially only sold with the "Hydramatic" three-speed. The first EH with a 179 ci engine and a manual gear box was called the "EH-S4", fitted with an up-graded manual gear box, with stronger gears than the 149ci gear box and an up-graded clutch. The three-speed manual (column shift) gear boxes had no synchromesh on first only second and third 'top gear'It was the first Holden to incorporate the new "Red" engine, with a 7 main bearing crankshaft instead of the 4 main bearing crankshaft used in the "Grey" engine. The larger capacity 149 ci (2400cc) engine was first only sold attached to a three-speed manual gear box or the "Hydramatic" three-speed automatic transmission with a (column shift). Although the Controlled Coupling Hydramatic used in the EH was actually a four speed, it effectively worked as a three speed unit except at full throttle. The 179 ci (2900cc) engine was initially only sold with the "Hydramatic" three-speed. The first EH with a 179 ci engine and a manual gear box was called the "EH-S4", fitted with an up-graded manual gear box, with stronger gears than the 149ci gear box and an up-graded clutch. The three-speed manual (column shift) gear boxes had no synchromesh on first only second and third 'top gear'Two tone, blue body and white roofon the boot of this car there is a 179 badge stating that this car was powered by the larger motor available. There was also a "Hydra-matic" badge showing this vehicle was fitted with an automatic transmission. Registered number 63454-Hholden, 1963 - 1965, car -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - L-30 Chain saw, Lombard, 1962 - 1964

This chainsaw was one of the earliest models sold in Australia. It was manufactured by the Lombard company which was established in 1894 when Nathaniel Lombard developed the first practical water wheel governor in Roxbury, Massachusetts, USA. In 1904, the company moved to Ashland, Massachusetts. During the first World War, Lombard Governor produced hydraulic lathes for the manufacture of artillery shells At the conclusion of the war, Lombard expanded into the areas of chain saws and plastic molding injection machines. This model, the L-30 was only produced for 2 years from 1962 - 1964, primarily due to safety concerns and the fact that it did not have any way to sharpen or tighten the chain. This chainsaw was sold by Mann of Wodonga and donated to the Wodonga and District Historical society by David Mann, owner and manager of Mann Wodonga.This item is significant as it was produced for a limited time. It was also sold by a prominent Wodonga business.A single operator chain saw from Lombard, Ashland, Massachusetts, USA. The chainsaw was relatively lightweight but had no safety features such as a chain brake. It was made primarily of sand cast magnesium. The main cylinder was constructed of aluminium with a cast iron sleeve. It had a manual oil pump, the crankshaft operated on ball bearings and it had a maximum rpm of 4,500. See the Model profile in the accompanying Media item for details.On side of fuel tank: "ONE HALF PINT/SAE-30 OIL/ FOR EACH/ GALLON GASOLINE/ MIX WELL IN SEPARATE CONTAINER/BEFORE FILLING" On opposite side: "STARTING INSTRUCTIONS 1: FILL FUEL TANK WITH PROPER FUEL MIXTURE ( AS NOTED ON TANK) 2. FILL OIL RESERVOIR WITH #30 MOTOR OIL 3. CLOSE CHOKE, MOVE LEVER BACK TOWARDS AIR FILTER 4. HOLD THROTTLE WIDE OPEN 5. PULL STARTER HANDLE SLOWLY UNTIL STARTER ENGAGES, THEN GIVE IT A SHARP YANK 6. AS ENGINE WARMS UP, EASE CHOKE LEVER TO OPEN POSITION"hand tools, vintage chainsaws, david mann, mann wodonga -

