Showing 47 items matching " baling of water"

-

National Wool Museum

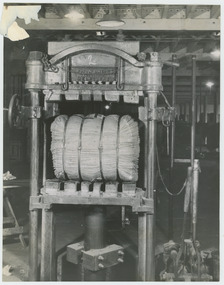

National Wool MuseumPhotograph - Bale Dumped and Strapped, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a wool bale in a Robinson Bro dumping machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W7 / W 7. Bale dumped and strapped.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - NEW CHUM DRAINAGE PROPOSALS

Six pages of handwritten notes regarding the New Chum Drainage Proposals. Extracts from the Bendigo Advertiser mentioning the rising of the water in the New Chum Mines. An Advertiser report 27/12/1910 mentions that deep mining will have to be abandoned owing to the absence of some proper scheme to cope with the water. An arrangement had been made by which the companies affected along the line should contribute to a scheme. Suggestions made that the water be lifted by electric pumps. Baling with tanks had been tried for 6 months and then abandoned. Directors Report Victoria Reef Quartz Jan 1911 mentions unwatering had been carried on with assistance of Government. On the 20th Dec, one rope gave out. Decided that replacing it and doing the necessary work could not be met in the present financial conditions. It was also considered that the costof trying to reach the bottom reefcut in the New Chum Railway could not be continued by baling as its cost proved too expensive, while it could probably be done economically & effectively by electric pump which is now subject to negotiations with the Mining Dept.' At the end of the report is a Balance Sheet. Document from Albert Richardson Collection of mining history.document, gold, drainage problems, drainage problems, new chum drainage proposals, bendigo advertiser 11/1/1911 page 7, victoria quartz, victoria consols, bendigo advertiser 5/7/1910 page 3, mr h v whitelaw, mines dept, insp ross, lansell's 180, 222, new chum consolidated, lazarus, bendigo advertiser 6/7/1910 page 7, 9/7/1910 page 9, drainage troubles, bendigo advertiser 8/7/ page 8, new chum railway, south belle vue, eureka ext'd, bgo adv 25/7 1910, 27/12/1910 page 2, rae's machine, bendigo advertiser 2/1/1911, mr mcbride, mines dept, mr stanfield, mines act, bendigo advertiser 16/1/1911 page 3, victoria reef quartz half yearly meeting 1911, directors report and balance sheet, geo paynting -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - MINERS SENSATIONAL EXPERIENCE AT THE VICTORIA QUARTZ

Handwritten notes from a Bendigo Advertiser report, Thursday June 16th 1910. Management had for some time been apprehensive that the flooding in the deep mines to the south would affect them. Lansell's 180 took the precaution of baling. On the Tuesday night the men at the Victoria Quartz had a sensational experience. The storage dam at 3324 ft level receives the overflow from the flooded mines to the south. The level connects with the 3310 level at the Big 180. The water flows uninterrupted into thestorage dam which has a capacity of about 270 tanks. The dam had been emptied on Tuesday morning and work continued until 10 pm that night. The platman noticed that the water was coming down the shaft in a regular torrent. They didn't take much notice as they thought it was a leakinig outlet valve on the ascending tank. At 11 pm the releiving shift came down the shaft and said that the dam at 3,324 ft must be overflowing. The velocity of the water pouring down the shaft increased and the men made a hurried exit from the bottom of the shaft which is down 310 ft from the 4.254 ft plat (a total depth of 4,564 ft). An inspection of the dam at the 3324 ft level found it to be overflowing. By morning (Wednesday) the shaft had filled, and the water rose to 7 ft in the plat at 4254 feet. Mining inspector hgave orders that men were not to go below the 3324 ft level. Baling continued without cessation at the Big 180 all day and could not lower the water. Drilling machines etc and a powerful air winch at the 4254 ft plat are under water. An inspection made of the 3100 ft level at the 180 mine where the workings are connected with the New Chum & Victoria showed that water was running strongly from that mine proving that the inrush was due to flooded water from the southern deep mines to the south. Document from Albert Richardson Collection of mining history. Document from Albert Richardson Collection of mining history.document, gold, drainage problems, new chum drainage scheme, miners sensational experience at the victoria quartz, bendigo advertiser 16/6/1910 page7, lansell's 180, big 180, new chum & victoria -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - ELLENBOROUGH FLOODED

Handwritten copy of a report in the Bendigo Advertiser 24/5/1907. ''Serious break in Water Main which is situated about 100 yards south of the mine. Main service pipe which supplies Harveytown has been leaking for some time past. Water soaking through old surface workings into the Belmont & Saxby shaft where it rose 60 feet and filled two x-cuts, one out weat 208 ft, and the other out east about 45 ft. Ellenborough began baling on Sunday 26th May, and it will take many days before work can be resumed. The mine was only working one shift and no men were underground at time of in rush''. Document from Albert Richardson Collection of mining history.document, gold, drainage problems, drainage problems, ellenborough flooded, bendigo advertiser, 27/5/1907, harveytown, belmont & saxby, ellenborough, albert richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - NEW CHUM LINE DRAINAGE PROBLEMS 1910

Handwritten extract from the Bendigo Advertiser 27/12/1910 Page 2. ''The Victoria Quartz, having deepened its shaft to 4,614 feet, had to abandon sinking on account of an inrush of water from the flooded mines to the south on the line. The influx occurred on the 15th of June, and notwithstanding that baling has been carried on almost constantly the company has failed to get the water out. It appears that the deep ground will have to be abandoned, owing to the absence of some proper scheme to cope with the water.'' Albert Richardson Mining History Collection.document, gold, drainage problems, drainage problems, new chum line drainage problems 1910, bendigo advertiser 27/12/1910 page 2, victoria quartz, albert richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - DRAINAGE 1905 - 1908

Handwritten notes from the Bendigo Advertiser 22/6/1910, listing the mine, Gallons baled, Deepest depth baled from, Total amount Rec'd, ? ? Coy for Financial Year ended 30/6/1908. Mines mentioned are: New Chum Railway, Eureka Ext'd, New Chum Con'd, Lazarus, Garibaldi, Lansells 180, Victoria Quartz, Lansell's 222, New Chum & Vic., Shamrock and New Shenandoah. Note along the side: re - Vict Quartz Inrush Water. Adv. Wed. 22/6/1910. (b) Handwritten notes on the New Chum Drainage Ass'n 1905 - 1908 from the Bendigo Advertiser 22/6/1910. Listed is the Year, Water Raised (Gallons), Total Amount Re?ed and Amount Re? Coys. The New Chum Drainage Ass'n was formed in 1901 and practically ceased to exist in 1908. Victoria Quartz at time of inrush of water on Tuesday night, the shaft had reached a depth of 4,614 feet. Water has since risen in the shaft to above 4,154 ft plat & the large workings at 4,254 feet, and 4,154 feet have also been t filled. As there are no reef workings from 4,154 to 3,424 feet the water will no doubt rise rapidly until that level is reached. Document from Albert Richardson Collection of mining history.document, gold, drainage problems, new chum drainage association, drainage 1905 - 1908, bendigo advertiser 22/6/1910, victoria quartz, new chum railway, eureka ext'd, new chum con'd, lazarus, garibaldi, lansell's 180, lansell's 222. mew chum & vic, shamrock, new shenandoah -

National Wool Museum

National Wool MuseumFunctional object - Auctioneer's Gavel, c. 1950s

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...Michael Crooks was the auctioneer responsible for selling Australia's million dollar wool bale on the 11th January, 1995 in Geelong, using this gavel. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Small wooden hammer, with handle and double sided face.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore -

National Wool Museum

National Wool MuseumPhotograph - Appledore Family, Growers Gallery, National Wool Centre, Geelong, 11 January 1995

... was washed to condition the water, then nine bales of extra super... was washed to condition the water, then nine bales of extra super ...This photograph depicts people gathered in the Growers Gallery on the 11th January, 1995 at the National Wool Centre, Geelong. It shows the emotions of Murray, Ian and Kaye Appledore while bidding took place for the million dollar bale. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of rows of people seated and standing in room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

National Wool MuseumPhotograph - Sale Room, National Wool Centre, Geelong, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...This photograph shows bidding underway for the million dollar bale in the Sale Room on the 11th January, 1995 at the National Wool Centre, Geelong. People depicted include Sale Team Baxter Murray, Auctioneer Michael Crooks and Wool Manager Keith Jackson. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of people seated at rows of tables with an auctioneers stand at front of the room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

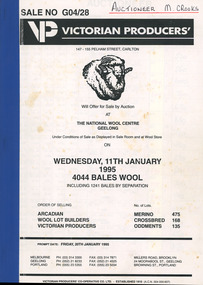

National Wool MuseumDocument - Victorian Producers' Sale Catalogue, National Wool Centre, Geelong, Victorian Producers' Co-operative Limited, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...This sales catalogue was the one used by Auctioneer Michael Crooks on 11th January 1995 when the million dollar bale was sold at the National Wool Centre, Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Bound paper booklet, approximately 35 pages, with printed and handwritten text.Front: [handwritten] AUCTIONEER M. CROOKS Front: [printed] SALE NO G04/28 / VICTORIAN PRODUCERS' / 147-155 PELHAM STREET, CARLTON / Will Offer for Sale by Auction / AT / THE NATIONAL WOOL CENTRE / GEELONG / Under Conditions of Sale as Displayed in Sale Room and at Wool Store / ON / WEDNESDAY, 11TH JANUARY / 1995 / 4044 BALES WOOL / INCLUDING 1241 BALES BY SEPARATIONmichael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

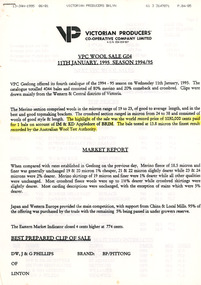

National Wool MuseumDocument - Victorian Producers' Market Report, Victorian Producers' Co-operative Limited, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...Victorian Producers Market Report, featuring details of the sale of the million dollar bale on Wednesday 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Two pages held with staple in top left corner with printed black text.Front: [printed] VP / VICTORIAN PRODUCERS' / CO-OPERATIVE COMPANY LIMITED / A. C. N. 004 059 607 / VPC WOOL SALE G04 / 11TH JANUARY, 1995 SEASON 1994/95michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

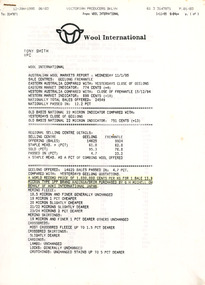

National Wool MuseumDocument - Australian Wool Markets Report, Wool International, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...Australian Wool Markets Report, featuring details of the sale of the million dollar bale on Wednesday 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Three pages held with staple in top left corner with printed black text.Front: [printed] Wool International / TONY SMITH / VPC / WOOL INTERNATIONAL / AUSTRALIAN WOOL MARKETS REPORT: WEDNESDAY 11/1/95michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Million Dollar Bale, National Wool Centre, Geelong, Gordon Robertson, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...This photograph shows Growers Ian Appledore, Kaye Appledore and Murray Appledore, Wool Manager Keith Jackson, Wool Classer Phillip Gibson, Geoff Allibon and Brendan Dart posing with the million dollar bale after it was sold on 11th January 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three six men and one woman standing around a bale of wool.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Million Dollar Bale, National Wool Centre, Geelong, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...This photograph shows Grower Ian Appledore, Auctioneer Michael Crooks and Wool Manager Keith Jackson posing with the million dollar bale after it was sold on 11th January 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men standing around a bale of wool.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Armed Guards with Million Dollar Bale, 11 January 1995

... wool was washed to condition the water, then nine bales... wool was washed to condition the water, then nine bales ...This photograph shows armed guards and Wool Manager Keith Jackson posing with the million dollar wool bale after it was sold by auctioneer Michael Crooks on the 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men with a bale of wool in front of an armaguard truck. Two of the men are armed guards standing either side of the wool bale, one is holding a shotgun. Another man in a suit and tie is crouching near the bale.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, armed guards, armaguard -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - DEBORAH MINE - QUARRY HILL

Handwritten notes from a report by J. J. Caldwell, District Geologist. Ref. M. & Geological, July 1938. Page 29. Depth of Shaft 30 - 9 - 1937 - including well was 1025 feet as at 3 - 10 - 1932. Water was then making 500 gallons per hour. Baled with tanks.document, gold, mining reports, deborah mine quarry hill, m & geological, j j caldwell -

Flagstaff Hill Maritime Museum and Village

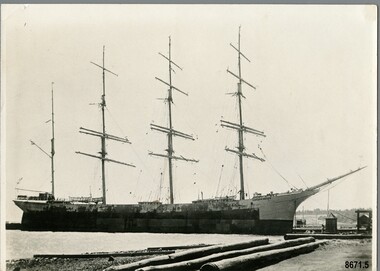

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel "Strathgryfe", late 19th or early 20th century

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. The "Strathgryfe" was a four masted steel barque built in 1890 by "Russell and Company", Port Glasgow and was owned by Duncan McGillivray (The Strathgryfe Ship Company Limited), Greenock. It arrived in Melbourne in December 1891 from New York. Between 1891 and 1910 it carried merchandise in and out of Australia to ports around the world - Melbourne to London (1892), Newcastle to San Francisco (1894), Capetown to Newcastle (1894), New York to Shanghai (1897), New York to Melbourne (1898), Frederickstadt to Melbourne (1899), Liverpool to Sydney (1900), San Francisco to Brisbane (1903), Newcastle to Pisagna, Chile (1905) and Rotterdam to Melbourne (1910). It carried breadstuffs from San Francisco, coal from Newcastle, wool from Sydney, saltpetre from Hamburg and wheat from Brisbane and Melbourne as well as a variety of general merchandise. In 1898, whilst on route between New York and Melbourne, it came across the Captain and crew of the missing barque "Glen Huntley" which had been reported as "lost" several months earlier. They had been marooned at Tristan D'Acunha (a remote group of volcanic islands in the South Atlantic ocean). Captain McIntyre, of the Strathgryfe, offered to bring Captain Shaw (of the Glen Huntly) on to Melbourne with them but the "old mariner" decided to stay on with his crew till arrangements could be made for rescuing the whole of them. In 1899, when in Melbourne, seven of its crew refused to go to sea in it due to its unsafe conditions. They said the vessel was unseaworthy and that the rigging was unsafe and the lifeboats, not watertight. The Captain (Donald McIntyre) denied the allegations and produced a marine surveyor's certificate as evidence of the condition of the vessel. The men were sentenced to three weeks imprisonment. In 1901 there was a fire on board the Strathgryfe just after it left Sydney for London which resulted in many bales of wool being destroyed. In 1902 it was beached at Shellback island (near Wilson's promontory) for several weeks and had to be considerably dismantled in order to lighten its load enough to allow tugs to pull it back into deep water. In 1910 it was sold to a German firm and renamed "Margretha". It continued to operate in Australian ports until 1914 when it left Sydney for the English Channel with 42,438 bags of wheat. However owing to W.W.1 breaking out, it made for the port of St Michael's where it remained for twenty-one months. Later it was seized by the Portuguese Government and renamed "Graciosa" and was leased back to the English Government. It was sunk by two German submarines in 1918.This photograph is significant as a record of the world wide mercantile trade Australia was engaged in at the end of the nineteenth century and beginning of the twentieth century.Black and white photograph of a four masted barque moored at a dock. The rigging and two lifeboats are clearly visible. Three large timber logs are in the foreground. On the back of the photograph, the donor's name and telephone number have been written in black ballpoint pen and the name of the ship has been handwritten (incorrectly) in pencil in cursive script.Back of Photo - donor's name and telephone number "Strarthgryfe" [Strathgryfe] / "late" / "Margurita" [Margretha]flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, strathgryfe, barque, steel barque, margretha, graciosa, frederick trewartha, mercantile trade, russell and company, merchandise, cargo ship, glen huntly, w. w. 1