Showing 1821 items in the category Tools And Equipment with item type Tool

-

Mont De Lancey

Mont De LanceyTool - Maul and Wedge, Unknown

Used in the 19th CenturyA large handmade wooden barrel shaped headed maul with two steel bands at each end. The handle is a metal pipe. It has a worn piece of a leather flap near the flanged join of the handle where it meets the head. A solid steel rectangular wedge which was used to split logs is displayed with the maul. It was used in the 19th Century.mauls, striking tools, long handled heavy wooden mallet, steel, wood, tools, wedge, splitting tools, splitting wedges, woodworking tools -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - GOLD MOULD

Cast Iron gold mould. Mould used in gold pour to shape ingot. Rectangular shape mould with rectangular handle.gold mines, mining equipment, gold mould -

National Wool Museum

National Wool MuseumTool - Shearing Handpiece, c.1890

Ford and McFarlane shearing handpiece c.1890. This shearing handpiece is from ‘Wellington Lodge” in Tailem Bend, South Australia. Wellington Lodge today is an Angus beef farm; however, the property has a long history which includes wool farming. Wellington Lodge has been in the McFarlane family since the 1840’s and was originally around 19000 acres. The donor, Brian Licence, assembled this handpiece out of spare parts he found while classing wool on the property in the 1960s. Brian showed the finished handpiece to the owners once his classing work was completed and was told he could keep the handpiece as a souvenir. Brian also classed wool at “Jockwar” and “Pleasant Park” in Penola for members of the McFarlane family during the 1960s. The handpiece is named after Ford, the name of the engineer who designed the handpiece and McFarlane, the owners of Wellington Lodge Station and employers of Ford. This handpiece was developed as a prototype for use on the property. The handpiece which is made of solid brass is in a “used condition” and has been patched with solder. The handpiece is stamped with the number 10. Internally, the handpiece is powered from a drive mechanism of compressed air, this compressed air was typically produced by burning mutton fat. The handpiece comes from the pre-electrical– steam engine era of shearing. Brass metal shearing handpiece. A three-pronged fitting to hold both the comb and the blade protrudes from one end. A cylindrical stem extends vertically from the other. This is likely where a connecting rod to the shearing plant would be found. Below this vertical stem, the handpiece has an additional threaded hose fitting. This is likely where compressed air was delivered into the handpiece. The inscriptions can be found on the rear, near the previously mentioned vertical stem. Around this stem is also where the repairs of solder can be found. These repairs are unique to this handpiece and are not common practise.Etched. Base of handle. “FORD & McFARLANE . SHEEP SHEARER . Etched. Base of handle. “10”sheep shearing, shearing equipment, ford & mcfarlane, wellington lodge, tailem bend, south australia, shearing handpiece, shearing -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - IRON HOOKS: HAND FORGED

Iron Hooks: Hand Forged. One 40cm long with eyelet. One 30cm long has curved hook on both ends. Cast Iron.cottage, miners -

Mont De Lancey

Mont De LanceyTool - Fork Hoe, Unknown

Used in the 19th Century. A forged steel two pronged Forked Hoe head used to break up very hard or dry ground. There is a bend at the top of the fork with a hole for the handle. It was made by a blacksmith and used in the 19th century.agricultural tools, gardening tools, steel, pitchforks -

Parks Victoria - Days Mill and Farm

Parks Victoria - Days Mill and FarmTool - Tool, wooden

Wooden tool, possibly a levering device. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - Harris Collection: Garden Fork

Jonathan Harris operated a winery on the banks of the Axe Creek, Axedale in the 1850s.A garden fork with four one centimetre diameter, 26 centimetre long tines. It has a four centimetre diameter, 67 centimetre long wooden shaft which has metal reenforcing with TORJAN engraved on it. On top of the shaft is a 'U' shaped metal piece 11 centimetres wide and eight centimetres heigh which holds a three centimetre diameter wooden handle. Part of the Harris Collection.harris collection, garden fork -

Clunes Museum

Clunes MuseumTool - NAPPING HAMMER, CIRCA 1851

NAPPING HAMMER- CAST IRON EQUIPMENT USED IN MINING.local history, mining, equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Crowbar

Believed to have been borrowed from and many years later returned to Schwerkolt CottageA large crowbartool, crowbar -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Carpenter's Brace and 8 bits, c1880s

Brace is a U shaped frame with a wooden handle in centre, a round metal wheel at one end and a metal handle at the other end. Bits are corkscrew shaped and sharpened to make a hole in wood.trades, carpentry -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Tool - Vaginal dilator associated with Dr Graeme McLeish

This dilator is labelled as being from the rooms of Dr Graeme McLeish.Hollow glass cone which flares to a rim at base. There is an indent in the glass just above the rim on one side.intrauterine device -

National Wool Museum

National Wool MuseumTool - Drum Carder, Kacoonda, c.1980

This drum carder was purchase by Gill Stange at the Whittlesea Show in the late 1980s. The carder allowed Gill to spin fleece from her own Merino sheep. Merino is a difficult wool to spin when compared to other popular varieties, such as Corriedale or crossbred wool. The carder helped her to tease out the fleece, slightly separating the fibres before spinning. It also allowed for easier removal of foreign matters, such as seeds and mud. Little is known about the Kacoonda brand who produced the carder. They were Australian based and appear to have only operated throughout the 1980s.The carder has one large central roller with two smaller rollers on either side. The larger roller rotates in the inverse direction of the two smaller rollers. The carding cloth is a mint green in which closely spaced wire pins are embedded. The shape, length, diameter, and spacing of these wire pins is that of a standard carder. On one side of the carder a handle is found that is used to spin the three rollers. Additionally on this side is a sticker which reads “The Kacoonda Carder. Subject to Patent Action”. A Silver grip for the easy movement of the carder can also be found high on this side. On the opposite side of the carder, many nuts and plates can be found which hold the rollers in place. This is opposed to the other side of the carder, which has a brown plastic cover plate attached underneath the handle. The walls providing a path for the carded wool to follow when being carded, are made of wood. The carder comes complete with a teasing tool. This tool has the same mint green carding cloth as the carder’s rollers. It is attached to a simple wood handle for ease of use.Wording, green, printed. Sticker on side of carder. “The Kacoonda Carder / SUBJECT TO PATENT ACTION”whittlesea show, drum carder, textile production, carding wool, kacoonda -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryTool - Blade, Laryngoscope, Macintosh

Curved MAC (Macintosh) HEINE laryngoscope blade with light bulb, size 4. Made in Germany with stainless steel materials. Minor scratches and hit surface marks are around the piece, mostly near the base of the blade. Connector point located at the base of the blade is slightly worn out. Stamped on the base of the blade back edge side, HEINE / STAINLESS / W.-GERMANY Stamped at the lateral back side of the blade, MAC 4airway, laryngoscope, alfred hospital, melbourne, mac 4 heine, heine, blade, ball, christine -

Geoffrey Kaye Museum of Anaesthetic History

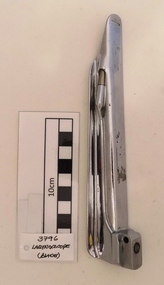

Geoffrey Kaye Museum of Anaesthetic HistoryTool - Blade, Laryngoscope, Soper, circa 1947

A Soper straight laryngoscope blade adult size with bulb only. The blade has minor scratches over its surface and below the arm's blade because of its use. Presence of an old sticky tape mark under the blade. The contact stud at the base of the blade is worn. The end of the blade has a perforated line as part of its design. The metallic base of the light bulb has an oxide spot on it. No inscriptions. No inscriptionssoper, laryngoscope, blade, adult, light bulb -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plough, Syracuse Chilled Plow Co, 1876-1900

The Syracuse Chilled Plough Company was created in 1876 and specialised in the manufacture of agricultural ploughs. Harry Wiard invented the chilling process in plough manufacture. The company was originally founded as the Robinson Chilled Plough Company in 1876 and changed its name 3 years later. At its peak, in the early 20th century. The company made more than 100,000 horse-drawn ploughs and road scrapers of various designs that were sold from the Syracuse plant each year and exported around the world. The company slogan of the day was, “The sun never sets on a Syracuse plough." Eventually, other farming implements were added to the line. The company employed more than 300 people in its local plant, which covered a square block on the cities Near West Side. In 1910-11, Deere and Company began expanding its holdings, and with the success of the Syracuse Chilled Plough Company, Deere sought to acquire the company. The management of the Syracuse operation after John Deere took over remained in the hands of Wiard and Chase, and the manufacturing operations were left in Syracuse. The only change from previous Syracuse operations was the selling of the companies products through Deere retail outlets instead of directly to the trade. The factory in Syracuse continued to produce ploughs until 1955. The subject item in the Flagstaff collection is an early model Syracuse Chilled plough with a wooden beam frame it is very much lighter in weight and was adapted to work sandy or light loamy soil. This plough has a sloping landside, which tends to keep the clods and dirt from falling into the furrow, making the ploughman's work much more comfortable and easy. This design was made in eight sizes for both right and left-handed ploughing and became very popular in the far West and South of the USA. Note: The definition of a chill plough means : a plough having the share and mould-board of chilled semi steel or cast iron.The subject item is believed to be a very early plough given its wooden beam frame and was made before 1900 probably around 1880. This makes it a significant example of the types of plough that early settlers were using in Victoria. There would not be very many of this type of vintage plough left with a wooden beam and frame, making it today a desirable collector's item. Syracuse Wood Beam Chilled single furrow plough metal wheel in front. Syracuse Chiller Co Syracuse & 50 L stamped on ploughshare.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plough, syracuse chiller co, chiller plourh, farm equipment, furrow -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - Wiltshire rasp file combination

a course file or similar metal tool for scraping, filing or rubbing down wood, metal or other materials. It has two rasp and two file grades.Wiltshire V V Australia tools, rasp, file -

Kew Historical Society Inc

Kew Historical Society IncTool, Moseley & Son, Moulding Plane, 5/8” Beading, 19th Century

In woodworking, a moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed.Bertie Robert Edgar Greenwood was born c. 1880/81 and died aged 82 in Hawthorn in 1963. His father and possibly his grandfather were also carpenters. Bertie’s work as a cabinetmaker required precise planing to give lovely edges and other elaborate decorations. The major item in the tool collection is Bertie’s wooden box, which houses 45 different moulding planes. Later in his life, he used these skills extensively when he worked as a patternmaker for a plastering company. Bertie worked through his seventies, retiring when he lost a finger. The tool collection was donated to the Kew Historical Society by Bertie’s granddaughter, Pamela Webster Bloom, a former resident of Kew.Plane - Wooden Moulding, Beechwood & Metal, 5/8” Beading, Moseley & Son LondonStamped ‘5/8’, and owner name ‘G. Greenwood’ with ‘G’ subsequently over-stamped with ‘B’. Later engraved number ‘5’ added on entering the collection in 2010.carpentry, bertie greenwood, woodworking tools, moulding planes, burwood road — hawthorn (vic.) -

Mont De Lancey

Mont De LanceyTool - Steel wedge

Used in the 19th century.A solid steel rectangular wedge fluted three quarters of the way down on both faces, used with a maul to split logs and timber, particularly hardwoods. It was used in the 19th Century.splitting wedges, steel, wood splitting wedges, woodworking tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Brace - Carpenter's

Hand brace - 'U' shaped with split end to take a tapered end drill. Drill is secured by a bolt to tighten split end. Metal breast plate.trades, carpentry, tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Coke Sieve, c1920

Sheet metal frame with metal mesh sieve. Used for sieving 'breeze' or dust from coke to help in maintaining a clean fire.rural industry, farm machinery, trades, blacksmithing -

Greensborough Historical Society

Greensborough Historical SocietyTool - Hammer head, 1900s

Hammer headHammer head, rusted.tools, hammers, hand tools -

Kew Historical Society Inc

Kew Historical Society IncTool, Moseley & Son, Moulding Plane, 5/8” Cove, 19th Century

In woodworking, a moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed.Bertie Robert Edgar Greenwood was born c. 1880/81 and died aged 82 in Hawthorn in 1963. His father and possibly his grandfather were also carpenters. Bertie’s work as a cabinetmaker required precise planing to give lovely edges and other elaborate decorations. The major item in the tool collection is Bertie’s wooden box, which houses 45 different moulding planes. Later in his life, he used these skills extensively when he worked as a patternmaker for a plastering company. Bertie worked through his seventies, retiring when he lost a finger. The tool collection was donated to the Kew Historical Society by Bertie’s granddaughter, Pamela Webster Bloom, a former resident of Kew.Plane - Wooden Moulding, Beechwood & Metal, 5/8” Cove, Moseley & Son London. Stamped ‘10’. Also stamped with owner name ‘G. Greenwood’, with ‘G’ subsequently over-stamped with ‘B’. Later engraved number ‘9’ added on entering the collection in 2010.woodworking tools, moulding planes, burwood road — hawthorn (vic.), bertie greenwood, carpentry -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - CIGAR CUTTER: BUTTON STAMPER

