Showing 267 items matching "kitchen object"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales, Imperial weights & large bowl, c1900

A pair of scales or dishes in which objects to be weighed and the weights / masses against which to weigh them are placed is an "Apparatus for weighing. The pan, or each of the pans, of a balance." These common kitchen / dairy scales would be used by the householder to weigh flour, sugar, cereal, vegetables, fruit, meats, butter, cheese etc. prior to cooking or storing . c1900 A set of steel weighing scales with a balance beam that holds 1 large metal dish for the item to be weighed and a smaller tray holding the weights. The object/ substance to be weighed is placed in 1 dish and the weights are added to the other dish until the two dishes balance equally on the beam. The base , balance beam and tray are decorated with a floral pattern Its parts include a fulcrum, a beam that balances on it, two pans at the ends of the beam to hold the materials to be weighed, and counter-balancing weights.Each weight is engraved with Imperial Measure = 2lb, 1lb, 6ozmarket gardeners, early settlers, fruit vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour, . -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales, Domestic Imperial, ‘Fairway Melbourne’, c1930

Fairway Company Melbourne manufactured this pair of domestic scales with a dish / pan in which objects to be weighed and the weights / masses against which to weigh them are placed. These common kitchen / dairy scales would be used by the householder to weigh flour, sugar, cereal, vegetables, fruit, meats, butter, cheese etc. prior to cooking or storing . Its parts include a fulcrum, a beam that balances on it, two pans at the ends of the beam to hold the materials to be weighed, and counter-balancing weights. A set of domestic scales made by ‘Fairway’ Melbourne c1930. Painted cream steel with 1 metal bowl / pan and Imperial measure weights 2LB, 1LB, 4OZ, 2OZ, 1OZScales ; MADE BY / DOMESTIC SCALES / FAIRWAY / MELBOURNE AUST. Weights ; 2LB, 1LB, 4OZ, 2OZ, 1OZ market gardeners, early settlers, fruit vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour -

Heidelberg Repatriation Hospital

Heidelberg Repatriation HospitalFunctional object - Sugar bowl, c.1947

Used in the hospital setting as general kitchen ware. For patients and staff in dining rooms. Stainless steel selected due to robust nature. Reflects an earlier era before individual serves, bulk sugar being the only availability.Significant as it is reflective of an earlier era and a somewhat expensive and decorative piece that is no longer in use in society.Stainless steel sugar bowl with single hinge lid with single knob and two oval like handles, on opposite sides, Bell like in shape. Cutout in lid for spoon location is representative of a rectangular shape.Embossed on lid "R.G.H.H". Embossed on bottom "EXHIBIT/ E.R.N.S.AS"sugar bowl, stainless steel, kitchen ware, repatriation general hospital heidelberg -

Heidelberg Repatriation Hospital

Heidelberg Repatriation HospitalFunctional object - Scoop, c. 1970

Metal scoop used in industrial kitchen. U shaped utensil with metal handle.Pressed into Handle: M industrial kitchen, metal work, moulding -

Heidelberg Repatriation Hospital

Heidelberg Repatriation HospitalFunctional object - Scoop, c. 1970

Metal scoop commonly used in industrial kitchens. U-shaped with handle.On handle base: TAIWANindustrial kitchen, metal, moulding -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Landers, Frary & Clark , 1897-2000

Landers, Frary & Clark were a housewares company based in New Britain, Connecticut. It operated from 1865 until its assets were sold to the General Electric company in 1965. They manufactured a wide variety of products over the years, including stainless steel bull-nose rings and electric ranges, kitchen scales and vacuum bottles, window hardware and ice skates, mouse traps and percolators, can openers, corkscrews, cutlery, straight razors, aluminium cookware, and thousands of other products. Many of these items were marketed under the brand Universal. Some of the non-electric kitchenware assets were acquired from G.E. in 1984 by Universal Housewares, Inc./Universal Trading, Inc., who still market "Universal" meat grinders and coffee mills.An early domestic item its function was for use in the home kitchen that's the original patented design from 1897 is still being produced today under its brand name of Universal by Universal Trading Inc USA.Food mincer cast iron with wooden handle & thumbscrew for bench attachment.Marked "No. 2 Universal".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, mincer, food mincer, universal brand, kitchen appliance, food grinder, lander frary & clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Food Safe

Wooden Kitchen Safe for storing food, with hinged door (with key-hole) and three galvanised preformatted sheet metal windows. Front legs machine turned wood.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, food safe, kitchen safe, kitchen furniture, food storage, food preservation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, 1890-1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown salt glaze stoneware bottle None (possibly made by Royal Doulton UK)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, flagstaff hill maritime village, great ocean road, bottle, stoneware bottle, storage, kitchen ware, salt glazed, stoneware, shipwreck coast -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1900 - 1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance and origin of manufacture is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past. Stoneware jug badly cracked and repaired with handle and short neckNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, earthenware jug, kitchen storage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1920-1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthenwares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s. Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown Stoneware jug with short neckThe number "1" under neck flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, salt glaze -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880 to 1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had.Kettle, cast iron ware, black with some rust. . With lid of questionable origin. Made by "T & C Clark "C" inside 6 pointed star, England RD 665875 3 quarts No 3 First Quality"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Terracotta Cooler Top, Ovens Pottery, c. 1890-1892

The Ovens pottery operated from 1881 to1892 they had taken over H L & E pottery at Beechworth in 1888 but mounting debts forced the Ovens company to close in 1892. During their short ten years of operation they produced stoneware garden urns, vases, cheese dishes, ginger beer bottles, butter coolers, water filters, wine and spirit barrels, bread plates, jugs, teapots, storage jars, pots, tiles, flower pots, spittoons, basins, bowls, demijohns, lidded crocks, pipes and bricks.A significant item made by an early Australian pottery in Beechworth Victoria, this company made many utilitarian items for the Victorian domestic market. It gives us today a snapshot into early Australian companies that were unable to sustain manufacturing their products into the 20th century, due in part to the rising imports of cheaper items from overseas.Red terracotta butter cooler comprising, round base with ridged lip, and bell shaped, domed lid with spherical handle on topMarked "Ovens Pottery, Co Ltd, Patd 1890, Beechworth" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooler, terracotta cooler, utensil, kitchen ware, terracotta, food container, food preservation, butter cooler, ovens pottery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Knife Sharpener, Johann Friedrich Dick, 1873 to 1900

Johann Friedrich Dick founded the company in 1778 to manufacture files, the company continued in the manufacture of files as its main product line until 1873, when Paul Friedrich Dick took over the company and began the production of sharpening steels, with the logo of “F Dick” on their products. One hundred years after the founding of the company, a factory in Esslingen began construction. At that time the company had 20 employees. In 1881, company commissioned Germany's first file production machine. In 1889, Friedrich Dick built a new factory in Kollwitz/Fleischmannstrasse in Esslingen, employing 100 people and expanding the product line to include knives for butchers and chefs, cleavers and other specialized tools. Files manufactured ranged from the smallest watchmaker's file to the largest (over 45 cm in length) square file. In 1997, the F Dick company moved to a new headquarters in Deizisau, Germany. The old factory in Esslingen is now a class listed monument and the town's landmark.An item made by a world class manufacture of cutlery for chefs, the subject item is significant as its manufacture was probably early in the firms beginnings when Friedrich Dick took over in1873 when he specialised in making sharpening steels. The company is still producing these items today as well as other specialised knives for professionals. Early manufactured steels such as the subject item are sought after today by collectors and quite rare. Sharpening Steel or Knife sharpener with bone handle with ribbed pattern, brass knobs and ring at end of handleMarked F Dick Esslingenflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, sharpening steel, knife sharpener, kitchen tool, carving, kitchen utensil, cooking, f dick -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, Kande Kitchenware, Circa 1924

Kande Kitchenware was established by Patrick Kavanagh and William English (the name Kande was formed from their initials, K and E) in 1922 and had its Sydney factory in Little Collins Street, Surrey Hills. Kavanagh and English, a subsidiary of Kande Kitchenware, became a limited company in 1924, with both founders as directors. Another director was Test cricketer Jack Gregory, an all-rounder who slipped easily into the role of businessman. Gregory enjoyed success in business as on the cricket field, helping the company grow from a tiny operation to a major manufacturer and exporter that employed 80 people in 1931. They managed to survive the Depression and kept manufacturing at least until the late 1960s.An appliance made by an early and successful Australian company that manufactured metal kitchen items during the first half of the 20th century. Colander enamel rusty holes in base of bowls, 2 handles, bowl shape.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, colander, kitchen item, domestic item, kitchen strainer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking Pot, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had.Cast Iron cooking pot with lid separate Straight rod handle painted black.On base "T&C Clark and Co Ltd, RD455270 First Quality"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, iron cooking pot, cook ware, saucepan, kitchen utensil, cast iron enamel ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1800-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had.Kettle lid solid metal, handle and spout - has been painted black. Badly rusted on base"T C Clark, England"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, iron kettle, cook ware, kitchen ware, cast iron enamel ware, t c clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. Cast Iron Kettle straight metal handle painted black. Rusted inside and holed in the bottom, "T C Clark England" RD665876, 3 quarts No3" and other unreadable inscriptions.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, iron kettle, kitchen ware, t c clark, enamel cook ware, cast iron kettle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cruet Set, William Hutton & Sons, Circa 1900

