Showing 354 items matching "worsteds"

-

National Wool Museum

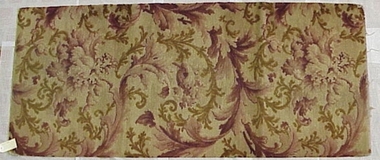

National Wool MuseumSample, Carpet

Sultana worsted Axminster border made by John Crossley & Sons, Dean Clough Mills, Halifax, England. The border framed the edge to stripe of object 88.0048 (old registration number), laid to fill floor space. Part of the ten piece collection originally presented to the Queensland Museum by Mr Doug Glanville.Sultana worsted Axminster border made by John Crossley & Sons, Dean Clough Mills, Halifax, England. Sultana worsted Axminster border made by John Crossley & Sons, Dean Clough Mills, Halifax, England.Sultana worsted 3 1' 10 1/2" 5/8 Border Carpetweaving, john crossley and sons, carpet -

National Wool Museum

National Wool MuseumSample, Carpet

Sultana worsted Axminster 27" carpet body sample made by John Crossley & Sons Ltd. Related to border sample 88.0047 (old registration number). Part of ten piece collection originally presented to the Queensland Museum by Mr Doug Glanville.Sultana worsted Axminster 27" carpet body sample made by John Crossley & Sons Ltd. Sultana worsted Axminster 27" carpet body sample made by John Crossley & Sons Ltd.Sultana worsted wool Axminster linen back manfd. 1893 4 27" body carpet J.C & Sons Ltd Halifax Englandweaving, john crossley and sons, carpet -

National Wool Museum

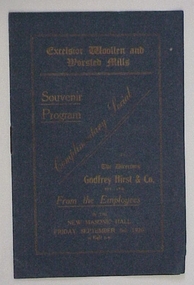

National Wool MuseumProgram, Excelsior Woollen and Worsted Mills: Souvenir Program 1920

Excelsior Woollen and Worsted Mills: Souvenir Program 1920 for a Complimentary Social from the employees to the directors Godfrey Hirst & Co.Excelsior Woollen and Worsted Mills: Souvenir Program 1920 for a Complimentary Social from the employees to the directors Godfrey Hirst & Co.Excelsior Woollen and Worsted Mills/ Souvenir Program/ Complimentary Social/ to /the Dorectors/ Godfrey Hirst & Co / Pty Ltd/ From the Employees/ IN THE NEW MASONIC HALL/ FRIDAY, SEPTEMBER 3rd 1920/ at eight pmweaving mills textile industry weaving, godfrey hirst and co. pty ltd excelsior woollen and worsted mills, weaving mills, textile industry, weaving -

National Wool Museum

National Wool MuseumPhotograph Album, The Valley Worsted Mills, Geelong

Photograph album containing 15 photographs of the textile processes which took place at the Valley Worsted Mill which was established in 1923.Photograph album contains 15 photographic postcards of textile processes from the Valley Mill, c.1920s. Valley Mill, Geelong, c.1920s. Wool sorting at the Valley Mill, Geelong, c.1920s. Wool scouring at the Valley Mill, Geelong, c.1920s. Woollen carding at the Valley Mill, Geelong, c.1920s. Worsted carding at the Valley Mill, Geelong, c.1920s. Combing and drawing at the Valley Mill, Geelong, c.1920s. Woollen spinning at the Valley Mill, Geelong, c.1920s. Worsted spinning at the Valley Mill, Geelong, c.1920s. Winding at the Valley Mill, Geelong, c.1920s. Warping at the Valley Mill, Geelong, c.1920s. Weaving at the Valley Mill, Geelong, c.1920s. Mending at the Valley Mill, Geelong, c.1920s. Wet finishing at the Valley Mill, Geelong, c.1920s. Dry finishing at the Valley Mill, Geelong, c.1920s. Warehouse at the Valley Mill, Geelong, c.1920s.PHOTOGRAPHS THE / VALLEY WORSTED MILLS / GEELONG WOOL SORTING / WOOL SCOURING / WOOLLEN CARDING / WORSTED CARDING / COMBING & DRAWING / WOOLLEN SPINNING / WORSTED SPINNING / WINDING / WARPING / WEAVING / MENDING / WET FINISHING / DRY FINISHING / WAREHOUSE C.J. Frazer Photographer / Melbournetextile mills warehouses, weaving, textile production, textile mills, valley worsted mill, scouring, carding, combing, drawing, spinning, winding, warping, wet finishing, mending, milling, dry finishing, textile mills - warehouses -

National Wool Museum

National Wool MuseumPhotograph, Worsted room

Worsted room, R S & S mill.Worsted room R S & S /worsted spinningtextile machinery textile mills - history textile mills, returned soldiers and sailors mill, spinning machinery, cloth - worsted, kidman, mr g. l., textile machinery, textile mills - history, textile mills -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

