Showing 50 items

matching grain mill

-

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Horse drawn wagons loaded with bagged Grain

Black and white photograph of Stawell Flour Mill owned by Frayne family for many years. Photograph copied from "Stawell & The Grampians " booklet p32. Published 1911 (Cat no 3580 m/box 3 room 2).Wooden 3 storey building verandah and wooden paling fence. stawell industry -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Grain Handling Corp -- Old Wimmera Flour Mill 1970 -- Coloured

... Coloured photo. Flour Mill is now Grain Handling... grampians Colour photo of Grain Handling Corp old Flour Mill 1970's ...Colour photo of Grain Handling Corp old Flour Mill 1970'sColoured photo. Flour Mill is now Grain Handling Corporation. Two vehicles parked at front of building; small white building nearest railway with 2 solos. Demolition begins roof removed.Grain Handling Corporation Pty. Ltd. Crown Beef Co.stawell industry -

Stawell Historical Society Inc

Stawell Historical Society IncNewspaper, Two Newspaper Articles in the Stawell Times News 1988 about the Demolition of the Flour Mill plus 4 colour photographs

Two Newspaper Cuttings Stawell Times News, September 30, 1988. The newspaper cutting show the demolition of old flour mill with views of the building from the front and back. The four colour photographs 139 c, d, e, f, show detail of the internal rooms being demolished.Black & white demolition photos 139 a and b from Stawell Times News. Four colour photographs 139 c - f of internal rooms being demolished. The Grain Handling Corporation PTY LTD Crown Beef Co. Page 2 Stawell Time-News Friday September 30, 1988.stawell industry -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Wimmera Flour Mill with horse drawn wagons loaded with wheat -- 2 B/W Photos

Photos of horse drawn wagons loaded with wheat in front of Wimmera Flour Mill. Railway trucks in front of mill. William Frayne built and owned the mill (181-01). This photograph was taken near the railway station. Rail trucks indicate late 1870's, railway opened 1876.Two black and white photos of horses with loaded wagons. In the first photo there are 4 men and many loaded wagons in front of the wooden three-story mill. In the second photo there are six horses pulling a loaded wagon with bagged grain and driver seated on the load. stawell business industry farming -

Stawell Historical Society Inc

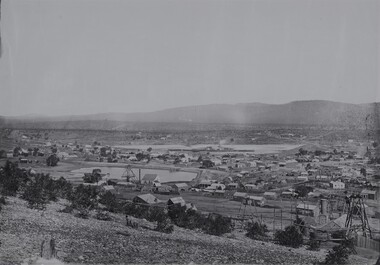

Stawell Historical Society IncPhotograph, View of Stawell from Big Hill 1874 showing mines looking towards South end of Black range -- 4 Photos

Visible Nelsons Criterion Hotel, Wimmera Crushing Mill, Odd Fellows Arms hotel, F.H. Oliver & Co Grain Merchant, Reefs Restaurant.Holtermann Black and White photograph of Stawell from Big Hill with mining in foreground. April 1874. Wimmera Crushing Mill and settling pond at centre of photograph. Stawell water supply centre left of photo. Black Range in Background.mining, panorama -

Friends of Westgarthtown

Friends of WestgarthtownHook, bag

... to lift heavy bags of wheat, and milled grains such as bran ...One of the original bag hooks used on the farm at Ziebell’sHessian bags were used pre 1970 and bag hooks were used to lift heavy bags of wheat, and milled grains such as bran and pollardSmall instrument for hanging and moving bags, bifurcated hook with wood handlerural industry, agriculture, hook, farming, transportation, tool -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillMachine - Auger, wood

Augers were used in processing the grain, however this wooden auger is possibly a pattern for a cast metal auger.A long piece of hexagonal wood with a descending spiral of square wooden blades. On the top it has a circular piece of wood -

Parks Victoria - Andersons Mill

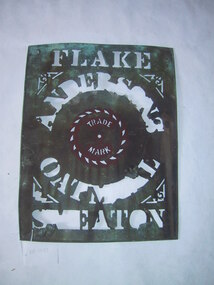

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.Rectangular copper stencil plate, ribbed edging; Anderson's Mill trademark (circular saw) in centre; some lettering is difficult to read due to corrosion / breaking of this section; some green surface corrosion; red paint around central trademark saw and lettering."FLAKE / ANDERSON'S / OAT MEAL / SMEATON" -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.Rounded trapezoidal shape, metal, letters stamped out. Hole bottom RH corner."A PAT / KINGSTON" -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.(approx) Rectangular metal stencil for oat or flour bag; rectangular section has been cut away from top LH corner, triangular section has been cut away from top RH corner; significant surface rusting; one letter of the stencil marking (letter R) has been covered over with a rectangular metal piece soldered onto stencil surface."SGC (R) / PORT SWETTENHAM" -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.Metal stencil (steel), rusty rectangular shape, corners cut off. Lettering surrounded with blue paint. Square hole top RH corner."BMTC / PENANG" -

Parks Victoria - Andersons Mill

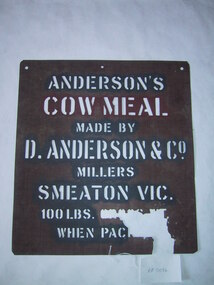

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.Rectangular, brown, vinyl type material. Lettering: Andersons (blue) Cow Meal (red) Made by D. Anderson & Co Millers, Smeaton Vic, 100lbs, when Pac" (all blue) Some lettering broken bottom right."ANDERSONS / COW MEAL / MADE BY / D. ANDERSON & CO / MILLERS / SMEATON VIC / 100 LBS / WHEN PAC" -

Parks Victoria - Andersons Mill

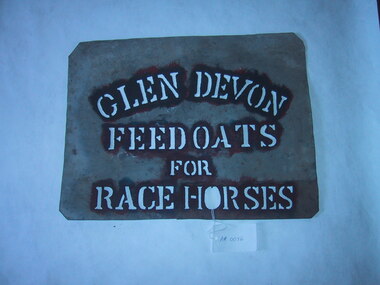

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain. Paint applied to stencil in the 1980;s for use on an interpretation display board.Rectangular, galvanised iron stencil for oat bag; small section cut away from each corner; bottom R corner cut-out and replaced with new stencil (Lettering 'Horses'), soldered on from behind main sheet. GLEN DEVON lettering surrounded by red paint, then later with blue paint.; red paint around other lettering (feed oats for racehorses)"GLEN DEVON / FEED OATS / FOR / RACE HORSES" -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.Rectangular; two pieces of iron welded together. Extensive rusting. Letters ANK 299 inside trapezoidal pattern. Kuala Lumpur cut out along bottom of stencil."ANK 299 / KUALA LUMPUR" -

Parks Victoria - Andersons Mill

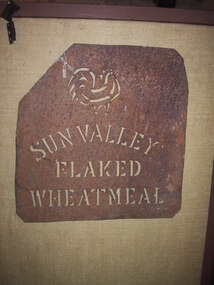

Parks Victoria - Andersons MillSign - Stencil

This stencil was used on bags and possibly other packaging containing grain processed and packed at Anderson's Mill. The stencil would have indicated the destination of, or origin of the grain.Large stencil, metal (tin?). 3 corners of stencil chipped off at angle. Large piece of corner missing from top left.Cut out of stencil depicts cockerel & the words "SUNVALLEY FLAKED WHEATMEAL" -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillVehicle - Trolley, bag

This is a bag trolley that was used to transport large bags of grain or other items at the mill.Wooden frame of trolley, with vertical handles with three stabilising cross bars. Base of trolley has a curved metal part. This mounted on two small metal wheels. -

Mont De Lancey

Mont De LanceyTool - Saw, Simond Steel and saw Co, Crosscut Saw, Unknown

Used in the 19th century.A forged steel narrow bladed double Peg and Rake toothed crosscut saw with no handles. It was used to saw rough wood or cross cut wood against the grain in the late 19th Century.Stamped on the saw: made of Simond Steel, Trade mark Reg. Warranted The Simond Saw Est 1832, Simond Steel & Saw co USA. Crescent Ground Steel Mill, Lockport New York. Factories Fitchburg Mass, Montreal Quebec No 325hand tools, woodworking tools, carpentry tools, steel, hand saws, saws, cutting tools, crosscut saws -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph, Charlton Shire, Charlton Flour Mill, c.1987

A previous mill had operated in Charlton by Mr. W.E. Foreman on the banks of the Avoca River and was acquired in 1919 by Noske Bros. The present Flour Mill was built by Noske Bros and opened in May 1927. It was taken over by the Grain Elevator Board in the 1970s. Colour photograph of Charlton Flour Mill and silos. Intersection of Kaye & Davies Streets in the foreground. One large silver silo and three taller greyish concrete silos to the left. Three other cream coloured silos behind. There are pipes and sheds on top of the silos. There is a cream single story building to the right of the silver silo and a multi-storey building behind with eight window in the upper level. There is a small red brick building on the far left of the photo.w.e. foreman, noske bros, flour mill charlton, business, industry