Showing 193 items

matching domestic machines

-

Flagstaff Hill Maritime Museum and Village

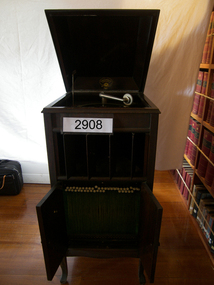

Flagstaff Hill Maritime Museum and VillageGramophone, 1911

Until late 1925, all record players reproduced sound by purely mechanical means and relied on a so-called "amplifying" horn to efficiently couple the vibrations of the stylus and diaphragm to the space occupied by the listeners. In 1906, the Victor Talking Machine Company, Columbia's arch competitor, introduced a line of models in which the horn and other hardware were concealed within a cabinet, made to look like fine furniture rather than a mechanical device. They named the new style a "Victrola". It quickly proved to be very popular and successful. Other makers, adopting the distinctive suffix, introduced their own "-ola" internal horn machines, such as Edison's Amberolas and Columbia's Grafonolas. They were soon outselling the external horn models. At first, like nearly all other early record players, all Grafonolas were driven by a spring motor that the user had to wind up with a crank before playing a record. In 1915, Columbia began to introduce electric-motor-driven models, as a majority of urban areas had been wired to electrical grids. The electrified Grafonolas supported both alternating and direct currents from 110 to 220 volts. Electrified Grafonolas never gained the popularity enjoyed by the spring motor-driven versions due to substantially higher prices and a lack of electrical service in rural areas. Grafonolas were manufactured under the 1886 United States Letters Patent No. 341,214 which Columbia Graphophone company acquired through its predecessor American Graphophone Company. Two models were available; a portable table model and bigger stationary floor model, offering limited mobility through the application of casters. The most notable table models included Grafonola Favorite introduced in 1911 and Grafonola Savoy introduced in 1915. The most notable floor models included Grafonola Symphony Grand introduced in 1907, Grafonola Regent introduced in 1909, Columbia Mignon introduced in 1910, Grafonola Princess introduced in 1911, Columbia Colonial introduced in 1913. Various period Grafonolas were introduced in 1917 to cater to an increasingly prosperous clientele. Columbia Phonograph Company began to manufacture a series of ornate, limited edition period machines. These were highly priced (some as high as US$2,100 ) special orders that provided consumers with options to choose styles which matched their interior décor. Although the Gramophone does not have a large monetary value, it is of social significance as it demonstrates the progress made in audio reproduction from the first Edison cylinder machines to improvements that allowed ordinary people to be able to buy music discs and enjoy music in their own homes. Gramophone with internal horn, floor model, mechanically operated by a crank handle. Colombian Grafonola Princess (Type F2) brand. Gramophone is in a wooden display cabinet with room for record storage underneath and is complete with handle. Manufactured in 1911 by Columbia, USA."Columbia Grafonola Type 2 Made in USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, record player, gramophone, mechanical gramophone, floor model gramophone, gramophone record, columbia graphophone company, american graphophone company, columbia, grafonola, grafonola princess, music, playing music, audio reproduction, sound equipment, domestic entertainment, 1911 gramophone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

... churns were machines used to produce butter by the violent ...This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

... , Domestic object Sewing Machine Singer Sewing Machine Company ...In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

... drawers plus instruction manual Domestic object Sewing Machine ...In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBag Whitening Agent Reckitts, circa early 1900s

This little bag of "whitener" additive for the washing of white clothes was manufactured in Hull in the United Kingdom mid and later 1900's. The Manufacturer, Ricketts, was one of the first manufacturers to employ women in equal proportions with males (a rarity before 1914). This product was used to improve the appearance of white fabrics. This ability to use a product that would "whiten" clothes chemically rather than the "hard boiling" of clothes was a time saver and a lot easier on the fabrics. This is a boon to rural families where time was of the essence (boiling took time). The blue coloring was introduced because the white colour perception is enhanced by the blue (fadeable and not permanent). The "washing machine industry" of the late 1900's emphasised "whitening" agents that were not so haphazard in producing blue stains, and allowed a "gentle" washing action. This item is very significant in detailing the early 1900's rural household domestic "chore" of washing white clothes to a "social" standard of cleanliness. White shirts were the mark cleanliness that those outside of the family judged the family unit by. The best clothes were worn to church on Sundays. Hard and mostly rural activities/work in the Kiewa Valley encompassing farming, crop cultivation, cattle/sheep and "field work" to do with the SEC Vic Hydro Scheme involved provided a stain prone environment. As appearances, of clothing, was on the whole not significant it was a different scenario at social and religious scenes. The ability to attain "brilliant" white shirts, dresses and bonnets by a less drastic method to that of "boiling" of clothes in vats, was a boon of that "era". The anti establishment revolt came later in the 1950's onward took longer to migrate from the cities and larger rural townships to eventually sneak into the Kiewa valley.This "blue bag" is a whitening agent wrapped in flannel or muslin, or sold ready bagged (1 ounce).It was used in the final rinse to "whiten white coloured clothes" The string was used to facilitate finger grip onto the "bag" after the wash had finished for easy removal to stop the hand and other surfaces from being stained by the blue colour residue drips.domestic and commercial laundries, starch and whitening additive, washing brightener -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Washing Machine, 1930s

... on the side of the tub. Domestic object Washing Machine QUEENS HEAD ...This washing machine is an early model hand machine which came from Allansford, near Warrnambool.This item is an interesting example of an early washing machine with its primitive and simple parts.This is a cylindrical galvanised metal tub mounted on a metal stand. It has a metal ring around the top of the tub and a wooden handle serving as the washing mechanism. The name of the manufacturer is stencilled on the side of the tub.QUEENS HEAD AUSTRALIAvintage household items, washing machine, mechanical washing machine, warrnambool history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, George Salter & Co, Circa 1921

The Hughes’ Family Scale No. 48 is a spring balance scale. It uses the Imperial measurements of ounces and pounds. There are 16 ounces (OZ) in one pound (LB), and each pound equals approximately 454 grams in Metric measurements. Scales have been used to measure and compare items for value for centuries. A weight was placed on one side of a balance and the object was placed on the other. Adjustments were made to either the weight or the object until the balance was horizontal, which meant that each side was the same weight. The Salter family business began in 1760 with spring makers, Richard and William Salter. In the late 18th century, Richard Salter invented the spring scale, where the weight of an object on the tray of the scale causes pressure on a spring in the scale. The pressure caused by gravity was then measured to calculate the weight of an object. Spring scales are still used today along with the more recent and accurate digital scales. The company began manufacturing in West Bromwich, England, in 1770. The firm was taken over by William’s sons, John and George. In 1824, after the death of John, the firm became George Salter & Co. The company produced a wide variety of products, including Britain’s first bathroom scale and the first English typewriter. In 1884 the Salter Trademark of a Staffordshire knot pierced by an arrow was registered. After over 100 years of manufacturing, the company was bought out by Staveley Industries, which was bought by Weigh-Tronix, and then that company was bought by HoMedics Company in 2004.This scale was made by Salter, the company that invented the balance scale, the first British bathroom scale and the first English typewriter. The scale represents the domestic equipment used for measuring in food preparation over 100 years ago. Modern kitchen scales are still using the same principal, along with scales used in business and industry.Scale; a domestic spring balance scale for measuring weight from 0 to 20 pounds. The scale’s grey metal case has a round white dial on the front with black markings, an arrow indicator and a round shallow metal bowl on a pedestal at the top. The scale is raised on a rectangular metal base with outward-sloping sides. An adjustable screw is on the dome top. The scale is marked from 0 to 20 pounds, with each pound marked in 1-ounce increments. The scale is named the Hughes Family Scale No. 48 and was made in Britain by Salter.“HUGHES’ / FAMILY SCALE / No. 48” “BRITISH MADE” “TO WEIGH 20 LBS BY 1 OZ” “SALTER” above logo [knotted rope with an arrow through loops]flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, hughes, salter, british made, family scale, no. 48, spring balance, scale, weighing instrument, weights and measures, weighing machine, kitchen utensil, baking accessory, domestic equipment, cookware, bakeware, kitchen scale, kitchen accessory, food preparation, recipes, cooking, measuring -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Apron, c. 1900

This apron was donated along with other well kept items of women's clothing. The clothing once belonged to members of a family who migrated from Faversham, Kent, England to Sydney, Australia in the late 19th - early 20th century and was passed down through the family. The items have been worn and have also been well cared for.This items is an example of ladies' clothing worn during the late 19th to early 20th century.Apron, ladies, machine made, cotton, Gathered waist, waist ties, small bodice with Brodery Anglais lace hand stitched onto it, neck ties. Would have been work for 'good' wear. C. 1900. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ladies garments 19th century, cotton garments 19th century, apron late 19th century, domestic clothing, domestic service, hospitality service, broderie anglaise, ladies’ clothing, hospitality clothing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Apron, c. 1900

This apron was donated along with other well kept items of women's clothing. The clothing once belonged to members of a family who migrated from Faversham, Kent, England to Sydney, Australia in the late 19th - early 20th century and was passed down through the family. The items have been worn and have also been well cared for.The apron is an example of late 19th century ladies' clothing for use in domestic service or hospitality.Apron, ladies size, cotton, machine made. Bodice has hand made Broderie Anglais lace trim and neck ties, skirt has gathered waist and ties, three pin ticks around hemline. Would have been worn for 'best' wear. C. 1900flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ladies garments 19th century, cotton garments 19th century, apron late 19th century, broderie anglaise, handmade lace, apron, domestic clothing, domestic work, domestic service -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWash Board Glass, mid 1900s

This washboard is relatively "young" in that the timber has not "aged," however it could have been used by a rural family to wash "delicate" clothing which could not be placed within a large family washing machine or "copper". This type of washboard i.e. glass washboard, was used extensively during the war periods, 1914 to 1918 and 1939 to 1945 when corrugated metal was in scarce supply. Rural areas were the last sectors in Australia where washboards where, through necessity( droughts and lack of domestic water), used up until the late 1900s. This lingering usage was due to the fact that rural properties, on the whole, had water supplies sourced from farm dams and be the ones whose priority feed was targeting crops and farm animals before clothes and other domestic requirements. In the two millennium however, most rural areas are well stocked with water supplies and the very strict edict of conserving water, especially during droughts, of earlier times is not so critical.The Kiewa Valley although well supplied by rivers, streams and artesian water does occasionally through severe drought lack of water for farm domestic washing requirements.This washboard is made of a wooden frame and glass insert (corrugated on one side and smooth on the other). The washboard glass panel is contained within the wooden frame by routered grooves. The frame extends beyond the glass to form two legs below the glass insert and a hand grip above it. This hand grip allows for one hand to hold the washboard firmly upright and one hand to rub clothes vigorously (up and down) against the glass ridges.This action combined with a soap and water based freeing agent loosen any dirt particles which can be rinsed off. The appearance of this washboard is basic but does not detract from its effectiveness. The lack of "wear and tear" on the wooden frame suggest limited use. The construction suggests good workmanship even though there is no manufacturer's logo to be found on it.hand washing, household washing, domestic clothes washing, laundry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMould Butter, unknown, post 1967

This butter mould/pat may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce. This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This well crafted circular wooden butter mould could also be used as a butter pat.The handle in the middle of the mould was not added after the crafting but has been fashioned from the initial block of wood when the bowl was crafted. The bowl structure has a rim around the edge.The top of the handle has an ink stamp "T. & W. Dav" on the top line and "Tawonga 3697" underneath.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950s

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter Pat/Profiler has on its base two patterns. On each end it has horizontal grooves cut into the wood which produce distinct lines onto the surface of the butter. between these grooves there is a section of two double lines crossing in the middle and separated by eleven horizontal lines The base has an elongated rectangular shape. The upper body has been sanded into a smooth convex shaped form where a wooden circular hand grip has been fashioned.On the top of the hand grip is stamped in black print"T. & W. Davies" and under this"TAWONGA 3697"domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter, Circa 1950

This butter pat profiler may have been manufactured post 1967 (year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (B). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry, butter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (A). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

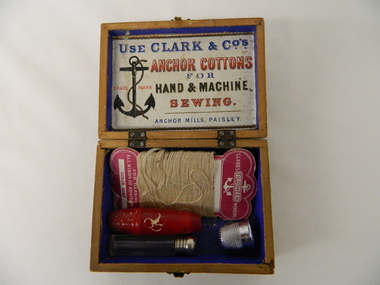

Kiewa Valley Historical SocietyBox Sewing Kit, pre 1952

This "sewing and darning" box was purchased before 1952 (the date that the Clark Brothers merged with J&P Coats). It was in an era where the production and alteration/modification to any household or personal clothing was carried out by a family member/s. This was at the period where self sufficiency in rural and especially remote areas was a requirement and not just a hobby. Clothing modifications and "hand me downs" was a way of life. The long and tiresome journey from home to millinery shops was a great force to ensure that home sewing was carried out in the majority of residential and farm areas.This sewing box was donated by a pioneer family in the Kiewa Valley. Its significance points to an era before the establishment of the Kiewa Hydro Electricity Scheme and the establishment of the Mount Beauty Township. It was a time when the rural industries of the Kiewa Valley was rich in production of beef, dairy products, tobacco leaf and before the mass of alpine adventurers that tourism sparked. It was a time rural enterprises out shone tourism.This wooden sewing box is covered with decorative paper. The lid is fastened to the bottom section with two small hinges each having four screws. Each side is fixed to the other by a mortise groove. At the front of the box is a small clasp for complete closure. The box contains needles, darrning thread, thimble, a glass vial with metal screwtop and a red plastic cylindrical container with a thimble screw on top(contains a small reel with three different cotton thread compartments).On outside lid "FROM A FRIEND. I DO NOT WISH THEE GRANDEUR, NOR YET A STORE OF WEALTH, I WISH THEE RICHER TREASURE, CONTENTMENT, PEACE & HEALTH", On inside lid "USE CLARK & CO ANCHOR COTTONS FOR HAND & MACHINE SEWING ANCHOR MILLS, PAISLEY" Each of the different sewing boxes from the Clark Bros. has a label with different "friend" passages.sewing box, hand stitching, domestic clothes alterations, haberdashery -

Kiewa Valley Historical Society

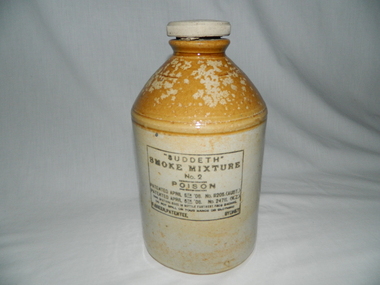

Kiewa Valley Historical SocietyJug Glazed, 1930s to 1950s

This item was used in conjunction with the Suddeth (Sudden Death) Carbon Bi-siilphide fumigator during many rabbit plagues that invaded Victoria and NSW before CSIRO introduced the myxomatosis virus in 1950.The contents of this jug was very important pre 1950 for all rural areas which suffered under the annual mice plagues, especially the wheat producing regions. Milk producers suffered from the mice by products contaminating their fresh milk containers and storage facilities. Rabbit warrens causing farm machinery instabilities and also horseback activities eg mustering herds.This glazed pottery jug has a screw on lid and a cream coloured body with a caramel brown neck. The remnance of a handle, which has been broken off is located at the top just below the the rim of the lid.On one side below the neck and within a black boundary mark "SUDDETH" and below "SMOKE MIXTURE No. 2" and sandwiched between two black lines "POISON". Below this and in five lines "PATENTED APRIL 6th '08 No. 11205(AUST.)" "PATENTED APRIL 6th '08 No. 24711 (N.Z.)" "THIS MIXTURE GOES IN BOTTLE FURTHEST FROM MACHINE" "DO NOT SPILL ON YOUR HANDS OR CLOTHING" "F, GREER, PATENTEE SYDNEY"ceramic bowls, contamination of farm produce, domestic farm hygiene, vermin extermination poisons -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTimer Mechanical, Circa 1950

This Timing Relay is quite a large (industrial type) apparatus. The Timer is started by having a voltage of 250 volts direct current (as supplied by batteries). A DC motor then rotates driving into a clockwork mechanism, the output of which is an arm rotating at the same speed as a minute hand on a clock. Attached to this arm is a mercury switch which tips and makes an electrical circuit operate in a sequence control system. The sequences that use these timers are when starting and stopping Hydro Generators. They check that the machine has connected to the power system grid before 20 minutes duration. Brakes must go on for a set time when shutting down a generator slowing at the right speed as measured by this apparatus. These generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This Timing Relay apparatus is very significant to the Kiewa Valley as its use was introduced during the Kiewa Hydro Scheme. Although only a relay apparatus, it was however part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both an industrial and a larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley. This Hydro Scheme was instigated by "the Government of the day" as a bold move and was the major force behind the acceptance of World War II refugee and "technical" workforce. Inclusion of skilled and unskilled migration into the Australian environment was of a higher priority than a selective quota system of later years.. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual, multi-cultural diversity of later years.sec vic kiewa hydro scheme, alternate energy supplies, alpine population growth -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMeter Ammeter Recorder, Circa 1950

This testing voltmeter recorder was last certified by SEC Vic laboratories on the 17/4/77. It was used extensively as mobile recorder placed for periods of one month at locations experiencing unacceptable fluctuations of power. These locations would cover the North East regions of Victoria. They cover voltage drops at domestic and business properties especially those that were experiencing regular fluctuations(daily) at approximately the same time of the day. As the electrical network is required to operate within a set level of voltage, fluctuations outside of this has to be investigated and necessary remedial action taken. This is especially so for rural properties where power "drainage" can occur through animal/bird and tree interference. It can also be the result of defective wiring and overloading at peek operational times (milking machines).This mobile voltage recorder is very significant to the Kiewa Valley because it highlights the difficulties that can occur in maintaining a power supply that experiences fluctuating power demands by the rural industries that it supplies. The requirement of a mobile testing apparatus to cover the various sections in the Kiewa Valley and other rural areas in the northeast region is one of necessity as electricity once connected to a rural property is a labour saving supply as generators on rural properties require a higher degree of maintenance an ultimately at a higher cost. The testing of the SEC Vic supplied electricity to rural properties,those who had previously run on generators, had to be quick and unassuming with certainty of correct supply levels.The mechanism of this voltage recorder has been installed(by the manufacturer) into its own protective wooden box. This box has a front (swing open) lockable section which permits direct access to the installed measuring equipment (for servicing and data collection). The top section of the box has two screw on terminals for access to the machine being tested. This tester has its own inbuilt ink supply facilities and a mechanical clockwork device that unwinds a roll of paper onto a second roll at a rate of 10 mm per hour. The recording chart is marked with time slots against voltage. There is a recording arm which has an ink pen at the end. Both arm and pen carry the ink supply from the ink reservoir, located on the left side of the cabinet door in specially constructed bottle holder( three small bottle capacity). To record a suspect power problem to a home or business establishment the voltmeter is connected to a power supply outlet being tested and wind the recording clockwork mechanism (gives a four week running time). Before leaving the recorder in situ the electrician checks to see if the chart is recording the correct voltage and that the clock mechanism is advancing correctly.On the front of the access "door" at the top a metal label "RECORDING AMMETER" below this "MURDAY SYSTEM" below this "ALTERNATING CURRENT" and below this the manufacturer's registered number "No. 139156" Below this is a metal tag with State Electricity Commission of Victoria Electrical Engineer's Section equipment number "338" Below these tags and above the viewing window is the manufacturer's dtails "EVERSHED & VIGNOLES Led LONDON"sec vic kiewa hydro scheme, alternate energy supplies, alpine feasibility studies temperature, rainfall, power outages -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyClothes Washing Tool

... ' washing machine domestic laundry This tool has been carved from ...This type of fork was used back in the days before electrical washing machines were invented. Ladies used to boil water in a 'copper' over a fire and wash the clothes and linen in it. The water was boiling hot. This wooden washing tool was used to retrieve the washing before hanging it on the line.This tool has been carved from wood. It is shaped like a two pronged fork and would have been used to lift washed clothes out of a copper (washing machine).washing clothes, 'copper' washing machine, domestic, laundry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine - Singer

This sewing machine was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's grandmother used it in 1942. It still works (2013).Historical: Type of sewing machine used by S.E.C.V. wives living in Mt Beauty during the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and School fetes. eg. children's clothes and dolls' clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Singer sewing machine - brown wood lid & base. Handle on top of inside of lid as is the wooden bench that clips on to the side of the machine and also the steel knee lever that fits into the front of the machine. Black steel machine with silver fittings. Brown and white electric cord plugged in. "Singer" on front centre of lid. On machine - "Singer" above light. "The Singer manufacturing Co. / Manufactured in Great Britain" top of machine. "Singer" on front side of machine. Front - Gold plate - "The Singer Manfg. Co. / Trade Mark." Decoration on machine base and silver end.singer manufacturing co.. sewing. fetes. clothes. domestic. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine Attachment - Buttonhole

This sewing machine was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's grandmother used it in 1942 to make button holes.Historical: Type of machine used by S.E.C.V. wives living in Mt Beauty in the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and chook fetes e.g.. children's clothes and dolls clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Green & white box containing black & silver metal with 4 parts for attaching to Singer sewing machine for sewing button holes."Singer Buttonhole Attachment" on green 'cloud' top of box. "The Singer manufacturing Company" on green 'cloud' on side of box. "For Light Manufacturing and Home Use" on green 'cloud' on side of box. "Made in Great Britain" on white top half of end of box & teen 'cloud' below end of box is "Singer / Buttonhole Attachment / No. 86662 / For Singer Lock Stitch/ Family Sewing Machines.singer manufacturing co.. clothes. fetes. domestic. sewing. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine Accessories

