Showing 474 items matching "boiler"

-

Clunes Museum

Clunes MuseumDomestic object - Boiler

.1 Boiler with handle, metal, galvanised .2 Lid, Metal, galvanisedOval Stamped Metal plate affixed to lid " Weickhart Makers, Clunes"weickhart, manufacturing in clunes, metal tools -

Federation University Historical Collection

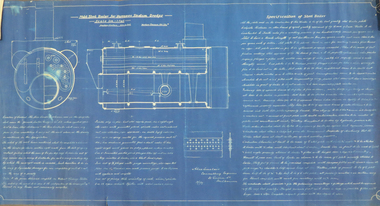

Federation University Historical CollectionPlan, Mild Steel Boiler for Yarrawee Suction Dredge, 16 January 1907

George Milford, a long term staff member of Thompsons Foundry Castlemaine, remembers discussing Alexander Sinclair with this son, Alex Sinclair Jnr. "When Alex Jnr was a boy, his father, a senior design engineer, was sent to Malaya to oversee the erection on site of a suction cutter dredge for Thompsons. This was an adaptation of the idea of a bucket-dredge, where gold is won from alluvial gravels. In the 1915-1920 era, the Thompsons Engineering Department designed a suction-cutter dredge, by which hydraulic suction with a revolving cutter at the end of a long proboscis would collect the alluvial soil and deliver it into the dredge for recovery of the precious metals. Export marketing was then ‘all the go’, and the tin dredges were ordered from Thompsons, using the new cutter design. The dredges were, of course, shipped to Malaya in pieces, ready to be assembled on site. A number of Thompsons employees were selected to travel to Malaya to assemble the dredges. There were fourteen men in the gang. These men sailed on 1st July 1925, their number including Delmenico, McKay and Charles Albert Hauser, an engine driver. C A Hauser died of malaria in Malaya shortly after arrival. Components for a further three of these dredges were in transit or on site when the first suction-cutter dredge was assembled and tested. The designers had failed to take into account the fact that, in the jungle floor in Malaya, many trees grow up, and fall down, in tropical conditions, and become submerged still waterlogged in the floor of the jungle, and in the tin-bearing gravels. The suction-cutter dredge was found to be inefficient in these circumstances, the price of tin had fallen and the Malayan client reneged on the contract. Faced with an outlay of over £4,000 on which no money would be received, the company went bankrupt on 25th August 1925. Alex Sinclair Snr was at that stage in Malaya, and received the news of the bankruptcy by telegram. Upon telegraphing his employers for funds to return home, he received the reply that there were no such funds available. Alex Sinclair Jnr told the story of how his father worked as a labourer in Malaya for two years, while his mother took in washing and ironing during the same period, until together they had assembled enough money to pay for his father’s return Anyone who talks about “the good old days” is talking nonsense!"Large blue printed paper plan outlining the conditions of contract for the making of a steel boiler. The Blueprint includes design drawings and written contract specifying materials, time frame and costs. Signed on front 'Alec Sinclair Consulting Engineer, 31 Queen Street, Melbourne'. Stamped on verso 'Printed by Paterson & Co, Colonial Mutual Chambers, Collins St, Melbourne'. blueprint, designs and plans, yarrawee suction dredge, conditions of contract, thompsons foundry castlemaine, george milford -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Instrument, No. 2 Boiler Drum Pressure Gauge

The pressure gauge has a clock a like look with scale from 0 to 2000 PSIG and is screwed into a wooden board with texts "HMAS Perth No. 2 Boiler Drum Pressure Gauge"HMAS Perth,HMAS Vampirehmas perth, pressure guage -

Buninyong & District Historical Society

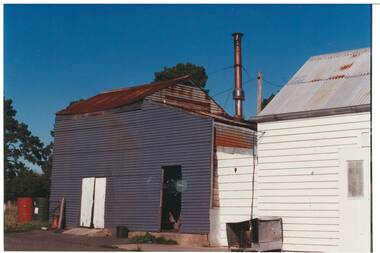

Buninyong & District Historical SocietyPhotograph - Original Colour Photograph, Geoff Little, Boiler House, Whykes & Sons' Slaughter House and yards, 1994

