Showing 3030 items in the category Domestic And Leisure with item type Domestic object

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Set of silver spoons and sugar tongs, c1930

This item is from a collection donated by descendants of John Francis Turner of Wodonga. Mr. Turner was born on 6 June 1885. He completed all of his schooling at Scotts Boarding School in Albury, New South Wales. On leaving school, he was employed at Dalgety’s, Albury as an auctioneer. In 1924 John was promoted to Manager of the Wodonga Branch of Dalgety’s. On 15/03/1900 he married Beatrice Neal (born 7/12/1887 and died 7/2/1953) from Collingwood, Victoria. They had 4 daughters – Francis (Nancy), Heather, Jessie and Mary. In 1920, the family moved From Albury to Wodonga, purchasing their family home “Locherbie” at 169 High Street, Wodonga. "Locherbie" still stands in Wodonga in 2022. The collection contains items used by the Turner family during their life in Wodonga. The registration number on the fork Rd. 758470 indicates that this design was first patented in 1930, therefore helping to establish provenance of this set.A set of 6 cake forks in a hinged brown box with apricot silk lining. The box has 2 metal clasps. A label "Best Electro Plate on Nickel Silver - Made in England" is in the box.On forks: "MADE IN ENGLAND" "Rd 758470"silver cutlery, electro plate -

Clunes Museum

Clunes MuseumDomestic object - D'OILEY, CIRCA 1920

DOYLEY - LINEN CENTRE WITH COTTON CROCHET EDGINGlocal history, handcraft, needlework, trembath, perry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Tea cosy, c 1960

Bought and used in the 1960'sPadded tea cosy made up of floral plastic cover with red cotton lining fixed to oval plywood base. Red cord draw string at top.domestic items, table setting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Clunes Museum

Clunes MuseumDomestic object - MANCHESTER

.1 Knitted pillow sham, cream coloured, peaked border, centre area consists of five knitted panels separated by six lace effect panels .2 Hand worked snowflake design on netting, larger netting worked on the centre and four smaller ones in corners. Outside edge is manufactured lace handsewn onto the fabric of the shamNilpillow sham, hand sewn -

Whitehorse Historical Society Inc.

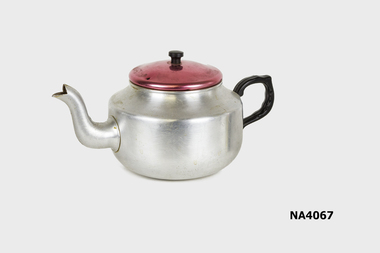

Whitehorse Historical Society Inc.Domestic object - Tea Pot, 1950

Belonged to Margaret Scarlett used for many years at 31 Drummond Street Blackburn.Aluminium tea pot with red iodised lid.Mark - Aluminium Waredomestic items, containers -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumDomestic object - Buttons

Used by internee Camp 3. Tatura5 Round Brass Coat Buttons with 4 holes in centre.tatura, costume, accessory, clothes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clock, late 1900s early 20th Century

