Showing 176 items

matching construction tool

-

Orbost & District Historical Society

Orbost & District Historical Societyfolder, Orbost Bridges - Snowy River Road Bridges, 1974 1976

... Engineer for the construction of the new bridges which were part ...This folder was compiled in October 2015 from documents, magazines. papers and photographs donated by David Jellie, engineer in charge 1974 - 1976. In early 1974, as an Engineer with the Country Roads Board, David came to Orbost as the Supervising Engineer for the construction of the new bridges which were part of an 8.4km Orbost bypass road design. This was a major project involving not only a new bridge over the Snowy River (including Lochiel Lagoon), but other bridges over Ashby’s Gulch and Watt’s Gulch. These new bridges were opened in November 1976 with the unveiling of a plaque on the eastern end of the $2.4M Snowy River Bridge. (ref. May Leatch)This item is a useful reference tool on the construction history of the Snowy River Road bridges.A white plastic folder - Orbost Bridges - Snowy River Road Bridges. it contains newspaper articles, booklets, photographs and documents relating to the construction of the Snowy River Road Bridge in 1974 -1976.on front cover - 1974 - 76 ORBOST / SNOWY RIVER ROAD BRIDGES * construction * photos * articles * plans Donated by David Jellie Oct 2015snowy-river-bridges jellie-david -

Orbost & District Historical Society

Orbost & District Historical Societymagazine, CRB News, August 1976

By 1910 it had become apparent that there was a need for a central roads authority to take over responsibility from the Board of Lands and Works for the care and management of the main roads of the state of Victoria. Because there was no consistent and systematic policy for road maintenance Victorian roads were in a deplorable condition. At this time the use of the motor car accentuated the demands for better roads. As a result of these needs the Country Roads Act 1912 was proclaimed in 1913 providing for the establishment of the Country Roads Board as a central road authority with responsibility for those roads within the State considered to be main roads. the C.R.B. was responsible for the construction of roads and bridges including the Snowy River road bridges in Orbost. This was a major project involving not only a new bridge over the Snowy River (including Lochiel Lagoon), but other bridges over Ashby’s Gulch and Watt’s Gulch. These new bridges were opened in November 1976 with the unveiling of a plaque on the eastern end of the $2.4M Snowy River Bridge. (ref. May Leatch) This is a useful reference tool on the history of the construction of the Snowy River road bridges.A journal, titled "CRB News" . On the front cover the title is in orange print with No. 33 August 1976 above a coloured photo of a truck carrying two tiers of new vehicles along a main sealed road. It contains information and photos of the construction of the Snowy River road bridges.on front cover - handwritten in black - "M. I. Gilbert"crb-news country-roads-board snowy-river-road-bridges -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wooden Screw Clamp, First quarter of the 20th century

A clamp is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. In the United Kingdom the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash clamp but a wheel, screw or surgical clamp. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. In the field of animal husbandry, using a clamp to attach an animal to a stationary object is known as "rounded clamping." A physical clamp of this type is also used to refer to an obscure investment banking term, "fund clamps." Anything that acts to hold two surfaces together may be called a clamp, so this gives rise to a wide variety of terms across many fields. The subject item is a wooden-handled screw clamp used in cabinet or woodworking projects to hold two surfaces together while glueing or fixing. An item that has not changed in shape or use since its inception hundreds of years ago. These types of clamps are still produced today in many sizes by many woodworking tool companies.Wooden hand Screw Clamp two lengths of wood each beveled at one end and standing parallel. Two long wooden screws with handles and predominant thread that fits through wood lengths.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden screw clamp, carpenters tools, cabinet makers tools, clamp -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Mitre & Trimmer Guillotine, Early 20th century

The mitre trimmer is a classic hand-powered tool for picture framers and trim carpenters that has remained relatively unchanged for decades. It is heavy, simple, and sturdily built of cast iron with tempered steel guillotine blades. It is used for taking super accurate, paper-thin slices off the ends of mitres and butt joints, and leaving behind a glassy-smooth surface. Also used in picture frame making or cabinet woodworking, by placing a piece of timber in one side after setting the desired angle and pulling a handle that operates a guillotine blade thereby cutting the timber or decorative trim to the required angle.A significant tool still in use today in many cabinet makers workshops. The subject tool gives insight into how this type of tool development, design and use has not progressed since it’s original invention. It is still for sale from many tool manufacturing companies and use in small craftsmen boutique workshops today as it was many decades ago.Cast Iron wood Trimmer bench like construction on raised feet with 2 adjustable gates. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cabinet makers tools, picture framing, mitre cutting, wood trimming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Knife Sharpener, Johann Friedrich Dick, 1873 to 1900

Johann Friedrich Dick founded the company in 1778 to manufacture files, the company continued in the manufacture of files as its main product line until 1873, when Paul Friedrich Dick took over the company and began the production of sharpening steels, with the logo of “F Dick” on their products. One hundred years after the founding of the company, a factory in Esslingen began construction. At that time the company had 20 employees. In 1881, company commissioned Germany's first file production machine. In 1889, Friedrich Dick built a new factory in Kollwitz/Fleischmannstrasse in Esslingen, employing 100 people and expanding the product line to include knives for butchers and chefs, cleavers and other specialized tools. Files manufactured ranged from the smallest watchmaker's file to the largest (over 45 cm in length) square file. In 1997, the F Dick company moved to a new headquarters in Deizisau, Germany. The old factory in Esslingen is now a class listed monument and the town's landmark.An item made by a world class manufacture of cutlery for chefs, the subject item is significant as its manufacture was probably early in the firms beginnings when Friedrich Dick took over in1873 when he specialised in making sharpening steels. The company is still producing these items today as well as other specialised knives for professionals. Early manufactured steels such as the subject item are sought after today by collectors and quite rare. Sharpening Steel or Knife sharpener with bone handle with ribbed pattern, brass knobs and ring at end of handleMarked F Dick Esslingenflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, sharpening steel, knife sharpener, kitchen tool, carving, kitchen utensil, cooking, f dick -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Knife

... of the first and most important tools that enabled rise of our... civilisation. As a vital tool for survival, combat, construction ...From the early days of our race, the knife represented one of the first and most important tools that enabled rise of our technology, military, culture, science and all other things that brought us to this point of modern civilisation. As a vital tool for survival, combat, construction and food preparation, the knife quickly became the most basic tool from which all others were born. In those ancient times, 500,000 years ago, sharpened stones started slowly evolving, becoming more and more like their modern counterpart. Before the time when fire enabled the melting of the various metals, and forging them into modern knives, their stone counterparts received several visual upgrades. Double bladed knives were most popular, and their wooden or stone hilts were decorated with animal skins and feathers. Those knives represented a great deal of pride for the warriors and elders who owned them, and that tradition continued to be practised with the arrival of the Bronze Age. The appearance of metallurgy brought the ability to create knives from softer types of metal. Even though knives from bronze did not provide durability over longer periods of time [easily dulled, and susceptible to corrosion), their sharpness and slim designed proved to be superior to any stone knife tool. As the centuries went on, iron and then steel became commonplace across the entire world. Knives created from those materials were much more durable and easier to maintain their sharpness after prolonged use. During medieval times in Europe, steel metallurgy managed to evolve knives from small single or double-bladed edges to larger sizes - swords, spears and axes. Even with all those advancements, the use of knives as an eating utensil continued to be used in some small circles. Even as early as the 15th century, wealthy circles of people started carrying personal knives, intended for double use - both eating and defending against threats. During those times the host were not obliged to provide their guest with any kind of eating utensil in addition to plates, so wealthy males used their eating knives for cutting their own meals, and the meals of nearby female guests. Slim double-bladed knives were good for cutting and piercing foods. As the use of forks became widespread in the whole of Europe by the late 17th century, most people used this kind of small knife on a regular basis (a combination of two knives, one for stabilising and other for cutting the meal). http://www.eatingutensils.net/history-of-cutlery/knife-history/The knife is one of the most important items that has enabled the development of civilisation over thousands of years.Carving knife with wooden handle and rusted slender metal blade.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, knife, kitchen equipment, dining -

Glen Eira Historical Society

Glen Eira Historical SocietyDocument - Box Family

This file contains two items pertaining to a property named Box Cottage (named after residents William and Elizabeth Box) located in Joyce Park, Jasper Road, Ormond 3204: 1/A typewritten document (two pages), the date and context unknown (albeit authored by A. Smith) about the property. The first part of the document describes the materials and techniques utilized during the property’s original construction around 1850 and during subsequent renovations, whilst the second part describes the reconstruction of the property at a nearby site by the City of Moorabbin Historical Society. 2. A printout of a page from the website of the City of Moorabbin Historical Society (authored by Yun Ma, last modified on 13/01/2013, and accessed 30/06/2014), about the property’s present usage as a museum. Included is some brief historical information about the property, plus advertising of some of the various artefacts on display therein. Also included are six black-and-white photographs (presumably hailing from the museum’s collection) portraying the property’s environs as they existed in the past.‘box cottage’, box family, box william, box elizabeth, cottages, smith a, a. lewis & co pty ltd timber merchants, building construction, construction materials, trees, city of moorabbin historical society, moorabbin historical society, ma yun, museums, museum displays, timber houses, joyce park, jasper road, ormond, timber, woodwork, woodworking, woodworking tools, farm and garden equipment, pioneers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Brush, 20th Century

A broom is a cleaning tool. It consists of stiff fibres attached to, and roughly parallel to, a cylindrical handle, the broomstick. In the context of witchcraft, "broomstick" is likely to refer to the broom as a whole. A smaller whisk broom or brush is sometimes called a duster. History of broom design Brooms have changed very much in their construction, since they developed from ad-hoc use of branches and bundles of several natural fibres. Originally, all brooms were round, a shape that is easy to construct but inefficient for actually sweeping. Brooms could be attached to a handle, either short for a whisk broom, or long for a broom used to sweep the floor or fireplace. The word for the tool was originally besom, broom simply being the material of which it was normally made. The fibres used in modern brooms are from broom corn. They are long, straight, durable, and bound together in the plant. The newest major change is the flat broom, invented by the Shakers in the 1800s, which has far more width for pushing dirt and nearly all brooms produced today are flat brooms. https://simple.wikipedia.org/wiki/BroomThis object is an example of how a simple material can be turned into a useful item.Brush of plaited green & orange coloured rope like material. Brush section is like taffeta, blonde.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brush, broom, rope -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedes Drill, 1900 to 1930s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool that has been nickel plated with brass fitting and easier to sterilise. The item therefore could have been used in the medical profession as a bone drill during surgery. Weighted Archimedes drill all metal construction, nickel plated with brass handles centrifugal typeNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, tool, drilling tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wooden Screw Clamp, Late 19th to early 20th century

A clamp is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. In the United Kingdom the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash clamp but a wheel, screw or surgical clamp. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. In the field of animal husbandry, using a clamp to attach an animal to a stationary object is known as "rounded clamping." A physical clamp of this type is also used to refer to an obscure investment banking term, "fund clamps." Anything that acts to hold two surfaces together may be called a clamp, so this gives rise to a wide variety of terms across many fields. The subject item is a wooden-handled screw clamp used in cabinet or woodworking projects to hold two surfaces together while glueing or fixing. An item that has not changed in shape or use since its inception hundreds of years ago. These types of clamps are still produced today in many sizes by many woodworking tool companies.Wooden hand Screw Clamp two lengths of wood each beveled at one end and standing parallel. Two long wooden screws with handles and predominant thread that fits through wood lengths.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden screw clamp, carpenters tools, cabinet makers tools, clamp -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - WOODEN MALLET

Wooden mallet. Natural wooden construction, possibly aboriginal club Previously #140 Timber knots on head end. Approx 50cm long. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - GOLD WASHING CRADLE

Gold washing Cradle - used on Central Victorian Gold Fileds. Previously on loan to National Museum of Australia. Wooden Construction. Circa 1860. On Display at Specimen Cottage 2014. Donated by r. E.T. Waterman, 17.4.75cottage, miners -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - WINE CRUSHER: WOODEN GRAPE PRESS

