Showing 385 items

matching glass manufacturing

-

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

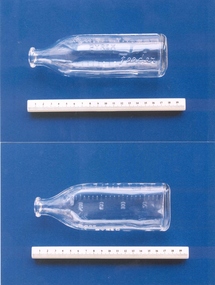

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Infant feeding bottle, 'Agee Pyrex Feeder', Crown Crystal Glass, c. 1961-63

... from the UK. In 1961, Crown Crystal Glass began manufacturing... the UK. In 1961, Crown Crystal Glass began manufacturing ...Crown Crystal Glass were an Australian glass manufacturer, who were the Australian vendors for Pyrex from 1926, importing from the UK. In 1961, Crown Crystal Glass began manufacturing their own Pyrex, under the name Agee Pyrex (until 1963), Crown Agee Pyrex (late 1960s), Crown Pyrex (1970s), Crown Ovenware (1970s) and Pyrex Ovenware (late 1970s until early 1980s). Source: That Retro Piece, 'PYREX | Australian', https://thatretropiece.com/collections/pyrex-australian "The use of pyrex bottles became more prevalent in Australia in the second half of the 20th century and baby’s bottles made of pyrex were popular as they were easily sterilised in the home environment." Source: Warrnambool and District Historical Society Inc., 'Bottle, The Perfect Agee Feeding Bottle, Mid 20th century', https://victoriancollections.net.au/items/592fe71ad0cdd520341b3954 Clear glass bottle tapering to a short narrow neck. Calibrations embossed on the glass in ounces (0-8) and mls (0-240). Embossed on the side: "Agee/PYREX/Feeder"."Agee/PYREX/Feeder"infant feeding, infant care -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Infant feeding bottle, 'Agee Pyrex Feeder', Crown Crystal Glass, c. 1961-63

... or juice to older infants. Crown Crystal Glass were an Australian... or juice to older infants. Crown Crystal Glass were an Australian ...Small feeding bottles were used to feed milk to newborns or juice to older infants. Crown Crystal Glass were an Australian glass manufacturer, who were the Australian vendors for Pyrex from 1926, importing from the UK. In 1961, Crown Crystal Glass began manufacturing their own Pyrex, under the name Agee Pyrex (until 1963), Crown Agee Pyrex (late 1960s), Crown Pyrex (1970s), Crown Ovenware (1970s) and Pyrex Ovenware (late 1970s until early 1980s). Source: That Retro Piece, 'PYREX | Australian', https://thatretropiece.com/collections/pyrex-australian "The use of pyrex bottles became more prevalent in Australia in the second half of the 20th century and baby’s bottles made of pyrex were popular as they were easily sterilised in the home environment." Source: Warrnambool and District Historical Society Inc., 'Bottle, The Perfect Agee Feeding Bottle, Mid 20th century', https://victoriancollections.net.au/items/592fe71ad0cdd520341b3954Small clear glass bottle with a short narrow neck. Imprinted with calibrations for ounces (0-4) and millilitres (0-120). Embossed on side of bottle: "Agee/ PYREX/ Feeder".infant feeding, infant care -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

... . Handmade glass bottle, manufactured in 1850's - 1900's. Glass... the bottles overboard. Handmade glass bottle, manufactured in 1850's ...This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, solid colour brown glass,concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. Label "c.1850's STUBBY ALE", "ENGLISH HAND MADE, CORK & WIRE SEAL", "PONTIL MARK ON BASE $6" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

... . Handmade glass bottle, manufactured in 1850's - 1900's. Glass... the bottles overboard. Handmade glass bottle, manufactured in 1850's ...This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020 The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, opaque brown glass, concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. "STUBBY 1850-1900 SMALL SIZE", ENGLISH 3 PIECE MOULD, HAND MADE TOP", "PAPER LABEL, CORK & WIRE SEAL $6flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyJar Glass - Mason's Patent, early 1900's

... in only specific manufacture to Glass Works that had paid... to Glass Works that had paid the manufacturing levy imposed ...This clear, light green, glass "hand blown" fruit preservation jar was used before the mass manufacturing of "screw topped" fruit preservation glass jars imported from Asia or great Britain. The "Mason's Patent" on the jar was for the screw-neck form of the jar top. The screw neck provided the jar with a vacuum seal (preservation) method of fruit jar storage. The reference on the jar of the actual date that the patent was established was in effect for 13 years with extension of a further 7 years. It was an American world wide patent which resulted in only specific manufacture to Glass Works that had paid the manufacturing levy imposed. The air bubbles in the glass suggests that this jar was "hand blown". This would then place the manufacture date before 1900. Preserves came in glass jars bought at the local grocery store or at a large city store on a shopping expedition. The shape of the jar changed as did the stopper used to seal it. Jars were recycled remaining the property of the manufacturer. History of Mason's.This fruit jar is significant to a rural area such as the Kiewa Valley and in the early 1900's when the preservation of fruit and vegetables was an intrinsic part of the typical rural farm/property family. Local shops could only supply fruit and vegetables as seasons permitted. The travelling "green grocer" was more prevalent in towns and cities but not in semi remote rural areas. Historical: Change of jars - shape, glass, stopper, embossing & use. Aesthetic: Display showing embossing & shape especially if in good condition.This vintage "Mason's Patent", screw on thread lid fruit jar was hand blown (air bubbles). It was produced for the home canning of local fruit. The jar is made from thick glass and is tinted light green. Clear glass jar with slight green tinge used for preserves. sides almost straight but jar has a slight bulge almost all the way to the top. Heavily embossed on 1 side. Horizontal print in large capital letters. At the top - manufacturer's name with emblem beneath it. The base has a slight bulge inwards with embossing.In a half ecliptical form "MASON'S" and underneath the Mason's logo.Under the logo "PATENT/ NOV 30 th / 1858". On the base "C201" (double molded).fruit and vegetable preserves, domestic fruit and vegetables bottling, off seasonal fruit and vegetable storage, jar, bottle, preserves, mason's preserves -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... This glass milk bottle was manufactured and used mid 1800's... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

... This glass milk bottle was manufactured and used mid... Centre 31 Bogong High Plains Rd Mt Beauty high-country This glass ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Wooden Trousers Hanger

... and joined with Barnet Glass & Sons Co. to manufacture waterproof... with Barnet Glass & Sons Co. to manufacture waterproof clothing; he ...Items such as this clothes hanger were widely used throughout Australia from the late 19th Century onwards. Francis (Frank) Stuart (1844-1910), manufacturer and politician, was born on 21 May 1844 at Penrith, New South. At 13 Frank was apprenticed to a Sydney draper. In 1866 he moved to Melbourne where Stuart joined the fashionable Collins Street mercery store of Alston & Brown. In 1884 he joined McIvor & Lincoln; on the death of the senior partner, Lincoln Stuart & Co., clothiers, was registered as a limited company in February 1889; when Lincoln retired, Stuart became sole proprietor. Among the business’ early success was a contract to supply uniforms to the New South Wales Sudan contingent. Stuart recognized possibilities in the rubber industry and joined with Barnet Glass & Sons Co. to manufacture waterproof clothing; he became a director of the company which was later taken over by Dunlop. Stuart was president (1885) of the Victorian Chamber of Manufactures and chairman (1887) of the Clothing and Manufacturers' Association. In April 1889 he was elected to the Victorian Legislative Assembly serving until 1894. In June 1904 he was returned to the Legislative Council as member for North Melbourne. He resigned in May 1907 to have more time for business. Frank Stuart died in 1910 and the business was carried on by his son Frank Jr. The company was taken over by John Snow & Co. Ltd in 1926, but continued to trade under Lincoln Stuart & Co. until it was finally deregistered in 1994.This item is representative of a range of clothing items and accessories popular throughout Australia and provided by a renowned Australian clothier. A wooden, leather and metal trouser hanger. It is inscribed with information about the manufacturer on both sides. it is made of two lengths of wood, connected by a leather strap and a metal buckle.Side 1: Lincoln Stuart & Co. Pty. Ltd. Wholesale and Retail Clothier Side 2: Flinders St. Melbourne Made in Germanydomestic appliances, lincoln stuart & co. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCap Liner, Between 1870 and 1908

