Showing 110 items

matching machine maker

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Badge, Warrnambool & District Pipes & Drums, Late 20th century

This badge comes from the Warrnambool and District Pipes and Drums and is presumably attached to an item of clothing. The Warrnambool Pipe Band was formed in 1906, originally to popularise Scottish music and later to foster a taste for bagpipe music. Simon Fraser, the first Pipe Major, held the position from 1906 to 1910. The band appears to have gone into recess during the latter years of World War One and was apparently re-formed in 1935. Again in World War Two the band was in recess The band has had several changes of title but is today known as the Warrnambool and District Pipes and Drums. The badge is of interest as an example of one of the badges belonging to Warrnambool & District Pipes and Drums, an important and long-serving band in Warrnambool. This is a multi-coloured cloth badge, circular in shape. The outside edge is machine stitched in yellow and there is a blue band with the wording in yellow ‘Warrnambool & District Pipes and Drums’. In the inner circle there is an image, in colours of white, red, yellow, black and dark blue, of two drums, a staff and bagpipes stitched on a blue background. The back has a paper label with the details of the maker. ‘Warrnambool & District Pipes and Drums’ ‘Action Badges Pty Ltd, 34 Tooronga Terrace, Beverly Hills, N.S.W., 2209, Telephone (023) 502 4077’ warrnambool & district pipes and drums, badge -

Lara RSL Sub Branch

Lara RSL Sub BranchStereograph, The Rose Stereographs

George Rose was well known Australian photographer and postcard maker in the first half of the 20th century. This sterograph shows recruits training at Geelong during the First World War. Soldiers were trained to attack in short rushes rather than advancing in line due to the lethal power of the machine gun. The stereograph was an early technology that used double images to achieve a three dimensional image. Rectangular piece of cardboard with a stereograph image attached to the front. The image is a double reproduction of a black and white photograph. the photograph depicts a line of soldiers lying on the ground. AUSTRALIAN EXPERDITIONARY FORCE, GEELONG. Training Recruits in the Art of Attacking in Short Rushes. Copyright by Geo. Rose.wwi, rose series, postcard, lara, geelong, rsl, training, stereograph -

Bendigo Military Museum

Bendigo Military MuseumHeadwear - HAT, UNITED NATIONS, Hills Hats, Post 1970

Hat, mid blue colour with brim, cotton fabric with - “United Nations. Nations Unies” - emblem machine embroidered in white thread on front of hat.Makers label inside hat crown: “Hills Made By Hills Hats In New Zealand Medium”uniform - military - army - un peacekeeping, costume-male headwear, passchendaele barracks trust -

Bendigo Military Museum

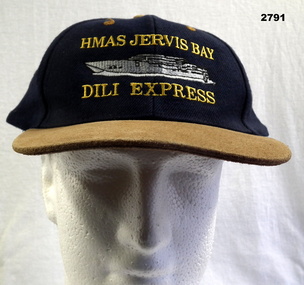

Bendigo Military MuseumHeadwear - CAP, NAVAL, post 1990

Cap, navy blue & brown colour, HMAS Jervis Bay machine embroidered in yellow thread over pale blue embroidered navy ship, Dili Express embroidered in yellow thread below ship.Makers label inside brim: 65% Wool 35% Acrylic Suede One Size Fits All Hand Wash Only Made in Chinauniforms - military - navy, costume - male - headwear, passchendaele barracks trust, hmas -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Edward Preston & Sons, Early 20th century