Federation University Historical Collection

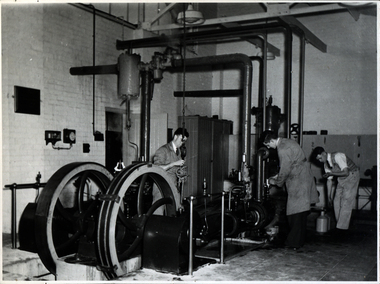

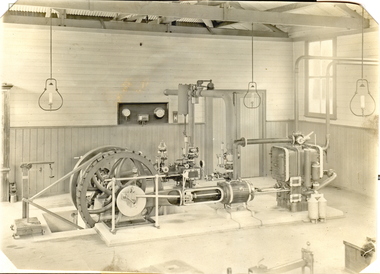

Federation University Historical CollectionPhotograph - Black and white photograph, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine. On the brake is returned serviceman Norman WIlliam Ludbrook (Diploma Electrical Engineering, 1952). Far right is Roy E. Mawby (Diploma Electrical Engineering, 1950)steam engine, model steam engine, davey paxman, electrical engineering, laboratory, scientific instrument, norman ludbrook, norman william ludbrook, roay mawby, roy e. mawby -

Federation University Historical Collection

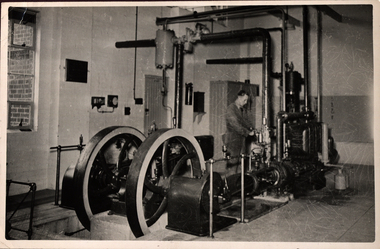

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Davey Paxman Experimental Steam Engine, c1902

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only. Black and white photograph of an experimental steam engine which was produced for the Ballarat School of Mines. It was designed for experimental purposes, such as testing of efficiency, etc. The laboratory which housed the steam engine was lit with gas lighting. davey paxman experimental steam engine, model steam engine, davey paxman, steam, thomas bath, thermodynamics -

Federation University Historical Collection

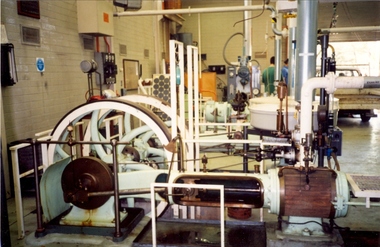

Federation University Historical CollectionPhotograph - Colour photograph, Davey Paxman Experimental Steam Engine in the Mount Helen Workshop, c1994

The Davey Paxman Experimental Steam Engine was purchased by the Ballarat School of Mines as the result of a bequest from Thomas Bath.The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.davey paxman experimental steam engine, model steam engine, steam, thermodynamics laboratory, thomas bath, bequest -

Australian Gliding Museum

Australian Gliding MuseumMachine - Auto-Tug Engine, 1983 or prior

The 1982 Ford V6 engine, built at the Ford Essex Engine Plant at Windsor in Ontario Canada, was released by Ford for installation in a number of car and light truck models manufactured in Canada, United States, Mexico and Venezula. Production probably exceeded 7 million items. The Australian Gliding Museum’s exhibit was an engine converted for aircraft use that was bought for the Gliding Federation of Australia “Auto-Tug” program from Javelin Aircraft Company in Wichita in USA. “Auto-Tug” was an experimental program sponsored by the Gliding Federation of Australia to equip a glider – sailplane Piper Pawnee PA-25-150 tug with a water-cooled engine to alleviate the costs of running and maintaining the Lycoming engines fitted to Pawnee tugs in Australia. The program began in 1988 and was aimed at obtaining limited certification for converting dedicated glider – sailplane tow planes. The engine equipped with modified intake manifolds produced 198 hp for flight with the same propeller RPM for take-off as the original Lycoming 0-540 engine. However, fuel consumption was halved as the water cooling of the Ford engine enabled quicker descents with throttle closed following the release of the sailplane. Based on the results of GFA’s program, CASA concluded that engine was quite suitable for an aircraft installation and rated it more reliable than the equivalent Lycoming and Continental aircraft engine. The use of the 1982 Ford V6 engine type for Pawnee tug conversions was discontinued when the General Motors LS1 5.7 litre V8 became available. It is understood that a small number of conversions have been done using the LS1 engine. This brief history is based on information obtained from Mike Burns and David Sharples who were involved in the Auto-Tug program from 1988 to 1992. Technical information relating to the 1982 Ford V6 automotive engine is contained in a paper by D.L. Armstrong and G.F. Stirrat of the Engine Engineering Office at Ford. Indicative of technological experimentation in the sport of glidingFord auto engine mounted on mobile standaustralian gliding, glider, sailplane, auto-tug, pawnee, tug, auto, engine, motor, ford, gliding federation of australia, burns, sharples. -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Monbulk RSL Sub Branch

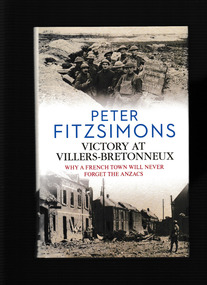

Monbulk RSL Sub BranchBook, Penguin Random House Australia Pty Ltd, Victory at Villers-Bretonneux : why a French town will never forget the Anzacs, 2016

It's early 1918, and after four brutal years, the fate of the Great War hangs in the balance. On the morning of 21 March 1918, the Kaiserschlacht (the Kaiser's battle) is launched. The biggest set-piece battle the world has ever seen. Across a 45-mile front, no fewer than two million German soldiers hurl themselves at the Allied lines, with the specific intention of driving all the way through to the town of Villers-Bretonneux, where their artillery can rain down shells on the key train hub of Amiens, thus throttling the Allied supply lines. For nigh on two weeks, the plan works brilliantly.The Germans are able to advance without check, as the exhausted British troops flee before them, together with tens of thousands of French refugees. In desperation, the British commander, General Douglas Haig, calls upon the Australian soldiers to stop the German onslaught and save Villers-Bretonneux. If the Australians can hold the line, the very gate to Amiens, then the Germans will not win the war. Arriving at Villers-Bretonneux just in time, the Australians launch a vicious counter-attack that hurls the enemy back the first time. And then, on Anzac Day 1918, when the town falls after all to the British defenders, it is again the Australians who are called on to save the day, the town, and the entire battle - even the warIndex, ill, bib, maps, p.764.It's early 1918, and after four brutal years, the fate of the Great War hangs in the balance. On the morning of 21 March 1918, the Kaiserschlacht (the Kaiser's battle) is launched. The biggest set-piece battle the world has ever seen. Across a 45-mile front, no fewer than two million German soldiers hurl themselves at the Allied lines, with the specific intention of driving all the way through to the town of Villers-Bretonneux, where their artillery can rain down shells on the key train hub of Amiens, thus throttling the Allied supply lines. For nigh on two weeks, the plan works brilliantly.The Germans are able to advance without check, as the exhausted British troops flee before them, together with tens of thousands of French refugees. In desperation, the British commander, General Douglas Haig, calls upon the Australian soldiers to stop the German onslaught and save Villers-Bretonneux. If the Australians can hold the line, the very gate to Amiens, then the Germans will not win the war. Arriving at Villers-Bretonneux just in time, the Australians launch a vicious counter-attack that hurls the enemy back the first time. And then, on Anzac Day 1918, when the town falls after all to the British defenders, it is again the Australians who are called on to save the day, the town, and the entire battle - even the war -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Holley Aircraft Carburettors, Holley Aircraft Carburettors Instruction Manual Third Edition

Instructions on servicing & maintenance of Holley aircraft carburetors, circa 1941Appears to be a duplicate itemnon-fictionInstructions on servicing & maintenance of Holley aircraft carburetors, circa 1941accelerating pump, cam, carburetor, clearance chart & diagra, compensator jet/needle/seat/spring/unit, diaphragm unit & vents, end blocks, fixtures & tools, fuel valves, inlets, limits, mixture control, nozzle bar, overhaul sheets, primers, power mixture valve, stabilizer valve, test stand, throttles, vapor separator, vent ring, venturi