Record of early industryColoured photograph (and b/w print) of Boiler House at Whykes & Sons' Slaughter House and yards, functioned for Whykes Butchers from 1863-1994, situated at Slaughterhouse Rd. Durham Leadbuninyong, whykes, butchers, slaughterhouse, industry, farming, boiler house -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Original Colour Photograph, Geoff Little, detail, Boiler House, Whykes & Sons' Slaughter House and yards, 1994

Record of early industryColoured photograph (and b/w print) of Boiler House at Whykes & Sons' Slaughter House and yards, functioned for Whykes Butchers from 1863-1994, situated at Slaughterhouse Rd. Durham Leadbuninyong, whykes, butchers, slaughterhouse, industry, farming, boiler house -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Original Colour Photograph, Geoff Little, detail, interior of Boiler House, Whykes & Sons' Slaughter House and yards, showing knocking box -crush, 1994

Record of early industryColoured photograph (and b/w print) of detail, interior of Boiler House, Whykes & Sons' Slaughter House and yards, showing knocking box -crush, functioned for Whykes Butchers from 1863-1994, situated at Slaughterhouse Rd. Durham Leadbuninyong, whykes, butchers, slaughterhouse, industry, farming, boiler house, knocking box -

Buninyong & District Historical Society

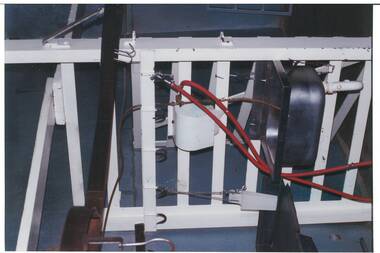

Buninyong & District Historical SocietyPhotograph - Original Colour Photograph, Geoff Little, detail, interior of Boiler House, Whykes & Sons' Slaughter House and yards, showing railing and washing area for carcasses, 1994

Record of early industryColoured photograph (and b/w print) of detail, interior of Boiler House, Whykes & Sons' Slaughter House and yards, showing railing and washing area for carcasses, functioned for Whykes Butchers from 1863-1994, situated at Slaughterhouse Rd. Durham Leadbuninyong, whykes, butchers, slaughterhouse, industry, farming, boiler house, washing area -

Port of Echuca

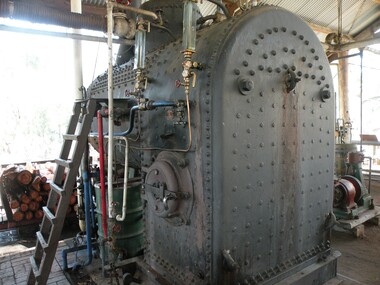

Port of EchucaFunctional object - Locomotive Type Fire Tube Boiler, 1927

This Johnson Bros. (USA) Locomotive Type Boiler was from a steam shovel (that moved on rails) that excavated rock and soil during the construction of Stevens Weir near Deniliquin NSW in 1934. It has a working pressure of 100psi. This is an example of a fire tube boiler where the fire from the fire box heats the water surrounding the fire tubes running through the boiler, smoke escapes out the smoke stack and the steam is captured in the dome and sent through pipes toward other engines in the Port of Echuca Steam Display. Two glass gauges are fitted on the side of the firebox. Two safety valves are fitted at the top of the boiler to maintain the correct and safe pressure. It still functions today for visitors most days of the week.A good example of the technology and industrial history of the Riverina region of southern NSW and northern Victoria. It is an integral part of the Port of Echuca Steam Display running secondary engines off the steam produced within this boiler. Large cast iron, fire tube boiler with 124 fire tubes, fire box, steam dome and exhaust chimney. boiler, johnson bros, steam display, kevin hutchinson steam shed -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSteel Sample, ca. 1876

The sample of steel from which the S.S. Julia Percy’s boiler was made has been tested, according to the attached label. The test involved heating the steel to blood red temperature (or dark red colour) then dipping it into water and bending it when it was cold. A “very severe test for quality” was written on the ticket by T.H. Osborne. (Mr Thomas Hamilton Osborne was the secretary for the Western Steam Navigation Co, established in Warrnambool in 1886. The company’s office was on the corner of Timor and Liebig Streets in Warrnambool and its north-western wall is now part of the current Warrnambool Regional Art Gallery. ) Cold bending of steel in a press or through rollers is the typical method of curving steel for construction. The steel needs to be manufactured in such a way that it is strong enough yet still flexible enough not to crack when bent or rolled. The boiler on the Julia Percy could have been a Scotch Boiler, a design introduced in the 1870’s and still being used today. This design was more robust that previous boilers, generating higher working steam pressures. The design incorporate greater ability to roll iron plates, leading to greater strength, thicker plating and fewer riveted joints. They were originally made of iron then later incorporated steel sections until they were entirely constructed of steel. Many examples of this type of boiler can be found on wreck sites. Shipping was the cheapest and most practical means of carrying produce and goods during the period 1840-1890. Regular domestic steamer services commenced in the Warrnambool district in the late 1850’s and by 1870 the passenger trade was booming. Produce was loaded from the jetty into ‘lighters’ (small boats), which took it to the ships at anchorage in the bay. Passengers were taken to the ship’s side then climbed aboard up ladders or gangways. The coming of the railway in October 1889 meant the gradual decline and end of the steam shipping era. Originally the ship was known as the SS Julia Percy and was later renamed as the Leeuwin. She was an iron passenger-cargo steam ship built in Glasgow by Thomas Wingate for the Warrnambool Steam Packet Company, which commissioned the ship for the steamship trade in Victoria’s western district. She was first registered in Warrnambool, Victoria in 1876. At one point in time the Julia Percy would sail from Warrnambool to Melbourne every Friday and return from Melbourne to Warrnambool every Tuesday. The cost of a return ticket for a Saloon Fare was £1.0.0. She would sail “if practical and weather permitting”. The Julia Percy changed hands several times. Her next owner was the Western Steam Navigaiton Co of Melbourne (1887). It was the manager of this company, Mr. T.H. Osborne, who tagged ths steel sample above. Melbourne Steamship Co became the next owners (1890), followed by William Howard Smith and Sons (1901) for use in Queensland coastal trades, then she was bought by George Turnbull in 1903 and used for local mail contract in Western Australia. She was sold to the Melbourne Steamship Company Ltd. (1906) and re-named the Leeuwi but continued in her Western Australian coastal run. She was converted into a coal hulk in Melbourne in 1910 as a result of damaged caused when she was driven against the jetty at Dongara during a gale. The ship was eventually dismantled and scuttled in Bass Strait on 28 December 1934. The steel sample is significant for its association with the wreck of the Leeuwin (Julia Percy), which is on the Victorian Heritage Register. It is historically significant for being a rare artefact that has potential to interpret aspects of western Victoria’s 19th century steamship trade and Victorian cultural history, including the testing and manufacturing process associated with steam power. Leeuwin is listed on the Victorian heritage Register as being historically significant ‘as one of only four wrecks of steamships in Victorian waters associated with the western district of Victoria’s coastal steamship trade. Her registered number is VHR S413. A sample of the steel from which the boiler of the "SS Julia Percy" (later named Leeuwin) was made. The piece of steel is a ‘C’ shape with the ends almost meeting. A luggage ticket is tied onto the steel and has an inscription on it. The steel is rusty.Ticket with typed information “Steel of which the Boiler of the “Julia Percy” (Warrnambool Steam Navigation Co) was made. TEST: Made Blood hot or Dark Red then dipped into water and bent cold. A very severe test for quality T.H. Osborne. Below these words is the hand written inscription in black “FM 151 / 9.75” julia percy, leeuwin, steel, boiler, steam ship, metal testing, western steam navigation co., flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t.h. osborne -

Clunes Museum

Clunes MuseumDrawing, Harry E Sando

ARCHITECT DRAWING OF CLUNES PRESERVING BOILER HOUSE .1 DATED 12 MARCH 1897 .2 DRAWING "BUILDING OF THE BOILER", LONGITUDAL ELEVATION APRIL 1987 .3 DRAWING NO. 1 DATED 12 MARCH 1897 .4 DRAWING OF MAIN BUILDING TESTING ROOM .5 DRAWING OF CAST IRON RING AND WROUGHT IRON COVER TO BOILER 21/4/1897.5 THESE ARE THE DRAWINGS REFERRED TO IN TENDER DATED 9 DAY OF APRIL 1897 FOR BUILDING BOILER AND OTHER WORK AT THE LOTHAIR BOILER HOUSE, DATED AT CLUNES THIS 29 DAY OF APRIL 1897 SIGNED BY THE CONTRACTOR, WITNESS TO SIGNATURE HARRY SANDO clunes preserving company, boiler house, lothair boiler house -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white print, 689/1/2, 1947