National Wool Museum

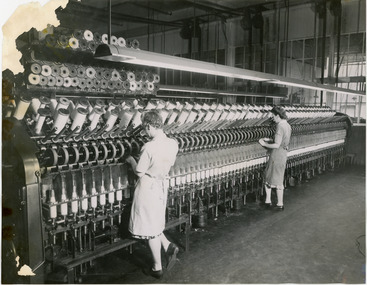

National Wool MuseumPhotograph - Worsted Spinning, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing two women working at a worsted spinning machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W19 / W19. , Worsted Spinning.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumCatalogue, Detached piece catalogue of the Hattersley "Standard Model" Fancy Woollen and Worsted Loom

Catalogue of woollen and worsted loom produced by George Hattersley & Sons Ltd.Catalogue of woollen and worsted loom produced by George Hattersley & Sons Ltd.textile machinery, george hattersley and sons ltd -

National Wool Museum

National Wool MuseumPhotograph

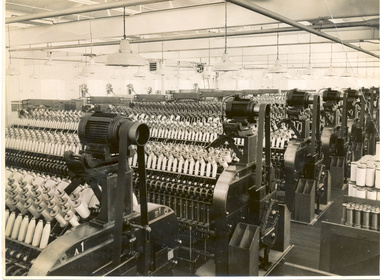

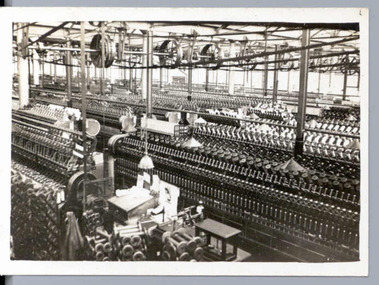

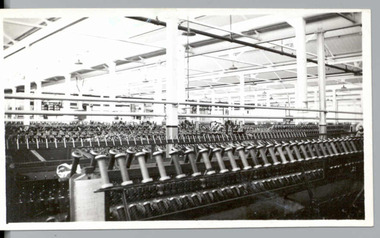

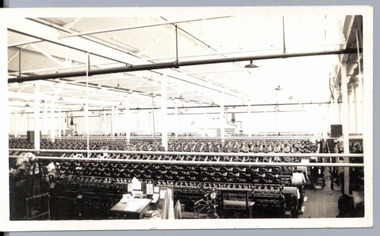

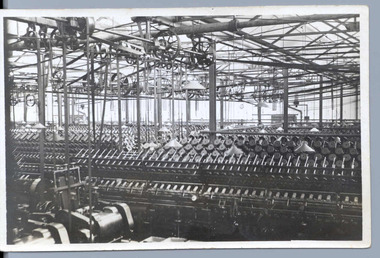

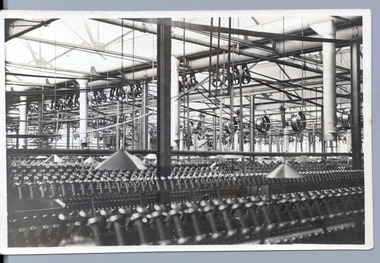

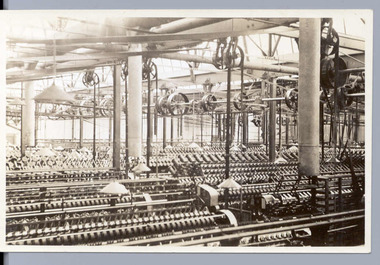

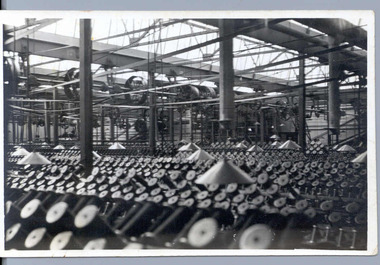

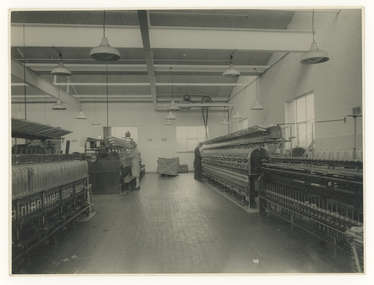

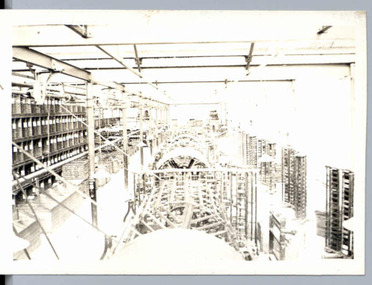

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

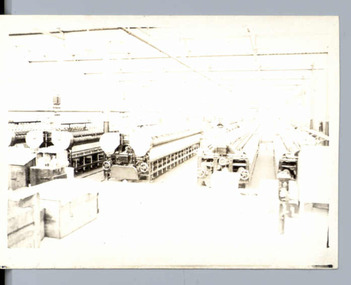

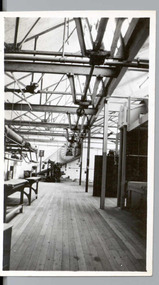

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

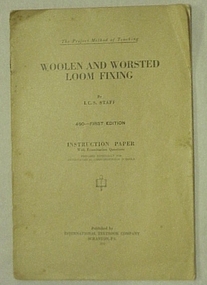

National Wool MuseumBook, Instruction Paper No.490: Woolen and worsted loom fixing, 1st ed

