Historical information

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles.

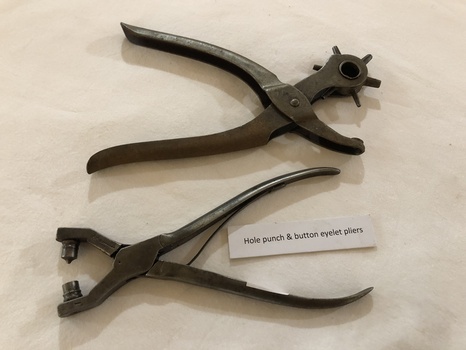

Bootmaking is a complex process requiring a variety of tools.

The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave.

Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.

Physical description

A metal hole punch, and metal button eyelet pliers, both used for shoe-making.

Inscriptions & markings

AMG Darholey