Soil Sterilizer. Built 1946." EMG"April 1947. Soil Sterilizer - Boiler. Built 1946." EMGsoil sterilizer, boiler, e. m. gibson collection -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, George Coop, Power transformer on a QB boiler/flat wagon on display at Spencer Street Railway Station during the 1954 Victorian Railways Centenary Exhibition, Sep. 1954

"V.R. Cavalcade" Centenary 1854-1954 Exhibition (11-25 Sep 1954) presented a model railway occupying about 1,400 square feet in the Lower Town Hall featuring a number of model railway working scale models. The exhibition also included a display of rolling stock, track, electrical and other railway equipment held at Spencer Street Railway Station.Digital TIFF file Scan of Kopdak 620 black and white negative transparencygeorge coop collection, display, spencer street railway station, v.r. cavalcade, victorian railways centenary 1854-1954 exhibition, power transformer, qb boiler/flat wagon, qb-13 -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaManual - Manual, Ship engineering, PLIBRICO, Plibrico Modern Boiler Settings, 1960s

Mariner Duncan had a particular regard for the Mission to Seafarers. A plate for display on a commissioned new table at the MTSV acknowledges his bequest and the material donated. Collectively the G W Duncan material includes: photographs, professional data memorabilia and written and commercially printed resources. The memorabilia relates to his career at sea and in particular the role of an engineer, including a handwritten manual of notes and references relating to the mechanical and engineering aspects and areas of responsibility for maintenance. A stapled book with black cover and the word PLIBRICO in ochre printed at top centre.mariner manuals, manual, boilers, maintenance, engineers, engine rooms, george winfield duncan (1922-2017), ship engineer, s.s. athenic -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkKitchen boiler, Copper Kitchen boiler, Approx 1900

Joseph Fowler (1888-1972), businessman and municipal councillor, was born on 28 February 1888 at Bagworth, Leicestershire, England, one of thirteen children of John Fowler, groom, and his wife Mary, née Ash. With his brother Sydney, in the early 1900s Joseph worked in a fruit-preserving business run by an uncle at Maidstone, Kent, and continued with the firm after 1908 when it was relocated at Reading. At St Andrew's parish church, Leicester, on 7 September 1910 he married a nurse, Elizabeth Harris (d.1965); they emigrated in 1913 and settled at Camberwell, Melbourne. Encouraged by his commercial experience, and by the variety and quality of fruit in Australia, Fowler set up a fruit-bottling business in the rear of his small house in Burke Road. Trading as J. Fowler & Co., by 1915 the company had begun producing home-bottling kits which contained a sterilizer, bottles, lids, rings and a thermometer. To acquire the capital to establish a factory, Fowler travelled the district, selling his kits door-to-door from the back of a cart. In 1920 he bought a shop at the corner of Power Street and Burwood Road, Hawthorn, and registered his business as a private company. During the Depression his kits became a household name. In 1934 Fowlers Vacola Manufacturing Co. Ltd was registered as a public company. Housewives, nationwide, were urged to bottle their own fruits and jams by 'Mrs B Thrifty', the dainty cartoon character who graced the firm's advertisements. Numerous recipes and instruction books, such as From Orchard to Bottle the Fowlers Way, advertised the necessary preserving equipment, extending to jelly bags and juice extractors. Australian-made glass and imported steel and rubber were used in the production of Fowlers Vacola Bottling Outfits. Determined to put something back into the community which had supported him so well, in 1933-60 Fowler represented Yarra Ward on the Hawthorn City Council (mayor 1938-39 and 1945-46). He served as vice-president of Swinburne Technical College (1942) and of the Hawthorn branch of the Australian Defence League (1943); he was also a Rotarian, and a warden and vestryman of St John's Anglican Church, Camberwell. Changed demands in World War II encouraged Fowlers Vacola to diversify their product. Canned goods were manufactured for allied troops in the South Pacific. In 1953 new buildings and plant, including a giant pressure-cooker, were installed to increase productivity: from that time Fowlers Vacola sold canned and bottled food throughout Australia and abroad. By 1960 the factory occupied more than 122,000 sq. ft (11,330 m²) and further expansion was to occur when the firm moved to Nunawading. Fowler retired in 1961, but remained chairman of directors; his son Ronald succeeded him as managing director. Variously described as a generous, jovial man with a sense of humour, and as a strict and astute manager whose company was his life, Fowler was renowned for his straight business dealings and his 'no-nonsense' attitude. Survived by his son and daughter, he died on 24 April 1972 at Camberwell and was cremated. His estate was sworn for probate at $204,424. On Ronald Fowler's death in 1978, the company was bought out by the Sydney firm, Hooper Baillie Industries Ltd; it in turn sold to Sabco Ltd of South Australia; in 1994, when Sabco went into receivership, Australian Resource Recovery Technologies re-established Fowlers Vacola Australia Pty Ltd's headquarters in Melbourne. Copper boiling pot for home preserves, handles, lid and removable thermometer, also acc ompany instruction booklet. "Fowlers Method of Bottling Fruits and Vegetables"Fowler's "Vacola" Reg. No. 68081 Sterilizer -