Instruction Paper No.490: Woolen and worsted loom fixing, 1st ed, 1925Instruction Paper No.490: Woolen and worsted loom fixing, 1st ed, 1925weaving textile machinery textile industry - history textile industry - education, international correspondence schools ltd, cloth - woollen, cloth - worsted, weaving looms, weaving, textile machinery, textile industry - history, textile industry - education -

National Wool Museum

National Wool MuseumPhotograph, Worsted spinning R S & S

Worsted room, R S & S mill.Worsted spinning /R S & Stextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, spinning machinery, cloth - worsted, kidman, mr g. l., textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumBook, Instruction Paper No.486: Woolen and worsted cam-looms

"Instruction Paper No.486: Woolen and worsted cam-looms.." - International Correspondence Schools Ltd."Instruction Paper No.486: Woolen and worsted cam-looms.." - International Correspondence Schools Ltd.weaving textile machinery textile industry - history textile industry - education, international correspondence schools ltd, cloth - woollen, cloth - worsted, weaving looms, weaving, textile machinery, textile industry - history, textile industry - education -

National Wool Museum

National Wool MuseumCatalogue, Dobcross spares and service manual woollen and worsted loom

"Dobcross spares and service manual woollen and worsted loom" -Hutchinson, Hollingworth and Co. Limited"Dobcross spares and service manual woollen and worsted loom" -Hutchinson, Hollingworth and Co. LimitedDYER AND PHILLIPS PTY LTD/ 89 FLINDERS LANE/ MELBOURNEtextile machinery, hutchinson, hollingworth and co. limited, weaving looms, weaving machinery -

National Wool Museum

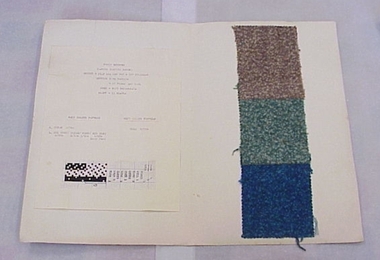

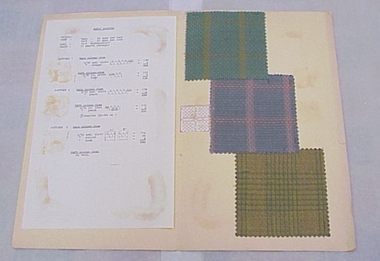

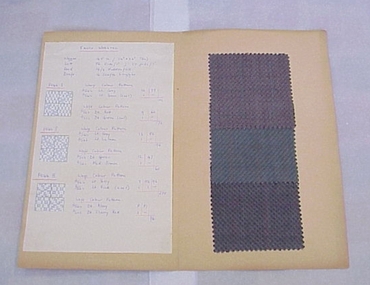

National Wool MuseumFolder, sample

Weaving samples folder: 3 "FANCY WORSTED" patterns with 1 brown, 1 green and 1 blue cloth samples5651 (ink) FANCY WORSTEDweaving textile industry textile design, weaving, textile industry, textile design -

National Wool Museum

National Wool MuseumProgram, Excelsior Woollen and Worsted Mills: Souvenir Program 1920

Excelsior Woollen and Worsted Mills Complimentary Social Souvenir Program, to the Directors of Godfrey Hirst and Co. from the employees, in the New Masonic Hall, Friday September 3rd, 1920.Excelsior Woollen and Worsted Mills Complimentary Social Souvenir Program, to the Directors of Godfrey Hirst and Co. from the employees. Excelsior Woollen and Worsted Mills Complimentary Social Souvenir Program, to the Directors of Godfrey Hirst and Co. from the employees. Excelsior Woollen and Worsted Mills Complimentary Social Souvenir Program, to the Directors of Godfrey Hirst and Co. from the employees.weaving mills, godfrey hirst and co. pty ltd excelsior woollen and worsted mills -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: "L. BOENUDA" contains "FANCY WORSTED" pattern sheet and 3 cloth samples (1 blue, 2 green).L. BOENUDA (ink) FANCY WORSTEDtextile production weaving, textile production, weaving -

National Wool Museum

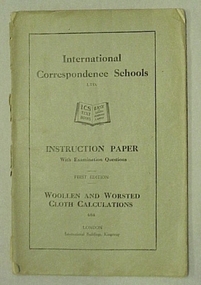

National Wool MuseumBook, Instruction Paper No.484: Woolen and worsted cloth calculations, 1st Ed

"Instruction Paper No.484: Woolen and worsted cloth calculations, 1st Ed." - International Correspondence Schools Ltd."Instruction Paper No.484: Woolen and worsted cloth calculations, 1st Ed." - International Correspondence Schools Ltd.weaving textile machinery textile calculations textile industry - education, international correspondence schools ltd, cloth - woollen, cloth - worsted, weaving, textile machinery, textile calculations, textile industry - education -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: "H.A. WILKINSON" contains "FANCY WORSTED" pattern sheet and 3 cloth samples.FANCY WORSTED (ink) H.A. WILKINSON (pencil)textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery