Showing 39 items matching "yarn - worsted"

-

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

... Yarn - worsted... Limited Yarn - woollen Cloth - worsted Yarn - worsted Wool Tops ..."Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

... Yarn - worsted... Limited Yarn - woollen Cloth - worsted Yarn - worsted Wool Tops ..."Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

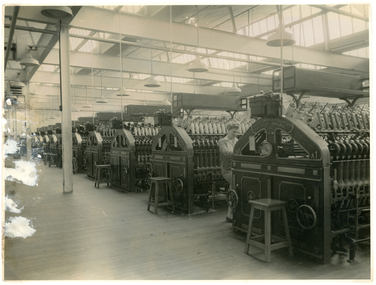

National Wool MuseumPhotograph, R S & S worsted spinning

... yarn - worsted... machinery yarn - worsted textile machinery textile mills - history ...Worsted spinning department, R S & S mill.R S & S worsted spinning AUSTRALIAN OFFICIAL PHOTOGRAPH/ DEPT OF INFORMATIONtextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, spinning machinery, yarn - worsted, textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumBook, Hand books of the textile industry, vol 2: manufacture of narrow woven fabrics

... Yarn - worsted... Weaving Weaving Looms Yarn - woollen Yarn - worsted Ribbon Textile ..."Hand books of the textile industry, vol 2: manufacture of narrow woven fabrics" - E A PosseltK M Chisholm/ Denholm/ Bowenfelstextile calculations textile industry weaving textile industry - education, weaving, weaving looms, yarn - woollen, yarn - worsted, ribbon, textile calculations, textile industry, textile industry - education -

National Wool Museum

National Wool MuseumPamphlet, Worsted Card for Man-Made Fibres Type CS-2

... Yarn - worsted... Bielsko Textile Machinery Works Carding Yarn - worsted Worsted ..."Worsted Card for Man-Made Fibres, Type CS-2" - Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.textile machinery, metalexport bielsko textile machinery works, carding, yarn - worsted -

National Wool Museum

National Wool MuseumBook, Worsted Carding and Combing

... Yarn - worsted... Carding Combing Yarn - worsted Stanley Mr W. - Port Phillip Mills ..."Worsted Carding and Combing: covering the syllabus of the City and Guilds of London Examination in this subject" - John R. Hind, London, 1932.FOR AND ON BEHALF OF / PORT PHILLIP MILLS PTY. LTD. / W. Stanley / Managing Director. / 16/11/32port phillip mills pty ltd, carding, combing, yarn - worsted, stanley, mr w. - port phillip mills pty ltd -

National Wool Museum

National Wool MuseumBook, The Worsted Industry

... Yarn - worsted... and Industries series). Wool Processing Yarn - worsted Cloth - worsted ..."The Worsted Industry", by J. Dumville and S. Kershaw, c.1930 (part of the Pitman's Common Commodities and Industries series).wool processing, yarn - worsted, cloth - worsted -

National Wool Museum

National Wool MuseumBook, An account of research studies and mill processing trials on four apparel wools

... Yarn - worsted... Textile Fibres Dyeing Spinning Carding Yarn - worsted Merino sheep ..."An account of research studies and mill processing trials on four apparel wools"- J H Wakelin and W von Bergen 1953 : Wool research project, summary report for the period October 1948 to October 1952.merino sheep wool - characteristics wool - chemistry textile research textile calculations textile fibres, dyeing, spinning, carding, yarn - worsted, merino sheep, wool - characteristics, wool - chemistry, textile research, textile calculations, textile fibres -

National Wool Museum

National Wool MuseumBook, The woollen and worsted industry: an economic analysis

... Yarn - worsted... Weaving Yarn - woollen Yarn - worsted Cloth - woollen Cloth ..."The woollen and worsted industry: an economic analysis" - G F Rainnie (ed),1965textile industry textile fibres weaving, yarn - woollen, yarn - worsted, cloth - woollen, cloth - worsted, textile industry, textile fibres, weaving -

National Wool Museum

National Wool MuseumPhotograph

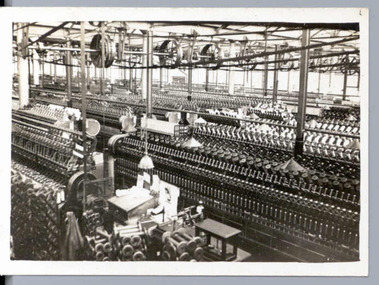

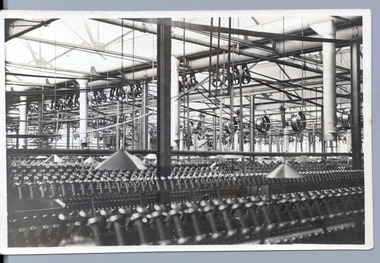

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

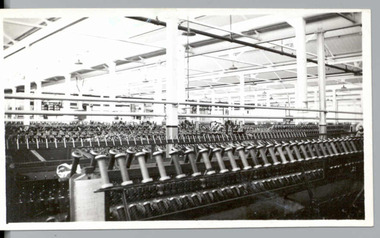

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

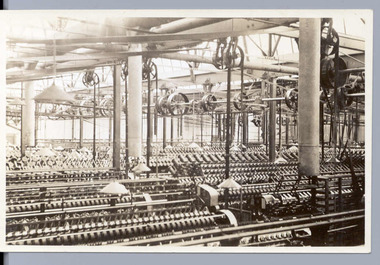

National Wool Museum

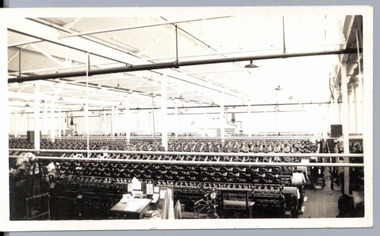

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

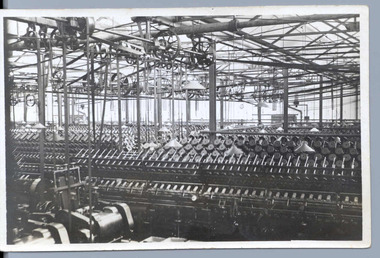

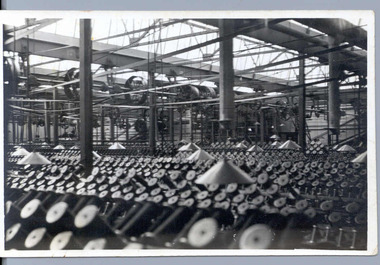

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

... Yarn - worsted... packs. Valley Worsted Mill Spinning Machinery Yarn - worsted ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumBook, Principles of worsted spinning

... Yarn - worsted... Priestman, 1921 Textile Fibres Yarn production Yarn - worsted ..."Principles of worsted spinning 2nd ed" - Howard Priestman, 1921textile fibres yarn production, yarn - worsted, spinning, textile fibres, yarn production -

National Wool Museum

National Wool MuseumBook, Worsted Machinery Catalogue

... Yarn - worsted... Spinning Machinery Twisting Yarn - worsted Cloth - worsted Book ..."Worsted Machinery Catalogue (French Section)" - Prince-Smith & Stells Limited, Keighley, England, c.1920. The catalogue is very comprehensive and describes in detail many types of combing, drawing, spinning and twisting machinery (French System).Book/catalogue - "Worsted Machinery Catalogue", Prince-Smith and Stells Limited, c.1920.textile machinery, prince-smith and stells limited jackson, mr george - mount gambier spinning mills limited, combing, drawing, spinning machinery, twisting, yarn - worsted, cloth - worsted -

National Wool Museum

National Wool MuseumBook, I.C.S Reference Library No. 106

... , mensuration, woollen and worsted yarn calculations, mechanical..., logarithms, mensuration, woollen and worsted yarn calculations ..."I.C.S Reference Library no. 106: arithmetic, logarithms, mensuration, woollen and worsted yarn calculations, mechanical definitions, mechanical calculations, reading textile drawings, wool, wool washing, wool drying, burring and carbonising, wool oils and oiling" International Correspondence Schools Ltd, 1923.textile production wool processing, international correspondence schools ltd, cloth - woollen, cloth - worsted, carbonising, burring, textile production, wool processing -

Parks Victoria - Cape Nelson Lightstation

Parks Victoria - Cape Nelson LightstationFunctional object - Flag set, navigational

... pennants) are made of bunting, a coarse fabric of worsted (open... fabric of worsted (open yarn wool) in various colour combinations ...The flags were used for communicating messages to passing ships. Knowledge of visual signaling was mandatory for all lightkeepers and all stations maintained a set of these flags. Although used for centuries, visual flag signaling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages.The Cape Nelson Lightstation is architecturally and scientifically (technologically) important as the most intact complex of lightstation buildings in Victoria. The octagonal signal station is a unique feature which is all the more important for its complete set of signal flags’. Cape Nelson Lightstation’s complete set of 41 alphabetic and numeric visual signaling flags (including substitute and answering pennants) are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations, and some of the fabric is hand sewn and bears inscriptions. Attachments include handmade wooden toggles, brass clips and hemp rope. -

National Wool Museum

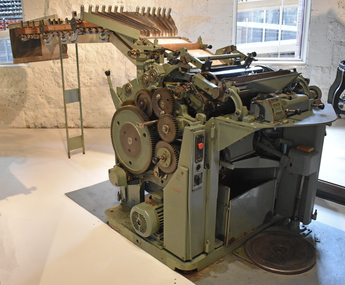

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

... for worsted yarn. These machines remove the short fibres and blend... needed for worsted yarn. These machines remove the short fibres ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

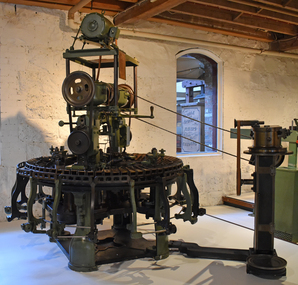

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

... for worsted yarn. These machines remove the short fibres and blend... needed for worsted yarn. These machines remove the short fibres ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlags & Pennants, navigational, signal

... or pointed ends. They are made of bunting, a coarse fabric of worsted.... They are made of bunting, a coarse fabric of worsted (open yarn wool ...The 41 alphabetic and numeric visual signalling flags (including substitute and answering pennants) have either square or pointed ends. They are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations. Some of the flags are marked with inscriptions, for example “B”. Attachments to the flags include hemp rope and metal clips. Each flag has its own galvanised canister and lid, each of which is painted grey and marked with a letter, number or word. The flags were used for communicating messages to passing ships. Knowledge of visual signalling was mandatory for all lightkeepers and all lightstations maintained a set of flags. Although used for centuries, visual flag signalling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages. The signal flags and canisters at Gabo Island form a complete set and are not historically linked to the lightstation and their provenance is unknown. It is known however that they originate from a lightstation in Victoria and for some years were on loan from AMSA to the Queenscliff Maritime Museum, where they were held in storage and not displayed. Three of the six lightstations that Parks Victoria manages have sets of signal flags in their collections. Forty navigational signal alphabet flags & numeral pennants. Flags are made of wool. -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlag canisters

... or pointed ends. They are made of bunting, a coarse fabric of worsted.... They are made of bunting, a coarse fabric of worsted (open yarn wool ...The 41 alphabetic and numeric visual signalling flags (including substitute and answering pennants) have either square or pointed ends. They are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations. Some of the flags are marked with inscriptions, for example “B”. Attachments to the flags include hemp rope and metal clips. Each flag has its own galvanised canister and lid, each of which is painted grey and marked with a letter, number or word. The flags were used for communicating messages to passing ships. Knowledge of visual signalling was mandatory for all lightkeepers and all lightstations maintained a set of flags. Although used for centuries, visual flag signalling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages. The signal flags and canisters at Gabo Island form a complete set and are not historically linked to the lightstation and their provenance is unknown. It is known however that they originate from a lightstation in Victoria and for some years were on loan from AMSA to the Queenscliff Maritime Museum, where they were held in storage and not displayed. In three of the six lightstations that Parks Victoria manages have sets of signal flags in their collections. Forty-one galvanised canisters with separate lids. The canisters are painted a grey/white colour and have either numbers, letters or words painted on the lid and on the cannister in black paint. There are variations in the style of canister and in the style of the inscriptions. -

National Wool Museum

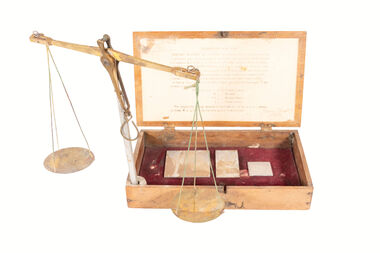

National Wool MuseumInstrument - Scales, 1880-1898

At the time of sale, the last of the Hirst family to work in the mill located in Geelong gave Donald (donor Bruce's father) Doherty a set of scales that had been used by several generations of Hirsts and adapted by them over time for specific use in their mill. These Scales were saved from waste and being thrown away at the time of sale to remain in use in the industry in the hands of someone who knew how to use them. The scales were used in calculating the weight of cloth and simultaneously calculating the amount of yarn required to weave it following the instructions printed within the box. The box bears the signatures of two Hirst family members, one being Lewis Hirst dated at 1898. The original brass pole has been replaced with a replica metal somewhere throughout the years after the brass pole broke through use. Hirst was brought by McKendrick in the 1960s and these scales sat for 12 months as part of the 12 month "cooling off" period. The scales were then handed to Donald rather than being disposed of.Scales used for weighing and calculating weight and thread count of textile samples. Originated from Godfrey Hirst Mills in Geelong. Writing describes how to utilise scales. Scales are made from brass, pole for holding scales once brass now replaced with metal pole. Scales held inside wooden box with black text in ink depicting use of scales on paper located inside and outside of box.Outside of box. Wording: APPARTUS for TESTING the WEIGHT per YARD of CLOTHS & COUNT of YARN from a small SAMPLE. -------------------------------------------------------------------------------------------------------------------------------------------------- Indispensable to Manufactures, Merchants & handling Woollen, Worsted, Cotton, Linen, Jute, Hemp, Flannel, Felt, Army, Navy, Police, Railway, Sail & other Cloths -------------------------------------------------------------------------------------------------------------------------------------------------- USED IN GOVERNMENT DEPARTMENTS -------------------------------------------------------------------------------------------------------------------------------------------------- The apparatus consists of Scales, Weights, 1, 2 & 4 sq. inch Cutting Templates & Book of Tables --------------------------------------------------------------------------------------------------------------------------------------------------By weighing a small Sample the accurate Weight in Ounces of a yard of Cloth any width from 18 to 64 inches, the Weight per Square Metre in Grams, the Counts* of Warp and Weft, and the approximate length of full & short ends of pieces of fabrics, [without unrolling and measuring for stocktaking & other purposes] can be ascertained without any Calculation --------------------------------------------------------------------------------------------------------------------------------------------------Price in United Kingdom, 25s., Carriage Paid. Price to Canada & U.S.A. $6.75 do. H. Lord. 10, And Place, Bradford, England. --------------------------------------------------------------------------------------------------------------------------------------------------*When ordering, state on what system you base your YARN COUNTS. Inside of box. Wording: DIRECTIONS FOR USE --------------------------------------------------------------------------------------------------------------------------------------------------TESTING WEIGHT OF CLOTHS. Place sample to be tested on a piece of cardboard, put a Cutting Template on it, cut card and cloth round template with scissors and weigh it according to instructions given in Book of Tables. TESTING FOR YARN COUNTS. Cut out 1 square inch of cloth, draw out wrap or weft threads, according to which is being tested, and the number of inches so drawn, that balance respective weight is the approximate Count. The same rule holds good when number of inches are drawn from a bobbin. In testing from the cloth, allowance has to be made for loss or gain in the process of manufacture. Weight marked C is for Cotton Counts " " W " " Worsted " " " WS " " Woollen Skeins " " L " " Linen Counts. The weights for testing samples of cloth are 20, 10, 10, 5, 3, 2, 1, grains in brass & '5, '3, '2, '1 [tenths of a grain] in aluminium. Inside of box. Signtures, handwritten: Bottom right: Lewis Hirst !898 Top Left (Smudge ?) W Hirst !935godfrey hirst, hirst family, textile design, textile creation -

National Wool Museum

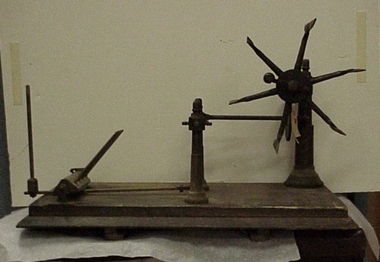

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

National Wool Museum

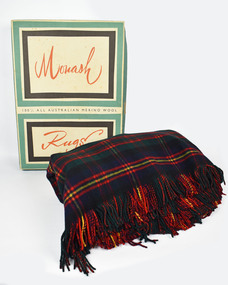

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumBook, Spinning Woollen and Worsted

"Spinning Woollen and Worsted: being a practical treatise for the use of all persons engaged in these trades" - Walter S. Bright McLaren, 1884.yarn production, spinning, cloth - woollen, cloth - worsted