Showing 55 items

matching awl

-

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP, Unknown

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, and nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together and neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A pair of handmade, adult brown leather work boots, with brown leather laces, decorative stitching, metal eyelets and are stitched with waxed thread. The soles are covered with hob nails in a decorative pattern. They have metal caps on the heels. bootlaces, boots, footwear, clothing -

Bendigo Military Museum

Bendigo Military MuseumAward - MEDAL SET WW1, post 1918

Maurice MONIGATTI No 3914 enlisted in the AIF on 31.7.1915 aged 20 years 2 months in the 12th reinforcements 5th Batt. Embarked for Egypt 23.11.1915, hospitalised 25.1.1916 with Mumps, rejoined unit 9.2.1916, WIA 25.7.1916 GSW to Chest and Arm, rejoin unit 6.8.1916, reported missing 3.3.1917. German records dated 4.6.1917 reported him captured at Thilloy on 2.3.1917 and he was imprisoned at Gefangenen lager Limburg A/Lahn Germany. Maurice arrived back in England on 19.12.1918. He was given leave and decided to make it longer and was let of a charge of AWL. He was discharged from the AIF on 27.7.1919.Medals, set of 3, mounted around a piece of cardboard sewn on re M E MONIGATTI/ 1. 1914-15 Star. 2. British War Medal 1914-19. 3. Victory Medal.“3914 Pte M MONIGATTI 5/BN A.I.F”award, medal set ww1 -

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

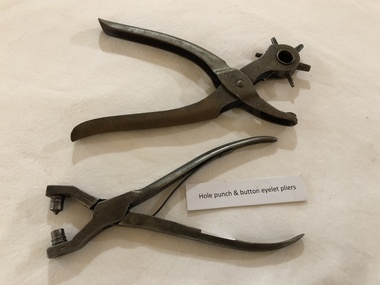

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

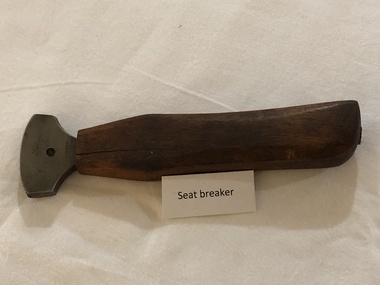

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

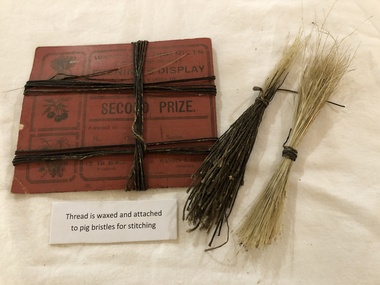

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 pairs of handmade, adult brown leather boots, with decorative stitching, eyelets and stitched with waxed thread. Soles covered with hob nails in a decorative pattern. 1 handmade child's brown leather boot, with decorative stitching, metal eyelets, heel has patterned nails.bootlaces, boots -

Flagstaff Hill Maritime Museum and Village

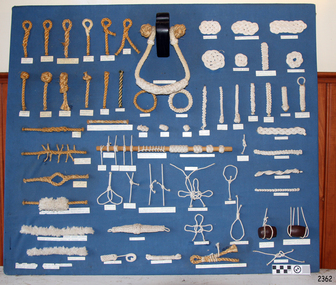

Flagstaff Hill Maritime Museum and VillageEducation kit - Display Board of Knots, Tom Long, DSM (Member of International Guild of Knot Tyers), Before Sept 1986

The Display Board of Konts was handmade in Kings Lynn, Devon, England, by Tom Long DSM, who is a member of the International Guild of Knot Tyers. This display board shows the knots and joins used in ropework performed by a sailmaker and other skilled ropeworkers. It demonstrates the uses of some of the knots, such as for knobs and handles, suspending lengths of wood, reinforcing spliced rope and even for decorative work. The sailmakers travelling as part of the ship’s crew stored their tool kit in a canvas ditty bag. It contained needles, awls, a sailmaker’s leather palmed glove with a heavily reinforced palm - a shuttle to mend and make nets, fids, knives, mallets, brushes, rulers, and rope gauges. Sailmakers used their ropework and knot-making skills for various purposes and chose the type of rope fibre for its particular properties. For example, Italian hemp rope was preferred for the light line used in shore-to-ship rescues because it was lightweight, not easily knotted, and absorbed less water. A supply of various types of rope was a commodity on board a ship and on land in the new colonies. It was flexible, easily stored, and could be worked to create an endless variety of objects on its own or with other materials like wood. An example is a simple rope ladder. Lengths could be combined to make various thicknesses and pieces could be skilfully joined together by splicing. The importance of knots in seafaring cannot be overestimated. When ships relied on only the wind for power and speed, there were a huge number of various ropes in use, particularly with regard to the sails and rigging. Seafarers would be judged on their ability to tie knots speedily and correctly. A mounted display of authentic seaman's knots is on a board covered in blue fabric. Various rope grades and fibres were used to work numerous knots and splices. Some of the uses are familiar, such as the toggle, the pineapple knot, and the Turk’s head. A selection of rope grades and fibres were used to work numerous knots and splices. Some of the uses are familiar, such as the toggle, the pineapple knot, and the Turk’s head. The name or purpose of the knot is on the label below it. Labels below each knot give its name or use.flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, knot display, knot making, ropework, marine technology, sailmaker's work, sailor's knots, ship's rigging, seamen's knots, handmade, rope craft, knots, splices -

Bendigo Military Museum

Bendigo Military MuseumPostcard - POSTCARDS, PHOTOGRAPHIC WW1, (.1) Dec 7.12.15, (.2) 31.10.16

Both letters to “Lena” are from Tom WATT. As well as his signature someone has written his name as in blue pen. One letter is just signed “Tom” the other “Gunner T H Watt”. It is believed this is "Thomas Henry WATT", born Bendigo. He had pre war service in the 67th Bn Senior Cadets, no dates given. Regt No 3670 shows he enlisted on 20th or 28th Dec 1915 in the 8th reinforcements 21st Bn age 20 years. It shows he embarked just 9 days or 1 day later on 29.12.1915. He transfers to the 60th then 57th Bn and then on 17.3.1916 5th Div Artillery. he is mustered as “Gunner” and transfers to 5th DIV DAC (Ammunition Column) on 25.5.1916. (.1) The letter is dated Dec 7.12.1915 two weeks or so prior to enlistment dates. The end of the letter talks about being sick and possibly missing going with the next draft. There are 3 other sketchy records showing enlisted 12.7.1915, 5th DAC 15.7.1915, AWL Bendigo 4.11.1915. This would fit in better than enlisting and embarking in not much more than a week. Tom married Margaret McCALL in Scotland 25.4.1919 prior to coming home. Refer Cat No 3996P re “Lena” and other cards, 4000.2 from “Tom”.(.1) Postcard photo, B & W showing a soldier seated on a chair with a crop, studio background. On rear extensive letter in black pen to “Dear Lena”. (.2) Postcard photo, B & W, portrait of a soldier, no hat, bandolier over shoulder, clear background. On rear brief letter in black pen addressed to “Dear Lena”. postcard, lena, 21st, thomas henry watt -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Dandenong/Cranbourne RSL Sub Branch

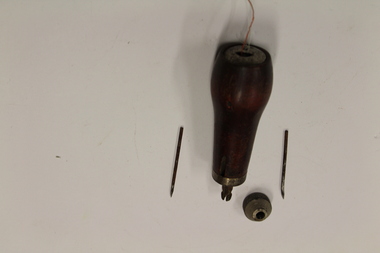

Dandenong/Cranbourne RSL Sub BranchAwl (Stitching

Pear shaped tool. Wooden handle (brown) and metal screw down connecter. Also includes 2 metal needles with eyelets. Thread spool inside handle for thread to be fed through to needle..