This sewing machine and its accessories was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's mother used it and the accessories in 1942. Historical: Type of machine used by S.E.C.V. wives living in Mt Beauty in the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and School fetes. eg. children's clothes and dolls' clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Dark green box with red & white inscription on top. Inside are 7 metal (silver coloured) attachments for Singer Sewing Machine including one for sewing zips, ruffling foot, rolled hemming foot .singer manufacturing co.. clothes. fetes. domestic. sewing. -

Kiewa Valley Historical Society

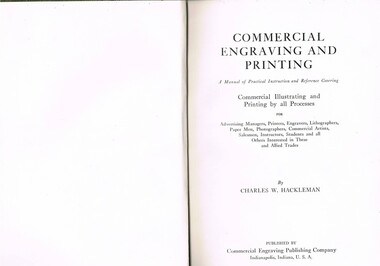

Kiewa Valley Historical SocietyBook - Reference Printing, Charles W. Hackleman, Commercial Engraving and Printing, Circa 1921

... infusion now used in large machines and domestic printers has ...This item relates to methods of reproducing photos on all forms of material in an era of physical offset printing.The offset method is being replaced by digital transfer direct to the final product,(paper or other porous and non porous surfaces). Newspapers and other "paper" information publications are still producing "hard copies" but these are slowly being phased out. This item was used Circa 1920s in the peek period of paper based media. From the 1940s radio and then television stepped into the mass media revolution.This book was produced when all printing, Government and private enterprise, was using the "off set" method. This method was used to a great degree in all schools within the Kiewa Valley. It was in an era before "photo-copying machines" were available. This was a period when printing inks for larger printing machines had to be purchased from specialised outlets and printing presses required to be washed after each "run" of printing before the next plate(aluminium) could be fastened onto the "off sett" machinery. Heat infusion now used in large machines and domestic printers has superseded this task. Faded green cloth covered book with green papered front and back sleeve pages.Photos and sketches are throughout the book. Gloss paper used from page 1 one to page 400. Pages 401 to page 432 are not gloss paper. The type of paper varies throughout the book until final advertisement and index pages, from page 833 to page 846, are on gloss paperThe spine cover is badly worn and wording is faded. Front cover has"Commercial Engraving And Printing" Author and publisher details written by Charles W. Hackleman. Published by Commercial Engraving Publishing Company, "A Manual of Practical Instruction and Reference Covering" Commercial Illustrating and Printing by all Processes.technical book, reference for engraving and printing -

Warrnambool and District Historical Society Inc.

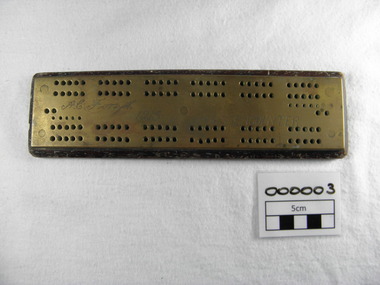

Warrnambool and District Historical Society Inc.Domestic object - Game, Cribbage board, Prior to 1913

This item is linked to the 'HMAS Encounter', possibly made on the ship c. 1913. In 1916 this ship visited a then unnamed island off the Western Australian coast, where the crew discovered two bronze cannons protruding from the sand. These cannons now in the WA Maritime Museum, Fremantle, have been linked to the "Mahogany Ship" legend by historian K.G. MacIntyre. Cribbage is a very popular card game, particularly with naval personnel. This cribbage score board belonged to Alexander Charles Forsyth who used it aboard H.M.A.S. Encounter in 1913. He was a stoker, service number 3086, from New South Wales. H.M.A.S Encounter, the fourth warship of that name, was built at Devonport Dockyard, Tasmania, for the Royal Australian Navy in 1905. She was a second class protected cruiser and in 1909 was lent for three years to the British Admiralty. In 1913 (the year marked on this cribbage board) she was in New South Wales and Queensland waters and in World War One she served in the Pacific region, taking part in the capture of German New Guinea. She was finally scuttled in 1932.Social significance: an example of leisure activities in early C20th. Historical significance: link to "Mahogany Ship" legend through H.M.A.S. Encounter. This is an interesting item with social significance as cribbage was a popular game, particularly in the 20th century, and it illustrates the pastimes of a generation past. It was given to Warrnambool and District Historical Society by a Wangoom couple and so may have local significance if A.C. Forsyth was related to this couple. H.M.A.S. Encounter was important in Australia’s naval history. Rectangular brass plate with rows of holes, grouped in tens. Plate mounted with 5 brass studs to a rectangular wooden base. 134 holes in brass, grouped in tens. Three holes in each end of wooden base. Board used for scoring made out of brass for game of cribbage Burnished gold on playing surface Reddish-brown on base 144 main indentations, 10 minor indentations Machine engraved "A.C. Forsyth" (in script)/ "1913"/ "H.M.A.S. ENCOUNTER" across middle of the plate, between the rows of holes. brass, ships, leisure, royal australian navy, cribbage board, games, mahogany ship, a s forsythe, encounter, alexander charles forsyth, warrnambool -

