Showing 82 items matching "safe working"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Carbide Lamp, Powell & Hanmer, 1920s

Francis Powell (1861-) and Francis Hanmer (1858-1925) founded Powell and Hanmer Ltd in the Summer of 1885 for the manufacturer of bike and carriage lamps. Their first advertisements began to appear in November of 1885. In 1890 they lodged a Patent for “velocipede” lamps to be used by lightweight wheeled vehicles propelled by a rider, such as a bike, tricycle and railroad handcar. In April of 1913, they were selling headlamps for cars and in 1914 built their second factory manufacturing dynamo lighting sets in Rocky Lane Birmingham, also for the production of dynamos for motor cars. Then in 1929 Powell and Hanmer Ltd, was acquired by the Lucas company which was at that time the main competitor for the manufacture of non-electrical equipment for cycles and motorcycles. When a director of Powell and Hanmer joined the board of Austin motor cars, Lucas feared that Austins might encourage Powell and Hanmer to start to produce electrical equipment for supply to the company and as a result this association might affect Lucas's business with other large vehicle manufacturers. As a result, Lucas made an offer to Powell & Hanmer and purchased the business for £500,000. Carbide lighting was used in rural and urban areas of Australia which were not served by electrification. Its use began shortly after 1900 in many countries and continued past the 1950s. Calcium carbide pellets were placed in a container outside the home, with water piped to the container and allowed to drip on the pellets releasing acetylene. This gas was piped to lighting fixtures inside the house, where it was burned, creating a very bright flame. Carbide lighting was inexpensive but was prone to gas leaks and explosions. Early models of the automobile, motorbike and bicycles used carbide lamps as headlamps. Acetylene gas, derived from carbide, enabled early automobiles to drive safely at night. Thick concave mirrors combined with magnifying lenses projected the acetylene flame light. These type of lights were used until reliable batteries and dynamos became available, and manufacturers switched to electric lights. Acetylene lamps were also used on riverboats for night navigation. The National Museum of Australia has a lamp made in about 1910 that was used onboard the PS Enterprise, an 1878 Australian paddle steamer, currently owned by the National Museum of Australia in Canberra. It is still operational, and one of the oldest working paddle steamers in the world, listed on the Australian Register of Historic Vehicles.Acetylene Carbide lamp, Model “Panther” distinct patterned side red and green lenses. These lamps were also known as acetylene gas lamps. They work off a chemical reaction between calcium carbide and water.Model 75flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, carbide lamp, motor vehicle, bike lamp, lighting, vehicle lighting, powell, hanmer, acetylene gas lamp, early lighting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Safe, Willow Ware Pty Ltd, 1920s -1950

Willow started business in 1887 as a metal working company based in Melbourne Australia, making tinned biscuit and tea canisters. The outbreak of the First World War saw their manufacturing change to making armaments and essential packaging for the war effort. In the early 1920’s, the Willow brand was established. Making tin plated canisters and baking pans with the well-known Willow pattern, imprinted on them. Some other items in production at this time include billies, boilers, basins and Coolgardie safes. In the late 1950’s, the company ventured into plastics production. Stepping away from its very successful tin plating industry of more than 50 years. In 1965, the company name changed to Willow Ware Pty Ltd, to be more closely linked to its Willow brand. Willow Ware is still in business today. A food safe known as a “Coolgardie” meat storage made by an emerging Australian company no longer in bushiness. This item gives a snapshot into early Australian manufacturing specifically aimed at the Australian market.Safe metal kitchen food safe with 2 shelves, a hinged door and latch and a small swivel wire handle at the top. Painted light green, rusting.Willowwarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, safe, food safe, meat safe, coolgardie safe, domestic object, kitchen object, willow ware, food preservation, kitchen safe -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944

Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment, and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards, and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering, and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air, and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman's fortunes began to decline as an aging Sir Robert Davis failed to invest, or change the company's business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998). (For information regards the diving helmet & Frank King see Notes Section at the end of this document)The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job. Frank Kings' diving helmet and compressor (communication pipe stored separately). Compressor is hand cranked. US Navy diving helmet, Mark V. Two maker's plates attached. Made in 1944.On rear "WATER SUPPLY" On front 'PATENT" " Logo: Images (Lion, Crown, Horse, Shield within an oval) "SIEBE, GORMAN & Co. Ltd. SUBMARINE ENGINEERS, LONDON.flagstaff hill, warrnambool, maritime museum, great ocean road, us navy diving helmet, commonwealth government salvage, diving helmet, marine salvage, frank king, diver, siebe. gorman & co ltd, submarine equipment, diving equipment, communication under water, hand cranked, diving compressor -

Federation University Historical Collection

Federation University Historical CollectionDocument, James Baker, Ballarat School of Mines Collector, James Baker, 1870, 1870

Information related to the establishment of the Ballarat School of Mines, the first of its kind in Australia. Federation University Australia was established on 1 January 2014. Formerly known as the University of Ballarat, its enabling legislation was the University of Ballarat Amendment (Federation University Australia) Act 2013. Although formally created as a University in 1994, the University of Ballarat has a lineage back to 1870 with the establishment of the School of Mines Ballarat, making it the third institution of higher learning to be established in Australia and the first to be established in regional Australia. On 1 January 1994, Ballarat University College became the University of Ballarat and in 1998 the University merged with three TAFE Institutes to become a dual sector institution with multiple campuses. On 1 January 2014, the University of Ballarat amalgamated with the Monash University Gippsland Campus to form Federation University Australia. The Gippsland Campus also had a long lineage dating back to 1928 with the establishment of the Yallourn Technical School which became a predecessor institution to the Gippsland College of Advanced Education formed in 1968. In 1990, it was renamed the Monash University College and in 1993 became the Gippsland Campus of Monash University. In 2016, Federation University Australia announced plans to take possession, over a two-year period, of Monash’s Berwick Campus in the south-east corridor of Melbourne. Federation University Australia, or FedUni, is headquartered in Ballarat and offers programs in Higher Education and Vocational Education and Training to regional Victoria and beyond. The University’s commitment to educational and social equity, teaching excellence, research distinction, environmental sustainability and regional capacity building has enabled it to develop in a way that draws on its proud heritage to inform its future. Its regional character sets a framework for the University’s priorities but does not constrain it from serving wider community interests, nationally and internationally. The name Federation University Australia was chosen to convey the scope and capacity of an expanded regional university with a federated network of campuses.Copy of a letter signed by James Baker outlining that he had been appointed Collector to the proposed Ballarat School of Mines, and requested co-operation and pecuniary assistance torwards the establishment and maintenance of the new school. School of Mines for the COlony of Victoria Ballarat, 1870 Sir,- Having been appointed to the Trustees of this proposed Institutin, I have the honor to request your co-operatoin and pecuniary assistance towards its establishment and maintenance. Your attention is respectfully requested to the appended outline of the Institution, with the names of gentlemen who have accepted provisional offices. The object sought to be obtained is the cobinatin of the highest scientific with the most practical training for all men engaghed in the enterprise of mining in its various branches, whether so engaged as mining managers, engineers, surveyors, mechanists, working miners, directors or promoters of companies. Hitherto, in this Colony, no means of scientific educatin, in this most important occupation has been provided. The result has been an enormous waste of captial, time, and labor. Indeed, it may be fairly stated that the persent depression in the mining market and the distrust of mining property as an inverstment may in great part be traced to the numerous failures of enterprises either ignorantly entered upon or unscientifically, pursued. The scientific education of those engaged in mining pursuits would, it is believed, not merely render gold mining a safe and generally more productive speculation, but would bring into profitable prominence and activity many branches of mining now wholly neglected, or distrustfully, and consequently unsuccessfully, pursued. The Government has so far recognised the attempt to estalish this, so much wanted, Institution as to grant a ease, at a nominal lease, of the old Court-house in Lydiard street : and steps are being taken to put the building in repair and adapt it to the requirement so fhte proposed School. You will see from the appended Outline that L600 at least much be subscribed before the School can be opened. Towards thos sum several public bodies and private persons have given subscriptions; either as Life Governors, Annual Governors, or Donors, by whose liberality the Institution may be not only opened, but permanently maintained in the highest state of efficiency. I trust therefore that you will pardon my earnestly requesting your assistance, which many be effectually rendered by your returning to me one of the enclised forms, signed by you either as a Life Governoe (L50), and Annual Governor (L3 3s), or simply as a Donor of any sum which you may see fit to give. I have the honor to be, Sir, Your most obedient Servant, James Baker, Collector to School of Mines.ballarat school of mines, ballarat school of mines establishment, balalrat school of mines collector, james baker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Carbide Lamp, Powell & Hanmer, Late 19th to early 20th century

Francis Powell (1861-) and Francis Hanmer (1858-1925) founded Powell and Hanmer Ltd in the Summer of 1885 for the manufacturer of bike and carriage lamps. Their first advertisements began to appear in November of 1885. In 1890 they lodged a Patent for “velocipede” lamps to be used by lightweight wheeled vehicles propelled by a rider, such as a bike, tricycle and railroad handcar. In April of 1913, they were selling headlamps for cars and in 1914 built their second factory manufacturing dynamo lighting sets in Rocky Lane Birmingham, also for the production of dynamos for motor cars. Then in 1929 Powell and Hanmer Ltd, was acquired by the Lucas company which was at that time the main competitor for the manufacture of non-electrical equipment for cycles and motorcycles. When a director of Powell and Hanmer joined the board of Austin motor cars, Lucas feared that Austins might encourage Powell and Hanmer to start to produce electrical equipment for supply to the company and as a result this association might affect Lucas's business with other large vehicle manufacturers. As a result, Lucas made an offer to Powell & Hanmer and purchased the business for £500,000. Carbide lighting was used in rural and urban areas of Australia which were not served by electrification. Its use began shortly after 1900 in many countries and continued past the 1950s. Calcium carbide pellets were placed in a container outside the home, with water piped to the container and allowed to drip on the pellets releasing acetylene. This gas was piped to lighting fixtures inside the house, where it was burned, creating a very bright flame. Carbide lighting was inexpensive but was prone to gas leaks and explosions. Early models of the automobile, motorbike and bicycles used carbide lamps as headlamps. Acetylene gas, derived from carbide, enabled early automobiles to drive safely at night. Thick concave mirrors combined with magnifying lenses projected the acetylene flame light. These type of lights were used until reliable batteries and dynamos became available, and manufacturers switched to electric lights. Acetylene lamps were also used on riverboats for night navigation. The National Museum of Australia has a lamp made in about 1910 that was used onboard the PS Enterprise, an 1878 Australian paddle steamer, currently owned by the National Museum of Australia in Canberra. It is still operational, and one of the oldest working paddle steamers in the world, listed on the Australian Register of Historic Vehicles.Acetylene Carbide lamp, marine pattern burner housing and reflector missing Carbide Lamp, metal. Has plate for attaching to wall, & gimbal to allow lamp to remain vertical. Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, carbide lamp, motor vehicle, bike lamp, lighting, vehicle lighting, powell, hanmer, acetylene gas lamp, early lighting, marine lighting -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Surgical kit used by Lord Joseph Lister, Archibald Young of Edinburgh, 1870s

This surgical instrument kit, c1870s, originally belonged to Lord Joseph Lister. On his retirement in 1892, Lord Lister presented the instrument kit to his friend Dr Alexander Matthew. The donor of the surgical kit, Professor Ian Stewart Fraser, is the great grandson of Dr Alexander Matthew. The donor, Ian Fraser, checked with his mother about the inscription "Ethel Livie". There was no one of that name in his mother's family tree and the instruments were passed down from his mother's family.This surgical kit, made by Young of Edinburgh Scotland in the 1870s is significant because it belonged to and was most likely used by an internationally important figure in modern medicine, Lord Joseph Lister. Joseph Lister, 1st Baron Lister, Bt., OM, FRS, PC (5 April 1827 – 10 February 1912), known as Sir Joseph Lister, Bt., between 1883 and 1897, was a British surgeon and a pioneer of antiseptic surgery. By applying Louis Pasteur's advances in microbiology, he promoted the idea of sterile surgery while working at the Glasgow Royal Infirmary. Lister successfully introduced carbolic acid (now known as phenol) to sterilise surgical instruments and to clean wounds, which led to a reduction in post-operative infections and made surgery safer for patients. Surgical instruments in original timber case, containing two steel sharp hooks with the manufacturer's stamp,"YOUNG EDINBURGH" on the handles, five steel scalpels with ebony handles in assorted sizes. Also included separately are autopsy hooks, one metal blowpipe [commonly used with urine testing apparatus] and two dissector forceps. "YOUNG EDINBURGH"; "ETHEL LIVIE"surgery -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

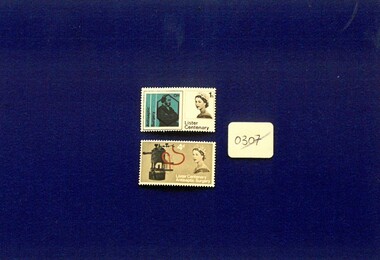

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Ephemera - Commemorative stamps issued in the United Kingdom for the centenary of antiseptic surgery, 1961

The Royal Australian College of Surgeons (RACS) holds one of Lister's carbolic sprays in its collection.Joseph Lister, 1st Baron Lister, Bt., OM, FRS, PC (5 April 1827 – 10 February 1912), known as Sir Joseph Lister, Bt., between 1883 and 1897, was a British surgeon and a pioneer of antiseptic surgery. By applying Louis Pasteur's advances in microbiology, he promoted the idea of sterile surgery while working at the Glasgow Royal Infirmary. Lister successfully introduced carbolic acid (now known as phenol) to sterilise surgical instruments and to clean wounds, which led to a reduction in post-operative infections and made surgery safer for patients.Two postage stamps issued in the United Kingdom, 1961. The first stamp is a one shilling stamp, depicting an upper body portrait of Joseph Lister against a blue background on the left, with a profile image of Queen Elizabeth II on the right. Text printed on the stamp reads 'Antiseptic/Surgery/Lister/Centenary'. The second stamp is a four pence stamp, depicting Lister's carbolic spray against a grey background on the left, with a profile image of Queen Elizabeth II on the right. Text printed on stamp reads 'Lister Centenary/Antiseptic Surgery'.surgery -

Unions Ballarat

Unions BallaratFramework of flesh : Builders' Labourers battle for health and safety, McQueen, Humphrey, 2009

An oral history. "McQueen uses labourers' own words to retell their battles around scaffolding and shithouses, for the safe removal of asbestos, prompt and adequate compensation, and a decent burial. The stories start in convict times and cover the six states and the ACT. The labourers' struggle for health and safety is followed into their dismantling of the framework of fear erected by the Building and Construction Commission. By tracking on-the-job experiences of demolishers, dog-men, hod-carriers and navvies, McQueen confirms the conviction of an early official of the BLF, Ben Mulvogue: "A union constitutes a school for the working class, wherein they learn self-reliance, learn their rights, privileges, opportunities, as well as their possibilities. Every new demand for better physical protection of the workers ensures a great ideal development for a future generation.'"--Publisher's website. Relevant to the history of health and safety in the building industry and the building unions.Paper; book.Front cover: author's name and title.btlc, ballarat trades hall, ballarat trades and labour council, oh&s, occupational health and safety, workers health, building workers, unions, history, oral history -

Ballarat and District Irish Association

Ballarat and District Irish AssociationImage, Joseph Chamberlain, 1864

Joseph Chamberlain was was an important businessman and a politician. He worked to improve education, and cities. He was a Member of Parliament from 1876 to 1914, and Colonial Secretary (controlling British colonies) from 1895 to 1903. His son Austen won the Nobel Peace Prize and another son Neville was Prime Minister from 1937 to 1940. (Wikipedia) Chamberlain was a Unitarian, a Christian who believes Christ was an example of the way to live life, but was not divine (not a part of God). Unitarians try to work to help society. There were many problems in Birmingham after the industrial revolution, and many men were not allowed to vote. In 1868 Chamberlain helped a liberal man to become the Member of Parliament for Birmingham. In 1869, he started a group working for free primary education for all children. In November 1869, he became a member of Birmingham City Council. There he worked for cheaper land prices for rural (countryside) workers, and became very popular. In 1873 he became the Mayor of Birmingham. He bought the gas companies and water companies for the city, so people were able to have clean and safe water. He made parks, roads, schools museums and built new houses for poor people. In June 1876 he became the Member of Parliament (MP) for Birmingham. In parliament he worked to unite radical M.P.s (MPs that wanted change) against the Whig party who were in power. His work helped William Ewart Gladstone to become Prime Minister in 1880. Chamberlain often spoke about education in parliament. (Wikipedia)Image of a man called Joseph Chamberlain.ballarat irish, chamberlain, joseph chamberlain -

Old Colonists' Association of Ballarat Inc.

