Showing 36 items matching "internal combustion"

-

Puffing Billy Railway

Puffing Billy RailwayBlackstone Oil Engine, 6 November 1908

... or heavy-oil engine) is a type of internal combustion engine... engine (also hotbulb or heavy-oil engine) is a type of internal ...8HP Blackstone Lamps Start Oil Engine engine number 71076 Engine Details Maximum operating RPM of 240. Fitted with a 3'9" Flywheel Tested on the 6th of November 1908. Shipped to Cluter buck South Australia for installation on concrete base. Recovered and restored during the 80's in South Australia Purchased privately in 2013 in Tailem Bend South Australia and transported to Victoria. Currently on loan to the Puffing Billy Museum at Menzies Creek as an operating exhibit. Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom. In 1896 they built lamp start oil engines. The Lamp or hot-bulb engine (also hotbulb or heavy-oil engine) is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine. Most hot-bulb engines were produced as one-cylinder, low-speed two-stroke crankcase scavenged units Historic - Industrial - single cylinder, horizontal, 4 stroke, hot-bulb ignition oil engine Blackstone 8HP Oil Engine made from steel, wrought iron and brassOval Plate with Black Stones and Clutter Buck Brass Plaque engine number 71076blackstone, oil engine, clutter buck, black stone, puffing billy, hit and miss, engine, blackstone & co -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

... and efficient than internal combustion engines, required operators... their boilers, but they were less convenient and efficient than internal ...Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

Puffing Billy Railway

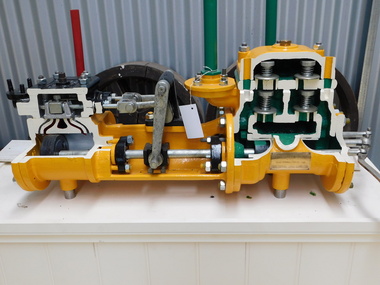

Puffing Billy RailwaySectioned Tangye Steam Operated Water Pump, 1900s

... production of internal combustion stationary engines based on Horace... production of internal combustion stationary engines based on Horace ...Sectioned steam pump so that the pump workings can be seen. Inscriptions & Markings: Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque) The Colonial Gas Association was originally formed in London on 2 February 1888, as The Australasian Gas Association Limited. The primary objective of the company was to provide investment capital to help finance the construction and management of gasworks being established by the London engineering firm John Coates & Co in metropolitan cities and regional towns throughout Australia and New Zealand. By 1890, the Australasian Gas Association had acquired gasworks at Benalla, Shepparton, Wangaratta, Warragul, Maldon and Seymour, and had constructed a large gasworks at Box Hill to supply the eastern suburbs of Melbourne. In 1893, the company's name was changed to the Colonial Gas Association Limited. During the 1890s, the company acquired regional gasworks in Queensland, Western Australia and South Australia, followed by its first gasworks in New South Wales, in 1911. In 1914, the company consolidated its metropolitan supply area by purchasing the Oakleigh and Footscray gasworks. Further expansion occurred in the 1920s with the purchase of established gasworks at Williamstown, Frankston and Dandenong and the acquisition of ten further gas undertakings in Queensland and New South Wales, making the firm the fifth largest gas producer in Australia. info from The Colonial Gas Association Limited, circa 1893 https://collections.museumvictoria.com.au/items/1553322 Originally formed by the five Tangye brothers from Cornwall as James Tangye & Brothers in 1857, this Birmingham engineering firm grew to become one of the largest suppliers of jacks, pumps, steam and oil engines, hydraulic presses, gas producers and machine tools in the late 19th and early 20th centuries. The successful sideways launching of I.K. Brunel's 'Great Eastern' from the mud of the Thames in 1857 using Tangyes hydraulic jacks gave the firm much needed publicity and new orders flowed in. To finance expansion, George Price provided additional capital and the company name became Tangye Brothers & Price in 1859. A new factory known as the 'Cornwall Works' was built in Clement Street, Birmingham. In 1872, the firm became Tangye Brothers and in about 1879- 1880 began production of internal combustion stationary engines based on Horace Robinson's patents, later using the Otto four-stroke design for its Soho range of gas engines. Examples of the Soho engine were exhibited by the firm at the 1880 Melbourne International Exhibition. Petrol and oil engines were made from the 1890s onward, and by 1910 had developed into the Model B, BR and AA series engines. Tangyes supplied custom-built pumps and presses for particular applications, becoming a major exporter of engineering equipment. In 1884, Tangye Brothers opened a custom-built branch office, showroom and warehouse in Melbourne at Cornwall House in Collins Street West, advertising the full range of engineering products. These lantern slides images are taken from Tangyes product catalogues from the 1910-1925 period and are believed to have been used as sales promotional aids in Australia by the Tangye Brothers. info from https://collections.museumvictoria.com.au/articles/4670 Historic - Industrial Steam Operated Water Pump built by Tangye Bros and used by the Colonial Gas Company - Melbourne, Victoria, AustraliaSectioned steam pump so that the pump workings can be seen. Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque)puffing billy, steam pump, sectioned, tangye bros -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Iron

Before the introduction of electricity, irons were heated by combustion, either in a fire or with some internal arrangement. An "electric flatiron" was invented by American Henry Seely White and patented on June 6, 1882. It weighed almost 15 pounds (6.8 kg) and took a long time to heat. The UK Electricity Association is reported to have said that an electric iron with a carbon arc appeared in France in 1880, but this is considered doubtful. Two of the oldest sorts of iron were either containers filled with a burning substance, or solid lumps of metal which could be heated directly. Metal pans filled with hot coals were used for smoothing fabrics in China in the 1st century BC. A later design consisted of an iron box which could be filled with hot coals, which had to be periodically aerated by attaching a bellows. In the late nineteenth and early twentieth centuries, there were many irons in use that were heated by fuels such as kerosene, ethanol, whale oil, natural gas, carbide gas (acetylene, as with carbide lamps), or even gasoline. Some houses were equipped with a system of pipes for distributing natural gas or carbide gas to different rooms in order to operate appliances such as irons, in addition to lights. Despite the risk of fire, liquid-fuel irons were sold in U.S. rural areas up through World War II. In Kerala in India, burning coconut shells were used instead of charcoal, as they have a similar heating capacity. This method is still in use as a backup device, since power outages are frequent. Other box irons had heated metal inserts instead of hot coals. From the 17th century, sadirons or sad irons (from Middle English "sad", meaning "solid", used in English through the 1800s[4]) began to be used. They were thick slabs of cast iron, triangular and with a handle, heated in a fire or on a stove. These were also called flat irons. A laundry worker would employ a cluster of solid irons that were heated from a single source: As the iron currently in use cooled down, it could be quickly replaced by a hot one. https://en.wikipedia.org/wiki/Clothes_ironThis iron is typical of the clothes iron used before electric irons superseded it.Salter iron no. 6, painted black but with rust showing through. Salter iron no. 6.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, iron, clothes, laundry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Match Safe, after 1830's

This match safe was amongst various items collected from a sea dive in Port Phillip Bay. The diver was the caretaker of the Port Lonsdale Lighthouse, who dived on various wrecks in the bay during the 1960's. After the caretaker's death, his son sold off many of the shipwreck artefacts. The match safe was purchased from the caretaker's son in the 1990's by a previous owner of the Marine Shop, Queenscliff, Victoria. Pocket match safes or match safes were small portable boxes, or containers made in a great variety of forms and shapes, each with lids or covers to contain matches and retain their quality. Matches came into use around the 1830's and were produced extensively between the years 1890 and 1920. During this period everyone carried strike anywhere matches, so they could ignite stoves, lanterns and other devices. Early matches were unreliable and prone to ignite from rubbing on one another or spontaneously. Accordingly, most people carried a match safe to house their matches. Wealthy people had ‘match safes made of gold or silver, while common folk had ones made of tin or brass. They were made throughout the world including the United Kingdom, in the U.S.A., continental Europe and Australia. Significant English makers of cases were, Sampson Mordan and Asprey & Co. Significant American manufacturers of match safes include Wm. B. Kerr, Gorham, Unger Brothers, Battin, Blackington , Whiting, George Scheibler and Shreve & Co. Different patterns and types run into thousands as well as plain and decorative examples. They were also made in a wide range of materials, including pressed brass, pressed tin, gunmetal, nickel silver, gold, bone, ivory, the wood of varying types, early plastics like tortoiseshell and Bakelite, and ceramics. A distinguishing characteristic of match safes is that they have a ribbed surface, usually on the bottom, for lighting the matches. The item gives a snapshot into the social development through it's application in every day use match safes were used at a time when there were no safety matches and the early use of matches was a dangerous affair given they were easily combustive if rubbed together in a pocket for example. The item is also an example of the shipwreck artefacts gathered along the southwest coast of Victoria.Match Safe; hollow brass cylinder with ribbed match striker texture on base and screw thread around top. Fitted brass lid has an internal screw thread, and the top's flat surface has concentric circles design, with a twisted rope pattern grip around the edge. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, shipwreck artefact, port phillip bay, port lonsdale lighthouse, wreck, 1960’s diver, queenscliff marine shop, match container, match safe, matches, fire lighter, fire safety, heat, fire, portable match safe, 19th century -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Aircraft piston engines, Aircraft Engines

... of internal combustion engines, circa 1940, for aircraft engineers ...Outline of principles of internal combustion engines, circa 1940, for aircraft engineersBlue covered book; printed 1940non-fictionOutline of principles of internal combustion engines, circa 1940, for aircraft engineers