Showing 65 items

matching electric appliances

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Landers, Frary & Clark , 1897-2000

Landers, Frary & Clark were a housewares company based in New Britain, Connecticut. It operated from 1865 until its assets were sold to the General Electric company in 1965. They manufactured a wide variety of products over the years, including stainless steel bull-nose rings and electric ranges, kitchen scales and vacuum bottles, window hardware and ice skates, mouse traps and percolators, can openers, corkscrews, cutlery, straight razors, aluminium cookware, and thousands of other products. Many of these items were marketed under the brand Universal. Some of the non-electric kitchenware assets were acquired from G.E. in 1984 by Universal Housewares, Inc./Universal Trading, Inc., who still market "Universal" meat grinders and coffee mills.An early domestic item its function was for use in the home kitchen that's the original patented design from 1897 is still being produced today under its brand name of Universal by Universal Trading Inc USA.Food mincer cast iron with wooden handle & thumbscrew for bench attachment.Marked "No. 2 Universal".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, mincer, food mincer, universal brand, kitchen appliance, food grinder, lander frary & clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Federation University Historical Collection

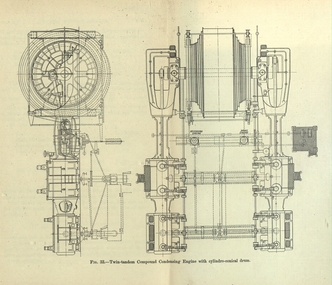

Federation University Historical CollectionBook, Winding Engines and Winding Appliances, 1912, 1912

George McCulloch was an inspector of machinery for the Western Australia Department of Mines. Brown hard covered book of 452 pages including illustrations and index. Contents include Design; Tail ropes; Winding from Great Depths; Colliery Winding; Electric Winding; Steam engine details, Drims; brakes; Clutches; Safety Devices; Winding ropes; Cages; Skips; Cage Safety Gear, Safety Cages; Cage Guides; Head gearsmining, winding, engines, steam engines, safety devices, winding ropes, cages, safety cages -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, 'Smoothwell' electric flat iron c1935, c1935

c1881 Henry W Seely, of New Jersey, USA, designed and patented an electric sad iron for pressing and smoothing material. He continued to modify and improve his designs, with his partner Richard Dyer, and other electrical appliance firms, e.g Hotpoint, began producing these flat irons that could provide continuous heat by connecting via an electrical flex to a light socket and hence without the need for hot fires, ash, or burning hot handles. Women with access to an electricity supply were delighted and their ironing chore became much less arduous No heat was felt at all from the iron as it is all concentrated on the bottom surface. By the early 20th century enthusiasm was building for the new electric smoothing irons: clean, powerful, adjustable, and labour-saving. This c1935 Premier System 'Smoothwell' flat iron was used by a resident of City of Moorabbin and is an example of the progress made from the sad irons used by the pioneers that are displayed beside it.A "Premier Smoothwell" electric flat iron with switched control lead and original box, c 1935 On plate of handle attached to Iron ' HARRODS Ltd. / LONDON On attached plate at rear of iron ' The "SMOOTHWELL" / "Premier System" /......... Plate on cord Plug " PREMIER/ FLAT IRON CONNECTOR/ THIS SIDE OUTWARDS/ (2 columns) 1) FOR 100-125 VOLTS/ USE THREE TERMINALS/ THUS ..... 2) FOR 200 - 240 VOLTS/ USE TWO RIGHT/ HAND TERMINALS/ ONLY/ THUS......seely henry w., sad irons, electric flat irons, dyer richard, edison thomas, hotpoint pty ltd., premier electric company birmingham england, pioneers, early settlers, moorabbin, bentleigh, cheltenham, laundry, sewing, craftwork, table ware, irons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ice Chest, 1927

... equipment kitchen appliance refrigerator non-electric refrigerator ...This particular small ice chest was once part of the domestic furniture of Dr W.R. Angus and his young family in 1927 when they lived in the Nhill and Ballarat districts. The family relocated to Warrnambool in 1939 and brought the ice chest with them. An ice chest, also called an icebox or refrigerator, was invented by Thomas Moore in 1802 and had become a common home appliance from the mid-1800s until around the 1930s, when electric refrigerators became affordable and safe. The non-mechanical ice chest allowed perishable food to be kept fresh for longer than the food-safe or ‘Coolgardie’ used in colonial days in Australia. It required the use of ice blocks, which were delivered to households by the ‘iceman' and his horse and cart. The ice man would use an ice pick to cut the blocks into the right size for the buyer’s ice chest. The ice came from an ‘ice house’, a factory where the ice was made. The ice chest required a block of ice to be placed into the insulated top section on top of the corrugated iron stand. The ice would cool the air and the cool air would flow downwards through the oval hole under the stand and into the refrigerator compartment below. The water from the melted ice would drain from the sloping floor of the top compartment and into the hooded pipe. The pipe went through the refrigerator and ended below its floor, where the drained water would be collected in the metal bowl placed there for that purpose. The lip on the bowl allowed it to be easily removed and emptied at regular intervals before it overflowed. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This ice chest is significant for representing a method of refrigeration and food preservation used in the 19th to mid-20th centuries when people were beginning to afford powered domestic refrigerators. After the second world war, most households replaced their food storage cupboards and ice chests with refrigerator appliances. The ice chest is also significant for its connection with the domestic furniture of Dr W.R. Angus and his family, and its inclusion in the W.R. Angus Collection.Ice chest; single front wooden cabinet with two doors and a flap, and three accessories. The top door is a lid with a metal handle at the front and two metal hinges along the back. The front door has two metal hinges on the right-hand side and has a metal lever catch. A hinged flap fits between the front legs at bottom of the ice chest and swings upwards. The front legs have wheels. The insulated top compartment has a metal lining and its floor slopes towards the centre of the back wall. In the floor are a formed oval air-flow hole and the open end of a pipe that has a hood partly covering it. The front compartment is an insulated metal-lined cupboard with a vertical pipe down the centre of the back wall and horizontal rails in the centre of each side wall. The accessories are a rectangular corrugated iron stand, a rectangular wire grid shelf and a round aluminium bowl with a lip and two sides pushed in. The ice chest was made circa 1927 and is part of the W.R. Angus Collection.flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, doctor angus, dr angus, ice chest, ice box, antique, food preservation, refrigeration, domestic equipment, kitchen appliance, refrigerator, non-electric refrigerator, non-mechanical refrigerator, w.r. angus collection -

Bendigo Historical Society Inc.

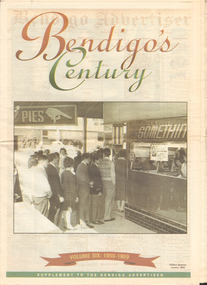

Bendigo Historical Society Inc.Newspaper - LONG GULLY HISTORY GROUP COLLECTION: BENDIGO'S CENTURY VOLUME SIX: 1950 - 1959