A Cigar cutter? Or Button Stamper? The blade/stamper is missing. Has a black wooden handle. It is constructed of steel, painted black with gold painted patterning, displaying flowers and leaves. The base is 18cm x 8xm and the height is 15cm Previously numbered #113. -

Clunes Museum

Clunes MuseumTool - BICYCLE KIT

.1 LEATHER CASE WITH STRAP TO FASTEN .2 TIN WITH PATCHES, SCREW AND USED TUBE .3 USED EMERY PAPER .4 TWO TYRE LEVERS .5 SPANNER.2 POCKET VULCANISER CYCLE TUBES, SYRO, A SYRO PRODUCTbicyc le kit, repair kit -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, A Mathieson and Son, 20th century

Plane, moulding type, made by A Mathieson and Son. 3/8th no blade Stamped; "A MATHIESON & SON / GLASGOW & EDINBURGH" around a symbol [Crescent and star]flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, a mathieson & son, glasgow, edinburgh, hand tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - File, Early 20th century

This file would be used by a tradesperson or home handyman to smooth the edges of the wooden piece he or she was working on. The surfaces of the file would be of different abrasiveness to suit different stages of the job. A file would be part of a woodworker's tool kit.The design of a file hasn't altered significantly over the last century. This file is an example of an early 20th century file but would be at home in the workshop today.Large file with wooden handle. Brass collar sits between handle and file.flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, file, woodworking, carpentry, tool, trade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyTool - Ruler, City of Port Melbourne Electricity Supply Department, 1980s - 1990s

30 cm white ruler stamped with 'City of Port Melbourne Electricity Supply Department'utilities - electricity -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture.Compass saw with wooden handle and metal blade. Small teeth. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

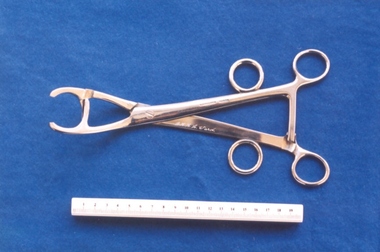

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Tool - Bonney's myomectomy clamp used by Box Hill Hospital labour ward, Down Bros., London

Victor Bonney (1872- 1953) was a gifted and innovative surgeon. One of Bonney’s most notable achievements was his development of a successful procedure for myomectomy. After his wife developed fibroids and had her uterus removed early in their marriage, Bonney took a great interest in the practice of conservatism in surgery. Prior to Bonney, myomectomy “had fallen into disuse because of excessive blood loss during the operating and the infections that commonly followed” (Chamberlain, 'The master of myomectomy') , but Bonney saw an opportunity to revolutionise this practice. In his words: “I set myself to make myomectomy so feasible, successful and safe as to render it a fair alternative to hysterectomy in every case… Excepting only in a very few instances… I have succeeded, and now enter the operating theatre free of the trammels which at one time too often compelled my hand against my heart.” (Bonney, 'The fruits of conversatism') Bonney’s crucial innovation was the development of a new surgical clamp, an instrument which is now referred to as Bonney’s myomectomy clamp. The clamp was ingeniously designed to cut off blood supply to the uterus by compressing the uterine arteries, immediately reducing the excessive blood loss which had previously been associated with the procedure. Although technological advances mean that these are now seldom used, Bonney’s success with this procedure was such that his clamps were regularly used for myomectomy procedures for decades after his death. This instrument was included with other obstetric instruments, mostly destructive instruments, given to RANZCOG from Box Hill Hospital labour ward in February- March 1998. The maternity service at Box Hill Hospital combined with St George's Hospital in Kew to be known as Birralee Maternity Service. These instruments were collected by Julie Collette, Unit Manager, St George's Kew and given to RANZCOG Museum Curator, Susan Barnett. Stainless steel clamp. Scissor type instrument with two sets of finger grips and a locking ratchet mechanism. The blades close to form two apertures which can be selectively decreased in size."DOWN BROS LONDON STAINLESS" upper surface of RH handle; "B.H.H.L. WARD" inner surface of LH handle.surgery, obstetrics