Orbost & District Historical Society

Orbost & District Historical SocietyBread maker, Landers Frary and Clark, Early 20th century

Bread machines were made for quite a long time from the 1890's on. They came in different heights and capacities. The advertisements at the time stated that making bread with their machine was superior to hand kneading, This item is good example of a domestic appliance used when most foods were home-made. Access to commercial bread was limited in rural areas and housewives became skilled at bread-making.Metal bucket with lid. Lid has hole in centre through which a handle for turning the dough hook comes. Grey rusty coloured.Put in all liquids first, then flour, turn 3 minutes, raise in pail. After raising, turn until dough forms a ball. Take off cross piece, lift out dough with kneader.bread domestic-appliance bread-maker food-technology bakery -

Orbost & District Historical Society

Orbost & District Historical SocietySewing machine, 1895 -1910

Donor, Connie Cruikshank was grand-daughter of Poppy Kerr whose father was the first doctor in Orbost. Machine belonged to her grandmother, Mrs Hilda Kerr(Temple).This item is significant for its use by an influential and well-known Orbost identity. It is also an example of a common domestic appliance of the late 19th-early 20th century.Hand-operated sewing machine. Black with gold designs, large metal turning wheel. All set on large polished block of wood.Wertheim Francfortsewing-machine kerr-dr temple-hilda cruikshank-connie wertheim -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, late 19th or early 20th century

... -village textile machines sailmaker's machine maritime sewing ...This Eclipse model, treadle operated sewing machine was made by the Oldham Sewing Machine Company in Greater Manchester U.K.. It was used by sailmakers for sewing sails with box shape top and slim neck. Sewing machine, foot treadle, for sewing sails with box shape top and slim neck. Brand is Eclipse. Cast iron base is bolted to square wooden table-top with drawer under table. Drawer has 3 partitions and wood fitting with 5 drilled holes for needle storage, lock has diamond shaped, decorative metal surrounds; half of inside drawer is painted black. Decorative metal stand, painted green, with 2 foot pedals; 1 foot pedal drives the wheel wheel. Padals both have "ECLIPSE" cast into the iron.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, textile machines, sailmaker's machine, maritime sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jug, Hoffman Pottery Pty, Ltd, Circa 1929

The Hoffman company was established in 1870 to mass-produce bricks using the Hoffman patent kiln and the Bradley and Craven brick press. Once established the company entered a period of expansion aided by Melbourne's building boom from 1870 to 1890. During this time approximately ten brick machines were in operation producing some 18,000 bricks per hour. An extensive pottery works were established initially supplying mainly tiles and drainpipes and later domestic pottery such as the company's Melrose ware. The company even had its locomotive shunt the works siding which connected with the Victorian Railways at South Brunswick. By 1890 Hoffman was the largest brick and pottery works in Victoria, however, the 1890s depression halted company expansion. The company joined the Brick Co-operative when it was formed in 1896. The cooperative regulated prices and output from member brickworks. As the depression ended business picked up and the works were expanded to increase the production of stoneware pottery, especially domestic wares. The brickworks, however, never recovered the momentum of the early period. During the 1920s and 1930s, the works gradually ran down, and following the Second World War, production reached an all-time low. The No.1 works were stripped and sold. (For further information regards Hoffman Kilns see note section of this document.) An item made in Melbourne by at the time the largest pottery works in Australia making industrial and domestic wares for the home and building industries. Stoneware Demijohn jug with cream and brown glaze. Printed around base of jug, MELBOURNE, 1929"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, melbourne, 1929, stoneware jug, hoffman potteries