Showing 65 items

matching pottery jugs

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ewer, First half of the 20th century

This object and the set of five items is believed to have been made in or around the Staffordshire area in the United Kingdom. Over 1500 pottery firms have operated in Stoke-on-Trent since the early 1700's - Some lasted only a few years and some for well over 200 years. Some potters built and owned their own works. Many others were tenants in works built by others and a succession of potters occupied the same works. It was also a common practice for a works to be split between two different pottery companies or for a larger manufacturer to let out a smaller section of his works to a potter who would make wares which were not of interest to the pot works owner. Some potters purchased 'blanks' from other manufacturers and put their own decoration on them some items have two back stamps some have no marks at all. This adds to the confusion and frustration of trying to trace details of a particular manufacturer such as the subject item.The subject item at this time cannot be associated with an historical event, person or place, provenance regards manufacturer is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Ewer or jug, cream ironstone with brown flower spray floral decoration.(Part of 5 piece set containing ewer, bowl, brush vase, soap dish lid and soap dish)Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, porcelain container, toilet container, beauty container, ceramic, decorative object, pottery object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1904-1930s

This Sharpe Bros. one gallon stoneware Demijohn is in excellent condition and includes its original stopper. It was made between 1904 and 1930, the date from the patent of the handle until the time that the factory no long produced returnable items. The bottle was once part of Dr W.R. Angus' household and is part of the W.R. Angus Collection and could have been purchased from Warrnambool's Sharpe Bros. factory. SHARPE BROS. 1903-1972- The first Sharpe Bros. cordial factory was opened in Dunedin, New Zealand, in 1903 by English prohibition brothers John and Percy Sharpe. Sharpe Bros. made ‘health’ beverages that were non-alcoholic drinks such as ginger beer, ginger ale, lime juice, soda and cordials. The containers of these drinks were not sold with the drinks but were marked as returnable items, to be cleaned and re-used, until this practice ceased in the 1930s. Sharpe Bros. made a niche in the soft drink market by delivering drinks by horse and cart to its customers’ homes. John Sharpe patented the unique wire spiral handle in 1904. By 1905 the New Zealand company also had factories in Australia. By 1910 the company had over 20 factories including Wanganui, New Zealand; Adelaide, Albury, Ballarat, Bathurst, Forbes, Geelong, Goulburn, Lithgow, Melbourne, Newcastle, Orange, Sydney, Tamworth, Warrnambool and Wollongong. The Warrnambool factory was established in 1919 and existed until 1951. The company won awards at Australian exhibitions for its carbonated drinks, including First Prize for its ginger beer made in the Brisbane factory. The company was taken over in 1962 by Tarax Drinks Holdings Ltd, which was in turn taken over by Cadbury Schweppes in 1972. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This stoneware Demijohn is connected to the history of Warrnambool, as it was owned by the daughter of Dr W. R. Angus and his wife Gladys. It is part of the W.R. Angus Collection, which is notable for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. It is also connected through its manufacturer Sharpe Bros. which had a branch in Warrnambool from 1919 to 1951, overlapping the time when the Angus family resided there from 1939 to the 1970s. The bottle is also significant as an example of the early-20th-century beverages found in local households and could have been purchased from the local Sharpe Bros. factory.This stoneware Demijohn is glazed, with a brown neck with internal thread and shoulders and a cylindrical cream base. The one gallon bottle has a flat, black stopper with a cork stem and a rubber, threaded tip. The ‘U’ shaped wire carry handle has a spiral of wire around the handpiece. An overhanging lip is on top of the bottle’s short neck above its rounded shoulder. The clay has been joined at the base of the neck, shoulder and body. The underneath is unglazed. The brown glazing on the shoulder has a run mark. Inscriptions are on the stopper and bottle. This container is part of the W.R. Angus Collection.Stamped in black on the shoulder: “KEEP THE / STOPPER TIGHT” Stamped in black on the body: “THIS JAR IS THE ABSOLUTE PROPERTY OF AND MUST BE RETURNED TO SHARPE BROS. AUSTRALIA / & NEW ZEALAND. ORIGINAL & LARGEST HYGIENIC BREWERY. CAUTION Persons Damaging, Willfully Retaining, Trading with or Misappropriating the Use of this Jar WILL BE PROSECUTED “ Stamped in script writing: “Sharpe Bros. TRADE - - - ED “ Embossed on the stopper: “AUSTRALIA AND NEW ZEALAND, SHARPE BROS.”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, sharpe bros., bendigo pottery, bottle, stoneware bottle, demihohn, one gallone bottle, soft drink, non-alcoholic drink, drink container, jar, jug, warrnambool soft drink, hygienic brewery, cordial factory, new zealand, australia, john sharpe, percy sharpe, non-alcoholic, spiral wire handle, ginger beer, w.r. angus collection, demijohn -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - BENDIGO POTTERY COLLECTION: SMALL ROUND JUG

... BENDIGO POTTERY COLLECTION: SMALL ROUND JUG...A small round jug from Bendigo's pottery.... BUSINESS Retail material Bendigo Pottery's website Bendigo Pottery ...A small round jug from Bendigo's pottery.Bendigo Pottery Australia logo next to the handlebusiness, retail, material, bendigo pottery's website -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - BROWN POTTERY JUG

... BROWN POTTERY JUG..., white interior. Domestic Object BROWN POTTERY JUG ...Brown glazed Langley Ware jug with applied handle, smooth glaze on top section with rough finish on base, white interior.Permashe Leadless Glaze 1 1/2 PTdomestic equipment, food storage & preservation, jug -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - SMALL POTTERY JUG

... SMALL POTTERY JUG... and rough pattern on bottom. Domestic Object SMALL POTTERY JUG ...Small brown Langley ware jug with applied handle, smooth glaze on top portion and rough pattern on bottom.1/4 Pintdomestic equipment, food consumption, jugs -

Clunes Museum

Clunes MuseumContainer - JUG, SHARPE BROS

... Clunes Museum 36 Fraser Street Clunes goldfields JUG USED ...JUG USED TO CONTAIN GINGER BEERSTONEWARE JUB WITH WIRE HANDLE, BROWN CERAMIC GLAZE AT THE NECK OF THE JUG AND CLAY COLOURED GLAZE AROUND TO JUG BELOW THE BROWN"HEALTH BEVERAGES - WHEN EMPTY RETURN TO SHARPE BROS AUSTRALIA AND NEW ZEALAND" IN BLACK LETTERING ON THE BODY OF THE JUGstoneware, jug, ginger beer -

Clunes Museum

Clunes MuseumDomestic object - STONE JAR

... Pottery Jug... Jug Doulton & Coy Doulton & Coy Lambeth Pottery London CREAM ...CREAM COLOURED STONE JUG WITHOUT HANDLEDoulton & Coy Lambeth Pottery Londonpottery jug, doulton & coy -

Clunes Museum

Clunes MuseumDomestic object - STONE JAR

... pottery jug...Clunes Museum 36 Fraser Street Clunes goldfields pottery ...CREAM COLOURED STONE JUG WITH HANDLENilpottery jug, stoneware -

Clunes Museum

Clunes MuseumDomestic object - STONE JAR

... Pottery Jug...Clunes Museum 36 Fraser Street Clunes goldfields Pottery ...CREAM COLOURED STONE JAR OR DEMIJOHNpottery jug, stoneware -

Anglesea and District Historical Society

Anglesea and District Historical SocietyCream Jug, Estimated 1937

Crown Ducal Florentine Jug. Small off-white light cream colour. The top half is embossed with Florentine pattern. Gold band around top of centre of jug. Gold decoration on handle.Crown illustration. Crown Ducal, Florentine Made in Englandjug, creamer, crown ducal -

Nillumbik Shire Council

Nillumbik Shire CouncilPottery: Gilbert BUCHANAN, Stoneware Jug

... Nillumbik Shire Council melbourne Stoneware Jug Pottery ... -

Nillumbik Shire Council

Nillumbik Shire CouncilPottery (jug): Phyl DUNN (b.1915 Vic, AUS - d.1999 AUS), Black brown jug

... Pottery (jug): Phyl DUNN (b.1915 Vic, AUS - d.1999 AUS)...Nillumbik Shire Council melbourne Black brown jug Pottery ... -

Nillumbik Shire Council

Nillumbik Shire CouncilPottery (jug): Bruce DAVIDSON, Pale Blue Jug

... Pottery (jug): Bruce DAVIDSON ...Nillumbik Shire Council melbourne Pale Blue Jug Pottery ... -

Nillumbik Shire Council

Nillumbik Shire CouncilPottery (jug): Geoffrey DAVIDSON, Jug

... Pottery (jug): Geoffrey DAVIDSON ...Nillumbik Shire Council melbourne Jug Pottery (jug ... -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Ceramics, Pottery Jug

... Pottery Jug... thrown jug.. Pottery Jug Ceramic Ceramics wartook Pottery Gilbert ...Hand thrown jug.. australian landscape pottery, landscape, gilbert buchanan, sheparton, graham wood, redbyrne pottery, ceramics -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Artwork - Ceramics, Pottery Jug by Gellibrand Pottery

... Pottery Jug by Gellibrand Pottery... gellibrand pottery studio pottery Photo of a hand thrown jug ...Jon and Alda Hubbard were operating Gellibrand Pottery around the late 1980s on the Old Beech Forrest Road in Gellibrand near Colac in the Otway region.Photo of a hand thrown jug with glaze decoration. It is stamped (impressed) "Gellibrand Pottery". ceramics, pottery, gellibrand pottery, studio pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Old Ballarat Pottery, Old Ballarat Pottery Jug

... Old Ballarat Pottery Jug.... Old Ballarat Pottery Australian Studio Pottery jug Pontresina ...Old Ballarat Pottery was set up by John Gilbert as part of the Old Ballarat Village, opposite Sovereign Hill. Gilbert had lectured at Ballarat College of Advanced Education before establishing the Edinburgh Pottery at Sovereign Hill in 1972 to enable visitors to see traditional trades at work. The Old Ballarat Pottery was a much larger concern, producing wares for sale through department stores and on party plan via Faberware as well as through the village. Early works looked as though they might have been made in the 1850s, with unturned bases, crude marks and dark treacle-like glazes. Peter Pilven, one of Gilbert's students, worked there after graduating from the Ballarat College of Advanced Education, teaching throwing to students like the potter John Ferguson, who was there from 1978-79. Potters were initially employed by Gilbert's company Pontresina Pty Ltd, registered in 1973. (The Old Ballarat Pottery was registered as a company from 1984-1994.) Early works are marked with an impressed long-tailed 'B', or an 'OB' on either side of a mine tower. A printed stamp also features a mine tower surrounded by the text 'Old Ballarat Pottery Made in Australia'. Later work is impressed 'Stoneware Old Ballarat Pottery Australia' with a kangaroo.Hand thrown blue glazed jug.Stamped 'Stoneware Old Ballarat Pottery?old ballarat pottery, australian studio pottery, jug, pontresina, ceramics -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Vitclay Pipes Pty Ltd, 1995

First owners, Whites of England - hand made bricks, coffee jugs, hand made agricultural pipes and garden edgings. 1911 Commonwealth Insulator Co run by Gee Brothers - stone ginger bottles, insulators for PMG. 1920 Parker & Strangwood. Closed for a short while. 1931 Descendants of Gee Brothers. 1936 Commonwealth Art Tiles, Bricks & Pottery Works. 1961 Brick and Pipe Industries. 1971 Amalgamation leading to Vitclay.Four coloured photos ( a-d ) of the dismantling of Vitclay buildings in 1995 and subsequent vacant land for housingvitclay pipes pty ltd, pipeworks, commonwealth potteries pty ltd, clay industries, gee family, commercial insulators, brick and pipe industries, commonwealth art, tile, brick and pottery works -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Ceramics, Jug by Gilbert Buchanan of Redbyrne Pottery

Photograph of a hand thrown ceramic jug. ceramics, gilbert buchanan, redbyrne pottery, sheparton, australian studio pottery -

Ballarat RSL Sub-Branch Inc.

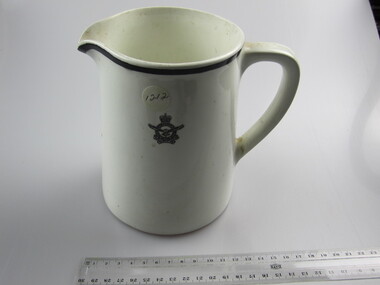

Ballarat RSL Sub-Branch Inc.Jug - RAAFA Insignia Porcelain Medium

Inscription = 24 No. 10 North Staffordshire Pottery, Hanley, Made in Englandcollectables, ballarat rsl, ballarat -

Melbourne Legacy

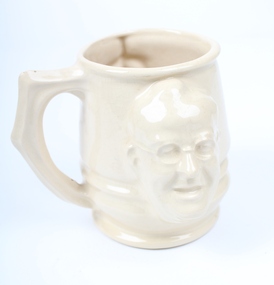

Melbourne LegacyCeramic - Mug, Legatee Stan Savige 1946, 1946

A tankard mug that was produced in 1946 to honour Legatee Stan Savige service to Melbourne Legacy. See Frank Doolan's account at 01287.10. The mug was produced by EG Greenway Pty Ltd, a pottery manufacturer in Blackburn, associated with Legatee Herb Greenway.Shows the importance of Stan Savige to Legacy that they honoured him by portraying him in a mug.Cream coloured ceramic Toby jug with handle. Relief portrait of Legatee Stan Savige on one side and relief insignia of Legacy Torch and laurel wreath on the opposite side.Under side of mug is etched with Legatee Stan Savige 1946souvenir, founding legatee, stan savige -

Moorabbin Air Museum

Moorabbin Air MuseumCeramic (Item) - Australian National Airways Milk/Cream Jug

Vitrified/Globe Pottery Co .Ltd Shelton England. Supplied by John Dynon & Sons Melbourne. -

Friends of Westgarthtown

Friends of WestgarthtownGravy jug, … Pottery'

... blue marks on inside. Gravy jug … Pottery' ...White china gravy boat with blue floral pattern on exterior, extending from rim to around 1/3 down the side, and leaf pattern on rounded handle. Large spout or lip for pouring. Some blue marks on inside.Maker's mark on base, circular stamp with female figure in centre. 'PEONY' printed at top, '… Pottery Coy Ltd. Glasgow' printed around circle, some missing because of bad printing. 'Made in Scotland' at bottom.domestic items, food & drink consumption, gravy, boat, container, blue and white, china, peony, scotland, glasgow -

Parks Victoria - Mount Buffalo Chalet

Parks Victoria - Mount Buffalo ChaletCrockery

The jug and cup were purchased from a second - hand shop in Bairnsdale. Jug is older than cup as the chalet is represented as a single storey structure. The cup is later as the second storey appears in the illustration. 'Souvenirs in relation to the Chalet and Mount Buffalo wee first mention in December 1912... A large range of souvenirs has since been associated with the Chalet and Mount Buffalo from crafted wooden items, silver spoons, cups etc... The collection includes a broad selection of products that have been sold throughout much of the Chalet's history, each representative of the transient fashions of their period.' (Pg. 114. Historica) 'A group of tableware items is notable for its black transfer printed decoration, which features the Chalet building. Interestingly, the printed designs represent the Chalet at two different stages in its building history under the Victorian Railways, in 1926 after completion of the north wing, and 1937-39, after the second storey is added to the front.. manufactured in England by A.B. Jones and sons, a Stoke on Trent pottery firm which operated under the trade name of Grafton China between 1900-1972.' (Pg. 114. Historica)Listed in Draft Inventory of Significant Collection Items . Appendix A.3. Souvenirs. (Pg 168. Historica)..1] Ceramic jug. Souvenir of Mt Buffalo. White ceramic squat milk jug with a black transfer illustration/drawing on front side. Picture is of the MtBuffalo Chalet from the front. Some worn gold glaze detail. It appears to be a single story building with a planted garden at the front with a fence. Trees to one side and people walking up steps. "THE CHALET, MT BUFFALO NATIONAL PARK, VICTORIA." is written under the illustration. Jug has a faint crack. .2] White ceramic cup with gold edging around top of cup. Black transfer drawing of the chalet with a second storey. Rocks and tree in foreground and "THE CHALET. MT BUFFALO." underneath transfer. .1] "THE CHALET, MT BUFFALO NATIONAL PARK, VICTORIA." is written under the illustration. On the base of the jug, with sun motif, "ENGLAND / GRAFTON CHINA /A / B J / & SONS / LOFTUS MORA / PTY. LTD" .2] "THE CHALET. MT BUFFALO." underneath transfer. Under cup, "A.B.J. / GRAFTON / CHINA / MADE IN / ENGLAND" -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCannie Ridge Pottery, mid 1970s

CANNIE RIDGE POTTERY OPENED SEPT 1976 BY ALLAN & MARY LETTS, AND SON GARY AND JENNY, APPROX 16 EMPLOYEES PRODUCED MEMORABILIA FOR THE POPE'S VISIT IN 1988 AND HOUSEHOLD ITEMS INCLUDING WINE BARRELS, GOBLETS, CASSEROLES, TEAPOTS, JUGS, PLATES AND EVEN DINNER SETS EACH bearing the distinctive Eucalyptus patterns.Products of a now-closed ceramic pottery located in Harcourt.BLUE GLAZED 5 SIZED CANNISTERS GUM LEAF MOTIF WITH BLUE LIDSCANNIE RIDGE STAMP ON BOTTOM -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Earthenware Bottle - House of Seppelt, Elischer Pottery, c1970

The Seppelt company was founded in the Barossa Valley in 1851 by Joseph Seppelt, a German immigrant. In 1902 the family business was registered as B. Seppelt & Sons Ltd. As part of the expansion of this successful business, they acquired the Clydeside Cellars in Rutherglen from the estate of Mr. David G. Hamilton in 1914.,Due to changing conditions the vineyards were sold in the 1980s and all stock taken back to their property at Seppeltsfield in South Australia. From 1984 until the present, the Cellars in Rutherglen has had several operators including Jolimont Cellars (Doug Shears), Tony Lamb and 2 different Asian-owned conglomerates operating as Rutherglen Estates. In 2018 Rutherglen Estate was purchased by De Bortoli Family Winemakers of Griffiths, NSWThis jug is representative of leading pioneers and companies in the Australian Wine industry located in Northeast Victoria.A ceramic wine carafe produced by the House of Seppelt. It features the coat of arms of the House of Seppelt on one side and a portrait of Benno Seppelt on the opposite side. The lower section of the carafe is beige in colour and the top half, coat of arms and portrait are in blue. THE HOUSE OF / SEPPELTb. seppelt & son, australian wine industry, northeast victorian wineries -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Ironstone China Wash bowl and jug

Ironstone china pieces were common domestic items during the 19th to mid 20th century in many Australian households. This kind of china is not porcelain but porous earthenware, made of clay mixed with feldspar. Patented in 1813 by Charles James Mason in Staffordshire, England, it was an immediate success and became widely produced by a range of Staffordshire potters. J & G Meakin Pottery dates back to 1845 when James Meakin started a pottery business at Lane End in Staffordshire.nIn 1848 he moved the business to Hanley in Staffordshire, before retiring in 1852 and handing the business over to his two sons James and George, who carried on with the pottery, trading as J & G Meakin. The "SOL" and sun face trademarks were registered in 1912. The firm was taken over by the Wedgwood Group in 1970. In 2000, production under the Meakin name ceased. W. H. Grindley was founded at the Newfield Pottery in 1880 by William Harry Grindley (principal partner). Mr Turner and Mr Alfred Meakin were also involved. Early advertisements stated that they produced Earthenware and Ironstone China - particularly for the Canadian, United States, South American and Australian markets. The mark on this jug was used from c1891 until 1925. W. H. Grindley China was manufactured until 1991, making it one of the last Stoke on Trent potteries.These items are representative of a common domestic item used by households in the Wodonga district and throughout Australia, many manufactured specifically for the Australian market.A white ironstone jug and bowl. The jug features a leaf design embossed on the surface. The bowl has a small circle pattern around the rim. They are not as set as the jug bears the mark W. H. Grindley and the bowl was made by J & G Meakin.Underneath Bowl: above and below image of the sun: "IRONSTONE CHINA/ REGD. SOL 391413/ J & G MEAKIN/ENGLAND Underneath jug: above and below the royal insignia: ROYAL IRONSTONE CHINA / W.H. GRINDLEY & CO. / ENGLAND"ironstone, domestic items, staffordshire pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Jug, Emu Jug by Albury Pottery, c1980s

... Emu Jug by Albury Pottery... 2024.) Albury Pottery emu A ceramic jug with a brown top ...Albury Pottery was established in the late 1970s to supply pottery for the party plan company Cooperware, a spin-off from Faberware. Located in Hudson Crescent, Lavington, the pottery was managed by Rudolph Dybka until 1983, then by Ron Petch, who had previously worked as sales manager for Cooper Pottery, one of Cooperware's UK suppliers. By the mid-1980s, the pottery had four throwers and a further 5-6 employees, and was specialising in stoneware with distinctive ribbed forms and light blond glazes. In 1985, the pottery was sold to the NSW Government as a workers' cooperative, and Petch moved to Old Ballarat Pottery as production manager. In 1987, the Petch's bought back into the business with partners Pat and Ken Snape, moving to slip casting, doubling the operating area, opening a terracotta plant in a separate location and establishing a tourism presence in the Old Cheese factory between Albury and Wodonga. As the business grew it took on more partners and this proved problematic in a declining market for production pottery. The Petch's pulled out in 1991 and the pottery closed shortly afterwards. (CC BY NC SA Judith Pearce, accessed https://www.flickr.com/groups/1281707@N21/discuss/72157629392131982/, 15 October 2024.)A ceramic jug with a brown top, and an emu on a white ground.albury pottery, emu -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Ceramics, Glazed Jug

... ceramics Australian Studio POttery jug Photograph of a hand ...Photograph of a hand thrown ceramic jug. ceramics, australian studio pottery, jug