Showing 215 items matching "traditional crafts"

-

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Black and White, Interior of the Former Ballarat East Library, c1979, c1979

... school of traditional crafts... and managing the Ballarat East Free Library as a School of Traditional... East Free Library as a School of Traditional Crafts ...This photo was most probably taken when the Ballarat School of Mines was considering the former Ballarat East Library as a campus. In 1980 the Ballarat School of Mines Council presented a proposal to the Ballarat City Council regarding occupying and managing the Ballarat East Free Library as a School of Traditional Crafts. The proposal included maintaining the building in optimum condition.Three black and white photographs of the interior of the former Ballarat East Library. .1) Room in the former Ballarat East Library housing remnants of the Ballarat Historical Society (probably during transfer of the Ballarat Historical Society Collection to the Gold Museum) .2) Room in the former Ballarat East Library with built in show cases at one end, and modern classroom tables and chairs. Brian McLennan sits writing at a table. .3) Roofing detail in the former Ballarat East Libraryballarat east library, ballarat east free library, school of traditional crafts, brian mclennan, ballarat historical society, museum -

Slovenian Association Melbourne

Slovenian Association MelbourneSlovenians at Royal Melbourne Show 1959, Slovenians in national costumes at the Royal melbourne Show in 1959, 1959

... shows the tourist attraction Lake Bled and many traditional... of Lake Bled and Slovenian traditional crafts.... Traditional Slovenian crafts, national costume and the tourism jewel ...The Slovenians enjoyed participation at the Royal Melbourne Show 1959 where they could showcase the Slovenian traditions, arts and crafts, and at times,culinary goodies as well.Traditional Slovenian crafts, national costume and the tourism jewel Lake BledSlovenian couple dressed in Slovenian national costume of Gorenjska region at the Royal Melbourne Show in 1959. The painting shows the tourist attraction Lake Bled and many traditional items of craft were placed in the exhibition as well. The man in the photo is Leopold Jalk.Couple dressed in Slovenian national costume, painting of Lake Bled and Slovenian traditional craftsslovenian national costume, slovenian crafts, lake bled, royal melbourne show -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 10, January 1981 to June 1981

... move for school of traditional crafts... for school of traditional crafts new plumbing/sheetmetal complex ...Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 13/01/1981 to 06/06/1981.Book with white cover, front, spiral bound. staffing advertisements, courses available, smb to run certificated courses on computers, new skills for a new era, annette chappell-lawrence, adult education programs, unemployment takes toll of unskilled in workforce, induction program for electrical apprentices at smb, business studies upgrade of typewriters, smb first country venue for sec distribution officers' training course, training of apprentices, move for school of traditional crafts, new plumbing/sheetmetal complex at smb, smb's land laboratory, lesley blanchard and nerida smith are commonwealth employment service success stories, ballarat city council defers smb request for funds, governor-general sir zelman cowan to open founders hall at bcae, concern at tafe expectations, 'great hall' has strong lines, hall achieves all that donors hoped, help with spelling problems, school transition group, ballarat special school, mary shone co-ordinator, 700 attend opening of founders hall, mittagundi outdoor program, education mission from china, tractor for smb farm course - international harvester, andrew hammond peter drake and tim murphy top motor mechanic apprentices, stuart harwood and john mitchell win australian welding institute awards, financial limits on tafe, students build in mud bricks, john michell wins engineering prize, smb wine appreciation workshop -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumDocument, John E Wulff, Biography Hans E Wulff, 2019

... The Traditional Crafts of Persia... SA and Tatura Victoria. Hans Wulff The Traditional Crafts ...Biography of Hans E Wulff, an internee Loveday SA and Tatura Victoria. 4 A4 sheets of typed information regarding Hans E WULFF, written by John WULFF.hans wulff, the traditional crafts of persia, biography, loveday internee, tatura internee -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTextile - Crocheted Sauce Bottle cover

... Traditional crafts... of traditional crafts in the late 19th and early 20th centuries ...This crocheted sauce bottle cover was made and used by Esther Elizabeth Hore at the Bogong Hotel. She was the wife of John Richard Hore who owned the Bogong Hotel from the early 1890s. In 1925 their daughter Myrtle Anne Hore (Dolly) moved to Tawonga with her husband Rod Barton. Rod worked to rebuild the hotel by constructing a series of bungalows behind the existing building. The next generation of the Hore Family continued to operate the hotel until the early 1950s. Rod and Dolly Barton later moved to the family dairy farm "Kent Meadows” in Gundrowing on land which had been selected in the 1860s by Rod’s father. Here they raised a family of six sons and six daughters through the hard years of the Depression and World War II. Dolly and the older children carried on the work on the farm whilst Rod was away on active service, as well as being actively involved in the Red Cross, Church Guild, CWA and Fire Brigade. Dolly passed away on 28th February 1991. This item was donated to Wodonga & District Historical Society by Betty Barberis nee Barton, a recognised artist both locally and internationally, one of Dolly’s 12 children.This item is significant because it is representative of traditional crafts in the late 19th and early 20th centuries and was owned by a prominent Wodonga and District family.A crocheted cotton cover designed to be placed over a sauce bottle. It has been made for decorative purposes only.traditional crafts, handcraft, barton family of gundrowing -

Whitehorse Historical Society Inc.