Bay Steamers Maritime Museum

Bay Steamers Maritime MuseumBook, J.N. Williams, Boiler House Practice, 1953

Beige hard cover book with dust jacket of 600 pagesInside front cover, brown sticker with white printing "HALL'S BOOOK STORE / New, Use and Rare Books / 371 Bourke Street, Melbourne / 262 Chapel Stree, Prahran" Front page hand written in blueink "J.T. Young / 27 Jeffrey St / Bentleigh/ Vic" On same page, same information stamped three times -

Bay Steamers Maritime Museum

Bay Steamers Maritime MuseumBook, Standards Association of Australia, Australian Standard SAA Boiler Code Part V Welding, 1951

Ringbound book of 146 pagesnon-fiction, boilers, standards, welds, welding -

Robin Boyd Foundation

Robin Boyd FoundationBook, Patrick Goldring, The Boiler House Society, 1969

Hardcover w/Dust Jacketgreat britain, social conditions, society, walsh st library -

Nillumbik Historical Society Incorporated

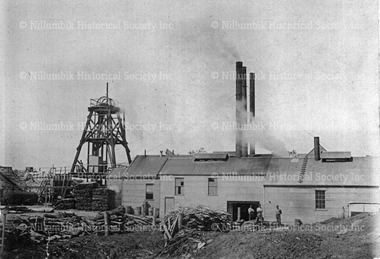

Nillumbik Historical Society IncorporatedPhotograph - Black & white photograph, Diamond Creek Gold Mine with Poppet Head and a Chimney for Each Boiler

A comprehensive view of the buildings of the Diamond Creek Gold Mine during the period the boiler houses were shared with the Union Gold MineBlack & white photographdiamond creek gold mine, union gold mine, diamond creek, nillumbik, poppet head -

![Photograph, [Hoppers feeding coal into boiler]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f609821f50e3cc9f506/item-media/54065f609821f50e3cc9f507/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Hoppers feeding coal into boiler]

Acquired when "Classweave Industries" closed down.29 1/3 textile mills - staff woollen mills, classweave industries pty ltd federal woollen mills ltd, boilers, textile mills - staff, woollen mills -

Department of Health and Human Services

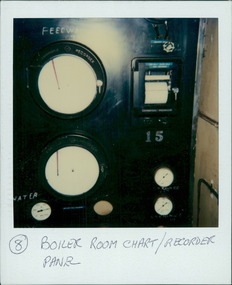

Department of Health and Human ServicesPhotograph, Photo of an analogue temperature chart recording panel used in the boiler room at Caloola Training Centre Sunbury

Colour Photo -

Department of Health and Human Services

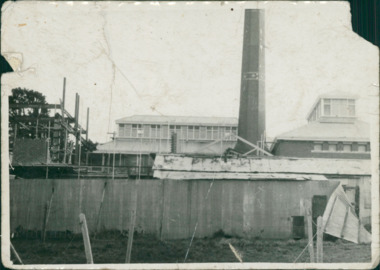

Department of Health and Human ServicesPhotograph, Photo showing construction of new buildings & boiler room chimney at Caloola Training Centre Sunbury - Black & White Photo

