Showing 35 items

matching jumbuck wool pack

-

National Wool Museum

National Wool MuseumPhotograph

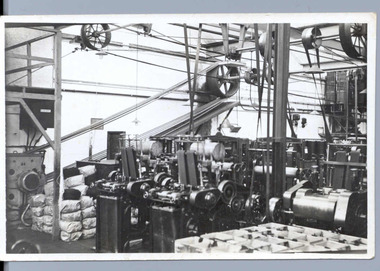

... Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool... Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the area and machines used for blending (the mixing of various fibres to produce the required quantity of yarn). The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, blending -

National Wool Museum

National Wool MuseumPhotograph

... Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool... Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the area and machines used for blending (the mixing of various fibres to produce the required quantity of yarn). The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, blending -

National Wool Museum

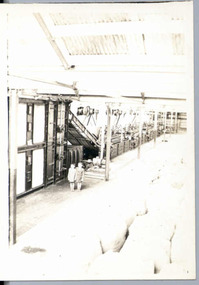

National Wool MuseumPhotograph

... ) to produce Jumbuck Nylon wool packs....) to produce Jumbuck Nylon wool packs. Valley Worsted Mill Mending ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the mending room, with the sloping tables which held the cloth to be mended. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, mending -

National Wool Museum

National Wool MuseumPhotograph

... (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.... (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs. Valley ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the mill maintenance shop, as a grinder, a diesel drum and a container for nuts and bolts can be seen. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

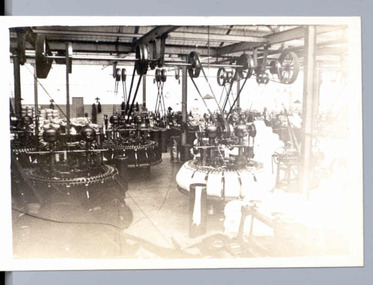

National Wool MuseumPhotograph - Noble Combs, Valley Worsted Mill, 1923

... ) to produce Jumbuck Nylon wool packs. "These 12 machines ended...) to produce Jumbuck Nylon wool packs. "These 12 machines ended ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs. "These 12 machines ended their working life in 1981 when the mill switched from the Bradford system of wool combing to the Continental system, the reason being was that the cost of maintaining them became too high, also the replacement rectilinear combs production rate was far greater and achieved higher yields although it could be argued that the Noble combs quality was superior". - Greg AldridgeBlack and white image showing the interior of a textile mill with machinery. Slightly overexposed on the right side.valley worsted mill, combing, noble comb, geelong