William Hutton & Sons were manufacturing silversmiths founded in 1800 in Birmingham with company transferring to Sheffield in 1832. William Hutton had established the firm and with the move to Sheffield, they also became platers having licensed the electroplating technique from the firm of Elkington's. This gave them much early success in the field of electroplating. William's son William Carr Hutton continued the business after his father's death using the same business name until 1864 it was then changed to William Hutton & Son when William Carr's son Herbert Hutton joined him. When William Carr died in 1865, the firm name was again changed to William Hutton & Sons when Herbert's brothers (James & Robert) joined the company. They opened a London showroom in Holborn in 1863 which they moved to Farringdon Road, in 1891 operating until 1918. Hutton's had developed a new nickel alloy that was good for plating and in the late 1800s becoming known as British Plate. They sent their machine-made silver flatware from Sheffield to be hallmarked in London. Hutton's went on to acquire Rupert Favell & Co in 1893 and also registered as a limited company as William Hutton & Sons Ltd in 1902. The Hutton's had also bought Creswick & Co and had started to use their crossed arrows trademark. Hutton's became renowned for the quality of their Arts & Crafts silverware items at the turn of the 19th and 20th centuries. In 1930 Hutton's were taken over by James Dixon & Sons. A significant item that was made around the time electroplating was being developed as a means of producing quality utilitarian items in quantity for domestic use that we're able to be purchased by working-class people.Cruet set of silver plated frame with upright handle protruding from tray base. Holds 5 containers of varying shape and size; 3 have metal lids. Inscription is on the base. Some containers have contents in them.On base "WMH&S" and "01548" etc.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cruet set, condiments set, kitchen ware, electroplate, britannia metal, w m hutton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cheese Dish

Cheese Dish, square shape with cut corners, white ceramic, 2 parts; base with cut corners and lid with decorative handle and air hole.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cheese dish, covered cheese dish, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooler, First half of the 20th century

An unusual item believed to have been made by carving from a solid piece of sandstone for domestic use no history or manufacturing provenance currently available item could have been made as a one off.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Sandstone cooler round barrel shape. 2 equal sections. Top section has small wooden knob for lifting.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cooler, kitchen ware, sandstone cooler, kitchen item, ice bucket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Food Safe, 1920s

The first commercially available, Australian-made domestic refrigerator to operate without ice was produced by Edward Hallstrom in 1923. It used kerosene as a power source and was promoted as ideal for outback stations where ice was not available. According to Museum Victoria, Hallstrom introduced the 'Silent Night' which ran on electricity or gas in 1935. However, Hailstorm's great-grandson, stated that the Silent Night refrigerator was introduced in 1928. Although Australians were among the pioneers of refrigeration in the 1850s, the technology wasn't adapted for domestic use until many decades later. The first domestic electric refrigerator was sold in America in 1913. It had an air-cooled refrigeration unit mounted on top of an ice box. The Frigidaire and Kelvinator brands date from 1918 when the first self-contained fridges were sold. Before this food safes were used as well to keep food away from flies and to keep items cool.A significant item used from the late Victorian era until around 1940 when people were beginning to be able to afford domestic refrigerators. After the second world war, most households had replaced their food storage cupboards or safes with refrigerators. The subject item gives a snapshot of domestic life from this time.Wooden kitchen food safe, 2 door with wire mesh at sides. Raised back panel has shaped edges and includes a shelf above bench area that has turned legs. The safe has 4 plain legs.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, food safe, kitchen safe, kitchen furniture, food storage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pressure Cooker, T & C Clarke and Co Ltd, Late 19th to early 20th century

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to cook food safely without the concern that the metal interior may contain lead or arsenic as earlier cooking utensils had. Pressure cooker, cast iron , pressure vent on top. Removable lid held down by 3 riveted heart shaped clips where they join the base. Metal drop down carry handle.T & C Clarke and Co. on base & size 2 1/2 gallonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pressure cooker, cook ware, cooking pot, clarke and co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Container, 1900 to 1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s. Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Stoneware circular container with wide opening, brown top and off white base. Handholds moulded on each side glazed finish, cracks in base.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, container, stoneware container, kitchen storage, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, 1900-1920

A colander, sieve or cullender is a kitchen utensil used to strain foods such as pasta or to rinse vegetables. The perforated nature of the bowl allows liquid to drain through while retaining the solids inside it is sometimes also called a pasta strainer or kitchen sieve. Conventionally, colanders are made of a light metal, such as aluminum or thinly rolled stainless or plated steel, colanders are also made of plastic, silicone, ceramic, and enamelware. The word colander comes from the Latin Colum meaning sieve.Early 20th century kitchen item possibly of French manufacture due to the design and shape of the bowl this design appears to have been favoured by the French around 1910 for smaller Colanders. This item gives a snapshot into domestic life around the late 19th and early 20th centuries and the types of kitchen equipment in use.Strainer or colander, metal, with concave base and wood handle, plated metal construction with welded or folded seams. Handle painted black, perforated base.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, strainer, food strainer, seive, food preparation, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fruit Press, 1890-1900

The fruit juice or lemon squeezer is a small kitchen utensil designed to extract juice from lemons or other citrus fruit such as oranges, grapefruit, or lime. It is designed to separate and crush the pulp of the fruit in a way that is easy to operate. Lemon squeezers can be made from any solid, acid-resistant material, such as plastic, glass, metal (usually aluminum) or ceramic. The oldest known lemon squeezers were found in Kütahya, Turkey and date to the first quarter of the 18th century. These ceramic presses are in the traditional style of Turkish pottery of the 18th century and have a superficial resemblance to today's press equipment with cones, though they are designed differently. These examples were individually made, and specially designed for making the then popular citrus drink sorbet. Lemons are not native to northern Turkey, though during the 17th and 18th centuries they were imported in bulk to Constantinople.The fruit juice press is an example of early 20th century kitchen utensils and is not associated with an historical event, person or place, provenance is unable to be determined at this time and the item is believed to have been made around 1900. This item is currently being used in Flagstaffs Hill village display and regarded as significant as it demonstrates domestic kitchen utensils used around the turn of the 19th century and today is a collectable item. Vintage lemon/citrus fruits squeezer cast iron juicer with two sections hinged together strainer on one section has holes for letting liquid escape.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, food press, food preparation, fruit juice press, kitchen utensil -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. Cast Iron Kettle no lidT and C Clark and Co, London. No. 2, 5 pints capacityflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, cooking pot, cook ware, kitchen ware, cast iron kettle, t c clark ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Late 19th to early 20th century

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, frequently via a pole inserted through the lid of the churn, or via a crank used to turn a rotating device inside the churn. The use of butter is mentioned in biblical works and the earliest butter churn vessels belonging to Beersheba culture in Israel were found in Bir Abu Matar going back to Chalcolithic period between 6500–5500 BC. The butter churn in Europe may have existed as early as the 6th century AD, In the European tradition, the butter churn was primarily a device used by women, and the churning of butter was an essential responsibility along with other household chores. In earlier traditions of butter making, nomadic cultures placed milk in skin bags and produced butter either by shaking the bag manually, or possibly by attaching the bag to a pack animal, and producing butter simply through the movement of the animal. An item used to make butter in a domestic situation by turning a handle until the cream inside has turned to butter.Butter churn, wooden, lid pieces screwed or nailed together. Brass bearing on side with iron turning handle.Handle marked 28204 no other marks to indicate manufacturer or date of productionflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, churn, butter churn, wooden churn, butter making, food, dairy, kitchen utensil -

Flagstaff Hill Maritime Museum and Village

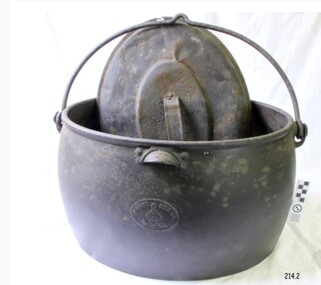

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Doulton Lambeth, Circa 1870 - 1890

The Royal Doulton company began as a partnership between John Doulton, Martha Jones, and John Wattis an English ceramic and home accessories manufacturer founded in 1815. Operating originally in Vauxhall, London, later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. The business was specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stone wares, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware's made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone china table wares and decorative items. An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects.Ink bottle, brown salt glazed stoneware with narrow mouth tamped Doulton Lambeth cork missing. Stamp impressed into clay on edge "(2)32 / Doulton / Lambeth" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, stoneware, stoneware jar, doulton lambeth, kitchen ware, salt glazed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic