Showing 23 items matching "tin opener"

-

Wodonga & District Historical Society Inc

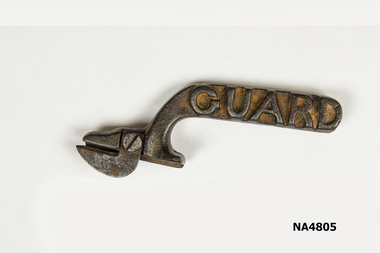

Wodonga & District Historical Society IncFunctional object - Cast iron tin opener

... Cast iron tin opener...Cast iron tin opener...Commercial tin openers first appeared in the mid 19th...This is a cast iron tin opener with a cutting blade...Commercial tin openers first appeared in the mid 19th ...Commercial tin openers first appeared in the mid 19th century and this model dates from the early 20th century. An improved version when a second serrated wheel was added came into operation about the mid 1920s. Tins (now cans) of food with sealed tops became popular in the 20th century and all households needed a tin opener. Today the can opener is still used but increasingly the can lids have an inbuilt clip that is pulled out to open the can.This tin opener has been retained as an early model of a tin opener from the past. It was used locally in Wodonga and donated by a Wodonga resident. It is also in relatively good condition.This is a cast iron tin opener with a cutting blade attached to a piece of metal with a screw. The metal handle curves out from the metal piece holding the blade. The opener is a little rusty in parts. The name ‘Guard ’ is on both sides of the handle in raised metal letters."GUARD" in raised letters on both sides of the handle.household items, cast iron appliances, can openers -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Household, Tin opener, Early 20th century

... Tin opener... Commercial tin openers first appeared in the mid 19th...This is a cast iron tin opener with a cutting blade... Commercial tin openers first appeared in the mid 19th century ...Commercial tin openers first appeared in the mid 19th century and this model dates from the early 20th century. An improved version when a second serrated wheel was added came into operation about the mid 1920s. Tins (now cans) of food with sealed tops became popular in the 20th century and all households needed a tin opener. Today the can opener is still used but increasingly the can lids have an inbuilt clip that is pulled out to open the can. This tin opener has no known local provenance but it is retained as an early model of a tin opener from the past. It will be useful for display. This is a cast iron tin opener with a cutting blade attached to a piece of metal with a screw. The metal handle curves out from the metal piece holding the blade. The opener is a little rusty in parts. The name ‘Guard ’ is on both sides of the handle in raised metal letters.‘Guard’ household items, history of warrnambool -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchKnife, Clasp, with Marlin Spike and Tin Opener, WW1 era to late 1930s

... Knife, Clasp, with Marlin Spike and Tin Opener...Knife, Clasp, with Marline Spike and Tin Opener...Knife, Clasp, with Marlin Spike and Tin Opener... Spike and Tin Opener, manufactured in England to the Standard ...Knife, Clasp, with Marline Spike and Tin Opener, manufactured in England to the Standard Pattern 6353/1905, as modified in 1913 with specific dimensions to the tin opener. This pattern was used by British forces, and was one of the patterns issued to members of the Australian Infantry Force during WW1. This pattern was used up until the late 1930s, where it was superseded by other patterns.Knife, Clasp, with Marlin Spike and Tin Opener, manufactured to the standard British pattern 6353/1905, as modified in 1913 with changed dimensions for the tin opener. The hilt of the knife has two chequered pattern sides secured by five metal rivets. The underside of the hilt has two recesses to allow storage of the blade and the tin opener. A tapered steel Marline spike is mounted on the other side of the hilt, pivoting at the opposite end to the blade and tin opener. A copper wire shackle is also secured at this end of the hilt that was used to attach the knife to a lanyard or belt clip. A fingernail indentation is located near the top of one side of the blade. The tin opener has bevelled edges tapered to a point on one side, with a steel post mounted in the middle of the other side.J. CLARKE & SON SHEFFIELDknife, clasp, ww1, steel, marline spike, australian infantry force, milirary -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchTIN Opener

... TIN Opener...TIN Opener... Somalia Army TIN Opener TIN Opener ...TIN Openerequipment, somalia, army -

Rutherglen Historical Society

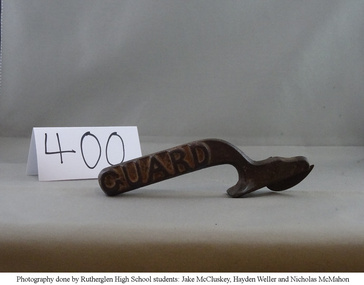

Rutherglen Historical SocietyDomestic object - Tin Opener, 1900s (Approximate)

... Tin Opener...Cast iron tin opener with handle...-country Name of Guard on handle Cast iron tin opener with handle ...Cast iron tin opener with handleName of Guard on handle -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Tin Opener

... Tin Opener...A metal bottle or tin opener with a round handle... Mitcham melbourne Guard A metal bottle or tin opener with a round ...A metal bottle or tin opener with a round handle and the name "Guard" stamped on Guard -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchKnife, Clasp, with Marlin Spike and Tin Opener - Carr Fast second pattern, World War Two era

... Knife, Clasp, with Marlin Spike and Tin Opener - Carr Fast... tin opener, manufactured in Australia in the World War Two era... pattern with the improved tin opener, manufactured in Australia ...Two patterns of clasp knife were supplied to the Australian Military Forces in the WW2 era by the Carr Fastener Company. These clasp knives were identical to those made by Whittingslowe Engineers that were made in the Whittingslowe factory under contract to Carr Fasteners. William Whittingslowe had a close association with Carr Fasteners prior to WW2 and had been Chairman of Carr Fasteners for some time.Smaller sized canoe shaped body military steel clasp knife. The clasp knife is the Carr Fast second pattern with the improved tin opener, manufactured in Australia in the World War Two era. The clasp knife has a blade, a tin/bottle opener, a marline spike as well as a screw driver and a copper wire shackle used to attach the knife to a lanyard or belt clip. The body of the knife is held together by steel rivets. Indentations to aid opening are located on the top RHS of the blade, and on the top LHS of the tin opener. The end of the tin opener is shaped to a point.CARR FAST CO AUST D (broad arrow pattern) Dclasp knife, world war two, australian military forces, steel -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Tin Opener

... Tin Opener...Tin opener - large wooden section with metal piercing... Mitcham melbourne domestic items cooking 33 Tin opener - large ...Tin opener - large wooden section with metal piercing section at one end and section for securing the tin at the other .33domestic items, cooking -

Clunes Museum

Clunes MuseumDomestic object - OPENER - TIN AND BOTTLE, Henry Lane Ltd

... OPENER - TIN AND BOTTLE...tin opener...Metal opener for tins or bottles. Corkscrew in centre... opener tin opener domestic tool cork screw Trademark Henry Lane ...Metal opener for tins or bottles. Corkscrew in centre of handle.Trademark Henry Lanebottle opener, tin opener, domestic tool, cork screw -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeOpener, tin

... Opener, tin...Heavy metal tin opener. Cast iron, hand held, blade... Marsh goldfields Early domestic utensil. Local. Heavy metal tin ...Early domestic utensil.Local.Heavy metal tin opener. Cast iron, hand held, blade attached separately. -

Frankston RSL Sub Branch

Frankston RSL Sub BranchOpener, Tin

... Opener, Tin...Standard issue tin opener used by Australian service... mornington-peninsula Standard issue tin opener used by Australian ...Standard issue tin opener used by Australian service personnel during World War 2. -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkTool - Carr Fast. Clasp Knife, Whittingslowe

... Metal handle. One blade folds out of the handle. One tin...Right side of tin opener: "CARR / Arrowhead symbol".... Military world war 2 knife Right side of tin opener: "CARR ...Clasp knives were made for military use in the Australian army during World War 2. The 'CARR' symbol indicates that the knife was made by Carr Fasteners company in Whittingslowe factories. The 'arrowhead symbol' below the 'CARR' symbol indicates that the knife was produced for military use.This item is significant as it provides insight into the tools used by the Australian Military in World War 2. It also provides historic insight into the companies that produced and supplied the tools to the military.Metal handle. One blade folds out of the handle. One tin opener folds out of the handle adjacent to the blade. On the opposite end and side of the handle a marlin spike folds out. On the end of the handle is a ring.Right side of tin opener: "CARR / Arrowhead symbol"military, world war 2, knife -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Tin Opener

... Tin Opener... is the blade, is welded by two studs to the handle Domestic object Tin ...Head, which is the blade, is welded by two studs to the handledomestic items, food preparation -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchEquipment

... and tin opener.... checkered handle with blade and tin opener. Equipment ...Folding pocket knife. Black checkered handle with blade and tin opener.1942 B. V Ler Ltd Sheffield -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncNewick

... Newick, combination tin/bottle opener... of Australia. Newick, combination tin/bottle opener Newick ...This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.Newick, combination tin/bottle opener -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchMess Tins

... Mess Tins with Opener (opener stored with ration packs)... Vietnam Army Mess Tins with Opener (opener stored with ration ...Mess Tins with Opener (opener stored with ration packs)equipment, vietnam, army -

Bendigo Military Museum

Bendigo Military MuseumEquipment - HEXAMINE STOVE-SUGAR-OPENER, estimated Vietnam War era

... serves in plastic wraps 567.3 Combination ration pack tin opener..., 4 serves in plastic wraps 567.3 Combination ration pack tin ...567.1 Stove, metal, rectangular, hexamine, folds open for use, when closed hold packet of hexamine. 567.2 Sugar, 4 serves in plastic wraps 567.3 Combination ration pack tin opener, spoon“567.3 61-1983-7330-66-010-0931”accessories, hexamine, utensil, sugar -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Australian Army Issue Clasp Knife

... included a blade, a tin opener and a marline spike as well as screw... included a blade, a tin opener and a marline spike as well as screw ...Australian manufactured clasp knives were a standard issue to Australian Military Forces during World War 2. The most commonly encountered knife was an all metal model with a canoe shaped body. This knife was a Whittingslowe first pattern clasp knife which included a blade, a tin opener and a marline spike as well as screw driver and shackle to attach the knife to a lanyard or belt clip. These knives were given a dull Nickel plating to protect them. William Thomas Whittingslowe was born in Wales in 1888, he was educated in England and at 18 migrated to Canada and then to Australia, arriving in about 1912. After working in various states, he settled in South Australia and in the 1920s set up his own business, Whittingslowe Engineers Limited. He specialised in ironworking and knife manufacturing. His firm produced a large amount of blade ware during World War 2. He also designed and built manufacturing equipment for General Motors Holden. He died at Murray Bridge (SA) in 1956.This item is significance because it was donated by a member of the community of Wodonga which has a strong connection to Australian military history.A clasp knife made completely from metal with nickel plating. The accessories all fold into a canoe-shaped body. It included a knife, can opener and marlin spike.On knife blade: WE over a broad arrow/I\australian army equipment ww2, thomas whittingslowe, australian army -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

... of can came with its own kind of opener. Tinned fish and meat... of can came with its own kind of opener. Tinned fish and meat ...It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

... of can came with its own kind of opener. Tinned fish and meat... of can came with its own kind of opener. Tinned fish and meat ...It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Mont De Lancey

Mont De LanceyCan opener, Koppers, Circa 1910

... -and-dandenong-ranges tin-openers Koppers Can Opener Pat. Oct 99 Circular ...Circular cast iron can opener with adjustable screw and spike to pierce can. Outside edge is scalloped shaped and has a small knob to hold onto the can. c1890/1910Koppers Can Opener Pat. Oct 99 tin-openers -

Mont De Lancey

Mont De LanceyCan opener

... in 1950 aged 82 years. Tin-openers Cast iron can opener ...Belonged to Mrs. J. George's grandmother, who died in 1950 aged 82 years.Cast iron can opener, with a cow's head sculpted on one end.tin-openers -

Mont De Lancey

Mont De LanceyTool - Kerosene Tin Cutter, Chapman and Co, Unknown

... openers Tools Tin Cutter Farming equipment 'Chapman and Co ...Used in the late 19th or early 20th century.A large triangular shaped metal blade tin cutter for manually opening kerosene and petrol tin lids which were often recycled for use on farms in the 19th and early 20th century. It has a rectangular shaped tubular steel handle attached to the top side by two rivets. On one of the triangular points of the blade is the manufacturer's brand ' Chapman and Co, Enfield S.A'. It was Australian made.'Chapman and Co, Enfield S..A'. tin openers, tools, tin cutter, farming equipment