Newspaper supplement titled Bendigo's Century Volume six: 1950 - 1959. Front page has a photo of Gillies' famous corner, 1954. Each year has heading of Who's Who, Weather, Sport and Business. First year is 1950 titled Gillies: it's a Bendigo icon. 1951 is titled It's party time. 1952 - City mourns King George. 1953 - Mining ceases. 1954 - City thrilled at royal visit. 1955 - Push to save old Joss House. 1956 - Olympic fever grips Bendigo. 1957 - State Cabinet visits Bendigo. 1958 - Plan to keep historic mine. 1959 - Water storage woes solved. Back page has the Gillies Story.bendigo, history, long gully history group, the long gully history group - bendigo's century - volume six: 1950 - 1959, gillies' corner, bendigo advertiser, john lienhop mlc, north deborah mine, les gillies, alan gillies, norm gillies, black swan hotel, sir dallas brooks, cr a g weynton, bert mundy, cr poulston, the northern district school of nursing, lister house, the bendigo free library, rev dr c irving, shamrock hotel, sir albert dunstan, the most rev dr john mccarthy, jack davey, 1950 empire games, hercules gold mines, amy castles, ben templeton, cobb & co, cr norman oliver, reg parker, fred amer, les hammer, colonel george victor lansell, john quick, mr l w galvin, mr p j clarey mhr, hanro knitting mills, flooding, bendigo pottery, snow fall, the last lamp-lighter, the north deborah, aids & appliance shop, boardwalk, the late king george vi, the north deborah, beehive building, st paul's, st kilian's, upper reserve, bendigo trades hall, bendigo blackout, bendigo hospital, shamrock hotel, gerald smith, britannia hotel, mr a j harris, william morris (billy) hughes, andrew hampson, deborah anticline, north deborah, central deborah, diamond hill mine, north nell gynne mine, robert ross haverfield, sandhurst commercial courier, arthur moore lloyd, robert ross haverfield, angus mackay, jj casey, james henderson, david stuart, bendigo independent, colonel george lansell, bendigo base hospital, bendigo town hall, victorian electric traction association, the most rev b d stewart, st vincent's memorial college, commonwealth athletic club, south atlas racetrack, harp and shamrock hotel, mr and mrs f drake, cr f w clayton, cr r poulston, j h abbott & co, sir george lansell, clan macleod, bendigo gaol, queen alexandra fountain, belfast hotel, commonwealth bank, st vincent's college, lyric threatre, des duguid, brian cahill, lord's raceway, red white & blue extended gold mining company nl, central napoleon gold miningcompany nl, joss house, harry john, bendigo advertiser, mr leggatt, university of melbourne, anz bank, golden drive-in theatre, bank of australasia, john brown industries, bendigo football league, bendigo trotting club, faith leech, racv, bendigo sewereage authority, bendigo base hospital, bendigo benevolent asylum, henry bolte, jack davey, russell oakley, neville stilwell, channel seven, bendigo's olympic pool, annie caudle centre, strathfieldsaye aerodrome committee, southern airlines, cr d j osborn, cairn curran reservoir, state savings bank, commonwealth bank of australasia, belfast hotel, bennett's arcade, eppalock weir, bendigo cenotaph, sir edmund herring, cr a s craig, bendigo creche, bendigo high school, bendigo pottery, shamrock hotel, the venerable ronald richards, bishop riley, all saints cathedral, mr albert bush, bendigo arcade company ltd, woolworths, bull's head hotel, pike's corner, arcade hotel, upper coliban reservoir, cr tom flood, crystal egg co, sailor's guide, central deborah, central nell gwynne mine, bendigo benevolent home, ron masters, george daniel, eppalock dam, water commission, public works committee, bendigo central victoria telecasters ltd, channel nine, royal princess theatre, sir george lansell, volunteer defence corps, bendigo independent, countess erna cadorin, count ettore cadorin, ernst mueller, sutex pty ltd, dick turner, marco cavasassi -

Robin Boyd Foundation

Robin Boyd FoundationFunctional object - Appliance

... Walsh St appliances robin boyd Electric frying pan Functional ...The Boyd family recalls this frying pan being used, but not sure of where it was located. The kitchen drawer where this frying pan is currently located was the toaster drawer. The drawer has a power point in it. "The drawer was pulled out and the drop down front lowered for toasting. When shut, no toaster was in sight! In the bottom of the drawer, at one side, there used to be a small slot for sweeping out any dropped bread crumbs."Electric frying pancookware, walsh st appliances, robin boyd -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Washing Machine, c.1970

... laundering electrical technology appliances & accessories Simpson ...Was used by owner until concerned that children may have hurt themselves on the wringerSimpson electric washing machine with wringer attached above bowl. White, round with removable lid. Front lever: Wash/Stop; three buttons on front: Empty-Wash-Off indicated. Appliance on castors attached wringer with metal drip tray and two rubber rollers. Wringer will pivot.Simpsondomestic items, laundering, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Wall Clock, 1945s

UnknownClock square with rounded corners cream bakelite electric wall clock with art deco style corners. Silver edged clock face with black numbers on silver edge with cream centre. Black filigree hands with a red minute hand. Black adjustment knob at bottom. Made in Great Britain by Smiths Sectric is marked on face. Back is black bakelite 'Smiths English Clocks' 200/250V 50SFC - Reg Trade Mark. Made in England. Instructions to set hands, press and turn knob. Made under one or moe Brit. Patents 366710 369 336 374 713 384441 484222. Back is cream with black book and white electric cord with black ring-grip plug 250V - 10amp. Made in Australiahorology, clocks, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

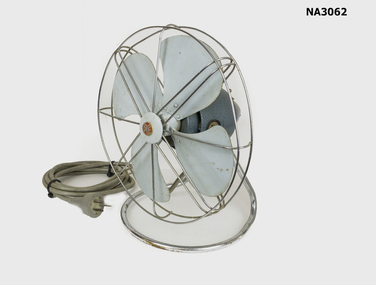

Whitehorse Historical Society Inc.Domestic object - Fan

Four blade electric fan. Grey blades enclosed in chrome guard. Connection grey electric cord and connectionPyedomestic items, cooling, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Electric Fan

... the 1930s DOMESTIC ITEMS Cooling ELECTRICAL TECHNOLOGY Appliances ...Fan was used by Robert Gardiner,s father during the 1930sElectric fan with four blades enclosed in wire guard. Round metal disk on front of guard. Round base supporting electrical connection. Three metre cord and fittings attached to base.G.E.C.domestic items, cooling, electrical technology, appliances & accessories -

Hume City Civic Collection

Hume City Civic CollectionDomestic object - Electric Iron

This electric iron was manufactured by Hecla, Australia and possibly manufactured in the 1940's-1950's. The iron was used mainly by housewives to iron items of clothing and various items of linen used in the home. Some items were sprinkled with water to make them damp and therefore help to make the ironing easier. Later steam irons were produced.A heavy black handle electric iron with frayed cord attached.Hecla/Australiadomestic appliance, domestic items, irons, ironing, hecla australia -

RMIT Design Archives

RMIT Design ArchivesDomestic object - Object, General Electric KE12 Kettle, designed by Barry Hudson

... appliances Orange and brown electric kettle General Electric KE12 ...The GE12 Electric Kettle was designed by Barry Hudson for General Electric and in 1978 won the Australian Design and the Prince Philip Prize awards for Australian Design. The kettle was innovative in many ways; it was an early example of an all plastic electric kettle with a single-handed opening-spout. According to design historian Ian Wong ‘The use of an integral hinge for the spout opening mechanism utilised the unique live hinge property of polypropylene, now common but at the time a novel use and very efficient to manufacture.’ The kettle was available in Carpentaria Orange, Blaze Yellow and Lime Green with a contrasting base. Barry Hudson (1935-2008) studied Mechanical Engineering at the Melbourne Technical College (MTC). In the 1970s he was Research and Development Manager at General Electric, and he also worked with the industrial design practice Rosenfeldt, Gherardin and Associates. He established Barry Hudson Industrial Design in the 1980s and began a teaching career at the former MTC, now known as RMIT University. Ann Carew, 2020 1978 the Kettle won an Australian Design Award and the Prince Philip Prize for Australian Design.Orange and brown electric kettlekettle, industrial design, rmit university, domestic appliances -

RMIT Design Archives

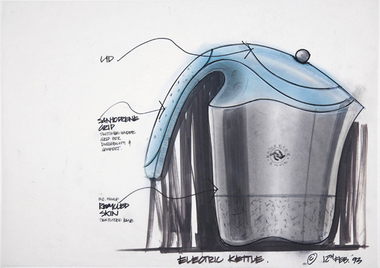

RMIT Design ArchivesDesign drawings, Paul Taylor for Form Australia, Kambrook Axis Kettle concept rendering

The Axis Kettle was developed through the EcoRedesign project funded by the Federal Government and based at RMIT in the 1980s and 1990s. The project involved the expertise of significant Victorian designers such as Paul Taylor, Gerry Mussett, Liam Fennessy and Michael Grima, as well as prominent sustainability experts such as academics John Gertsakis, Chris Ryan and Alan Pears. Axis changed the way kettles were used, guiding users to save resources through their behaviour. It is regarded globally by academics from prominent design institutions such as Loughborough and Delft as one of the first successful eco-design projects. The drawing is part of the Centre for Design collection, RMIT University. Simon Lockrey, 2017 The drawing is historically significant as an early eco-design project. Design drawing of KambrookKettle by Paul Taylor for Form Australia as part of the Centre for Design at RMIT University, featuring electric kettle drawn in black pen + ink with blue ink where kettle lid is. Written design descriptions appear along side the image and title below.LID / SANHOPRENE / GRIP / RECYCLED SKIN / ELECTRIC KETTLE. c 12TH FEB. '93household appliances, industrial design, sustainability, rmit university -

Robin Boyd Foundation

Robin Boyd FoundationDocument - Manual, Appliance brochures

A collection of appliance manuals, warranties, receipts, post 1971. They include Sunbeam electric blankets, Sunbeam automatic kettle, Sunbeam iron, Breville toaster, Bosch gas hotplate, Rheem electric hot water, Actron air conditioner, Dishlex dishwasher, B&D Australia repair, Goodguys invoice.Assorted manuals and warranties and invoices. -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Report, Willits H. Sawyer, "Report on the Status and Affairs of the State Electricity Commission of Victoria and the Scope and workings of the SEC Acts", 1926

Thirty two page report titled "Report on the Status and Affairs of the State Electricity Commission of Victoria and the Scope and workings of the SEC Acts", prepared by Willits H. Sawyer, dated 1926. Royal Commission into the status and affairs of the SEC, undertakings, works, programmes, charges, acquisition of power companies, extension of the power system, tramway and railway power systems, use of brown coal, council facilities, substations, nature of the power supply, sale of appliances, coal mining methods, distribution of power supply systems. Presented to both houses of the Victorian Parliament . Folded and stapled in the centre. Sheets have rounded corners.Stamp of the "Electric Supply Co. of Victoria Ltd" in top right hand corner dated 27 Apr. 1927"trams, tramways, sec, yallourn, power supply, royal commission -

Kew Historical Society Inc

Kew Historical Society IncEquipment, Morphy-Richards Auto-Control Safety Electric Iron, 1948-1949

The company Morphy Richards was founded in 1936 in the United Kingdom by Donal Morphy and Charles Richards. The company developed the first electric iron in the UK.Intact appliance with original warranty and packaging.Iron (electric) - Morphy-Richards Safety Control Electric Iron, in original packaging with instructions for installing and using, and Warranty.domestic equipment, electric irons -

Kew Historical Society Inc

Kew Historical Society IncEquipment, Hotpoint, Electric Iron, 1930s

Hotpoint Irons were first developed in 1903 in California. The invention was named Hotpoint, after the heating elements that converged in the iron's tip, allowing it to be used to press around buttonholes and in and around ruffles and pleats on clothing and curtains.Early electric iron manufactured under license by Hotpoint Australia. The iron has a metal base into which a separate power cord is plugged. The iron has a wooden handle.Label: " Hotpoint. Made in Australia. Licensed by Edison Elelectric Appliance Co. Inc. Chicago, U.S.A. Cat.915 F61. W.575, W200."hotpoint -- australia, electric irons -

Kew Historical Society Inc

Kew Historical Society IncEquipment, Hotpoint, Electric Iron, 1930s

Hotpoint Irons were first developed in 1903 in California. The invention was named Hotpoint, after the heating elements that converged in the iron's tip, allowing it to be used to press around buttonholes and in and around ruffles and pleats on clothing and curtains.Early electric iron manufactured under license by Hotpoint Australia. The iron has a metal base into which a separate power cord is plugged. The iron has a wooden handle. Missing cord.Label: " Hotpoint. Made in Australia. Licensed by Edison Elelectric Appliance Co. Inc. Chicago, U.S.A. Cat.915 F61. W.575, W230."electric irons, hotpoint australia -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncFridge, circa mid 20th century

Electric fridge with rounded corners, made of cream enamelled steel. One compartment with lever-type handle.Contractor's sticker on RHS for 'POLMEAR PLUMBING' . Serial No 4454domestic items...appliances; refrigeration -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Electric Toaster, Hecla Electrics Pty Ltd, c1940s

Hecla produced a wide range of appliances for domestic use, beginning with heaters and later branching out to a wider range of kitchen appliances Hecla was established by Clarence William Marriott, a young Melbourne metal worker. He began manufacturing Australia's first carbon filament electric radiators in 1899. He originally worked for his father James Marriott who commenced business in Melbourne as an art metal worker in 1872 and was, in 1907, appointed as the official art metal worker to the Victorian Government producing items including the ornate iron gates and gas lamp standards outside Melbourne's Parliament House. With the invention of nickel chromium wire after 1900, C.W. Marriott began making more efficient heating elements using this new material in 1916. After being influenced by the eruption of Mount Hekla in Iceland, on 19 December 1918, Clarence registered the brand name "HECLA" with an erupting volcano as its logo. The company Hecla Electrics Pty Ltd was officially registered in 1922. In 1928 the company adopted the advertising slogan, 'By Hecla, it's Good'. The Hecla range rapidly expanded to include electric heaters and radiators, electric foot warmers, electric kettles, ceramic & metal electric jugs, immersion hot water elements, electric fans, electric coffee percolators, electric toasters, electric grillers and stoves, electric irons and electric frypans, clocks and curling wands. Electric blankets were introduced shortly after WWII.In 1930, a controlling interest in Hecla Electrics Pty Ltd was acquired by General Electric Corporation. Clarence William Marriott died in June 1967 in Melbourne, Victoria.This item is representative of a common domestic appliance used throughout Australia. It was manufactured by a pioneering Australian company.A small chrome steel toaster manufactured by Hecla Australia. It has a door on either side which flips down to insert or remove a slice of bread on each side, Each door has two black Bakelite knobs. The electric element is placed down the centre of the cavity. A detachable electric cord is included.240 Volts, 600 Watts. Cat. No. T4 Submitted to Electrical Approval Board Ref Application A1/AD01 SECV 240 Volt 600 Watt MANFED. IN AUSTRALIA SOLID BRASSelectrical appliances, hecla corporation australia, clarence william marriott, domestic appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Floor Polisher, Hoover Ltd. Great Britain, 1950

The history of Hoover dates back to the early 1900s and directly to Mr. James M. Spangler, an American janitor who invented the first vacuum cleaner to assist in dealing with his asthma. Originally founded in Ohio in 1908, Hoover Limited became a registered company in the United Kingdom in 1919. The first factory, in Perivale, Middlesex, England, opened in 1932. Hoover became the undisputed leader in the floor-cleaning market, so much so that in USA vacuuming became referred to as “hoovering”. This model was widely advertised in Australia from 1952 to 1958. Advertisements referred to it as “The Wonderful Hoover Floor Polisher”. It came complete with Scrubbers, Felt Pads, Lambswool Pads and Built - in Head Light and in 1952 sold for £32/8/-, or could be purchased with a deposit of £8 and weekly payments of 15/-. They claimed that the Hoover Polisher would take the drudgery out a woman’s work and appealed to men by saying the lambswool pads could be used to perfectly polish the headlights and duco of cars.This item is represented of domestic appliances used throughout Australia in the 1950s and 1960sAn upright Hoover electric polisher made from die-cast aluminium with Bakelite outer casing and electrical components.On plate attached to back: THE HOOVER ELECTRIC POLISHER MODEL 0212A./TRADE MARK D.C. OR A.C. 0-60) CYCLES VOLTS / 300 WATTS RATING SERIAL NOPF 533695 PROTECTED BY PATENTS, REGISTERED DESIGNS AND TRADE MARKS IN GREAT BRITAIN AND THE PRINCIPAL COUNTRIES OF THE WORLD MADE BY HOOVER LTD. GREAT BRITAINhoover appliances, domestic appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Light 'N Easy Electric Iron, General Electric Housewares Pty Ltd, c1950s

From the late 1920s several brands of irons, including Hotpoint and Light' N Easy were manufactured in Australia by the Australian General Electric Co. Ltd. Light' N Easy irons were marketed as a versatile iron, small and light enough to be taken with you if you needed to travel away from home.This iron is representative of electrical appliances developed under licence in Australia from the late 1920s onwards.Small yellow steam iron. There are controls and a water level indicator on the side of the iron. There are 25 steam vents in the base. Steam and dry iron with surge of steam. A 3 metre electrical cord is attached.Label: " General Electric Housewares Pty Ltd. Vic/ Nottinghill Melbourne 3166/ 700 Watts/ APP NO. V79008 Cat 04/06 240 Voltsdomestic appliances, light 'easy irons -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - "Creda" Electric Iron, Credenda Conduits Co. and Simplex Electric Company Ltd, c1950s

Creda had its origins in two companies: the Simplex Steel Conduit Company Ltd. (later Simplex Conduits Ltd.) formed in 1898, and the Credenda Company Ltd. which was the first to use Creda as a brand name. These companies were two of the founding companies of Tube Investments Ltd. From 1919, the Simplex name was used for installation equipment ranges, and Creda for heating, cooking and other domestic appliances. In 1932 Simplex Conduits Ltd. and the Credenda Company Ltd. merged to form the Simplex Electric Company Ltd., but the distinct Simplex and Creda brands continued in use. In 1987 the Simplex Electric Company was taken over by General Electric Company, and formed part of General Domestic Appliance Company Ltd. the following year. In 2015 the large corporation, Whirlpool, took over the Indesit Appliance Company, which owns the Creda brand name. Since then the Creda brand as such has become rare, and where it does appear it is as a re-badged version of Indesit and Hotpoint home appliances.This iron is typical of the electric irons used in the 1950s. It is representative of appliances used by women in their domestic roles.A "Creda" Electric Iron with plug-in cord. It has a metal steel base iron with a wooden handle and a thumb rest. The handle is bolted onto the iron with 2 large screws. The cord socket plugs in behind the handle of the iron. On attached metal plate: "CREDA/ Cat. No 6; Volts 240; AMPS 8"domestic appliances, creda irons -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Airzone Vacuum Cleaner, 1950

Standard Telephones and Cables Pty Ltd was a telecommunications company that began as part of Western Electric, a telephone manufacturing company set up by Alexander Graham Bell. Following the First World War, Western Electric diversified to include electric generators and wireless receivers, all still imported. In 1925, Western Electric was sold to the International Telephone and Telegraph Company. In Australia, it became known as Standard Telephones and Cables (Australasia) They worked closely the Postmaster Generals department to set up telephone and radio networks throughout Australia. Its first factory was in Chippendale, New South Wales but ut developed to have branches in all stated of Australia. By the end of the Second World War STC was Australia's biggest manufacturer due to its critical role in producing telecommunications equipment, domestic radio receivers, telecom cables, military equipment and electron tubes. The company returned to peacetime manufacture. Rather than reduce staff it used its excess capacity to produce electric irons and other domestic appliances including vacuum cleaners and floor polishers. This model was produced at the beginning of the 1950s. It was once owned by Mr. Stiff from Stiff and Gannon, Wodonga.This item has local and national significance. It was used in a local Wodonga business and is representative of domestic appliances used in the 1950s. It also has national significance as it is an excellent example of good produced by the manufacturing industry in Australia during that period.Model 30 Airzone Vacuum Cleaner and accessories. Manufactured in AustraliaMetal logo for Airzone including engine specificationsdomestic appliances, standard telephones and cables pty ltd -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - COLEMAN Fuel Iron

Coleman, originally known for making lanterns, made over 30 different models of irons from 1929 to 1948. They generally came in an enamel coloured finish. The best known and most commonly found today is the “Cool Blue” enamel Coleman’s 4A gasoline iron. The Coleman 4A gasoline iron was much lighter than the previous ‘sad irons’ and no longer required to be heated on the stove or by charcoal. Instead, the pump was used to build up pressure in the fuel tank and a match was lit underneath the iron, making a flame inside the iron that would distribute the heat on the surface. Despite these benefits, fuels irons made ironing a potentially dangerous job. They had a very real possibility of causing a fire or exploding. Gas-pressure irons, that had been manufactured as early as 1900, were eventually replaced by electric-powered steam irons, in the 1970s as an affordable and safer alternative.This item is significant because it is an example of domestic appliances used widely throughout the Wodonga District.A self-heating iron which made from metal and enamel plate which included a small tank for fuel which powered the unit. A small wooden pump was used to build up pressure in the iron’s fuel tank. It has a wooden handle.domestic appliances, coleman fuel irons