Showing 38 items matching "feeding machine"

-

Vision Australia

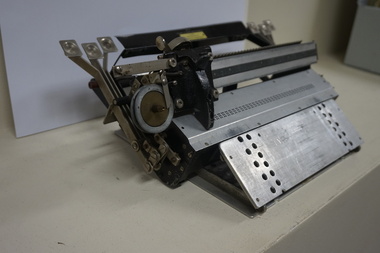

Vision AustraliaEquipment - Object, Ellams Duplicator Co, Ellams Self Feeding Rotary Duplicator

Founded in 1891, the Ellams Duplicator Company produced drum and flat duplicators that copied a stenciled sheet and allowed multiple copies to be made. Considered desk top, this rather heavy machine was operated by turning the handle and could turn out 100 copies a minute. This would have been useful for donation request letters or large print newsletters.1 black case holding a black drum and metal platesEllams Rotary Duplicator Self Feeding Ellams Duplicator Co Ltd 12 King Street London E.C. Alfred Street, Brisbane, Australiaoffice equipment, ellams -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Cream Separator

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. ALFA-LAVAL SEPARATORS The principal works and head office of Aktiebolaget Separator was established by Gustaf de Laval in Stockholm. The first Laval milk separator was patented in1884. In Australia three old established firms commenced pioneering the Alfa Laval cream separators in about 1885. These were A. W. Sandford & Co. Ltd., in Adelaide, J. Bartram & Son, of Melbourne, who have ever since been the Victorian agents of Aktiebolaget Separator. In New South Wales and Queensland, the pioneering firm was Waugh & Josephson Ltd. J. Bartram & Son, the distributor of the separator in this collection, established their business in Melbourne in 1881. In 1892 Bartram & Son estimated that 1,130 of these machines were operating throughout Victoria. This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is made from cast iron. The cover and vat are made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A name plate featuring the Victorian distributor, J Bartram & Son of Melbourne and a plate outlining patent information are attached to the base by screws.Around edge of wheel "Aktiebolaget Separator Stockholm/ 2236"dairying industry, dairy machinery, milk separators -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Lister Cream Separator, R.A. Lister & Co. Ltd, c1910

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. LISTER - A prominent make of separator which became very popular with the dairy farmer, was the "Lister" separator. The early separators sold by R. A. Lister in the 1880's, were made by "Koefoed & Hauberg", Copenhagen. Denmark, called the "Alexandria". Ashton Lister became the sole agent for Koefoed & Hauberg made separators in England and all the English Colonies, throughout the world. Being an enterprising salesman, Ashton, sent his son Edward on a three-year sales tour of Australia & New Zealand in 1890, (hence the strong presence of Lister in Australia.) Initially, the separator was totally manufactured in Denmark and assembled in Dursley, England. By 1892 Lister were making parts at their Victorian Iron Works, and around about the early 1900's, Lister began manufacturing separators in their own right, severing ties with Koefoed & Hauberg. The Lister firm is still going today, under the name of Lister Petter, England, but do not manufacture separators, as the manufacture of farm / domestic separators ceased in the early 1960's.This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is metal plated with blue enamel. The vat is made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A metal plate featuring the manufacturer information is attached to the side of the handle. Model CR 15 hand operated table version.On metal plate attached to handle" Lister/ MADE BY R. A. LISTER & Co.LTD. / AT DURSLEY ENGLAND / VICTORIAN AGENTS / GIPPSLAND & NORTHERN CO-OP/ CO. LTD. / MELBOURNE C.1"dairying industry, dairy machinery, milk separators, lister separators -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - Hay Bale Saw

Hay bale saws were a common agricultural tool. Ed Nolt, a Dutch resident of Pennsylvania, USA, invented the prototype for the small square baler back in the 1930s. His patent was purchased and mass produced during the 1940s. These balers quickly spread throughout the world and became a common agricultural machine. The hale bale saw was used to cut up the bales when distributing feed to livestock. As modern agricultural production has turned more to the use of large round bales, these small saws have become obsolete. This saw was used by a farmer in North Barnawatha approximately 18 kilometres from Wodonga, Victoria.This saw is representative of the agricultural tools in the mid to late 20th century.A metal saw with 2 wooden handles. The saw has a very coarse serrated edge. One of the handles is parallel to the blade, and the other handle is perpendicular to the blade.agricultural tools, hay bale saws, north east victoria -

Vision Australia

Vision AustraliaMachine - Object, Matrix Braille writer model G, circa 1968

Black box containing a Matrix Braille writing machine, with a paper spool attached to the feeding mechanism. The front portion of box is hinged and lifts up to reveal keyboard. Top half of box lifts to reveal Braille writer which is bolted to a wooden base that can be lifted out. The base is secured with a metal latch. Machine has black keys and the wooden case has black leather-like covering, hinged lid, metal clasps, and leather handle on the side. "Model G, Matrix, Coventry Gauge & Tool Company, Ltd., No. 792, For The Royal National Institute for the Blind, London W.I." is stamped on the front,Black vinyl-covered case containing black metal writer and paper spool"Model G, Matrix, Coventry Gauge & Tool Company, Ltd., No. 792, For The Royal National Institute for the Blind, London W.I." is stamped on the front.braille equipment, royal national institute for the blind -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionIncendiary machine

The Canadians developed a machine that used "ping pong balls" instead of cylindrical incendiary capsules and, in 1977, the FCV purchased a Premo machine for evaluation. The 32mm-diameter balls were made from high impact polystyrene and contained 3.5g of potassium permanganate. They were injected with 1ml of glycol which would ignite after a short delay The first Premo machine used four slipper blocks, which were loaded via a hand-operated hopper which, when rotated forward, the balls would be fed into four feed chutes to individual slipper blocks. Each slipper block has an opening allowing individual balls to enter and exit once injected. The original design of the machine was not suitable to meet the burning objectives and a number of modification were necessary. Following close inspection and field testing it was clear that utilising four slipper blocks was excessive and would generate too much fire. It was acknowledged that satisfactory spacing could be achieved by using just one slipper block. Selective spacing could be achieved by the speeding up or slowing down of the slipper block transferring the capsules during the injection process. Regulating the speed that the injected capsules were being dropped controlled the amount of fire created on the ground. This machine was the result of many years of experimentation at AltonaSignificant development of aerial incendiary machines enabled expansion of the fuel reduction burning program across Victoria.Aerial Incendiary machine for use in helicopters Modification at the Altona workshops over many years by Barry Marsden forests commission victoria (fcv), planned burning, bushfire, bushfire aviation -

Vision Australia

Vision AustraliaEquipment - Object, Pyke-Glauser Braille machine

... Edward Pyke and Jean Maurice Glauser invented this machine...Edward Pyke and Jean Maurice Glauser invented this machine ...Edward Pyke and Jean Maurice Glauser invented this machine with the intention of enabling the easy and quiet production of Interpoint Braille. Although widely agreed to be one of the best Braille machines of its time, production of the machines was stopped during the Second World War because of rationing and high material costs. The machine has a keyboard arrangement at one end, the other end folds out to form a platform which is held up by a metal strut with rubber capping. An upward writing model, the paper feeds from the rear and passes under the space bar. The machine has no paper feed rollers. The only movement is that of the carriage that moves from left to right.Painted metal machine with metal keys that move a carriage across inserted sheets of paperRoyal National Institute for the Blind 228 Great Portland St London W1 Pyke-Glauser Braille Writer PG 48braille equipment, royal national institute for the blind -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Sight Feed Type Water Depression Flowmeter, 1925

... Depression Gas Sectioned Slight Feed Anaesthetic machine Inscription ...This object dates back to 1925 and was sectioned by Dr Geoffrey Kaye in 1938. Flowmeters were attached to an anaesthetic machine to measure the flow rate of gas or liquid.Metal cylinder with glass inner chamber and gauge inside. The object has been sectioned for teaching purposes.Inscription on top screw valve. "K/38, Screw Lightly, Oxygen Fine." Inscription on back of top screw valve. "Direct Ox." Inscription on top of flowmeter tube. "G. Kaye fecit. 1938"flowmeter, water depression, gas, sectioned, slight feed, anaesthetic machine