-

Moorabbin Air Museum

Moorabbin Air MuseumBook (Item) - Standards Association Of Australia S.A.A Boiler Code.Tge Design, Construction, Inspection And Operation Of Boilers And Unfired Pressure Vessels And Their Appurtenances, Standards Association Of Australia S.A.A Boiler Code

Code No. CB.1-1942 -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler pot with lid, clark and co, early 1900's

Cooking pot used on wood stoveThis is a domestic cooking pot used for food preparation.oval shaped boiler with a handle and lid, cast ironClark and co. 2 1/2gallonsdomestic, kitchen, pot, boiler, cast iron -

Puffing Billy Railway

Puffing Billy RailwayFormer Puffing Billy Locomotive Boiler 6A

Former Puffing Billy Locomotive Boiler 6A - front tube plate missing Historic - Former Puffing Billy Locomotive Boiler 6A - front tube plate missing Former Puffing Billy Locomotive Boiler 6A - front tube plate missing Made of iron , wrought iron , metal;puffing billy, 6a boiler -

Port of Echuca

Port of EchucaFunctional object - Boiler engine, 1927

This is the Ruston and Proctor engine and boiler from the PS Little Wonder built by R Barbour, Cornella NSW. It was launched in December 1878. Owned by Murray River Sawmills, it was used for logging operations until 1904, when the vessel was dismantled. The engine and boiler was purchased by the Robins family and ran a pump on their property by the Goulburn River. The boiler was later condemned by the engine continued to be used with steam supplied by another boiler up until the 1950s. Now considered to be beyond repair. A good example of the technology and industrial history of northern Victoria and along the Goulburn River. boiler, steam display, steam garage, ruston and proctor -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler Pot, A.Kenrick, Early 20th century

Food preparationThis is a typical cast iron cooking pot used on a wood stove. Used for food preparation.cast iron, oval boiler with centre hook in the handle, 3 gallon capacity, no lidA. Kenrick and sons. West Bromerickdomestic, kitchen, pot, boiler, cast iron -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler, Early 20th Century

Domestic item used for cooking and food preparationLocal historyCast iron oval cooking pot. Hooked handle attached to lugs on side of pot. Tin lid has central handle.Clark & Co 2 1/2 G embossed on side of pot. domestic, cast iron, clark, food preparation, iron pot -

Lake Bolac & District Historical Society

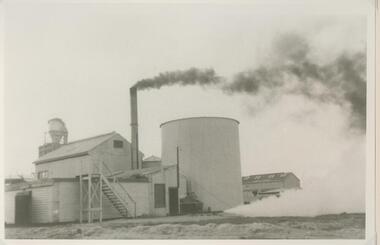

Lake Bolac & District Historical SocietyBlack and white photograph, Lake Bolac Flax Mill

Photograph of Lake Bolac Flax Mill boiler house and pits in full production. The mill operated between 1942 and 1959 and was located on the shores of Lake Bolac. Local farmers grew flax which was transported into the factory to be processed. The mill employed Land Army girls, locals and migrant workers.Photograph of Lake Bolac Flax Mill boiler house and pits in full production. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pipe Brush

This ship's boiler pipe brush would have been used to keep the steam boiler pipes in good working order. The bristles are arranged in a round shape to fit against the sides of the boiler pipe and clear away debris. The brush has a loop for storing it on a hook so the bristles won't become damaged. The ship's boilers created steam to power the ship's engines. Some larger steamships had several boilers and therefore several funnels. Early steamships also have masts and sails, giving them the option of steam power or wind power. The first successful steamboat trial in America was in 1787 when John Finch displayed its features on the Delaware River in Philadelphia. The first steamboat in Australia was the Sophia Jane, which arrived in Sydney in 1831. The ship traded cargo and passengers between Sydney and Newcastle. This ship's boiler pipe brush is unique in our collection and an essential item in the maintenance of steam boilers. It is connected to the era of steamships, which in Australia began in 1831 with the arrival of the first steamship in Sydney. Pipe brush; long twisted wire handle with stiff bristles around the base section, arranged in a cylindrical shape, and a loop at the other end. Used for cleaning pipes of a ships boiler.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, steam boiler, steam boiler brush, boiler maintenance, boiler brush, pipe brush, steam boiler pipe, steamship, steamboat, steam power