Showing 54 items

matching boot last

-

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

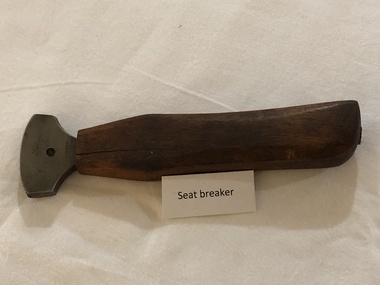

Mont De LanceySeat Breaker

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

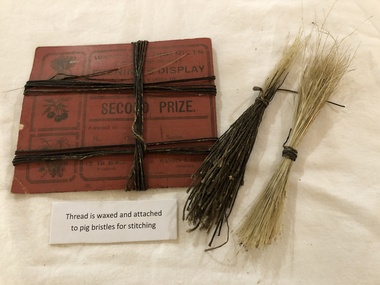

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making... to, a wooden last to form the boot. Once attached to the insole ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - Holden ZB Calais

Joint project between Opel (Europe) and Holden Australia. The Australia released car differs from the European released vehicle in both handling dynamics and engines.Last car to bear both the Holden and Commodore logo'sWhite bodied four door sedan, has a factory sunroof, alloy wheels dual exhaust outlets.Holden emblem both grille centre and boot lid, Calais V boot LHS. V6 AWD sign low both driver and passenger doors.vehicle, commodore, sedan -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - EJ Special sedan

The styling of the EJ was a radical departure from the previous model, the EK, with a lower roof line, a flatter boot and the absence of fins. This was the last car manufactured by GMH that utilised the "original" gray motor. Transmissions were a three speed manual, an automatic using the Hydra-matic. Auto was available in all models, including commercial vehicles for the first time.This is the last vehicle that was to be fitted with what was commonly referred to as the 132.5 cubic inch Grey motor4 Door blue with white roof sedanChrome strip along sides of car, Special badge on front Guards, Holden name across top of grill and across boot lid .Number plate Club permit 63455 Hej special sedan, manual, car -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VZ Holden Monaro

Final saleable Monaro, but, the second last produced The last Monaro was sold by Holden on E-Bay to a Queensland collector, collecting $187600 for the leukaemia foundationTurismo (Blue) painted body, alloy wheels air scoops bonnet centreGM lion emblem grille centre and boot centre also. Monaro logo rear quarter panel both sides CV8Z stamped into all alloy wheels.holden, monaro, cv8z -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VS model commodore, April 1995

The extent of exterior changes veered not much further than a redesigned Holden logo and wheel trims. An updated Ecotec (Emissions and Consumption Optimisation through TEChnology) version of the Buick V6 engine coincided with the changes to the engine in the United States. The Ecotec engine packed 13 percent more power, an increase of 17 kilowatts (23 hp) over the VR, cut fuel consumption by 5 percent, and increased the compression ratio from 9.0:1 to 9.4:1. Holden mated the new engine with a modified version of the GM 4L60-E automatic transmission, bringing improved throttle response and smoother changes between gearsThe VS Commodore was the last of which to be sold as Toyota Lexcens, as Holden and Toyota ended their model-sharing scheme The last Lexcens were built during 1997This model was also sold between 1995 and 1997 in small numbers to Malaysia and Singapore as the Opel Calais.4 door sedan VS Commodore sedanLion and stone badge on Bonnet and on Boot centre, Commore on both mudguards Holden badge on Rear under tail lightsvehicle, vs commodore, car -

Linton Mechanics Institute and Free Library Collection

Linton Mechanics Institute and Free Library CollectionBook - Novel, Wynne, Pamela (pen-name of Winifred Mary Scott), The Last Days of Summer by Pamela Wynne, 1934 reprint (first published 1931)

Romance novel.Hardcover book, 285 pages. Book has a red cover. Original dust jacket removed, title and author's name handwritten on spine.fictionRomance novel.pamela wynne, winifred mary scott, romance, fiction -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP

... Wandin Thomas Sebire JP (1867-1960) learnt boot-making...Wandin Thomas Sebire JP (1867-1960) learnt boot-making ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 pairs of handmade, adult brown leather boots, with decorative stitching, eyelets and stitched with waxed thread. Soles covered with hob nails in a decorative pattern. 1 handmade child's brown leather boot, with decorative stitching, metal eyelets, heel has patterned nails.bootlaces, boots -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - WB Statesman Caprice series 2

This was the last "big" Holden produced following the switch to more compact Commodore range in 1978The very last WB series Statesman ever producedDark blue roof and boot lid and lower side panels, lighter blue bonnet and upper side panels. Rectangular headlamps, rectangular grille with chrome prison bar type fill invehicle, statesman, caprice -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - WN Caprice

Built between 2013 until 2017. This particular vehicle is the last one produced.This car is the last WN series Caprice built by GMHGrey bodied 4 door sedan, sun roof, spoiler on Boot lid, silver alloy wheelsHolden Lion emblem on boot and front grille, chrome strips both sides front quarter panels, VF series 2 RHS boot Caprice on LHS boot lidvehicle, caprice, sedan -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP, Unknown

... to, a wooden last to form the boot. Once attached to the insole... to, a wooden last to form the boot. Once attached to the insole ...Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, and nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together and neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A pair of handmade, adult brown leather work boots, with brown leather laces, decorative stitching, metal eyelets and are stitched with waxed thread. The soles are covered with hob nails in a decorative pattern. They have metal caps on the heels. bootlaces, boots, footwear, clothing -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Photographs of Lewis Lewis and others

Photographs of Lewis Lewis and Reg Ansett in various locations with family and friends. Three photocopies of photographs and 1 real photograph. They all have Lewis Lewis in them as well as others. The real photograph is a black and white photo of Lewis Lewis and his family beside a fence looking over the sea with large sea cliffs behind them (Image 3a). One of the photographs is a copy of this photo (Image 3b). Another photocopy is black and white photo of a different group of people in the same location by the sea (Image 3c). The last photocopy is black and white of a small plane with a group of people beside it (Image 3d). The real photograph has an attachment on the back that says, '1930 - 1940 on tour with Bus owner Booter and Bendigo (Image 3a). His Mother, his grandfather, his wife, Reg Ansett, his Aunty and Lewis Lewis.' The photocopy of the real photograph has black pen written on it that says, 'His mother, his grandfather, wife, Reg Ansett, his Aunty, Lewis Lewis, Garage Boort and Bendigo Bus owner 1920 - 1940. Built Medical Centre he left behind Rosanna,' (Image 3b). The last photocopy has blue pen written above the photo saying, 'History Lewis Lewis and Reg Ansett,' (Image 3d). lewis lewis, seaside, reg ansett, plane, buses -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: SNIPPETS OF BENDIGO

BHS CollectionBendigo Weekly from Friday, June 28, 2002 - Snippets of Bendigo history, the Pall Mall story, part two - by Edith Lunn. Close to the jeweller's shop, we came to Chancery Lane. Many early legal firms had their offices there. Among them were: Quick&Rymer, Luke Murphy&Don and Macoboy&Taylor. A branch of the Bendigo united Friendly Society's Dispensary opened on the corner. Other small business in the walk included a florist, men's hairdresser and a boot and shoes repairer. Moving on there was Betteridge's Agency for the Singer sewing machine company, Wilkinson's photographic studio, Sutton's music shop and Favaloro's cake shop and café the ''Savoy'' was opened in the 1920's. Whitelock and Carter had their men outfitters business in the building, Cocking's was a very popular drapery store. After Cocking's closed down, Stoneman's supermarket opened in the premises. Alongside there was a passageway that led upstairs to the office of Phillip Secher and Son, Accountants and the Bendigo jockey club. Mrs Allan's baby wear business and Lenten's the tobacconist came after and last but not least the Shamrock Hotel enhances Pall Mall. The clip is in a folder.newspaper, bendigo, bendigo weekly