Wine Crusher with 2 detachable steel handles. Early wooden grape press. Previously number#73 from Mechanics Institute, Eaglehawk. Temp Rec# C1.32 See photo Dungeon 1&2 005.jpg Wooden Construction, Rotating Drums and two carry handlescottage, miners -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - BENDIGO GAS COMPANY EMBOSSER

Bendigo Gas Company Embosser for Stamping , Paper, envelopes, stamps. Heavy metal construction in the form of swirling leaves, mounted on metal base approx 20cm by 8cms. With long handle. Painted black with gold trim. Temp Rec#C1.16bendigo, business, bendigo gas company -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - RALPH BIRRELL COLLECTION: EIG SCHOOL, c1966

EIG School - Ralph Birrell Collection. - Construction of Latrobe Uni. C1967. Bendigo Institute of Technology, Engineering School, Applied Science. View from inside one of the rooms of the new building, room has a lot of the builders' tools in it, along with a broken pain of glass.Perutzeducation, tertiary, latrobe university bendigo, eig school - ralph birrell collection. - construction of latrobe uni. c1967. bendigo institute of technology, engineering school, applied science. view from inside one rooms new building, room has builders' tools broken pain glass. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - RALPH BIRRELL COLLECTION: EIG SCHOOL, c1966

EIG School - Ralph Birrell Collection. - Construction of Latrobe Uni. C1966. Bendigo Institute of Technology, Engineering School, Applied Science. New cupboard with tool board mounted on the wall and tools placed in correct order. Machine front left corner of photo.Perutzeducation, tertiary, latrobe university bendigo, eig school - ralph birrell collection. - construction of latrobe uni. c1966. bendigo institute of technology, engineering school, applied science. new cupboard tool board mounted on wall tools correct order machine corner photo -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - MINERS AXEHEAD AND PICK HEAD

Miners Axehead and Pick head. Both items significantly rusted. Axehead displaying the process of construction in the forge by the apparent separation of metal layers/. -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider - Sailplane

MOBA2 is a 15 metre sailplane designed by Gary Sunderland, who was an aeronautical engineer working for the Department of Civil Aviation (Australia) and a member of the Victorian Motorless Flight Group (VMFG). The design gave effect to ideas that he developed circa 1970 for an aircraft that he could build himself. He entered a 13 metre wingspan version of his MOBA design (MOBA2B) in an Australian Gliding sailplane design competition that was announced in 1970. The competition called for sailplane designs with a maximum wingspan of 13 metres that could be built by amateurs in a small workshop with limited tools and facilities. In 1973, Gary’s MOBA was judged by the competition panel as equal best with the other outstanding submission, which were chosen from a field of 19 entrants. However, after gathering further information and deliberation by the competition panel neither of the two outstanding designs were chosen as the winner. Notwithstanding the outcome, in 1974 Gary proceeded built his glider to the original 15 metre design. The wing was equipped with camber changing flaps that were permitted under special standard class rules for the 1974 world championships. Changes were made along the way in the light of construction experience and the completed glider was given the designation MOBA2C. The glider first flew on 12 December 1979. It was never flown in standard class competition as by the time the glider was built the special 1974 rules were revoked and wing flaps were no longer permitted in that class. However, Gary flew MOBA2C in the Australian national gliding competitions held at Benalla in the summer of 1979 / 1980 competing in the open class. After adjustment to the aileron gearing during initial trials MOBA2C was found to fly well and in competition produced performances believed to be better than contemporary standard class sailplanes but not as good as the open class machines. The glider was later modified in a number of respects including amongst other things the installation of spoilers located just forward of the wing flaps and by increasing the chord marginally at the wing root. With these changes the glider type was given the designation MOBA2D. The last recorded flights occurred in February 1996 at which time MOBA2 had flown an aggregate of 401 hours and 59 minutes during its 297 launches. Its operational life was brought to an end due to expansion of the foam in the wings causing distortion of the wing surface.The MOBA2 is a notable home built 1970s sailplane design that featured a number of innovative elements including composite construction without the need for expensive jigs, nose cone canopy and asymmetrical placement of control column.Composite single seat glider / sailplane finished in bright yellowRegistration "GVI" on fuselage; Kangaroo, Australian Flag and VMFG decals on vertical stabiliseraustralian gliding, glider, sailplane, moba2b, moba2c, sunderland, moba2d, victorian motorless flight group, vmfg -

Maffra Sugarbeet Museum

Maffra Sugarbeet MuseumBeet Hoe

These hoes were the standard thinning tool for sugarbeet, and allowed a standard space between seedlings. Thinning was back-breaking work, usually carried out by a transient work force.These hoes are probably still commonly in the possession of old gardeners. They are important as the only tool required of a large, transient workforce that worked under extremely difficult conditions.A metal thinning hoe of four piece construction, with a turned wooden handle attached to the tool by a nail. The blade is welded onto a bent holder, which is in turn welded to the metal extension of the handle. There is cloth inside the ferrule.sugarbeet -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: SIX TIMBER PLANES AND ONE STEEL PLANE

Pittock collection: timber planes * six planes made of timber construction, varying between 145-560 mm L, 45-90 mm W. Only one plane with Marda manufacturering decal, this plane also marked Pittock * one steel plane175 mm L x 50 mm W, manufacturer's details unclear Items stored in Pittock coach builder's box, reference 13000.1. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: HANDMADE TRADESMAN'S BPOX

Pittock saddler's box: handmade tradesman's box light softwood box (possibly made from a fruit box) box has nailed construction, with leather hinges and latch screwed to boxnil -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: LARGE UNUSUAL METAL WRENCH

... but operable Unusal construction No maker's marks Tool PITTOCK ...Pittock saddler's box: large unusual metal wrench Rusted but operable Unusal construction No maker's marksnil -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: SMALL PIPE CUTTING TOOL

... construction, operaable, fair condition Tool PITTOCK COLLECTION: SMALL ...Pittock saddler's box: small pipe cutting tool Maker's mark : No 10 RIDCID USA, patent no. 287133 metal construction, operaable, fair conditionNo 10 RIDCID USA -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: SMALL CABINET DOOR HANDLE WITH KEYHOLE

... construction painted white Tool PITTOCK COLLECTION: SMALL CABINET DOOR ...Pittock saddler's box: small cabinet door handle with keyholemetal construction painted whitenil -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: OLD RUSTED SECATEURS

Pittock saddler's box: old rusted secateurs mertal construction, highly rusted, no catchnil -

Bendigo Historical Society Inc.

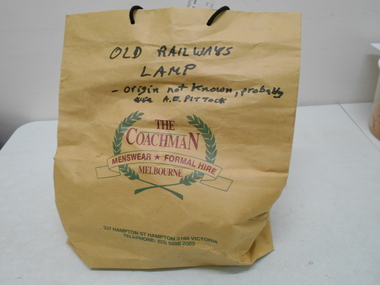

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: RAILWAY LAMP

Pittock coach builder's box: Old railway lamp, marked origin unknown, probably belonging to A. E. Pittock * stored in paper bag as detailed, refer 13000.44a * steel, glass construction * lamp is 310 mm tall, 150 mm round * lamp has three adjustable filters ( red / broken, blue and space for third (clear!) lens, which are set by rotating the handle to fixed loacations * lamp lit by kerosene wick, refer 13000.44e & f, brass container with mirror behind wick to intensify the light Item stored in Pittock coach builkder's box, reference 13000.1. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: TWO SQUARES FOR SET OUT

Pittock collection: two metal carpenter's squares for set out * green painted adjustable set out square, with imperial and metric scales, and level bubble, 305 mm L x 120 mm W. Marked Pittock with marker * adjustable set out for full range of angle set out. steel wood and brass construction. Marked Stanley, patented 9-6-04. Tool 204-325 mm L x 25 mm W x 20 mm D Items stored in Pittock box coach builder's box, reference 13000.1.