Showing 1034 items

matching drills

-

Cobram Historical Society Inc

Cobram Historical Society IncWoodworking brace, circa 1920 ???

used for drilling holes in woodworkOld Woodworking Brace, Forward and reverse drilling ratchet, chuck for interchanging drill bits of various sizes HerryBoker German -

Puffing Billy Railway

Puffing Billy RailwayHand Operated Drill Press, 1900s

Historic - Industrial drill - typical hand operated design used in workshops.Historic - Industrial drill - typical hand operated design used in workshops.Hand operated drill press. Bench mounted type hand drill press. drill, press, workshop, hand operated, puffing billy -

Puffing Billy Railway

Puffing Billy RailwayHand Operated Drill Press, 1900s

Historic - Industrial drill - typical hand operated design used in workshops.Historic - Industrial drill - typical hand operated design used in workshops.Hand Operated Drill Press Bench mounted type hand drill press. puffing billy, tools, hand tools, drill press -

Puffing Billy Railway

Puffing Billy RailwayRail Drill, Hand

Hand Rail Drill Out on the track in the old days, it was sometimes required to drill some holes in a piece of rail so that two rails may be joined together by a metal joiner – called a fishplate. Before the use of generators and oxy cutting, the only way to do this was with a hand drill. This is the machine operated by two people, that would drill a hole in the rail. With two to three holes to be drilled in each rail end (ie 4 or 6 holes), it was a tiring, back breaking job. And then there was usually the rail on the other side of the track to be done! Historic - Railways Permanent Way and Works - track equipment - Hand Rail DrillHand Rail Drill made of metal puffing billy, hand rail drill -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWooden Auger - two inches

Used to drill a two inch diameter hole by turning it around and pressing it into wood. Used by residents of the Kiewa Valley. A steel auger used to drill into wood. It is handheld and drills a hole two inches in diameter.wooden auger, woodworking tool -

Linton and District Historical Society Inc

Linton and District Historical Society IncStereograph, The Rose Stereographs, Melbourne, Sydney, Wellington and London, 12,927 Australian Expeditionary Force, Drill Excercise, Ballarat, Copyright 1914

One of two sets of stereographs donated by the O'Beirne family along with a stereoscope for viewing (Stereoscope is Registration no. 2014-51).Groups of soldiers undertaking drill training. Small group of drummers in foreground."12,927. MEMBERS OF THE AUSTRALIAN EXPEDITIONARY FORCE Undergoing Drill / Excercise at BALLARAT, VIC."stereographs, australian expeditionary force -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Mid to late 1800s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools.Archimedean drill with wooden grip and butterfly nut on chuck.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, fretwork tools, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool, the item therefore could have been used in various industries or professions where precise drilling is required. Archimedean drill with Rosewood hand, brass grip and fittings Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Steel Archimedes hand drill 'Hobbies', c1900

Archimedes drills, incorporate a bobbin sliding up and down a spiral shaft to bore a hole. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. Some of the most beautiful Archimedean drills appear in English tool auctions replete with brass, rosewood and even ivory. A steel hand drill with fine bit and sliding bobbin'HOBBIES' on top of handletools, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, blacksmiths, bobbins, augers, hand drills, marples william -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Magdala-Cum-Moonlight Mine Looking North West & with 2 miners using a modern rock drill 1902

Mining Scene of Drilling in Underground Magdala-Cum-Moonlight Mine 1902. A stope in rich stone looking North West. Some of the miners on the Magdala mine had early versions of the modern rock drill. Two of the miners are pictured here drilling in the rock face.Two miners underground working a rock drill stawell mining -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hand drill mounted on wooden stand, Early to mid 20th Century

This style of geared drill was commonly referred to as an egg-beater drill and was first patented in 1838. During the late 19th century these drills became more common due to the development of mass production. Users also began to mount the drill onto a frame. This allowed greater control over the drill and removed the need to be holding it in both hands. This gave the operater greater control over the item to be drilled. The drill could be easily removed when required. This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools. The construction of the basic wooden frame also demonstrates the ingenuity of early pioneers and tradesmen in adapting tools to suit their own needs.A metal hand drill which has been mounted on to an improvised wooden stand. hand tools, mass production, egg beater drills -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Blacknose Quarry, 05/11/1952

Port of Portland Authority ArchivesFront: 'DRILLING BLAST HOLES AT BLACKNOSE QUARRY MINERAL DRILLERS' E100 MACHINE 5.11.52 ' - printed on bottom frame Back: Purple PHT stampport of portland archives, blacknose quarry -

Puffing Billy Railway

Puffing Billy RailwayHand Operated Rail Drill

This hand operated drill was used to drill holes in the rails so that with fishplates (metal joiners) the rails could be bolted together to form a continuous length.Historic - Railways Permanent Way and Works - track equipment - Hand Operated Rail Drill Hand Operated Rail Drill made of cast Metalpuffing billy, hand operated rail drill -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Drilling near Condah Victoria, c. 1960

Possibly from Bowerbird MuseumBlack and white photo last drilling rig in the Condah area.Front: Kevin McLennish The last drilling rig 1960 Condah area Hand written blue biro -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools. Archimedean drill with Rosewood hand, brass bearings, steel twist and wooden grip. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, archimedean drill with wooden hand, drilling tool -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchUniform Khaki cotton drill jacket

Officers khaki drill cotton jacket with darkened Australian AIFmetal buttons and 3 pips denoting rank of Captain. Jacket has complete ribbon bar denoting 1939-45 StarMakers Tag; pre shrunk English drill -

Nillumbik Historical Society Incorporated

Nillumbik Historical Society IncorporatedTool - Portable Sleeper Drill, Early 20th century

This drill was used in the construction of the Eltham-Hurstbridge Railway extension in 1911. The device was placed over the wooden sleeper to drill holes for the iron spikes which held the rail down. Example of tools needed to build railway in early 20th Century in the Diamond Valley.Drill mechanism mounted on wooden frame. Mechanism tilts to enable holes to be drilled vertically (normal) or at angles up to 45 degrees using double hand cranks and gears. A rack can be engaged to raise and lower the mechanism and drill bit. Mechanism appears original. Base frame replaced recently. #drill, #railwayconstruction, #sleepers, #tilting, #handoperated -

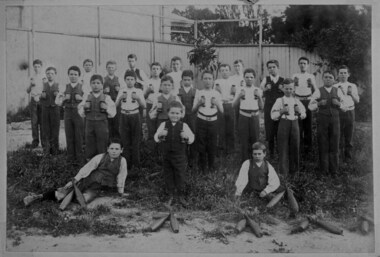

Deaf Children Australia

Deaf Children AustraliaNegative, Boys' Physical Drill Classes, 1893

B&W negative of the Boys Physical Drill Classes On label on packet "Boys' and Girls' Physical Drill Classes/1893/Photorestorations & copies, Beverley/ Crosby and Peter King, 1989" deaf children australia, vddi, victorian deaf and dumb institution, pupils, education, physical drill classes -

Stawell Historical Society Inc

Stawell Historical Society IncBook, Greg Cameron, Diamond Drill Mine Ledger 1873-1875, 2005

Photocopied Ledger pages of the DIamond Drill Mine.Green Plastic Covers with Green Plastic Ring BinderDimond Drill Mine Ledger 1873 - 1875 Magazine Box 21stawell gold mining -

Puffing Billy Railway

Puffing Billy RailwayFlat Belt Driven Drill Press

Industrial - Flat Belt Driven Drill PressHistoric - Industrial - Flat Belt Driven Drill PressDrill press. - made of Metal and Steel and cast ironHercus Made in Australiaflat belt driven, drill press, puffing billy -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesSlide - Glass slide, 1891-1905

Sale Agricultural and Horticultural Society '48. Sale AHS Using the Hand drill.-' and 'Sale AHS Intertillage of Mangolds.' 2 images on 1 slide.48. Sale AHS Using the Hand drill/Sale AHS Intertillage of Mangolds.school gardens, australia, sale, agricultural and horticultural society -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesSlide - Glass slide, 1891-1905

Sale Agricultural and Horticultural Society '52. -Sale A.H.S. Fighting the Aphis Blight,-' and, '-Sale A.H.S. Drilling in Oats.-' 2 images on 1 slide.52. -Sale A.H.S. Fighting the Aphis Blight/Sale A.H.S. Drilling in Oatsschool gardens, australia, sale, agricultural and horticultural society -

Williamstown High School

Williamstown High School1957 Orchestra Drill Hall

Black and white photograph of Miss Boardman with the Williamstown High School orchestra in the Drill Hall.On front of the photograph: Miss A.B. Boardman, Head Mistress, and school orchestra in Drill Hall 1957.williamstown high school, music, 1957, miss boardman, orchestra, drill hall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedes Drill, 1900 to 1930s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool that has been nickel plated with brass fitting and easier to sterilise. The item therefore could have been used in the medical profession as a bone drill during surgery. Weighted Archimedes drill all metal construction, nickel plated with brass handles centrifugal typeNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, tool, drilling tool -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

Drilling tests.mining, gold, gold mining, tin, tin mining, churn drill, drilling, machinery, el dorado, eldorado -

Stawell Historical Society Inc

Stawell Historical Society IncGeological specimen - Mining, Broken Dimond Drill Pieces

Used to drill through the red Iron stone - reefs end of Stawell. Found along Darlington Road after drilling to erect a Power Pole 2X Cylindrical Broken used Dimond Drill - Core Samples, Basalt - granite -

Mont De Lancey

Mont De LanceyTool - Breast Drill, Unknown

... Drills ...A steel manual breast drill with an attached curved flat plate at the top to apply pressure with the chest.. This plate is attached to the drill by a screw. A wooden handle turns the drill mechanism to operate it and a second wooden handle is to steady the operation. It was used for making cylindrical holes by rotation.drills, push drills, hand drills, tools, handtools, breast drills, woodworking tools -

Stawell Historical Society Inc

Stawell Historical Society IncJoiner, Joiner from Diamond Drill, C. 1955

Dimond drills are put down to identify locations of gold bearing ore deposits, before mining drives are put in to extract the Ore. Sectionso fth eDimond Drill core are analyised for gold content. Drill joiner found near shaft no 26 in Ironbarks, near the intersection of Golf Course & southwest road. Conctrete shaft Cover still in PlaceMetal pipe threaded at both ends, used to join diamond Drill pipeing c 1955mining, gold -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill