Showing 93 items

matching power tools

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower with a symbol "M"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower Size 9/16"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing wood Plane, Mid to Late 19th Century

A smoothing plane is a wood plane used for making a smooth surface to wood surfaces traditionally, these planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape or size required. The blade, or iron was likewise formed to the intended flat or level profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Large crown mouldings or smoothing plane surfaces required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by an unknown maker, that was made commercially for firms and individuals who worked in wood and needed a tool that could produce a flat or level finish to timber. These types of planes came in various shapes and sizes to achieve the required finish to timber surfaces used in cabinet making. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Smoothing Plane Coffin typeMaker J Moseley & Son London and 2¼" also has OS stamped on side (probably an owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Underwater Chainsaw, n.d

Underwater chainsaw, pneumatic operation, iron, steel and alloy, painted red, steel blade, no chain, power vane motor and steel hose attachmentsFront: Consolidated Pneumatic Tool Co, London. CP DANARM SAW, Danarm limited, Stroud Glos England M/C No CP4711781 -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

... A screwdriver is a tool, manual or powered, for turning... A screwdriver is a tool, manual or powered, for turning (driving ...A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

Ararat & District Historical Society (operating the Langi Morgala Museum)

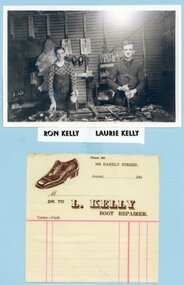

Ararat & District Historical Society (operating the Langi Morgala Museum)Photograph

L. Kelly Boot Repairer was located at 308 Barkly Street, Ararat, now the current site of Ararat Tyre Power (272 Barkly Street, Ararat). Old site in the early 1940s was Mr H. McMillan Garage for motor repairs. The boot repair section was rented by Laurie Kelly, then 308 Barkly Street. After World War 2 it became home of PMGBlack and white photograph of two men wearing aprons and standing at a work bench with tools. A docket featuring a shoe and a business address for L. Kelly Boot Repairer is beneath the photo.Ron Kelly, Laurie Kelly -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBuck Saw

A bucksaw is a hand powered frame saw similar to bow saw and generally used with a sawbuck to cut logs or firewood to length (bucking).Used by residents of the Kiewa Valley for clearing land, chopping firewood, cutting lumber. Also used while camping because it is portableFormerly UKV 239. Buck Saw with Lightning Tooth Blade. Operated by two men.Ref. Page 10 Tools for all Trade Catalogue. It consists of 3 horizontal bars, the top one being twisted wire and the bottom one being the metal blade with a wood bar in between. They are attached at each end to curved wooden bars. tool for wood, saw, buck saw -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyVacuum Cleaner - Electrolux

Vacuum cleaners have been part of the household for many years. Beginning as simple tools blowing the dust to the current sucking up the dust and being powered by electricity. From the shape of a barrel to those that stand upright, from being fitted onto a 'sled' to those with wheels and from heavy to light.Used by a resident in the Kiewa Valley Electrolux cannister steel vacuum with leather handle at the top, the electric socket (and cut power cord attached) at one end and the cloth covered hose at the other end. Two steel extension handles, hose and cord works. Parts with combination dusting and upholstery tool and hardwood floor dust mop and refrigerator crevice tool. The cannister sits on a 'sled' of two long rods on each side.Hand written on the cannister "1932 Model" "Electro / lux / Made in Sweden / Design Nr B156 Registered" on top On bottom "Ser 1234 No. 1456 / Volt Watt" ....(not legible)electrolux, vacuum cleaner 1932 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPlane Wood, 1890 -1900

... , outbuildings, furniture. It represents an era before power tools ...J.E. Bleckmann were German Blade makers, registry shows Bleckmann (1899, No. 37190):J.E.Bleckmann, Solingen, registry class 9b). As well as blades for wood working tools they were also sword makers (used in American Civil War), Bayonet makers 1871-1918 and also pocket cutlery (pocket knives) as per advertisement 1907.This wood plane holds historical importance as carpentry tools such as this would have been used in the construction of local homes, outbuildings, furniture. It represents an era before power tools. Investigation is ongoing as to ownership and specific use in the area. Hand made wooden hand plane with metal blade. Carpentry tool from 19th century1/38 / 34 mm stamped into wood on front edge of plane. Metal Blade inscribed "J.E. BLECKMANN/ WARRANTED / CAST STEEL / SOLINGEN/GERMANY"tool, blade makers, hand plane, woodworking. -

Orbost & District Historical Society

Orbost & District Historical Societynewspaper clippings, 1962

... research tool. orbost-power-water-supply A manila folder containing ...Collected by Mary Gilbert. This folder belonged to Mary Gilbert and was probably used by her whilst teaching at Orbost High School and as a member of the Orbost Historical Society. Mary Isabelle Gilbert was born in 1905 in Orbost, Australia. She was born to John Gilbert and Annie Cameron Gilbert, and had seven sisters and one brother. Four siblings died at a young age. .She was a teacher historian loved and respected by her family and the wider community. This item is a useful research tool.A manila folder containing b/w newspaper cuttings relating to the progress of Orbost power, mail and water supply. The articles are from various newspapers.. 732.2 is a report by Mr A. Sambell. C.E. on the Orbost Water Supply. 732.3 is from the Weekly Times, July 17 1968 and is titled "Snowy River Mail Follows Our Ancient Track". 732.4 is from the Snowy River Mail, May 16 1962 and is titled " Power To Orbost in Keeping with State's Progress. 732.5 is from the Snowy River Mail, May 16 1962 and is titled " The Vital Power of Electricity".orbost-power-water-supply -

Orbost & District Historical Society

Orbost & District Historical Societytrying plane, first half 20th century

... .. It is representative of an era before power tools. woodwork tools plane-trying ...A heavy trying plane would have been used in construction work on rural properties. It can be used for planing hard, difficult timbers.Tools such as this would have been used in the construction of local homes, or rural outbuildings in early Orbost.. It is representative of an era before power tools. A long, heavy wooden plane used in smoothing the edges of roughly planed wood.woodwork tools plane-trying -

Orbost & District Historical Society

Orbost & District Historical Societyscrew driver, first half 20th century

... of the 20th century before the widespread use of power tools. tool ...This screwdrivers is a woodwork toolused for driving screws into materials or for securing or loosening parts on machinery. It was probably used on a rural property in early Orbost...This is an example of a domestic tool commonly used in the first half of the 20th century before the widespread use of power tools.A large steel flat head screw driver with a rounded, wooden grooved handle.tool screwdriver woodworking -

Orbost & District Historical Society

Orbost & District Historical Societyratchet brace, first half 20th century

... century prior to the widespread use of power tools. woodwork tools ...This carpenter's clamp would have been used in confined spaces where a full turn of the brace cannot be achieved. It is fitted with a pawl mechanism - a hinged or pivoted device adapted to fit into a notch of a ratchet wheel to impart forward motion or prevent backward motion. This item would have been used on a rural property in constructing or maintaining infrastructure.This item is an example of a woodworking tool used in the first half of the 20th century prior to the widespread use of power tools.A metal ratchet brace with a wooden handle grip. It has a hinged mechanism device which fits into the notches of the ratchet wheel - a pawl.woodwork tools brace-ratchet -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill, Mid 20th century

... commonly used before the widespread use of power tools. tool hand ...This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools.A hand drill with three wooden handles. The main gear is painted red.On right handle - Made in China with some Chinese lettering.tool hand-drill -

Orbost & District Historical Society

Orbost & District Historical Societyrebate plane

... commonly used before the widespread use of power tools. woodworking ...This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools.A wooden rebate plane with a brass adjusting knob. It has a cutting edge, such as a sharpened metal plate attached to a wooden body,woodworking-tool hand-rebate-plane -

Orbost & District Historical Society

Orbost & District Historical Societyhand shears, early 20th century

... of power tools. tool hand-shears On blade - Red Reaper Hand Shears ...These hand shears were used for sheep shearing. They appear to be dual purpose sheep or topiary shears. They would have been used on a rural property in early Orbost. This item is an example of a hand tool used commonly before the widespread use of power tools.A pair of metal hand shears with a circular loop handle. On blade - Red Reaper Hand Shears 219 Ward & Payne 303 SHEFFIELD ENGLANDtool hand-shears -

Orbost & District Historical Society

Orbost & District Historical Societyplane, first half 20th ceentury

... woodworking tool commonly used before the widespread use of power ...A grooving plane was traditionally used for drawer bottoms or for flooring or lining boards.This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools.A wooden grooving plane - no blade.tool woodwork plane-grooving -

Orbost & District Historical Society

Orbost & District Historical Societysaw, first half 20th century

... used before the widespread use of power tools. tool woodworking ...This item is an example of a woodworking tool commonly used before the widespread use of power tools.A saw with a long, tapered narrow serrated blade for cutting small holes such as keyholes. The blade is held by two large head brass screws onto a wooden handle.tool woodworking keyhole-saw -

Orbost & District Historical Society

Orbost & District Historical Societybrace and bit, first half 20th century

... century prior to the widespread use of power tools. woodworking ...This carpenter's clamp would have been used in confined spaces where a full turn of the brace cannot be achieved. It is fitted with a pawl mechanism - a hinged or pivoted device adapted to fit into a notch of a ratchet wheel to impart forward motion or prevent backward motion. This item would have been used on a rural property in constructing or maintaining infrastructure.This item is an example of a woodworking tool used in the first half of the 20th century prior to the widespread use of power tools.A metal ratchet brace with a wooden handle grip. It has a hinged mechanism device which fits into the notches of the ratchet wheel - a pawl. The drill bit is jammed and the chuck is rusted.woodworking tool brace-and-bit carpentry -

Orbost & District Historical Society

Orbost & District Historical Societycarpenter's pincers, first half 20th century

... the widespread use of power tools. woodworking tool pincers carpentry ...The main purpose of carpenter's pincers is to pull out nails from wood without damaging the surface. These carpenter's pincers would have been used in Orbost in the construction of new buildings or on a rural property for maintenance.This item is an example of a domestic carpentry tool in common use before the widespread use of power tools.Pincers with long, rounded, pivoted metal handles ending in a pair of jaws for gripping and extracting nails or holding or gripping small objects.woodworking tool pincers carpentry -

Orbost & District Historical Society

Orbost & District Historical Societyratchet brace, first half 20th century

... century prior to the widespread use of power tools. A metal ...This carpenter's clamp would have been used in confined spaces where a full turn of the brace cannot be achieved. It is fitted with a pawl mechanism - a hinged or pivoted device adapted to fit into a notch of a ratchet wheel to impart forward motion or prevent backward motion. This item would have been used on a rural property in constructing or maintaining infrastructure. This item is an example of a woodworking tool used in the first half of the 20th century prior to the widespread use of power tools. A metal ratchet brace with a wooden handle grip. It has a hinged mechanism device which fits into the notches of the ratchet wheel - a pawl -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Cooper’s Hollowing /Jigger Knife, William Greaves & Sons, 1823 -1850

William Greaves was once a prolific company that highly prospered in the 19th century during the boom of the tool and cutlery trades in Sheffield England as steel became more commercially available. William Greaves's works were situated at the Sheaf Works in the heart of Sheffield, at Maltravers Street, opening in 1823 and was known to be the largest business in this area at this time. The Sheaf Works made a range of tools and saws including cutlery, penknives and razors and also even made its steel in-house. The factory used its perfect position for water power being built on the edge of the Sheffield canal and also used the railway line nearby giving them the perfect opportunities for transporting its goods. The factory itself was also a revolution because it attempted to bring together as many cutlery manufacturing processes as possible together in one place, something that had not been attempted before. The money to build these huge works came from Greaves' trade with America, where they sent razors, table cutlery and sturdy Bowie knives. This allowed the Greaves’ to build the factory and expand their production, which made them even more money. This made William Greaves very rich indeed, and it was reported that when he died in 1830 he left each of his five surviving daughters £30,000 each, an astronomical sum at the time. In today’s money that is approximately £2.3 million. The firm finally dissolved in 1850, but Sheaf Works continued to be used by many cutlery manufacturers until the 1980s. With most of the buildings still standing today.A significant item made by a successful cutlery manufacturer in England during the first half of the 19th century. This company undertook many new processes to streamline cutlery production and introduced innervations regards working with steel that are still in use today. This item is now regarded as a collector's item given the company ceased trading in 1850. jigger/hollowing knife with internal bevel, Electro Boracic Steel. Stamped 3.1/2″ William Greaves, Sheaf Works, Sheffield flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cooper's jigger, howeling knife, wm greaves & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chain Drill Attachment, Millers Falls Co, 1900-1931