... . These round, coarse-glass inserts formed part of the screw lids used... produced by a number of glass manufacturing companies ...This Zinc Cap Porcelain Liner was recovered from the (1908) shipwreck site of the FALLS OF HALLADALE. The purpose of cap liners was to assist with the safe preserving and storage of perishable foodstuffs in an age when refrigeration was generally unavailable. These round, coarse-glass inserts formed part of the screw lids used with the Ball Mason style of canning fruit jars. The liner was placed inside the zinc cap to stop the contents of the jar reacting with the zinc. It prevented the metallic tainting of food as well as the corrosion of the metallic lid. On March 30, 1869, Lewis R Boyd was issued with patent # 88439 for an “Improved Mode of Preventing Corrosion in Metallic Caps”. From the 1870s to the 1950s, large quantities of these liners were produced by a number of glass manufacturing companies. They are consequently difficult to date or identify. “It is assumed that most of the earlier versions of these liners have the name ‘BOYD’S’ or ‘BOYD’ embossed on them. Later versions may or may not have the name included in the lettering”. (http://www.glassbottlemarks.com). Only a few were made of porcelain, the great majority being made first of transparent and later of translucent or opaque glass. The different emblems of triangles, circles, and crosses embossed on the front face of the liners are assumed to signify mould or model types rather than the company that produced them. This particular artefact is one of 14 cap liners that were retrieved from the shipwreck site and are now part of the Flagstaff Hill Maritime Village collection. The Maltese Cross and “BOYD’S GENUINE PORCELAIN LINED” lettering are unique to this piece. However, it is evident from the markings and materials of the other cap liners, that they originally formed sets or series. Six are larger (8 mm depth x 85mm diameter), of greenish hue with ground glass texture, and support the raised emblem of a compass needle. Two are medium-sized (75mm diameter) with two raised dots in a central circle and the lettering “Patd. APR 25.82”. This particular cap liner is likely to have also been one of a mass-produced line being imported from America. The iron-hulled sailing ship FALLS OF HALLADALE was a bulk carrier of general cargo en route from New York to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. The FALLS OF HALLADALE came aground on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in1908-09 and 1910. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., they standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976). A circular translucent glass disc in good condition with raised upper case lettering around 8mm rim – “BOYD’S GENUINE PORCELAIN LINED” - and a raised central emblem of a Maltese Cross. On the reverse face in the centre of the disc, there is a raised numeral “3”. falls of halladale, wright, breakenridge & co of glasgow, unusual beautiful green american slates (roofing tiles), warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, zinc cap porcelain liner, boyd’s genuine porcelain lined, glass lid, opaque disc, food preserving, fruit bottling, cap liner, shipwrecked coast, flagstaff hill maritime museum, shipwreck artefact, 1908 shipwreck -

Orbost & District Historical Society

Orbost & District Historical Societybottle, Pre 1970's

Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips and Stone continued to manufacture soft drinks at Orbost until the early 1970's when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of a carpark. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass bottle with a screw thread top. The label and print ( in upper case) are white.Front- Refreshing Drinks Back-Manufactured by Phillips & Stone Base-1121 P&S Bairnsdale and Orbost Ask for Phillips and Stone Artificially Coloured & Flavoured Net Contents 30 fld ozscontainer beverage bottle phillips-and-stone -

Orbost & District Historical Society

Orbost & District Historical Societyjar, late 1800's

... by an early Australian food manufacturing industry. glass jar jonathon ...This item is an example of a glass food container used by an early Australian food manufacturing industry.A wide necked clear glass jar. It is seamed and has a circle on the base. There are some manufacturing signs near the bottom.In a diagonal banner across the glass - JONATHON REEVE PTY LTDglass jar jonathon-reeve food pickles-condiments -

Orbost & District Historical Society

Orbost & District Historical Societybottle, before 1975

Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips and Stone continued to manufacture soft drinks at Orbost until the early 1970's when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of a carpark. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass bottle with a metal screw cap. on the front is a painted red and white label. It contained lemonade.Lid - Lemonade Base - AGM M 6 inside a circle 9 Front - 30 fl ozs Back - Manufactured by Preservative added M21 A1 P & S Phillips and Stone 28 flavour LOK Ask for Bairnsdale and Orbost Phillips and Stone Preservative added Refreshing drinks Artificially coloured and flavoured Bairnsdale and Orbost bottle phillips-and-stone beverage lemonade container -

Orbost & District Historical Society

Orbost & District Historical Societybottle, after 1929

Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufactured by a local industry which no longer exists.A clear glass bottle which has a broken top. The bottle is seamed.Base - AGM F516 Front (written sideways) - A DROSSOU ORBOST Bottom (written around whole bottle) This bottle is the property of A Drossou Orbost M bottle drossou container soft-drink -

Orbost & District Historical Society

Orbost & District Historical Societybottle, 1930's

Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufactured by a local industry which no longer exists.A clear glass soft drink bottle with a crown seal top. The bottle is seamed.A DROSSOU ORBOST This bottle is the property of A DROSSOU ORBOST Base - AGM F 860 Mbottle container drossou -

Orbost & District Historical Society

Orbost & District Historical Societybottle, D. Drossou, 1930's

Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips and Stone continued to manufacture soft drinks at Orbost until the early 1970's when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of a carpark. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass cylindrical bottle with a tapered neck.D. DROSSOU ORBOSTbottle drossou orbost-cordial-factory food beverages -

Orbost & District Historical Society

Orbost & District Historical Societyink bottle, early 20th century from mid 1930's

An ink bottle was made of glass or ceramic and typically sat on a desk. The writer would dip the pen (or quill) into the bottle to put more ink on the pen. Because they sat on a desk, ink bottles were often decorative. 'Stephens' Ink' was invented by the British physician, Dr Henry Stephens (1796-1864), who in 1832 first developed his indelible "blue-black writing fluid" that became the basis of a successful manufacturing enterprise lasting over 130 years. Stephens' ink revolutionised office life in the latter half of the 19th century saving clerical workers much time previously spent mixing powdered inks and cleaning nibs. It was indelible and non-fading. After changes to the Australian import duties on inks, a local manufacturing works was established in the early 1930s by Stephens Inks (Australia) Ltd.We have mostly dispensed with ink bottles and quills. This item is an example of early stationery equipment commonly used in schools, households and commercial enterprises. A cylindrical brown glazed ceramic bottle with a pourer lip. This would have contained ink and had a cork seal. It would have had a paper label.Near base - This bottle is the property of Stephens' Inks Aust. Ltdcontainer ceramic stephens'-inks writing-equipment communication bottle stationery -

Orbost & District Historical Society

Orbost & District Historical Societybottle, late 19th -early 20th century

... in bottle manufacturing. bottle glass push-up-base kick-up-base punt ...This type of recessed base was commonly pronounced on wine, champagne or spirits bottles. Possibly done for bottle strengthening and stability. The push-up recess used to be formed by physically pushing upwards in the centre of the base with a tool while the glass was still hot and pliable.Glass objects generally include a wide range of shapes and colours with bottles and jars used for alcohol. This bottle is an example of a specific type of base used in bottle manufacturing.Tall brown glass bottle with recessed base. This bottle has a "push-up" or "kick-up" base. bottle glass push-up-base kick-up-base punt -

Orbost & District Historical Society

Orbost & District Historical Societybottle, first half 20th century

... gippsland This bottle reflects the developments in glass manufacture ...This bottle reflects the developments in glass manufacture during the first half of the 20th century.There is an aesthetic element, the shapes, colour and textures of the bottle are visually appealing.Green glass bottle with cork.Six sided straight sides.On base J 4bottle glass six-sided-bottle -

Orbost & District Historical Society

Orbost & District Historical Societybottle, D. Drossou

Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufacture by a local industry no longer existing.Drossou lemonade bottle. Large bottle tinted light blue.Front - D. Drossou, Orbost Bottom G938, 647drossou bottle glass lemonade-bottle -

Orbost & District Historical Society

Orbost & District Historical Societybottle, late 19th century

... an earlier stage of development in glass manufacturing. bottle glass ...This bottles is aesthetically pleasing and reflects an earlier stage of development in glass manufacturing.Very long, thin, green tinged bottle with spiralling glass neck. Contained salad oil.bottle glass container -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Washboard, 1900-1930

A washboard is a tool designed for hand washing clothing that are soaked in hot soapy water in a wash tub or sink, then squeezed and rubbed against the ridged surface of the washboard to force the cleaning fluid through the cloth to carry away dirt. With the invent of mechanized cleaning of clothing becoming more common by with the use of washing machines by the end of the 20th century the washboard was soon discontinued. The traditional washboard is usually constructed with a rectangular wooden frame in which are mounted a series of ridges or corrugations for the clothing to be rubbed upon. For 19th-century washboards, the ridges were often of wood, sometimes glass and by the 20th century, ridges of metal became common The first "fluted" metal washboard was patented in the United States by Stephen Rust in 1833 and Zinc washboards were predominantly manufactured in the United States from the middle of the 19th century. A significant item for cleaning clothes still in use today in many countries giving a snapshot into the domestic life of a housewife into the 20th century.Washboard wooden frame with a ribbed glass sectionNonewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, washboard, glass ripples, clothes cleaning, washing, laundry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Glass Jar, F H Faulding

Most surgical wounds are closed primarily, but some are allowed to heal by secondary intention. This usually involves repeated packing and dressing of the raw wound surfaces. Although the long-term care of such wounds has devolved to the care of nurses in the community or out-patient setting, the initial wound dressing or cavity packing is done by the surgeon in the operating theatre. Many surgeons are unaware of the growth of the discipline of wound care, and still use traditional soaked gauze for dressing and packing open surgical wounds and cavities. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1963638/ The control of bleeding and wound management is vitally important for the survival of the patient.Clear glass round jar and lid, with heavy metal screw turning. Contains 12 yards of 1/2 unmedicated absorbent ribbon gauze.Manufactured in England for F H Faulding & Co Ltd. Absorbent Ribbon Gauze. Green Cross. Unmedicated. 12 yards. ½ inch.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, medical, ribbon gauze, faulding -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBarometer, 1858-1869

The barometer was either made or sold by T. Gaunt & Co. of Melbourne, a manufacturer, importer and retailer of a wide variety of goods including jewellery, clocks and watches, navigational and measuring instruments, dinnerware, glassware and ornaments. Thomas Gaunt photograph was included in an album of security identity portraits of members of the Victorian Court, Centennial International Exhibition, Melbourne, 1888. (See below for further details.) Admiral Fitzroy Pattern Barometer History: The stick mercury barometer was named after Admiral Robert Fitzroy of the Royal Navy (1805-1865) for his detailed instructions on how to interpret the weather, which were included with the instrument. Fitzroy was the captain of the HMS Beagle, also a weather forecaster to Charles Darwin and the second Governor of New Zealand. He developed many different types of barometers and was the first person to introduce the science of weather forecasting to the British Isles. A local manufacturer of scientific instruments, Thomas Gaunt, produced the barometer that was adapted for the southern hemisphere by Robert Ellery, the State Astronomer based at the Melbourne Observatory. In the original sale catalogue for Gaunt's, the item is described as "Gaunt's Fitzroy Barometers" and it was priced from 25/- to ₤9.9s. History of Thomas Gaunt: Thomas Gaunt established Melbourne's leading watchmaking, optical and jewellery business during the second half of the 19th century. Gaunt arrived in Melbourne in 1852, and by 1858 had established his own business at 14 Little Bourke Street. Around 1869 he moved to new premises in Bourke Street on the corner of Royal Arcade. Gaunt's shop quickly became a Melbourne institution. Gaunt proudly advertised that he was 'The only watch manufacturer in the Australian colonies'. While many watches and clocks may have had Gaunt's name on the dial, few would have been made locally. Gaunt did make some watches for exhibitions, and perhaps a few expensive watches for wealthy individuals. Gaunt's received a telegraph signal from Melbourne Observatory each day to correct his main clock and used this signal to rate and repair ship's chronometers and good quality watches. His main horological manufacturing was directed at turret clocks for town halls, churches and post offices. These tended to be specific commissions requiring individualised design and construction. He made the clock for the Melbourne Post Office lobby, to a design by Government Astronomer Robert Ellery, and won an award at the 1880-81 Melbourne International Exhibition for his turret clock for the Emerald Hill Town Hall. He became well known for his installation of a chronograph at Flemington Racecourse in 1876, which showed the time for the race, accurate to a quarter of a second. The firm also installed the clockwork and figures for Gog and Magog in the Royal Arcade. Thomas Gaunt also developed a department that focused on scientific instrumentation, making thermometers and barometers (from imported glass tubes), telescopes, surveying instruments and microscopes. Another department specialised in electroplating for trophies, awards and silverware, and the firm manufactured large amounts of ecclesiastical gold ware and silverware, for the church including St Patrick's Cathedral. There are no records that disclose the number of employees in the firm, but it was large enough for Gaunt to hold an annual picnic for the watchmakers and apprentices at Mordialloc from 1876; two years previously they had successfully lobbied Gaunt to win the eight hour day. Gaunt's workforce was reportedly very stable, with many workers remaining in the business for 15 to 30 years. Gaunt's wife Jane died on September 1894, aged 64. They had one son and six daughters, but only three daughters survived to adulthood. Two became nuns at the Abbotsford Convent and one daughter, Cecelia Mary Gaunt (died 28 July 1941), married William Stanislaus Spillane on 22 September 1886 and had a large family. Gaunt died at his home in Coburg, Victoria, leaving an estate valued at ₤41,453. The business continued as T. Gaunt & Co. after his death. The barometer is historically significant as an example of the work of Melbourne’s leading scientific instrument maker, Thomas Gaunt. The barometer has social significance as an example of the type of scientific equipment that Thomas Gaunt expanded his horology business into producing. Further social significance lies in the fact that Robert Ellery, the Government Astronomer who designed the local version of the barometer, had a direct connection with the Melbourne Athenaeum founded in 1839 as the Melbourne Mechanics' Institution. Its purpose was "the diffusion of literary, scientific and other useful information". There are also records of a T Gaunt as a subscription and committee member of this the Athenaeum organisation during the 1870s and 1880s which may be Thomas Gaunt, unfortunately still unverified.Stick mercury barometer known as the Admiral Fitzroy Barometer. It comprises an oblong wooden case with glass front panel, ornate pediment, barometer with bulb cistern (empty of fluid), cleaning brush with printed instructions for interpreting information given by the gauge affixed to left and right face of instrument. Includes a thermometer. The barometer appears to be intact. Adapted to the Southern Hemisphere. Special remarks by Admiral Fitzroy. Made by Thomas Gaunt, Melbourne. Manufacturer's details are on back of wooden casing. Rear has upper and lower brass screw plates for securing to vertical surface."Manufactured by Thomas Gaunt, 14 Little Bourke Street, Melbourne. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, barometer, admiral fitzroy, thomas gaunt, thomas gaunt of melbourne, clockmaker, admiral fitzroy barometer, barometer instructions, gaunt’s fitzroy barometer, gaunt’s of melbourne, gog and magog designer, horological manufacturer, meteorological instrument, melbourne athenaeum, melbourne mechanics' institution, melbourne observatory time signal, robert ellery government astronomer, scientific instrument, stick mercury barometer, thermometer, weather forecast, t gaunt & co