By the end of the nineteenth century, the firm of Edward Preston & Sons was founded in 1825, becoming one of England's leading makers of hand tools and in many ways a British counterpart to America's "Stanley" for its wide range of quality utilitarian tools at affordable prices. Edward Preston Sr. (1798–1883) was first listed as a plane-maker at 77 Lichfield Street in the Birmingham Directory of 1833, but later listings and advertisements assert that the business was started in 1825. Preston is likewise recorded as a plane-maker living with his family in Lichfield Street in the 1841 census, at which time his younger son Edward was 6 years old. Around 1850, his son Edward left school to join his father's business and is recorded in the 1851 census as a plane-maker at his father's address. He appears to have been quite a talented and resourceful young man, as he had later been able to start up his own "wood and brass spirit level manufacturing business at 97½ Lichfield Street by 1864. By 1866, Edward Jnr had added planes, routers, joiners, coach, gun, cabinet, and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to much larger premises at 22–24 Whittall Street. This location became known as the Whittall Works and later was the office and factory of Edward Preston & Sons, Ltd. In 1889 Edward Preston Jnr and his three sons were brought into the firm and the name was changed to Edward Preston & Sons, becoming Edward Preston & Sons Ltd on incorporation in 1898. Part of the firm's output was a healthy line of malleable and gun-metal planes and patent adjustable iron smoothers, shoulder planes, bull-nose, and block planes - a range that was expanded in later years. The 1901 catalog shows several styles of planes that were unique to the Preston brand, along with the usual styles which had already been set by other makers. The death of Edward Preston Jnr was reported in the Lichfield Mercury of 26 September 1913. "Mr. Preston was decided of an innovative turn of mind," the newspaper wrote, "as many of the machines in use at his works, as well as of the tools produced were the invention of himself and his three sons, who now manage the business." The report noted that at the time of his death, the business was carried on at Whittall Works, Cheston Street, Aston, Birmingham. Falling on hard times, the firm of Edward Preston & Sons was sold to the Birmingham firm of John Rabone & Sons in 1932, and shortly thereafter manufacturing rights to some of the Preston range of planes were sold to the Sheffield firm of C. & J. Hampton, who would later merge with the Record Tool Company. Some of the Preston planes were directly added to the Record line by the Hampton firm, while others were modified or discontinued altogether. Generally, all Preston wooden planes are stamped on the front of the plane, the shape, size, and character type of the stamp indicating the age of the plane. On some metal planes, all the parts were stamped with a number or symbol during manufacture. This number was used to re-assemble the parts following a batch process. Not all Preston tools are trade-marked clearly. Early shoulder, rebate, chariot planes, and chamfer rebates commonly appear without trademarks but may have assembly numbers. The "E P" trade-mark was already in use by 1882. The trade-mark "Preston" also appears on some later tools that were manufactured in Sheffield, England. These are generally smoothing planes and appear modern and very similar in construction to other modern manufacturers' planes.The item gives a snapshot of one of England's premier tool manufacturing companies at a time when significant industrial changes were occurring in manufacturing and business structures in the World that were beginning to affect social changes.Ogee wood moulding plane Maker E Preston & Sons No 5 (Owner A T Nipe) also has A's stamped on ends and the No 7flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGestetner Machine, c. 1922 - 1929

... machine roneograph copier Maker’s plate “MANUFACTURED / BY / D ...This Gestetner Cyclostyle duplicating machine was invented and manufactured by David Gestetner. He claimed in 1922, once he had released several models, that if a Gestetner Durotype stencil was used together with his Cyclostyle machine, then 10,000 copies could be made from the one Durotype stencil, an amazing claim for office technology of that era. David Gestetner (1854-1939), was born in Csoma, Hungary. He has been called the “founder of the worldwide office copying and duplicator industry.). He moved to London and in 1879 filed his first copying patent. In 1881 he patented the Cyclostyle stylus (or pen), which was used in conjunction with his Cyclograph device for copying text and images, He established the Gestetner Cyclograph Company in England at this time (1881) to protect his inventions and to produce his products; stencils, stylos (stylus or pen) and ink rollers. HIs inventions included nail-clipper and the ball-point pen (although the latter is more commonly associated with Laszlo Biro). Gestetner’s patented Cyclograph duplicator was used with his Cyclostyle Stylus or pen to write or draw on special thin wax-coated stencil paper (originally used for kite making paper) in the following way; 1. The Cyclostyle stencil was placed on a lower, framed metal plate of the Cyclograph 2. An upper frame was clipped over the top 3. The Cyclostyle pen, with its tip being a small metal-spiked or toothed wheel, was used to write or draw on the stencil, punched small holes into the paper and removed the wax coating in those places 4. The upper frame and stencil was then removed and a piece of blank paper was placed onto the metal plate in the lower frame and the upper frame with stencil was replaced 5. A roller was given an even distribution of Cyclostyle ink and rolled by hand over the stencil in the frame. This forced the ink through the holes in the stencil to and made a copy of the stencil on the paper 6. The upper frame was raised, the printed paper removed and another blank sheet was put into place. The whole process was repeated until enough copies were made. Gestetner’s invention developed further in 1894, with a stencil that could be placed on a screen on a revolving drum. The drum was manually rotated, the stencil then wrapped around another drum and was fed between cloth-covered rollers on which ink was evenly spread. Each revolution of the drum forced ink through the holes in the stencil and transferred the ink onto paper that had been fed between rollers and pressed against the drum. The process was repeated for each page. The paper was still fed and removed manually in this earlier invention but became more automatic in later models. In 1902 Gestetner duplicator model 6 was put onto the market. This model included the improvement of an automatic paper feed that synchronised with the rotation of the stencil. The Gestetner machine was the first office printing machine. It was easily installed and it made exact copies of the sane document quickly, effectively and inexpensively. This changed the way offices operated, making information easily available to many more users. The machines were commonly used in small businesses, schools, churches, clubs and other organisations for the wide distribution of a wide variety of information in the form of worksheets, newsletters and more. In 1906 the Gestetner Works were opened in Tottenham Hale, North London, and thousands of people were employed there up until the 1970’s. Due to the fast growing success of the Gestetner Duplicator machines many international branches for sales and service centres were established. David Gestetner was succeeded by his son Sigmund, followed by his grandson’s David and Jonathan. Further advancement was made by using a manual typewriter with specifically designed stencils. The end product was a printed, typewritten copy similar to the print from newspapers and booklets. In the next few years there were further developments of this revolutionary invention. The Gestetner Cyclostyle duplicator in our Collection is dated c.1922 - 1929 and it uses Gestetner Durotype stencils The 1922 British Industries Fair’s catalogue contained advertising for the Gestetner Rotary Cyclostyle “The World’s Premier Duplicator”, demonstrated at Stand K 86.” A Notice at the foot of the advertisement’s page boasts "Important - D Gestetner's latest invention, the "Durotype" Stencil, enables you to obtain 10,000 copies from one original if desired. It contains no wax of any description, is indestructible, can be stored indefinitely and printed from as required” In 1929 the look of the Gestetner machines changed; American designer Raymond Loewy was invited by Gestetner to improve the look of his duplicators, resulting in a very streamlined appearance. Eventually, around 1960’s, offices replaced their Gestetner with small photocopying machines and printers. Gestetner took over ownership of other office machine companies over time, including Nashua, Rex Rotary, Hanimex and Savin and eventually all came under the holding company name of NRG (Nashuatech, Rex Rotary and Gestetner). In 1996 Ricoh acquired the Gestetner Company, and it was renamed the NRG Group. REFERENCES Cyclostyle, Stencil Duplicating Machines, antique Copying Machines, Early Office Museum, http://www.officemuseum.com/copy_machines.htm Duplicating machines, Wikipedia Duplicator, Collection online, Canada Science and Technology Museums Corporation http://techno-science.ca/en/collection-research/collection-item.php?id=1989.0229.001 Gestetner duplicators, Totterham-Summerhillroad.com http://tottenham-summerhillroad.com/gestetner_duplicators_tottenham.htm Gestetner Duplicator, V&A Museum http://collections.vam.ac.uk/item/O322014/gestetner-duplicator-duplicator-loewy-raymond-fernand/ Gestetner, Grace’s Guide to British Industrial History, http://www.gracesguide.co.uk/Gestetner Duplicating machines such as this one revolutionalised access to copies of printed material, changing the way that educational bodies, offices, small businesses and community clubs and charities operated.Duplicating machine, Gestetner Cyclostyle Durotype, a stencil-method duplicating machine with two rotating drums plus rollers. Hand operated, tabletop office machine. Front has folding Bakelite handle, oil filling hole, calibrating gauge with scale, and copy counting meter. Right side has printed manufacturer’s plate that slides out as a paper output tray. Left side has metal plate with protrusions and perforations, plus another similar plate that is detached. It also has a metal frame attached [that would have been used to hold a paper input board, adjusted for various sizes of paper]. Cover, metal, with folding wooden handle on top, attaches to base with metal clips. Inscriptions printed on machine, mostly in gold-coloured paint. Round metal manufacturing plate is stamped with Serial Number 95759. Made by D. Gestetner, London, c.1922-1929Maker’s plate “MANUFACTURED / BY / D. GESTETNER LTD, / No. 95759 / CYCLOSTYLE WORKS / TOTTENHAM HALE / LONDON, N” Copy counting meter shows “1 4 6 4 8 [space]“ copies. Calibrating gauge has divisions with numbers “0 1 2“, labelled “← [left arrow] “TO PRINT LOWER” and “→ [right arrow], TO PRINT HIGHER”. “The Gestetner”, “Cyclostyle”, “Gestetner” (Trade Mark), Right side print of manufacturing details includes “The / Gestetner / TRADE MARK” And “THE FOLLOWING TRAFE MARKS / - - - OF INK, STENCILS / - - - AND GUARANTEE OF PERFECT / - - - BOTH - - - AND MACHINE” and “CYCLOSTYLE / DUROTYPE / GESTETNER” and “D. Gestetner” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, office machine, copying machine, gestetner machine, duplicating machine, duplicator, stencil machine, gestetner cyclograph company, cyclograph, cyclostyle, d. gestetner ltd, gestetner durotype stencils, gestetner cyclostyle, printing machine, office technology, durotype stencils, david gestetner, raymond loewy, roneo, rotary duplicatorten, mimeo, mimeograph machine, roneograph copier -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Page Numbering Machine, EARLY 1900’S

Antique paging or page numbering machine, also referred to as a paginater. Machine prints six digit numbers consecutively. It was used in the printing industry to number consecutive pages of journals in the early 1900’s. Alex Cowan & Sons Ltd. of Melbourne, Sydney and Adelaide supplied printing equipment to other firms. The parent company, Alexander Cowan & Sons Ltd., manufactured fine paper in Valleyfield, Penicuik, Scotland from 1814-1937. This page numbering machine or paginater is an example of mechanical technology used in the printing industry in the early 1900's.Page numbering machine, also known as a paginater or paging machine. Printing machine with six digits for numbering pages consecutively. Steel frame, wooden treadle plate and bench. Inscription of maker's name on metal plate. Made by Alex Cowan & Sons Ltd.Inscribed on maker's plate, "Alex Cowan & Sons Ltd. / Printers Furnishers / Melbourne, Sydney, Adelaide". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, paging machine, treadle paging machine, printing machine, page numbering machine, paginater, alex cowan and sons ltd, australian printing industry -

Geelong RSL Sub Branch

Geelong RSL Sub BranchDocuments, Early 20th Century

These forms relate to the Service History of 1740 Pte K J McKenzie who enlisted 08 April 1915 and served with 6 Aust Machine Gun Coy on the Gallipoli Peninsula. Pte McKenzie was KIA in France 02 July 1916This is the Service History of 1740 Pte K J McKenzieSix (6) Pages of photographed documents Certified True Copies, relating to 1740 Pte K J McKenzieVarious AMF Documents, 1740 Pte K J McKenzieaif, ww!, mckenzie, gallipoli -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomCamera, Eastman Kodak Co, abt 1912

Camera used by No 59 Capt A Chanter, Machine Gun Section, 4th Australian Light Horse Regiment during WW1. The 4th Light Horse Regiment is an ancestor unit of the Regiment, serving with distinction in WW1. The user of this camera commanded the Machine Gun Section of the 4LH. His historically significant collection of photos is held by the Unit History RoomCamera, No 1 Eastman Kodak JRMaker's plate in camera Inside leather case - initials A L Ccamera, ww1, chanter -

Orbost & District Historical Society

Orbost & District Historical SocietyBread maker, Landers Frary and Clark, Early 20th century

Bread machines were made for quite a long time from the 1890's on. They came in different heights and capacities. The advertisements at the time stated that making bread with their machine was superior to hand kneading, This item is good example of a domestic appliance used when most foods were home-made. Access to commercial bread was limited in rural areas and housewives became skilled at bread-making.Metal bucket with lid. Lid has hole in centre through which a handle for turning the dough hook comes. Grey rusty coloured.Put in all liquids first, then flour, turn 3 minutes, raise in pail. After raising, turn until dough forms a ball. Take off cross piece, lift out dough with kneader.bread domestic-appliance bread-maker food-technology bakery -

Cheese World Museum

Cheese World MuseumVacuum recorder, E.M.P. Engineers Ltd, c1960

Used by first Warrnambool Cheese and Butter Factory Company Ltd Field Officer, Bruce McLaren, for on-farm testing in the Allansford area to check the amount of suction in milking machines.Phillips Rurakura Vacuum Recorder in a wooden box with lid, metal hinges and fastening clip, screw adjustment and name plate on outside. Inside has a clockwork-operated recorder with pen device to roll of paper.Internal: Trade mark Empel E.M.P. Engineers Ltd PO Box 5125, Hamilton, NZ Aust. Pat. 209 510. NZ Pat. 112 486. External: Empel Phillips Ruakura Type Vacuum recorder, Makers E.M.R. Engineers Ltd. PO Box 5125, Hamilton NZ -

Cheese World Museum

Cheese World MuseumButter printer, J Bartram & Son, c1900

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This butter cutter is part of the collection of items given into the care of the Cheese World Museum. It was in the early 1900s for hand-use in home dairies or small factories. An example of an early butter packaging machine.Wooden Eureka brand butter printer and weigher with dovetailed corners on the bulk butter box, wooden rollers for moving butter along once cut and wire cutter.Eureka/J Bartram & Son/sole makers Uebergang No. U027butter cutters, uebergang, allansford, dairy manufacture -

Cheese World Museum

Cheese World MuseumCatalogue, To Dairymen & Agriculturalists: Milk Cream and Butter

... and illustrations of a cow, separator, butter maker and butter slicer..., butter maker and butter slicer machines. To Dairymen ...This catalogue belonged to Alderdice Brass Foundry in Warrnambool. It was donated to the museum by John Downing from the foundry. The catalogue is for the firm of J Bartram & Son who were suppliers of dairy equipment. They were one of the earliest suppliers of mechanical milking machines in Victoria.The catalogue is significant as it is from an early dairy supplier and shows early dairy equipment. The Alderdice Brass Foundry has been in operation since the 19th century.Blue covered catalogue booklet with white text and illustrations of a cow, separator, butter maker and butter slicer machines.To Dairymen &/Agriculturalists/Milk/Cream/and/Butter J.BARTRAM & SON. PTY. LTD./586-588 BOURKE ST./MELBOURNEcatalogues, dairy industry, j bartram & son pty ltd, dairy machinery, milk, cream, butter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Dowel Maker (Moot), Mid to late 19th Century indication of this date range is due to the engraved handles and brass ferrules often used on hand tools of this era

A dowel is a cylindrical rod, usually made of wood. In its original manufactured form, a dowel is called a dowel rod. Dowel rods are often cut into short lengths called dowel pins.These are commonly used as structural reinforcements in cabinet making and in joining large timbers together. To make a dowel, a piece of wood is split or whittled to a size slightly bigger than desired and to place the stock into a vice then rotate past a fixed knife, or alternatively, to rotate the knife around the stock such as the subject tool was used. Machines based on this principle emerged in the 19th century. Frequently, these are small bench-mounted tools, prior to this time dowels had to be cut by hand. The tool is an example of early to late 19th century hand tool used to make timber dowels. It is not associated with an historical event, person or place, makers provenance is unable to be determined at this time. Many small American and British tool manufactures were taken over by Stanley tools after 1843 when the company was established and this item could have been made by one of these. However the subject item appears to be rare and would be regarded as a collector's item.An adjustable woodworking tool know as a Moot, used for making Trunnels or Treenails (Dowels) for fastening joints in timber. Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, moot, trunnels, treenails, circular, dowels, woodworking tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Lawn Mower, Alex Shanks & Sons Ltd Engineers Arbroth London, 1903-1925

The firm of Alexander Shanks & Sons Ltd of Arbroath, were engineers, founders and boiler makers the company was incorporated in the year 1893. At the Dens Iron Works, purchased by the firm in the same year, a wide variety of products was manufactured including cranes, hoists, pumps and lawnmowers. In the 1960s the firm was taken over by Alexander Shanks (1801-1845) was an Inventor of the modern lawnmower, who lived in Arbroath Scotland. While credit is usually given to the Englishman Edwin Budding (1795-1846) for the invention of the lawnmower, it is Shanks' machine which was the direct predecessor of the modern mower. Shanks' innovation was a machine which rolled the grass as well as mowing it. Although Shanks himself died at a young age, his son showed the mowers at the Great Exhibition in 1851 which led to a successful business that continued into the 20th century, supplying mowers to cut the tennis courts of Wimbledon, the cricket grounds at Lords and the Old golf course at St Andrews. The firm was also well known for the manufacture of portable steam engines and steam cranes. In 1968, the company was taken over by Giddings & Lewis Fraser Ltd, Engineers of Arbroath. The subject item is a good example of an early lawn mower made by the company that is credited with being the first to patent and manufacture such a machine. The company Alexander Shanks founded was known throughout the world as significant manufactures of large steam machines used from the middle of the 19th century to the first quarter of the 20th century. The subject item is now regarded as a collector's item.Lawnmower, cast iron handles has two wooden ends and two wooden rollers at front. Blades driven by chain fixed to metal roller. Shanks's Standard Chain. Shanks's Standard Chain Arbroth London. Alex Shanks & Sons Ltd Engineers Arbroth Londonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, hand mower, lawn mower, mower, shanks, arboth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Fob watch, 1882

The watch was given to William James Robe by the captain of the barque Fiji as a token for helping to save his life and that of the crew on September 6th 1891 when the steel barque Fiji had foundered off “wreck beach" near Moonlight Head Warrnambool during a voyage from Hamburg to Melbourne. William or Bill as he was called was the one who had hauled out the last man, the captain, after he had become tangled in the kelp. William along with many other onlookers on the beach at the time had taken it in turns to go into the surf and drag half-drowned seamen to safety. These rescuers along with William James Robe, included Edwin Vinge, Hugh Cameron, Fenelon Mott, Arthur Wilkinson and Peter Carmody. Years later Bill passed the watch on to his brother-in-law Gilbert Hulands as payment of a debt. The grandson of Gilbert Hulands, John Hulands, has donated this watch to Flagstaff Hill Maritime Museum. The Fiji Wreck: The three-masted iron barque Fiji had been built in Belfast, Ireland, in 1875 by Harland and Wolfe for a Liverpool based shipping company. The ship departed Hamburg on 22nd May 1891 bound for Melbourne, under the command of Captain William Vickers with a crew of 25. On September 5th, one hundred days out from Hamburg in squally and boisterous south-west winds the Cape Otway light was sighted on a bearing differing from Captain Vickers' calculation of his position. At about 2:30 am, Sunday 6th September 1891 land was reported 4-5 miles off the port bow. The captain tried to put the ship on the other tack, but she would not respond. He then tried to turn her the other way but just as the manoeuvre was being completed Fiji struck rock only 274 metres from shore. The place is known as Wreck Bay, Moonlight Head. Blue lights were burned and rockets fired whilst an effort was made to lower boats but all capsized or swamped and smashed to pieces. Two of the younger crewmen volunteered to swim for the shore, taking a line. One, a Russian named Daniel Carkland, drowned after he was swept away when the line broke. The other, 17-year-old able seaman Julius Gebauhr, a German, reached shore safely on his second attempt but without the line, which he had cut loose with his sheath-knife when it becomes tangled in kelp. He rested on the beach a while then climbed the cliffs in search of help. At about 10 am on Sunday a party of land selectors - including F. J. Stanmore, Leslie Dickson (or Dixon) and Mott - found Gebauhr. They were near Ryans Den, on their travels on horseback from Princetown towards Moonlight Head, and about 5km from the wreck. They found Gebauhr lying in scrub and a poor state, bleeding and scantly dressed and with a sheath-knife. At first, they were concerned about his appearance and gibberish speech, taking him to be an escaped lunatic. They were reassured after Gebauhr threw his knife away realising he was speaking half-English, half-German. They gave him food and brandy and some clothing and were then able to gain information about the wreck. Some of the men took him to Rivernook, a nearby guest house owned by John Evans, where he was cared for. Stansmore and Dickson rode off to try and summon help. Others went down to the site of the wreck. Messages for rescuing the rest of the crew were sent both to Port Campbell for the rocket rescue crew and to Warrnambool for the lifeboat. The S.S. Casino sailed from Portland towards the scene. After travelling the 25 miles to the scene, half of the Port Campbell rocket crew and equipment arrived and set up the rocket tripod on the beach below the cliffs. By this time the crew of Fiji had been clinging to the jib-boom for almost 15 hours, calling frantically for help. Mr Tregear from the Rocket Crew fired the line. The light line broke and the rocket was carried away. A second line was successfully fired across the ship and made fast. The anxious sailors then attempted to come ashore along the line but, with as many as five at a time, the line sagged considerably and some were washed off. Others, nearly exhausted, had to then make their way through masses of seaweed and were often smothered by waves. Only 14 of the 24 who had remained on the ship made it to shore. Many onlookers on the beach took it in turns to go into the surf and drag half-drowned seamen to safety. One of the rescuers Arthur Wilkinson, a 29-year-old land selector, swam out to the aid of one of the ship's crewmen, a carpenter named John Plunken who was attempting to swim to shore. Two or three times both men almost reached the shore but were washed back to the wreck, a line was thrown to them. It was thought that Wilkinson had struck his head on the anchor during the rescue and had remained unconscious, the carpenter survived this ordeal but Wilkinson died and his body was washed up the next day. The wreck of Fiji smashed apart within 20 minutes of the captain being brought ashore, and it finally settling in 6m of water. Of the 26 men on Fiji, 11 in total lost their lives. The remains of 7 bodies were washed onto the beach. They were buried on the clifftop above the wreck. Captain Vickers was severely reprimanded for his mishandling of the ship and his is Masters Certificate was suspended for 12 months. At the time there was also a great deal of public criticism at the slow and disorganised rescue attempt to save those on board. The important canvas ‘breech buoy’ or ‘bucket chair’ and the heavy line from the Rocket Rescue was in the half of the rocket outfit that didn’t make it in time for the rescue: they had been delayed at the Gellibrand River ferry. Communications to Warrnambool were down so the call for help didn’t get through on time and the two or three boats that had been notified of the wreck failed to reach it in time. Much looting occurred of the cargo that washed up on the shore, with nearly every visitor leaving the beach with bulky pockets. One looter was caught with a small load of red and white rubber balls, which were duly confiscated and he was 'detained' for 14 days. The essence of peppermint mysteriously turned up in many settlers homes. Sailcloth was salvaged and used for horse rugs and tent flies. Soon after the wreck "Fiji tobacco" was being advertised around Victoria. A Customs officer, trying to prevent some of the looting, was assaulted by looters and thrown over a cliff. He managed to cling to a bush lower down until rescued. Seaman Julius Gebauhr later gave his knife, in its hand crafted leather sheath, to F. J. Stansmore for caring for him when he came ashore. Flagstaff Hill’s Fiji collection is of historical significance at a State level because of its association with the wreck Fiji, which is on the Victorian Heritage Register (S 259). The collection also represents key aspects of Victoria’s shipping history and its items offer the potential to interpret maritime historical events and social history of the time. Along with the potential to yield information that will contribute to an understanding of Victoria’s cultural history.Sterling silver fob watch Fusee movement face has a white background with black Roman numerals on it. The minute hand is gold coloured with a leaf shape. Seconds dial is inset at position 6, with Arabic numerals around it. Watch has machine engraving flower pattern front and back. The spherical winder has a number and a symbol on the upper face and a hole through the centre, the ring for the chain is missing. Back of a the watch opens to reveal a concave cover with a winding hole, which has a border of overlapping crescent-shapes. Inside cover a diamond with initials “JR”(John Rotherham) inside, a date letter “G” (1882) with a Lion Passant (Sterling Silver) also 3 numbers “8 1 9“embossed beside each other. The clock face has “Rotherhams / London” printed on it. The winder is also marked with a maker and sterling silver mark. “Y” and numbers “688” “3 CI A” “3309” “819” “555 A” and other numbers including a set engraved around the edge possibly jewelers marks who did repairs or maintenance on the item over the years.1891, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwrecked artefact, flagstaff hill maritime village, shipwreck coast, warrnambool, fiji, pocket watch, william vickers, william robe, bill robe, fiji watch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Printing Press, Harrild and Sons, 1866

This Albion printing press was manufactured by Harrild & Sons of London and exported in 1868 from London to the colonial Western Victoria town of Coleraine, population of 700 at that time. It was installed in the Colerain Albion printing office. It was used to print the first edition of the Coleraine Albion newspaper in 1868 and continued until publication ceased in 1974. The Albion Press is still being used today by a volunteer printer in the “Examiners Office” in the village at Flagstaff Hill. Amongst the items produced are printed paper bags for the Tea Rooms and posters for visitors. ALBION PRINTING PRESS The Albion press was invented and manufactured in London by Richard Whittaker Cope around 1820 and was still being produced in the 1930s. The Albion was manufactured under licence by several companies from the 1850s onwards, one of which was Harrild & Sons of Fleet Works, London. Harrild & Sons describes its business as “printing materials manufacturer”. The business was established in 1807 by Robert Harrild and named R. Harrild & Co. In 1813 he showed that rollers could be used to ink a printing plate instead of inking balls, the method in use at the time. He then established a company to make the rollers. Eventually his company would make other printing materials and equipment. Robert’s sons joined him in the 1830s, when the company was renamed Harrild & Sons, and they continued to run the company after his death in 1853 and up until the mid-1900s. COLERAINE ALBION PRINTING OFFICE The Coleraine Albion Printing Office was established by W.L. Ambler. The first issue of the Coleraine Albion was dated 4th January 1868. Arrangements had been made to receive news from Melbourne, nearby provinces, other colonies and England. The second issue on 18 January 1868 printed articles from many agencies, including the Melbourne Age and the Warrnambool Examiner. The Albion office was sold to William Hatherleigh, formerly of Portland, in October 1868. Thereafter the Albion office had many owners. The last was L. A. & E. Oliver, who took over in January 1972 and was the last to be stated as printers and publishers of the Coleraine Albion. The office was wound up in 1974. The Albion Press and other equipment was distributed to Star printing in Terang. Star Printing donated the Albion press to Flagstaff Hill Maritime Village around 1980 and Stan Philp, owner of Philprint in Warrnambool, transported it to Warrnambool, brought it up to good working order and organised the supply of appropriate printer’s type. The Albion hand operated printing press is significant for producing the first newspaper in Coleraine, Western Victoria and continuing production for over 100 years. The Albion is technologically significant as a working example of a hand operated printer from the mid-19th century. The use of the printer is demonstrated by volunteers at Flagstaff Hill, printing items such as lolly and treat bays for use in the Village. The Albion is socially significant for its role in the isolated provincial colony, providing communication with the outside world, both in Australia and overseas. Newspaper printers were often amongst the first businesses of a small town. Printing press; hand operated Albion Press, Patent 2105. The machine has an upright iron frame at the back that supports the upper press that has a wooden handled metal bar is attached. The frame and legs support a thick metal flatbed. A metal leg supports the front of the press bed. The iron work is painted black with gold highlights. The decorative legs are finished with the golden feet of an animal. The frame above the metal bed includes a crown shaped finial symbol above the maker’s emblem. The maker’s details and the name of the printer are embossed on the upright frame. A plaque with the patent number is below a Lion and Unicorn emblem.Embossed maker’s emblem [A red cross - above a double ring – square inside ring – three banners below ring]. - Inside the double rings “PRINTING MATERIALS MANUFACTURE” - Inside the square, intertwined text “H & S” [representing Harrild & Sons] - Inside the three banners ““FLEET” “WORKS.” “LONDON.E.C.” Embossed across the shoulders “ALBION PRESS / HARRILD & SONS, / MAKERS LONDON.” Emblem above plaque [Lion and Unicorn] Embossed on the plaque “PATENT / 2105” Stamped into upright machine part above the printing bed “2105 / 1866” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, albion press, printing press, 1866 printing press, printing equipment, communications, coleraine albion printing office, coleraine newspaper, albion newspaper, south west victoria newspapers, harrild and sons london, richard whittaker cope, star printing terang, philprint, coleraine albion, hand operated press -

Federation University Historical Collection

Federation University Historical CollectionInstrument - equipment, Mechanical Pinwheel Calculator, c1940, 1935-1945

Willgodt T. Odhner invented his very successful “pinwheel” four-function calculator mechanism in Russia in 1874, and his invention was cloned by numerous companies, resulting in dozens of similar models that remained in wide use for almost a century. Numbers are dialed into the sliding levers on the top part of the machine, and are added to the register visible in the carriage at the bottom when the large crank is turned. Shifting the carriage sideways allows multiplication through a sequence of addition operations; the two small cranks zero the registers. The design includes ingenious error-preventing interlocks between all the controls: should the operator fail to return a crank to its resting position, the other controls are frozen until this is corrected. A bell indicates calculations in the negative. Used in Ballarat Institute of Advanced Education (B.I.A.E) Physics department.Black, mechanical calculating machine. Metal. Hand-operated, with three hand-cranks. 10x10 rotor with 13 digit result. Ser. No. 29-286781.5 Black symotape on base front: "PHYSICS". Maker's identification on top surface. Supplier's label (metal, silver & blue) on back: "STOTT & HOARE Pty. Ltd. 171 William St. Melbourne C1 M1991". Stamped on rear panel: "MADE IN SWEDEN". Cast lettering on underside: "M-602 07".calculating machine, pinwheel, calculator, scientific instruments, stott & hoare pty ltd, physics, odhner, ballarat institute of advanced education -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

... , an inventor, showed his Davis Sewing Machine to two brothers.... Job Davis, an inventor, showed his Davis Sewing Machine to two ...This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1911-1920s

This machine was made in Baden, Germany, for the Ward Brothers of Melbourne, who imported machines from various manufacturers and had them branded with their Ward Brothers decals. This machine is most likely dated after 1911, when the Ward Brothers became two separate businesses, as there are only remnants of two portrait decals on the machine bed. There is a fitted embedded ruler in the wood of the base. Many sewing machine manufacturers in Germany produced their machines specifically for export. A company could mass-produce its machines and give the same product several different brand names, according to their overseas buyers. There was a huge market for domestic machines as it enabled tailored clothing to be made in households at a fraction of the retail prices. Ward Brothers began in Australia in the late 1890s and early sewing machines sold by them had the three brothers on their decals. In 1911 the brothers divided into two separate firms, one operating on his own, the other two remaining together, and all still operating in Melbourne and at first still using the name Ward Brothers.This sewing machine is one of two hand-operated Ward Brothers machines in our collection that were made in Baden, Germany, and the only one that has the two Ward Brothers on its decal and that has side to side slide plates. This machine represents the early domestic market for sewing machines, making it possible for the everyday homemaker to produce fashionable garments and linen ware that was affordable. The owner of this machine could work at more than one location as it was portable and did not require a large space to set up. The machine is associated with the well-known Ward Brothers of Melbourne, who sold imported sewing machines that were branded with their own name.Sewing machine with case. The black-painted metal machine is hand-operated and the crank handle is wooden. The machine is on a wooden base and has a box included that contains many machine accessories. Made in Baden, Gemnamy, for Ward Brothers of Melbourne. There is an attached metal plate on the front with rows of groups of numbers on it. The wooden bed has an embedded ruler. The machine had decals with geometric designs and the maker's name.Printed in script: "Specially made in Baden / by Ward Broth Melbourne"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, sewing machine, hand operated, domestic sewing, homemade clothing, fashion, ward brothers, made in germany, baden, front and rear slide plates, post wwi, post 1911 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTypewriter, Fox Typewriter Company, Model 24 started from 1906 on

Fox's model 24 began production in 1906.Typewriter, Fox Typewriter brand, black with gold and green fancy transfers on sides, maker's name across top. Four rows of keys with Capital shift, back spacer pre-set shift. Keys include letters fractions, numbers, symbols, plus red and black type. Spacer marked in imperial measure. Printer on machine "FOX TYPEWRITER CO, GRAND RAPIDS, MICH USA" and "THE FOX TYPEWRITER CO. NO. 24 GRAND RAPIDS, MICH. USA" Printer on machine "FOX TYPEWRITER CO, GRAND RAPIDS, MICH USA" and "THE FOX TYPEWRITER CO. NO. 24 GRAND RAPIDS, MICH. USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, typewriter, office equipment, commerce, business, fos typewriter company, fox model 24 typewriter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920