An auxiliary tool for use with a breast drill or bit brace, when extra power is needed, or where pressure cannot be easily applied. The drill is automatically fed into the work by an adjustable friction feed which is automatically regulated by the resistance the drill encounters. These were made to fit on breast drills, and used for drilling metal, particularly round sections like a pipe. The chain is run around the object being drilled and gradually tightens as the hole is drilled, maintaining pressure while being a bit easier on the operator. Millers Falls Co. is a tool manufacturing company originally based in Millers Falls, Massachusetts, USA. It was established in Greenfield, Massachusetts in 1868 as Gunn & Amidon by Levi J. Gunn and Charles H. Amidon. Gunn and Amidon, along with a third partner, Henry L. Pratt built a factory in the north of Greenfield. After the Greenfield factory burned down, the company was reorganized as the Millers Falls Manufacturing Co. It merged with Backus Vise Co. in 1872 to form Millers Falls Co. In 1931 Millers Falls tools purchased the majority of the shares of Goodell-Pratt tools and merged with that manufacturer in 1932. In 1962 the company was acquired by Ingersoll Rand. In 1982, Ingersoll Rand sold the Millers Falls business to the newly created Millers Falls Tool Co. The company was head quartered in Alpha, New Jersey. Since 2002 the company trademark has belonged to Hangzhou Great Star Industrial, of Hangzhou, China. The item is associated with a tool manufacturing company established in the mid-19th century that pioneered the development of many types of tools used in many differing trades. The company grew to become a major supplier of tools around the world and today its tools that were produced during the mid-19th and early 20th centuries are now collectable items. Drill attachment with chain No 717 from 1925 catalogue 1/2 socket hole Millers Falls, Massachusettsflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, chain drill, mast drill, millers falls, drilling attachment, drilling tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, Ward & Payne Ltd, Late 19th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. The subject item was made by Ward & Payne of the Limbrick Works at Hillsborough, Sheffield England manufacturers of hand-forged tools. Their trademark registered in 1850 was a Letter "W" & "P" stamped into the steel. The firm was established by David Ward (1767-1822) in 1803 the company became David Ward & Sons, in 1837 after Ward's son Edward joined the firm. In 1845 Henry Payne the founder's son-in-law became a partner but died in 1850 after which the company reverted to the Ward family. The business then concentrated on making carving tools, chisels and gouges. In 1882 David Ward's grandson David Ward Jr. (1835-1889) purchased land and built a factory at Sheffield North known as the "Limerick Wheel". For a time Wards operated from both 106-114 West Street Sheffield and at Limbrick Road, Hillsborough on the river Loxley. By 1911 they had expanded into making spades, forks, sheep shears and many other types of edged tools including drills and wood planes. In 1967 Wilkinson Sword purchased all the company's share capital and continued to sell Ward & Payne tools until 1970 when a fire burned the factory down and housing development was built on the site. The subject item is significant as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Caulking tool with square end"WARD Sheffield"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, james s steele, caulking iron, caulking tool, shipwright tools, ward & payne sheffield, forged tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, A Mathieson and Son, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. The subject item was made by Alexander Mathieson & Sons but the company was established in 1792 when John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker”. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over by Mathieson and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. In the 1851 census, Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his father's name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, but it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. In the Company's later years both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as a tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 and took a rather different approach to engineer, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medalThe firm Alexander Mathieson & Sons were one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide. The subject item is of further significance as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Caulking tool Off-set. Stamped on blade "Mathieson & Son Glasgow" also stamped in handle, James S Steele tool box.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, james s steele, caulking iron, caulking tool, offset caulking tool, alexander mathieson & sons, shipwrights tools, ship building, clinker hull caulking, sailing ships -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw blade with wooden handle attached with wingnut.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Adze, Ward & Payne Ltd, Between 1843 to Mid 20th Century

An adze is an ancient and versatile cutting tool and has been in use for thousands of years. Adze are similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. They have been used since the Stone Age. Adzes are hand tools used for smoothing or carving wood. The subject item was made by Ward & Payne of the Limbrick Works at Hillsborough, Sheffield England manufacturers of hand-forged tools. Their trademark registered in 1850 was a Letter "W" & "P" stamped into the steel. The firm was established by David Ward (1767-1822) in 1803 the company became David Ward & Sons, in 1837 after Ward's son Edward joined the firm. In 1845 Henry Payne the founder's son-in-law became a partner but died in 1850 after which the company reverted to the Ward family. The business then concentrated on making carving tools, chisels and gouges. In 1882 David Ward's grandson David Ward Jr. (1835-1889) purchased land and built a factory at Sheffield North known as the "Limerick Wheel". For a time Wards operated from both 106-114 West Street Sheffield and at Limbrick Road, Hillsborough on the river Loxley. By 1911 they had expanded into making spades, forks, sheep shears and many other types of edged tools including drills and wood planes. In 1967 Wilkinson Sword purchased all the company's share capital and continued to sell Ward & Payne tools until 1970 when a fire burned the factory down and housing development was built on the site.The subject item is significant as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Adze with wooden handle curved painted green with patent number and maker's name inscribed on inside curve of blade. Inscribed "Patd 561 Ward" "2w". flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, smoothing tool, hand tool, carpenders tool, adze, coopers tool, woodworking tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture.Compass saw with wooden handle and metal blade. Small teeth. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw with wooden handle broken and metal blade. Small teeth.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw