Showing 7 items matching "wheel cast-iron machinery"

-

Orbost & District Historical Society

Orbost & District Historical Societywheel

... wheel cast-iron machinery... gippsland wheel cast-iron machinery A cast iron wheel. The rim ...A cast iron wheel. The rim is ridged with fine teeth. In the centre is a fixed axle - bent and snapped off. It has six circular holes.wheel cast-iron machinery -

Orbost & District Historical Society

Orbost & District Historical Societywheel, Late 19th century - early 20th century

This feed wheel is part of the drill press catalogued as No. 2030.A cast iron wheel ( a feed wheel) with three spokes (one has been broken off). It has a screw nut for fastening to the shaft of a workshop drill (cat. no. 2030).BUFFALO FORGE Co. BUFFALO N.Y.drill machinery engineering cast iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

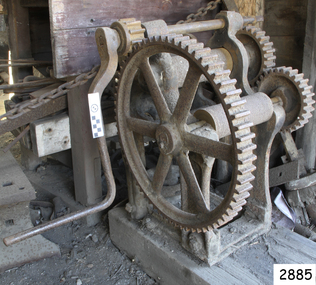

A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPetrol Engine, Early 20th century

Single cylinder horizontal petrol engine mounted on a 4 wheeled trolley. Two flywheels, one either side, no pulley. Galvanised cylindrical fuel tank mounted on a wooden box in front. Box contains a battery and ignition coil. Trolley has cast iron wheels and is designed for pulling by hand. Painted red and grey. Probably a power source for farm machinery. On a brass plate fixed to the cylinder. "Waterloo Boy Gasoline Engine / No. 81491, HP 4 / Waterloo Gasoline Engine Co. / Waterloo Iowa / Patented / August 7 1900, Dec 3 1901, Oct 7 1907 / Other patents pending / Sold by Waterloo Gasoline Engine Co." On each side of the water tank is an oval white transfer with "Waterloo Boy" above an illustration of a small boy wearing a wide brimmed hat.machinery ... engine ... petrol ... metalwork -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Cream Separator

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. ALFA-LAVAL SEPARATORS The principal works and head office of Aktiebolaget Separator was established by Gustaf de Laval in Stockholm. The first Laval milk separator was patented in1884. In Australia three old established firms commenced pioneering the Alfa Laval cream separators in about 1885. These were A. W. Sandford & Co. Ltd., in Adelaide, J. Bartram & Son, of Melbourne, who have ever since been the Victorian agents of Aktiebolaget Separator. In New South Wales and Queensland, the pioneering firm was Waugh & Josephson Ltd. J. Bartram & Son, the distributor of the separator in this collection, established their business in Melbourne in 1881. In 1892 Bartram & Son estimated that 1,130 of these machines were operating throughout Victoria. This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is made from cast iron. The cover and vat are made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A name plate featuring the Victorian distributor, J Bartram & Son of Melbourne and a plate outlining patent information are attached to the base by screws.Around edge of wheel "Aktiebolaget Separator Stockholm/ 2236"dairying industry, dairy machinery, milk separators -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkMachine - Chaff cutter, Bentalls, 1913

Chaff cutter. Bentall - 1913. Used to cut straw or hay into small pieces before being mixed together with other forage and fed to horses and cattle. Used on a small mixed farm in Emerald originally purchased by C. T. Alexander in 1920.A chaff cutter was an essential piece of equipment in early farms - of which there were many in the Emerald area - which were highly dependent on horsepower for agricultural work until the widespread use of tractors in the second half of the twentieth century.Chaff cutter with cast iron frame containing two sets of teeth which are connected to gears which are connected to a large wheel operated by hand. Missing from this particular chaff cutter are the cover for the gears, part of the handle, and the wooden chute into which the stalks were fed.Embossed on main chassis: 'BENTALL'S IMPROVED CHAFF CUTTER / 1913 / MALDON ENGLAND'. Embossed on wheel: 'BENTALL'S HEYBRIDGE MALDON ENGLAND / 1382'. Embossed on cover over feeder teeth: 'CDC BENTALL'. Embossed on feeder entrance: '947'.alexander, emerald, chaff cutter, early 20th century, bentall, agricultural machinery