Showing 16 items matching "tube boiler"

-

Port of Echuca

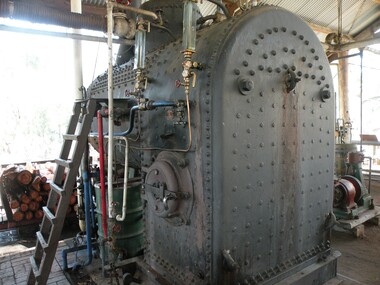

Port of EchucaFunctional object - Locomotive Type Fire Tube Boiler, 1927

... Locomotive Type Fire Tube Boiler... of a fire tube boiler where the fire from the fire box heats...Large cast iron, fire tube boiler with 124 fire tubes, fire... of a fire tube boiler where the fire from the fire box heats ...This Johnson Bros. (USA) Locomotive Type Boiler was from a steam shovel (that moved on rails) that excavated rock and soil during the construction of Stevens Weir near Deniliquin NSW in 1934. It has a working pressure of 100psi. This is an example of a fire tube boiler where the fire from the fire box heats the water surrounding the fire tubes running through the boiler, smoke escapes out the smoke stack and the steam is captured in the dome and sent through pipes toward other engines in the Port of Echuca Steam Display. Two glass gauges are fitted on the side of the firebox. Two safety valves are fitted at the top of the boiler to maintain the correct and safe pressure. It still functions today for visitors most days of the week.A good example of the technology and industrial history of the Riverina region of southern NSW and northern Victoria. It is an integral part of the Port of Echuca Steam Display running secondary engines off the steam produced within this boiler. Large cast iron, fire tube boiler with 124 fire tubes, fire box, steam dome and exhaust chimney. boiler, johnson bros, steam display, kevin hutchinson steam shed -

Federation University Historical Collection

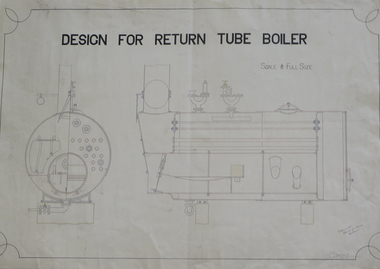

Federation University Historical CollectionTechnical drawing, Design for Return Tube Boiler, 1919

... Design for Return Tube Boiler... Tube Boiler ... Boiler Design for Return Tube Boiler Technical drawing ...Coloured ink on paper technical drawing: Design for Return Tube Boiler technical drawing, engineering drawing, boiler, s g barnett, l archibald -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Boiler, Jackson Boilers Ltd, 1920s

... tube water boiler... and sheet metal works made this tube water boiler. It was a fitting...Water boiler, free standing Jackson's Tube boiler. A tall... and sheet metal works made this tube water boiler. It was a fitting ...Jackson Boilers Ltd., brass founders, electro platers and sheet metal works made this tube water boiler. It was a fitting in the vessel Reginald M, a small cargo ship built at Port Adelaide in 1922 and named after her builder and first owner, John Murch. The Reginald M was launched at Largs Bay, South Australia, in 1922 to carry cargo around South Australia that included guano, barley, wool, horses, cattle, timber, explosives, potatoes, shell grit, and gypsum. It passed through numerous owners over the years and primarily maintained its purpose as a cargo vessel. In 1975, the decommissioned Reginald M was purchased by Flagstaff Hill Maritime Museum as an attraction. Although restoration efforts were undertaken and maintained for the craft above the water line, deterioration occurred below the surface and resulted in the ship being unsafe for visitors to board. It was broken up and removed from Flagstaff Hill in 2018, but items such as the historical boiler remain in Flagstaff Hill’s Collection. JACKSON BOILERS LTD.: - In 1911, Henry Jackson was the Managing Director at Jackson Boilers Ltd. He had gained around 30 years’ experience as a tin plate worker, plumber and gas fitter at Ilkey in 1881, then at Leeds by 1901. By 1921, he had changed employment from Jackson Boilers to Managing Director of Patent Water Boilers. During World War I, Jackson Boilers Ltd of Leeds performed war work like many other manufacturers at that time. The firm made cases for the explosive picric acid and electroplated fuse hole plugs. In 1918, the firm employed 15 males and 19 females. Jacksons Boilers became very successful throughout the first half of the twentieth century with showrooms and sales offices in Scotland, the Midlands and Southern England. It also had an office in Dublin, Ireland. In the post-war 1920s, the firm’s production included instantaneous water boilers and coffee machines for cafes, restaurants and canteens. Jackson Boilers also began to supply shipping lines with catering water boilers for their ships. The firm applied for a USA patent for the tube boiler in 1930, for the design which appears to have been invented in 1926. A 1971 advertisement adds the credentials, Members of the Catering Equipment Manufacturers’ Association. The tube water boiler was designed specifically for use in a ship's restaurant or dining area and patented by Jackson Boilers Ltd. of Leeds. The boiler is significant as a patented design, illustrating the evolution of maritime, commercial and domestic water boilers that have led to many innervations and improvements in today's boilers that are used in heating and in producing hot water for domestic and catering use. It is also significant as it is one of the earlier boilers the Jackson company made in the early 1920s before they applied for a US patent on their revised design in 1926.Water boiler, free standing Jackson's Tube boiler. A tall metal cylindrical stand with a metal sphere on top and several pipe fittings on the sides. A brass tap with a lever handle is connected to the front. A plaque with maker's details is attached under the tap. Details are also impressed into the cylinder above the tap.Jackson Boilers Leeds Ltd. "JACKSON'S PATENT" . Other details indecipherable. flagstaff hill maritime museum and village, flagstaff hill maritime museum, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, leeds, jackson boilers ltd, jackson boilers, henry jackson, brass founders, electro platers, sheet metal works, patent water boilers, leeds manufacturer, tube water boiler, domestic boiler, tube domestic boiler, tube boiler, water heaters, water boilers, self-feeding water boilers, sheet metal work instantaneous water heaters, engineering, allied trades, metal workers, metal trade, food machinery, hospitality equipment, ship equipment, ship water boiler, ship heater, catering boilers, café boiler, restaurant boiler, canteen boiler, catering equipment manufacturers’ association, cema, kitchen equipment, kitchen appliance, war work, world war i, wwi, picric acid, picric acid cases, fuse hole plugs, electro plated fuse hole plugs, reginald m, cargo ship, port adelaide, 1922, john murch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

... Multi Tube Boiler... kind of boiler is a water tube boiler, in which the water... kind of boiler is a water tube boiler, in which the water ...A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Puffing Billy Railway

Puffing Billy RailwayGeorge and George multi tube under fired boiler, 1929

... George and George multi tube under fired boiler... under-fired return-flue type 18 tube boiler capable... multi tube under fired boiler George and George ...Boiler purchased by Malvern city council to supply steam to a stationary vertical engine that drove a stone crusher. Built by George and George Pty. Ltd., Melbourne in 1929, it is an external under-fired return-flue type 18 tube boiler capable of supplying steam at 100 pounds per square inch (600 kPa). This boiler can be occasionally seen in steam at the Museum supplying steam for the operation of stationary engines on display near by. Donated by Malvern City Council in 1969. Historic - Industrial Steam Boiler EquipmentSteel, Cast IronGeorge and George Pty Ltd, Melbourne 1929george and george, malvern, steam, boiler, stone crusher, puffing billy -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryBrass Tube

... Brass tube ffrom locomotive boiler,using bore water... boiler,using bore water, on Richmond - Conclurry line Brass Tube ...Brass tube ffrom locomotive boiler,using bore water, on Richmond - Conclurry line -

Bendigo Historical Society Inc.

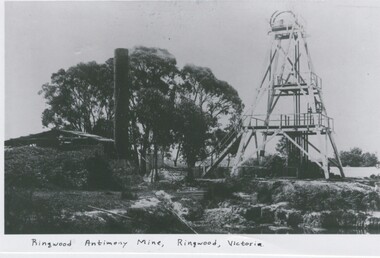

Bendigo Historical Society Inc.Photograph - RINGWOOD ANTIMONY MINE: RINGWOOD, VIC

... black and white photo of poppet head, shed, ( boiler tube... of poppet head, shed, ( boiler tube ) chimney. On front ...black and white photo of poppet head, shed, ( boiler tube ) chimney. On front , handwritten, Ringwood Antimony Mine, Ringwood, Victoria. On back RHSV stamp. Mng 34.organization, business, ringwood antimony mine -

Bendigo Historical Society Inc.

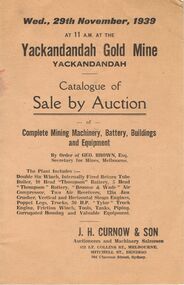

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - YACKANDANDAH GOLD MINE

... Includes:- Double 8in Winch, Internally Fired Return Tube Boiler..., Internally Fired Return Tube Boiler, 10 Head Thompson Battery, 5 Head ...Light tan coloured auction catalogue for a sale at the Yackandandah Gold Mine, Yackandandah on 29th November, 1939 of Complete Mining Machinery, Battery, Buildings and Equipment, By Order of Geo. Brown, Esq, Secretary for Mines, Melbourne. The Plant Includes:- Double 8in Winch, Internally Fired Return Tube Boiler, 10 Head Thompson Battery, 5 Head Thompson Battery, 'Broome & Wade' air Compressor, two Air Receivers, 12in Jaw Crusher, Vertical and Horizontal Steam Engines, Poppet Legs, Trucks, 30 H.P. 'Tylor' Truck Engine, Friction Winch, Tools, Tanks, Piping, Corrugated Housing and Valuable Equipment.J.; H. Curnow & Son were the auctioneers. Catalogue printed by The Cambridge Press.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - yackandandah gold mine, geo brown esq, j h curnow & son, the cambridge press -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Letter - MCCOLL, RANKIN AND STANISTREET COLLECTION: QUOTE FROM MILLER AND CO. MACHINERY, 25th May 1931

... type offered, the following is offered: return tube boiler... type offered, the following is offered: return tube boiler ...Five-page letter and quote, 25th May 1931, from Miller & Co Machinery, 27 Queen Street, South Melbourne. Bendigo office phone 50. Quote for Central Nell Gwynne shaft: steam winch, straight line steam drive air compressor, air receiver, Cornish flue boiler, Worthington duplex steam pump. Price for foregoing 740 pounds. Delivery of boiler at Redan shaft, poppet legs standing at Buttrey's Reward Mine and the whole of the balance of the plant F.O.R. Melbourne Monument Hill Shaft: steam winch double cylinder, straight line single stage steam driven air compressor, air receiver crown flanged ends, Cornish flue boiler, steam pipes, air pipes, iron chimney stack 26'0' x 3'.6' diameter, black steel wire ropes 1000' length Price for foregoing 610 pounds. If preferred, self-contained boiler in lieu of Cornish type offered, the following is offered: return tube boiler, by Roberts and Sons Bendigo. This boiler is self-contained Deborah shaft: straight line steam driven air compressor, air receiver. Price 200 pounds.bendigo, gold mining, mccoll rankin and stanistreet, miller and co., machinery., central nell gwynne gold mine, monument hill gold mine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBrush

Tube Brush also called a Flue Brush. Used for cleaning the tubes and flues of a steam engine or other boiler. L 6' 2"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: THE JOURNAL OF THE INSTITUTION OF LOCOMOTIVE ENGINEERS (LONDON )

The journal of the institution of locomotive engineers (London) with grey cover and black text. The journal president is M. F. Ryan Esq CBE. Publisher: the institution, 46 Malling St , Lewes Sussex , England. The contents include: new members, steel fireboxes and tubes, superheat estimation, Manchester meeting, Leeds meeting, relation of cylinder and boiler power to locomotive rating, writing on page 2 'J Badham 16 Abbott St Bendigo', item date 1919.M F Ryancottage, miners, j badham/the journal of the institution of locomotive engineers(london ) m f ryan -

Puffing Billy Railway

Puffing Billy RailwayFormer Puffing Billy Locomotive Boiler 6A

... Former Puffing Billy Locomotive Boiler 6A - front tube...Former Puffing Billy Locomotive Boiler 6A - front tube... Boiler 6A - front tube plate missing Historic - Former Puffing ...Former Puffing Billy Locomotive Boiler 6A - front tube plate missing Historic - Former Puffing Billy Locomotive Boiler 6A - front tube plate missing Former Puffing Billy Locomotive Boiler 6A - front tube plate missing Made of iron , wrought iron , metal;puffing billy, 6a boiler -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryBrass Tube

... of samples as 89a. From the iron boiler itself. Brass Tube ...From the same set of samples as 89a. From the iron boiler itself. -

Bendigo Historical Society Inc.

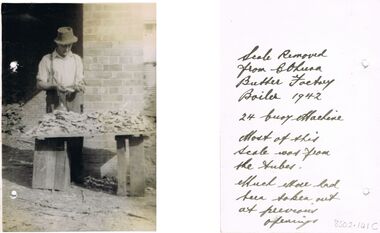

Bendigo Historical Society Inc.Photograph - BILL ASHMAN COLLECTION: MAN STANDING BESIDE BENCH PILED WITH SCALE

Black and white photograph showing a man standing beside a bench piled with scale. The bench is held up by a couple of boxes. He is holding some pieces of scale. Written on the back is : Scale Removal from Cohuna Butter Factory Boiler 1942. 24 buoy Machine. Most of this scale was from the tubes. Much more had been taken out at previous openings.sciences, bill ashman collection - correspondence, photograph, cohuna butter factory boiler -

Bendigo Historical Society Inc.

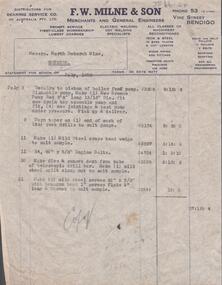

Bendigo Historical Society Inc.Document - NORTH DEBORAH G. M. CO. N. L. - STATEMENT TO NORTH DEBORAH G. M. CO. N. L. from F.W. Milne & Son

Statement from F. W. Milne & Son, Merchants and General Engineers, Vine Street, Bendigo to North Deborah G. M. Co. N. L. Copy of statement for the month of July, 1958. Top of the page is printed with 'F.W. Milne & Son, Merchants and General Engineers' of Vine Street, Bendigo and the name and types of goods and services offered. Statement is for repair to boiler feed pump, turn taper on end of rock drills to suit sample, make a mild steel cross head wedge to suit sample, supply of bolts, make dies and remove dent from tube of telescopic drill bar, make mild steel split clamp nut to suit sample, make 2 mild steel screws 2 1/2'' x 5/8'' with hexagon head 1'' across flats 1/2'' long and thread to suit sample. Statement is a typed, carbon copy. It has copy written in pencil under the typing. Albert Richardson Collection. document, gold, north deborah g. m. co. n. l., north deborah g. m. co. n. l., statement to north deborah g. m. co. n. l., f w milne & son -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future.