Showing 22 items matching "wool processing weaving"

-

National Wool Museum

National Wool MuseumBook, Craftmanship in Wool Throughout the Ages

... Wool Processing Weaving... in wool processing. Wool Processing Weaving National Wool Textile ..."Craftmanship in Wool Throughout the Ages: British Wool Cloth Leads the World" - National Wool Textile Export Corporation, 1951. Provides an overview of hand and machine techniques in wool processing.wool processing weaving, national wool textile export corporation, wool processing, weaving -

National Wool Museum

National Wool MuseumBook, Wool Year Book 1927

... Textile History Textile Finishing Wool Processing Textile... Finishing Wool Processing Textile Machinery Weaving Wool Year Book ..."Wool Year Book 1927" compiled by the editor of the 'Textile Mercury'.textile history textile finishing wool processing textile machinery weaving, textile mercury ltd, carding, spinning machinery, weaving machinery, textile history, textile finishing, wool processing, textile machinery, weaving -

National Wool Museum

National Wool MuseumBook, Wool Year Book 1949

... Textile History Textile Finishing Wool Processing Textile... Processing Textile Machinery Weaving H D Radford Wool Year Book 1949 ..."Wool Year Book 1949" - The Textile Mercury Ltd.H D Radfordtextile history textile finishing wool processing textile machinery weaving, textile mercury ltd, carding, spinning machinery, weaving machinery, textile history, textile finishing, wool processing, textile machinery, weaving -

National Wool Museum

National Wool MuseumBook, Wool Year Book 1927

... Textile History Textile Finishing Wool Processing Textile... Processing Textile Machinery Weaving Alexander Lau Pty Ltd Carding ..."Wool Year Book 1927" compiled by the editor of the 'Textile Mercury'.Mr A G .[?]textile history textile finishing wool processing textile machinery weaving, alexander lau pty ltd, carding, spinning machinery, weaving machinery, lau, mr alexander - alexander lau pty ltd, textile history, textile finishing, wool processing, textile machinery, weaving -

National Wool Museum

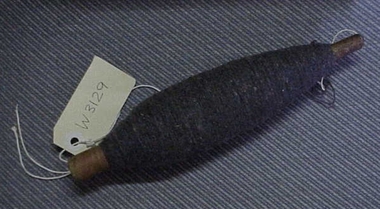

National Wool MuseumShuttle, estimate Mid-20th century

Example of a shuttle used for a loom in the weaving process. This shuttle was probably used as an advertising piece for Waddington's company as it is constructed differently to other examples of working shuttles in the museum collection. This shuttle is a a unique item in the collection as a shuttle made for advertising purposes instead of being made for use on a loom. Wooden loom with metal tips on either end. Loom is rectangular. One side has a green sticker. Metal pieces inside loom are not present.WADDINGTON'S/ FOR/ SHUTTLES OF QUALITY/ Phone Bradford 27668waddingston's, weaving, shuttle, loom, advertising, geelong, wool -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

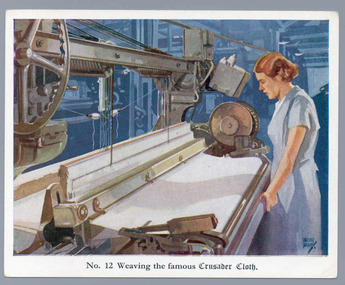

National Wool MuseumCard

This card is the twelfth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of weaving.Card no. 12 from the Crusader Mills information card set, c.1945-55. Verso of card no. 12 from the Crusader Mills information card set, c.1945-55.No. 12 Weaving the famous Crusader Cloth.australian woollen mills pty ltd stamina clothing company, weaving looms -

National Wool Museum

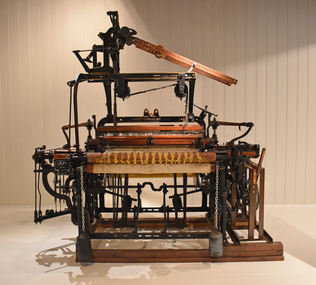

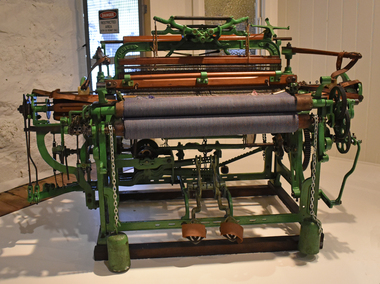

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

... Loom Wool processing Textile Industry Hattersley dobby loom ...Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1925

... hattersley and sons ltd weaving machinery Wool processing Loom ...Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley treadle loom (revolving box hand loom). Beam of loom was removed and sent to Foster Valley Mill in 1989 to be returned via Tom Crocker. The National Wool Museum gratefully acknowledges the contribution of Mr Fred Murgatroyd & Mr Bernard Tolan in making this Hattersley Loom Operational. Green painted Hattersley treadle loom (revolving box hand loom).weaving, george hattersley and sons ltd, weaving machinery, wool processing, loom, restoration -

National Wool Museum

National Wool MuseumPhotograph Album, The Valley Worsted Mills, Geelong

Photograph album containing 15 photographs of the textile processes which took place at the Valley Worsted Mill which was established in 1923.Photograph album contains 15 photographic postcards of textile processes from the Valley Mill, c.1920s. Valley Mill, Geelong, c.1920s. Wool sorting at the Valley Mill, Geelong, c.1920s. Wool scouring at the Valley Mill, Geelong, c.1920s. Woollen carding at the Valley Mill, Geelong, c.1920s. Worsted carding at the Valley Mill, Geelong, c.1920s. Combing and drawing at the Valley Mill, Geelong, c.1920s. Woollen spinning at the Valley Mill, Geelong, c.1920s. Worsted spinning at the Valley Mill, Geelong, c.1920s. Winding at the Valley Mill, Geelong, c.1920s. Warping at the Valley Mill, Geelong, c.1920s. Weaving at the Valley Mill, Geelong, c.1920s. Mending at the Valley Mill, Geelong, c.1920s. Wet finishing at the Valley Mill, Geelong, c.1920s. Dry finishing at the Valley Mill, Geelong, c.1920s. Warehouse at the Valley Mill, Geelong, c.1920s.PHOTOGRAPHS THE / VALLEY WORSTED MILLS / GEELONG WOOL SORTING / WOOL SCOURING / WOOLLEN CARDING / WORSTED CARDING / COMBING & DRAWING / WOOLLEN SPINNING / WORSTED SPINNING / WINDING / WARPING / WEAVING / MENDING / WET FINISHING / DRY FINISHING / WAREHOUSE C.J. Frazer Photographer / Melbournetextile mills warehouses, weaving, textile production, textile mills, valley worsted mill, scouring, carding, combing, drawing, spinning, winding, warping, wet finishing, mending, milling, dry finishing, textile mills - warehouses -

National Wool Museum

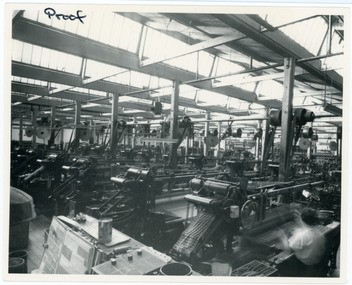

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the weaving room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumBobbin, Mule spinning bobbin

Spool of grey yarn used in the process of mule spinning.weaving mills -

National Wool Museum

National Wool MuseumCone

Designed for nce only use. Used for holding the yarn during yarn dyeing. The process was called "pressure dyeing" for a small amount of yarn. Doesn't create an even dye effect.Wangaratta Woollen Millsweaving mills, wangaratta woollen mills -

National Wool Museum

National Wool MuseumCreel

Used in the weaving process. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Clothing - Dress, Coat, c1960

Worn by donor at son's wedding.|Jacquard, a complex and intricate weaving process on a power loom invented bt Joseph Jacquard in 1801. It refers to fabrics or textiles woven by this process of punch cards, using damask, twill, silk or plain weave,wool. The design being woven into the material.1960 Apple green dress and matching coat. There is a silver thread through the weave of the material (Jacquard Design - see History). Dress also trimmed with silver braid. Stand up collar. Back zip and self covered buttons.|Matching coat has round neck - two sets of three self covered buttons and loops.costume, female -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

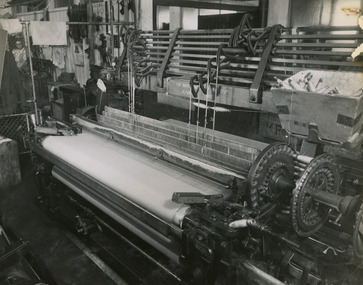

National Wool MuseumPhotograph - Weaving Machine, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a weaving machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W26 / W26. Weaving.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

Wyndham Art Gallery (Wyndham City Council)

Wyndham Art Gallery (Wyndham City Council)Sculpture, Kylie Stillman, The Remains, 2013

Something new has happened in Kylie Stillman’s work. It is not a departure. Perhaps a better way of explaining it would be an inward looking, a reflection on process and purpose. In the twelve small book stacks that make up this series, we find not birds or trees – the forms that have become familiar tropes in Kylie’s art – but a stroke, a scribble, a loop, a weave. In Kylie’s words these are: 'the basic structural elements and gestures that make things things - the stroke that makes a painting, the scribble that makes a pen work, the notation that makes writing, the intertwining of wool that makes a garment, the weave of fibres that make furnishings'. - Chloe Watson (2013)Paperback books and timber baseaustralian art, sculpture, female artist