In 1850 the Ansonia Clock Company was formed as a subsidiary of the Ansonia Brass Company by Phelps and two Bristol Connecticut clock makers, Theodore Terry and Franklin C. Andrews. Terry & Andrews were the largest clock manufacturers in Bristol at the time with more than 50 employees using 58 tons of brass in the production of about 25,000 clocks in 1849. Phelps decided to get into the clock making business to expand the market for his brass, while Terry and Andrews got access to better quality brass at better prices. They had then sold 50% of their business to Phelps and moved the business to Ansonia, Connecticut. In 1877 the clock company purchased a factory in New York and moved most of its production thereafter being spun off from the brass company. Henry J. Davies of Brooklyn, himself a clock maker, inventor and case designer, joined the newly reconstituted company as one of its founders. As President, he is thought to have been largely responsible for the figurine clocks, swing clocks and other unusual and desirable novelties for which the Ansonia firm became known. By 1879, a second factory was opened in Brooklyn, New York and by June 1880 employed 360 workers, while the Connecticut factory continued producing clocks as well with a workforce of 100 men and 25 women. Hence, clocks marked "Connecticut" were generally produced before 1879, while those marked "New York" were all produced after 1880 After the New York factory burnt down in 1880 the company rebuilt the factory on the same site, and reopened the expanded factory in 1881, with a capacity to exceed that of the Connecticut factory which by 1883 had closed. By 1886, the company had sales offices in New York, Chicago and London, with more than 225 different clock models being manufactured. In 1899, Phelps' grandson William Earle Dodge Stokes commissioned architect Duboy to build the "greatest and grandest hotel in Manhattan, New York” which became the city's first air-conditioned building. In 1929 the majority of the timekeeping machinery and tooling was sold to the Soviet government's US trading company Amtorg, just before the stock market crash. The parts, machinery and key skilled workers were shipped out of the USA to form the basis, along with the remains of a watch company purchased a year later, of the clock and watch industry in Moscow such as Poljot and Sekonda. In 1969, the rights to the use of the name, trademarks, and goodwill were transferred to Ansonia Clock Co., Inc., Lynnwood, Washington. The item marks the beginning of mass produced clocks in the United States, cheaply priced and available to all. The company had many innervation's during it’s life regards clock and later wrist watch making that led the way for other companies in many different countries to emulate.Clock, pendulum mantle model. Carved scallop "Ginger bread house" cottage clock. Oak case, white enamel face, floral etched glass door. Clock has an hour bell chime. Glass front opens to allow rewinding. Made by Ansonia Clock Co, New York. Marked "Manufactured by Ansonia Clock Co. New York, USA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, mantle clock, clock, pendulum clock, time keeper, horology, ansonia, ansonia clock co, america -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - BRASS FOOD WARMER

Brass Food Warmer With Lid (Methylated Spirits) three twist legs Cast Iron base under central conical tapered hole in centre of warmer approx. 15 cm diameter entire item 40 cm wide. Previous Catalogue Number 104 Accompanying tag reads ' Wilson Art Panel Art'.domestic equipment, food consumption, brass food warmer -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDomestic object - Candle Holder

Enamelled metal candle holder with dish and finger grip. Blue line around rim. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDomestic object - Cream Bottle (half pint), n.d

Clear glass wide mouth cream bottle generic, half pint.Front: '½ imperial pint' PLEASE WSH AND RETURN EMPTY BOTTLE' - embossed Back: Base: '15627' 2 - embossed -

Chiltern Athenaeum Trust

Chiltern Athenaeum TrustDomestic object - Spoon belonging to W.C.Busse

Wilfred Clarence Busse, born in Chiltern in 1898, His family moved to the region during the gold rush and continued to reside in the area, purchasing land adjacent the Murray River. Busse completed his secondary education at Wesley College in Melbourne then studied law at the University of Melbourne. Busse went on to become a barrister, often in the chambers of Sir Leo Finn Bernard Cussen (1859-1933) a judge of the Supreme Court of Victoria. He worked most of his life in Chiltern as a Barrister and Solicitor and gained the unofficial title of historian of Chiltern, leaving behind several manuscript histories and a scrap book. Busse was an avid fictional writer and in 1930 he published two novels. Time spent on a Victorian station in his early twenties, as well as careful documentary research, informed the writing of his historical novels of bush life. "The Blue Beyond; A Romance of the Early Days in South Eastern Australia” and "The Golden Plague: A Romance of the Early Fifties." "The Golden Plague” won the T. E. Role gold medal for the best historical novel which went on to become a best seller. Busse often drew inspiration for his novels from his younger years living Chiltern. His passion for the region lead him to write “The History of Chiltern” which was published in a serial form in the Chiltern Federal Standard from 1922-1923. Wilfred Clarence Busse was a member of Chiltern Athenaeum (where this object is now held) up until his death in 1960, he is buried in the Barnawartha Cemetery. The leaf shaped motif of this particular spoon appears to be stylised in a simple form of decorative arts and craft or even Art Nouveau style favoured in Europe between 1880-1920 and less representational than examples of Australiana flora captured in silversmithing from the 1850's onwards. According to Christine Erratt, due to the goldrush in the 1850's, there was increased wealth in the colony and an influx of immigrants from Europe to Australia who brought with them silversmithing skills which began ‘the golden age’ of Australian silver', Erratt says that 'Australia's unique flora has been portrayed in the decorative arts since the early colonial times of the last decade of the 18th century. The use of Australian flora to decorate silverware is of particular interest and diversity'. It is likely that those producing silverware at the time would be drawing on the decorative arts movement while incorporating elements of the natural beauty in the flora of their newfound environment into the silverware they produced. There are no discerning maker hallmarks to place where it was produced or ascertain the material accurately.Wilfred Clarence Busse was of social significance to Chiltern, he helped to document the cultural story of the area in his published works "The Golden Plague" and "The Beyond Blue" by recounting his own upbringing in a bush lifestyle. He was a respected Barrister and was the unofficial historian of the Chiltern Athenaeum for many years. This spoon represents a window into the domestic life of this person who was well loved in the area, and it continues its relationship to Busse as well as Chiltern by being held within the very collection he helped to maintain in his life. Domestic objects tell us the story about how people lived, objects of daily use hold particular meaning in that they can tell us the story of an individual, we feel closer to their life and habits, it humanises and connects us across time. A tarnished small silver teaspoon with leaf-shaped head and slim handlesilverware, wilfred clarence busse, busse, chiltern, chiltern athenaeum, federal standard, t. e. role, "the blue beyond, a romance of the early days in south eastern australia”, "the golden plague: a romance of the early fifties.", "the golden plague”, wesley college, university of melbourne, sir leo finn bernard cussen, supreme court of victoria, gold rush, murray river, “the history of chiltern”, silversmithing, spoon, decorative arts, floral, flora, australiana, australian flora, arts and craft movement, australian silver, cussen -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionDomestic object - Silver Plate

-

Colac RSL Sub Branch

Colac RSL Sub BranchDomestic object - Bottle containing message to mother, Graham Connor. Service No:2597, Message in a bottle, Post 27/10/1915

Private Edward Connor (Service No: 2597) embarked 27/10/1915 from ??? He threw the bottle overboard (containing the message) from the Transport ship HMAT A38 enroute to ??? The bottle was found at ??? and returned to his mother, Mrs Martha Connor, Bromfield Street, Colac. Message reads ................?significant historical itemGlass bottle with metal screw top. This item forms part of the Connor Family Collection Schweppes brand bottle. Green in colourww1 service man sent a message to his mother in a glass bottle -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Thermos, c. 1920

This is a vintage item from the early 20th century. It could have been used in a house hold context or by farmers in the paddocks, by hikers, family picnickers, campers or by workers in factories. This item has no known provenance and is kept as an interesting vintage domestic object..Deep blue enamel vacuum flask or thermos with a rusted metal handle and a lid which serves as a cup. There are rust patches on the base, sides and cup. The central section is round.vintage domestic item, vintage vacuum flask, vintage thermos -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - WHITE CHINA TEA CUP & SAUCER

White china tea cup with saucer decorated with gold shamrocks.domestic equipment, food consumption, kitchen -

Mont De Lancey

Mont De LanceyDomestic object - Mantel Clock, The Ansonia Clock Co. Manufacturers USA, 1880's - 1920's

The mantel clock has a rich history that dates back to the 18th century. These smaller clocks were designed during an age when people wanted elegant timepieces that fit on mantels or shelves. Their compact size and decorative designs made them a popular choice for homes of the time. They graced the mantelpieces or tables in homes, serving as both functional timepieces and sophisticated decorations. These clocks often feature ornate wooden carvings and intricate designs, with their gentle ticking and chimes adding a cozy ambiance to living spaces. It is from the home of Mr and Mrs Parker. It belonged to Mr Parker senior.A very ornately carved dark timber mantel pendulum clock with a white face and a brass clock face surround. It has black roman numerals and black metal hands. The Ansonia Clock Co. Manufacturers USA Trademark A is printed on the face. It has an ornate brass pendulum and the internal workings are visible. The very ornately embossed in gold decorated glass front door opens. There are two spirit plumb levels inside, one is aluminium metal and is attached to the wall, the other is brass with Wm Hunt Level Co with a triangle on top stamped on it. There is a brass key No.7 with two holes on the top of the winder handle. The Ansonia Clock Co. Manufacturers USA Trademark A. printed on the dial. Wm Hunt Level Co. stamped on the level.mantel clocks, clocks, timepieces, shelf clocks -

Greensborough Historical Society

Greensborough Historical SocietyDomestic object - Glass, Greensborough College, Greensborough College glasses, 1990s

Presented to graduating students.A limited number of these glasses would have been presented. Pair of clear glass water glasses, with gold rim.Printed in blue with 'Greensborough College' and emblem of gum leavesgreensborough college, commemorative glasses -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

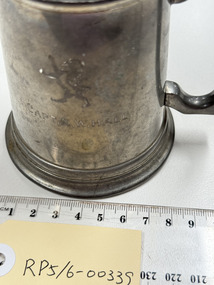

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionDomestic object - Mug

-

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomDomestic object - Silver Goblets, Before 1970

Pair of whimsical silver plated port goblets in shape of boots, with plastic inserts.On soles - Sgt G Piper, and, 4/19 PWLH On edge of heels - "Grenadier England" & "Silver Plate"port goblet, silverware, sergeants mess -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pot

Modern iron cooking ‘ranges’ were being introduced from the late 18th century, however a vast number of people cooked in open fireplaces, well into the 1800s. Generally they were fitted with iron rods suspended above the fire or ‘cranes’ that could be swung in and out for easier and safer access to the pots that hung from them. These cooking systems may seem rudimentary, but a skilled cook knew how to manage pots, pans, cauldrons and pokers and expose them to the right type of heat by positioning them in various parts of the fireplace. They were also very versatile, enabling multiple cooking techniques – boiling, stewing, frying, roasting, toasting – all at the same time, using different types of vessels and utensils. https://blogs.sydneylivingmuseums.com.au/cook/hearth-fire-cookery/This type of item was used extensively over the centuries over open fires. It is still used in camping.Metal cooking pot with handle designed to hang the pot over an open fire.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchenware, cooking, open hearth cookery -

Clunes Museum

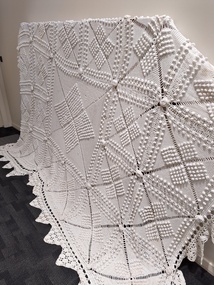

Clunes MuseumDomestic object - QUILT

Laura Hudson was a lifetime resident of Clunes. This quilt was donated to Clunes Museum by her GG GrandsonECRU HAND CROCHETED COTTON BED QUILThand crocheted item, laura hudson -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDomestic Object - Drink coaster, Roberts Shipping Transport Couriers

Small drink coaster for Roberts Shipping Transport CouriersRoberts Shipping. Shipping Transport Couriers 5-7 Prohasky Street Port Melbourneadvertising, roberts shipping transport couriers, transport - shipping -

Clunes Museum

Clunes MuseumDomestic object - GLASS PERFUME BOTTLE

DARK GREEN GLASS PERFUME BOTTLE (NO STOPPER)local history, personal effects, cosmetics -

Numurkah & District Historical Society

Numurkah & District Historical SocietyDomestic object - Button Hook

Metal with curved handle -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionDomestic object - Mug

-

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - A pair of baby sheets and pillowcase, C 1965

Used by Giselda Bannister as a baby.1 plain sheet, 1 top sheet with pink berry edging, 1 pink slip with pink berry edging all white-coloured.Higrade CAG all cotton. Made in Australia.giselda bannister, infant, linen -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Domestic Object, Pepper Shaker

Bone plastic conical shaped pepper shaker with seven small holes in the top and a screw-in base7350-66-028-3978 E.F.M 74pepper shaker -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Flat Iron

Flat Iron No 6domestic items, irons -

Embroiderers Guild Victoria

Embroiderers Guild VictoriaDomestic object - Enamel thimble celebrating Embroiders Guild Victoria' 20th year anniversary, The Embroiderrs Guild, 1980

Embroiderers Guild Victoria was founded in 1960. It is a not-for-profit organisation, focusing on teaching, sharing, encouraging and promoting the art of traditional and modern embroidery.One of a limited edition of three hundred produced for the 20th Anniversary of The Embroiderers Guild of Victoria Enamel thimble decorated with Embroiderers Guild logo on one side and Victoria 1960-1980 on other with sprigs of pink heath.The Embroiderers Guild, Halcyon Days backstamp, Bilston and Battersea Enamels Made In Englandembroiderers guild, enamel thimble, bilston & battersea