Showing 41 items matching "handpiece"

-

National Wool Museum

National Wool MuseumShearing Handpiece

Wolseley, No.7 5591 N shearing handpiece with original parts and handgrip c.1916-1930's. 'N' indicates long one piece bush instead of shot pressed bush and shot bush.Wolseley. No.7 5591 N Wolseley No. 3 Wolseley Hardenedshearing -

Cheese World Museum

Cheese World MuseumTelephone

Dovetailed wooden case of walnut colour. Telephone with bakelite mouthpiece attached to the front with four screws and a metal plate keyhole to the left. A bakelite handpiece with a black and white cord attached to the left hand side.The phone box with two bells attached to the top is joined to a backboard. A winder is on the right hand side. "Workings",including magnets, intact inside the box.EB L1 L2 BATT printed on the edge inside the box.uebergang, allansford, furniture domestic, communication, telephones -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

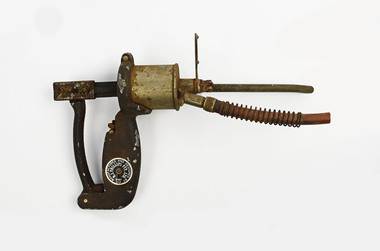

NJ Phillips was the first Australian company to invent a drench gun that overcame the problem of drench going the 'wrong way' down the throat and onto a sheep’s lungs. This was the drench gun that they developed. It had an ingenious double action on the handpiece. The first squeeze projected a long nozzle that went right down the oesophagus before delivering the dose of drench automatically once this was in place. It also had a readily adjusted dose lever seen at left which minimised overdosing. This company dominated the market for many yearsSilver metal with black finishing drench gun. Minimal curvature tips on gun protrude from the body. Features a thin squeezable trigger to the rear of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney” in circular design. On top of this body is a large silver chamber in which both tips meet. This chamber is for the liquid to be transferred from the tube and into the tip of the drench gun for delivery onto the ewe’s tongue. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.Right circular lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

Orbost & District Historical Society

Orbost & District Historical Societytelephone, L M ERICSSON & CO, c. 1901

A wall phone used in the early 20th Century in Australia, this one in the Orbost district.A wall-mounted telephone with a handpiece connected by a cord to the left hand side of the main box. On the right hand side is a winder. Near the top of the box are two round silver gongs which make the ringing sound of the phone call. The box is mostly made of wood, with the front-bottom section with a metal facing which is able to be opened to reveal the mechanism behind (including the battery). The phone has a wooden writing slope attached to the front. On the front of the metal section of the box are the words L M ERICSSON & CO trade mark STOCKHOLM. L M ERICSSON & CO TRADE MARK STOCKHOLMtelephone-communication wall-phone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1904-1930s

This Sharpe Bros. one gallon stoneware Demijohn is in excellent condition and includes its original stopper. It was made between 1904 and 1930, the date from the patent of the handle until the time that the factory no long produced returnable items. The bottle was once part of Dr W.R. Angus' household and is part of the W.R. Angus Collection and could have been purchased from Warrnambool's Sharpe Bros. factory. SHARPE BROS. 1903-1972- The first Sharpe Bros. cordial factory was opened in Dunedin, New Zealand, in 1903 by English prohibition brothers John and Percy Sharpe. Sharpe Bros. made ‘health’ beverages that were non-alcoholic drinks such as ginger beer, ginger ale, lime juice, soda and cordials. The containers of these drinks were not sold with the drinks but were marked as returnable items, to be cleaned and re-used, until this practice ceased in the 1930s. Sharpe Bros. made a niche in the soft drink market by delivering drinks by horse and cart to its customers’ homes. John Sharpe patented the unique wire spiral handle in 1904. By 1905 the New Zealand company also had factories in Australia. By 1910 the company had over 20 factories including Wanganui, New Zealand; Adelaide, Albury, Ballarat, Bathurst, Forbes, Geelong, Goulburn, Lithgow, Melbourne, Newcastle, Orange, Sydney, Tamworth, Warrnambool and Wollongong. The Warrnambool factory was established in 1919 and existed until 1951. The company won awards at Australian exhibitions for its carbonated drinks, including First Prize for its ginger beer made in the Brisbane factory. The company was taken over in 1962 by Tarax Drinks Holdings Ltd, which was in turn taken over by Cadbury Schweppes in 1972. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This stoneware Demijohn is connected to the history of Warrnambool, as it was owned by the daughter of Dr W. R. Angus and his wife Gladys. It is part of the W.R. Angus Collection, which is notable for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. It is also connected through its manufacturer Sharpe Bros. which had a branch in Warrnambool from 1919 to 1951, overlapping the time when the Angus family resided there from 1939 to the 1970s. The bottle is also significant as an example of the early-20th-century beverages found in local households and could have been purchased from the local Sharpe Bros. factory.This stoneware Demijohn is glazed, with a brown neck with internal thread and shoulders and a cylindrical cream base. The one gallon bottle has a flat, black stopper with a cork stem and a rubber, threaded tip. The ‘U’ shaped wire carry handle has a spiral of wire around the handpiece. An overhanging lip is on top of the bottle’s short neck above its rounded shoulder. The clay has been joined at the base of the neck, shoulder and body. The underneath is unglazed. The brown glazing on the shoulder has a run mark. Inscriptions are on the stopper and bottle. This container is part of the W.R. Angus Collection.Stamped in black on the shoulder: “KEEP THE / STOPPER TIGHT” Stamped in black on the body: “THIS JAR IS THE ABSOLUTE PROPERTY OF AND MUST BE RETURNED TO SHARPE BROS. AUSTRALIA / & NEW ZEALAND. ORIGINAL & LARGEST HYGIENIC BREWERY. CAUTION Persons Damaging, Willfully Retaining, Trading with or Misappropriating the Use of this Jar WILL BE PROSECUTED “ Stamped in script writing: “Sharpe Bros. TRADE - - - ED “ Embossed on the stopper: “AUSTRALIA AND NEW ZEALAND, SHARPE BROS.”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, sharpe bros., bendigo pottery, bottle, stoneware bottle, demihohn, one gallone bottle, soft drink, non-alcoholic drink, drink container, jar, jug, warrnambool soft drink, hygienic brewery, cordial factory, new zealand, australia, john sharpe, percy sharpe, non-alcoholic, spiral wire handle, ginger beer, w.r. angus collection, demijohn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

National Wool Museum

National Wool MuseumShearing Handpiece

Lister 147473 -

National Wool Museum

National Wool MuseumShearing Handpiece

Golden Lister -

National Wool Museum

National Wool MuseumShearing Handpiece

Used by 'fake' shearer in Gallery 1.Golden Lister -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchInstrument - Handpiece - Telephone Set TA-1/PT