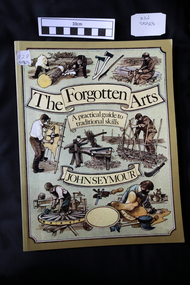

Whitehorse Historical Society Inc.Book, The Forgotten arts and crafts, 2001

... Description of traditional crafts and craft manufacture... household crafts'. 1987 Crafts and craft equipment Traditional ...Description of traditional crafts and craft manufacture in Europe.Description of traditional crafts and craft manufacture in Europe. Combined ed. of 'Forgotten arts' and 'Forgotten household crafts'. 1987Description of traditional crafts and craft manufacture in Europe.crafts and craft equipment, traditional -

Slovenian Association Melbourne

Slovenian Association MelbournePhoto, Exhibition at the Royal Melbourne Show, 1960

... Traditional Slovenian craft items17 x 20.50 cm... melbourne Exhibition Royal Melbourne Show Traditional Slovenian ...Black and white photo of the Slovenian stand at the Royal melbourne Show Exhibition in 1960Traditional Slovenian craft items17 x 20.50 cmexhibition, royal melbourne show -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for making sand casts. The traditional craft of sand casting is over... for making sand casts. The traditional craft of sand casting is over ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for making sand casts. The traditional craft of sand casting is over... for making sand casts. The traditional craft of sand casting is over ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for making sand casts. The traditional craft of sand casting is over... for making sand casts. The traditional craft of sand casting is over ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for making sand casts. The traditional craft of sand casting is over... for making sand casts. The traditional craft of sand casting is over ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for making sand casts. The traditional craft of sand casting is over... for making sand casts. The traditional craft of sand casting is over ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... . The traditional craft of sand casting is over 2000 years old.... The traditional craft of sand casting is over 2000 years old ...The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... patterns with a similar outline. The traditional craft of sand... patterns with a similar outline. The traditional craft of sand ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... . The traditional craft of sand casting is over 2000 years old.... The traditional craft of sand casting is over 2000 years old ...The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... patterns with a similar outline. The traditional craft of sand... patterns with a similar outline. The traditional craft of sand ...The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Federation University Art Collection

Federation University Art CollectionPainting - Artwork, 'Ring of the Nibellings' by David Noonan, 1989

... place'. Noonan is interested in combining art and traditional... place'. Noonan is interested in combining art and traditional ...David NOONAN (1969- ) Born Ballarat, Victoria. Lives and works Melbourne, Victoria and London, United Kingdom. Leaving secondary school as soon as he could, David Noonan enrolled in a Visual Art Course at the Ballarat School of Mines. He described this time as 'an inspiring time, with every art form covered and treated with passion and rigour.' He studied ceramics, photography, painting and knew that he had to be an artist. (https://art150.unimelb.edu.au/articles/david-noonan-making-art-in-a-dark-and-quiet-place, accessed 17 January 2020). Between 1987 and 1989 David Noonan completed a Bachelor of Fine Art at Ballarat University College, Victoria, Australia (Now Federation University Australia). He undertook Post Graduate Studies at the Victorian College of the Arts, Melbourne in 1991 and 1992. Since 2005 he has been based in London with his work featuring in a number of major international exhibitions of contemporary art, including 'Altermodern', the 2009 Tate Triennial at Tate Britain, London. Producing works in a range of media including painting, photography, film, print-making, collage and sculpture David Noonan's work often evoke the subconscious realm through their fragmented imagery, allusive qualities and complex layering of historical and cultural references. Animals, actors and masked figures are recurring motifs that imbue his works with a magical atmosphere that is suggestive of childhood memories or half-forgotten dreams. ( produced works in a range of media including painting, photography, film, print-making, collage and sculpture. His works often evoke the subconscious realm through their fragmented imagery, allusive qualities and complex layering of historical and cultural references. (https://www.ngv.vic.gov.au/essay/david-noonan-untitled/, accessed 17 January 2020) David Noonan has become known for large-scale monochromatic collages on linen comprised of fabrics which are torn, folded, cut, stitched and combined with silkscreened images. This approach was used to produce his 2018 atmospheric film 'A dark and quiet place'. Noonan is interested in combining art and traditional craft techniques. (https://artgalleryofballarat.com.au/gallery_exhibitions/david-noonan-stagecraft/, accessed 17 January 2020) This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007. Six stretched canvases making up the work 'Ring of the Nibellings'. art, artwork, david noonan, oil on canvas, alumni -

Federation University Art Collection

Federation University Art CollectionPainting, 'Through a Dark Glass Darkly' by David Noonan, c1989

... place'. Noonan is interested in combining art and traditional... place'. Noonan is interested in combining art and traditional ...David NOONAN (1969- ) Born Ballarat, Victoria. Lives and works Melbourne, Victoria and London, United Kingdom. Leaving secondary school as soon as he could, David Noonan enrolled in a Visual Art Course at the Ballarat School of Mines. He described this time as 'an inspiring time, with every art form covered and treated with passion and rigour.' He studied ceramics, photography, painting and knew that he had to be an artist. (https://art150.unimelb.edu.au/articles/david-noonan-making-art-in-a-dark-and-quiet-place, accessed 17 January 2020). Between 1987 and 1989 David Noonan completed a Bachelor of Fine Art at Ballarat University College, Victoria, Australia (Now Federation University Australia). He undertook Post Graduate Studies at the Victorian College of the Arts, Melbourne in 1991 and 1992. Since 2005 he has been based in London with his work featuring in a number of major international exhibitions of contemporary art, including 'Altermodern', the 2009 Tate Triennial at Tate Britain, London. Producing works in a range of media including painting, photography, film, print-making, collage and sculpture David Noonan's work often evoke the subconscious realm through their fragmented imagery, allusive qualities and complex layering of historical and cultural references. Animals, actors and masked figures are recurring motifs that imbue his works with a magical atmosphere that is suggestive of childhood memories or half-forgotten dreams. ( produced works in a range of media including painting, photography, film, print-making, collage and sculpture. His works often evoke the subconscious realm through their fragmented imagery, allusive qualities and complex layering of historical and cultural references. (https://www.ngv.vic.gov.au/essay/david-noonan-untitled/, accessed 17 January 2020) David Noonan has become known for large-scale monochromatic collages on linen comprised of fabrics which are torn, folded, cut, stitched and combined with silkscreened images. This approach was used to produce his 2018 atmospheric film 'A dark and quiet place'. Noonan is interested in combining art and traditional craft techniques. (https://artgalleryofballarat.com.au/gallery_exhibitions/david-noonan-stagecraft/, accessed 17 January 2020) This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.A large painting on canvas. art, artwork, david noonan, noonan, alumni, oil on canvas, available -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

... of the older, traditional craft skills. Between 1985 and 1998, Siebe... of the older, traditional craft skills. Between 1985 and 1998, Siebe ...This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

... of the older, traditional craft skills. Between 1985 and 1998, Siebe... of the older, traditional craft skills. Between 1985 and 1998, Siebe ...This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944

... of the older, traditional craft skills. Between 1985 and 1998, Siebe... of the older, traditional craft skills. Between 1985 and 1998, Siebe ...Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment, and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards, and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering, and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air, and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman's fortunes began to decline as an aging Sir Robert Davis failed to invest, or change the company's business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998). (For information regards the diving helmet & Frank King see Notes Section at the end of this document)The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job. Frank Kings' diving helmet and compressor (communication pipe stored separately). Compressor is hand cranked. US Navy diving helmet, Mark V. Two maker's plates attached. Made in 1944.On rear "WATER SUPPLY" On front 'PATENT" " Logo: Images (Lion, Crown, Horse, Shield within an oval) "SIEBE, GORMAN & Co. Ltd. SUBMARINE ENGINEERS, LONDON.flagstaff hill, warrnambool, maritime museum, great ocean road, us navy diving helmet, commonwealth government salvage, diving helmet, marine salvage, frank king, diver, siebe. gorman & co ltd, submarine equipment, diving equipment, communication under water, hand cranked, diving compressor -

The Beechworth Burke Museum

The Beechworth Burke MuseumCeremonial object - Message Sticks, Dja Dja Wurrung

These Message Sticks acknowledge the return of Dja Dja Wurrung Cultural material held by the Burke Museum. The Burke Museum is the current custodian of a significant collection of First Peoples’ cultural material from across South-Eastern Australia. These objects were sold to the Museum by Reynold Everly Johns in 1868. We recognise the harm caused by dispossession of cultural material, and by any inappropriate display and interpretation of this collection over the past 150 years. The Burke Museum is continuing to build relationships and collaborate with traditional owners, Aboriginal communities and the museum sector to ensure culturally appropriate outcomes for the collection, including repatriation of objects to communities of origin. Message sticks are a form of communication between Aboriginal nations, clans and language groups even within clans. Traditional message sticks were made and crafted from wood and were generally small and easy to carry (between 10 and 20 cm). They were carved, incised and painted with symbols and decorative designs conveying messages and information. Some were prepared hastily, like you might create a note left on a friend’s desk or a quick text message; others were prepared with more time to make the markings neat and ornate. There were always marks that were distinctive to the particular group or nation sending the message and often marks identifying the relationship of the carrier to their group. This way it could be identified and authenticated by neighboring groups and by translators when the message stick was taken long distances. Two solid cylindrical shaped pieces of wood bound together with black, red and yellow string. Each stick has etchings with angular lines and dots. dja dja wurrung, message sticks, burke museum, beechworth, beechworth museum, repatriation, reynold everly johns -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Pidgeon, Memorial to Alistair Knox, Eltham Cemetery, Victoria, 5 April 2021

Alistair Knox was an architect and builder who came to Eltham in 1948. Influenced by Frank Lloyd Wright and Walter Burley Griffin, he sought to create buildings that would blend into the landscape, enhanced by the planting of indigenous flora. The post-war shortage of building materials made traditional construction expensive. Adobe (mudbrick) provided a cheap and plentiful alternative, and one which would be aesthetically pleasing. Mud-brick manufacture was a problem at first. Sonia Skipper had been experimenting with Eltham clays for years to find the best mix for making bricks and render. Alistair employed her as building foreman on several of his sites. By the 1980s, he had brought mud-brick and earth building into the Australian mainstream, and a Knox-designed house had become highly desirable. Sonia said that he would craft a bespoke earthen house to fit with his client's lifestyle. He was drawn to the environmental movement, publishing three books on housing and the environment, and speaking on radio. He also served on the Eltham Shire Council 1971-1975, was Shire President 1974 and was instrumental in re-establishing the Eltham Community Festival in 1975. Alistair died in 1986 and is buried in a small garden setting at Eltham Cemetery.Born Digitaleltham cemetery, gravestones, heritage excursion, alistair knox -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Pidgeon, Grave of Alistair Samuel Knox, Eltham Cemetery, Victoria, 5 April 2021

Alistair Knox was an architect and builder who came to Eltham in 1948. Influenced by Frank Lloyd Wright and Walter Burley Griffin, he sought to create buildings that would blend into the landscape, enhanced by the planting of indigenous flora. The post-war shortage of building materials made traditional construction expensive. Adobe (mudbrick) provided a cheap and plentiful alternative, and one which would be aesthetically pleasing. Mud-brick manufacture was a problem at first. Sonia Skipper had been experimenting with Eltham clays for years to find the best mix for making bricks and render. Alistair employed her as building foreman on several of his sites. By the 1980s, he had brought mud-brick and earth building into the Australian mainstream, and a Knox-designed house had become highly desirable. Sonia said that he would craft a bespoke earthen house to fit with his client's lifestyle. He was drawn to the environmental movement, publishing three books on housing and the environment, and speaking on radio. He also served on the Eltham Shire Council 1971-1975, was Shire President 1974 and was instrumental in re-establishing the Eltham Community Festival in 1975. Alistair died in 1986 and is buried in a small garden setting at Eltham Cemetery.Born Digitaleltham cemetery, gravestones, heritage excursion, alistair samuel knox -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Proddey, Early 20th century

This wooden proddey has a rounded handle and a cone shape with a point at the bottom. It is used for making rag rugs. The wood is discoloured at the pointed end, indicating that is has been used. The tool is part of the W.R. Angus Collection. Traditionally, in the 18th and 19th centuries, rag rug making was a domestic craft. Old or worn-out fabrics and clothing would be cut into strips then proddey would be used to poke the strips through a woven backing fabric. The fabrics were re-purposed and the rugs provided warmth or protected the floors from fluids or dirt.The proddey is an example of a tool used for rag rug making, in the 18th and 19th centuries. The handcraft returned to popularity in the early 20th century. W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool.Proddey; teardrop or conical shape, light-coloured wood, used for rag rug making. Tool has a rounded handle and is decorated with two scored lines around the top of the cone. Part of the W.R. Angus Collection. Dr Angus lived and worked in Warrnambool with his family from the 1930s to the 1960s. He was the last doctor to pe appointed as a Port Medical Officer. He and his wife were actively involved in the local community. He enjoyed several pastimes, such as billiards, weaving, pastel drawing and rag rug making.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, hand craft, homemade, rag rug, rug making tool, proddie, recycled fabric, cottage craft, 18th century, 19th century, handmade, floor mat, mat, rug, w.r. angus, craft, handcraft, recycle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Life Jacket, Harry West Pty Ltd, Sailmakers, 1930s-1950s