Old Colonists' Association of Ballarat Inc.Photograph - Photograph - Colour, John Brooksbank's Old Identities' medal

The Old Identities' Association was a forerunner of the Old Colonists' Association Ballarat. John Brooksbank was a very early arrival to Ballarat in September 1851, which was not long after the discovery of gold at Ballarat. J. Brooksbank lost a dog in 1857 "LOST from the Half Way House, Smythe's Creek Road, a black bloodhound and kangaroo dog. Anyone detaining him after this date will be prosecuted. J. BROOKSBANK" (Ballarat Star, 30 December 1857) Another very early identity in Ballarat, James Oddie, advertised the sale of J. Brooksbank's hotel in 1860: "JAMES ODDIE & CO. have received instructions from the Mortgagees, to sell I by auction at their rooms, Dana street, on Thursday, 20th September, at twelve o'clock, All that desirable properly known as the , Halfway House Hotel, Together with all that piece or parcel of ' land situate in the parish of Cardigan and county of Grenville, containing 34 acres 1 rood 26 ½ perches, part of allotment 1, section 6, of said parish, situated on the Ballarat and Smythesdale road, and recently occupied by Mr J. Brooksbank. The property consists of a spacious stone building one story high, strong and substantially built, the internal fittings and arrangements are neat and complete. The house possesses all requisite accommodation for a respectable country hotel. In addition are stockyards, stables &c, all well and securely fenced. Terms at Sale. (Ballarat Star, 20 September 1860) Four years later Brookbank was selling his hotel in Lyons Street Ballarat: "RARE OPPORTUNITY.-FOR SALE the BLACK BULL HOTEL, Lyons street. The proprietor of the above hotel being about entering into another line of business, begs to call the attention of parties looking for a safe and profitable investment, the above having undergone thorough repairs, and is now in good working order and doing a fair share of business. The conditions will, be half cash, balance six, nine, and twelve months. Apply, J. Brooksbank, proprietor, on the premises. (Ballarat Star, 22 October 1864)Colour photograph of a sterling silver medal relating to The Old Identities' Association 1851-1854. The medallion, belonging to John Brooksbank, has a drilled hole at the top suggesting it was worn by the owner at some stage in its life. The medal has been engraved: Arrived "Sep 51 J. Brooksbankold identities association, old colonists' association ballarat, c.a. welch, silversmith, numismatics, j. brooksbank, medal -

Old Colonists' Association of Ballarat Inc.

Old Colonists' Association of Ballarat Inc.Photograph - Photograph - Black and White, John Brooksbank

The Old Identities' Association was a forerunner of the Old Colonists' Association Ballarat. John Brooksbank was a very early arrival to Ballarat in September 1851, which was not long after the discovery of gold at Ballarat. J. Brooksbank lost a dog in 1857 "LOST from the Half Way House, Smythe's Creek Road, a black bloodhound and kangaroo dog. Anyone detaining him after this date will be prosecuted. J. BROOKSBANK" (Ballarat Star, 30 December 1857) Another very early identity in Ballarat, James Oddie, advertised the sale of J. Brooksbank's hotel in 1860: "JAMES ODDIE & CO. have received instructions from the Mortgagees, to sell I by auction at their rooms, Dana street, on Thursday, 20th September, at twelve o'clock, All that desirable properly known as the , Halfway House Hotel, Together with all that piece or parcel of ' land situate in the parish of Cardigan and county of Grenville, containing 34 acres 1 rood 26 ½ perches, part of allotment 1, section 6, of said parish, situated on the Ballarat and Smythesdale road, and recently occupied by Mr J. Brooksbank. The property consists of a spacious stone building one story high, strong and substantially built, the internal fittings and arrangements are neat and complete. The house possesses all requisite accommodation for a respectable country hotel. In addition are stockyards, stables &c, all well and securely fenced. Terms at Sale. (Ballarat Star, 20 September 1860) Four years later Brookbank was selling his hotel in Lyons Street Ballarat: "RARE OPPORTUNITY.-FOR SALE the BLACK BULL HOTEL, Lyons street. The proprietor of the above hotel being about entering into another line of business, begs to call the attention of parties looking for a safe and profitable investment, the above having undergone thorough repairs, and is now in good working order and doing a fair share of business. The conditions will, be half cash, balance six, nine, and twelve months. Apply, J. Brooksbank, proprietor, on the premises. (Ballarat Star, 22 October 1864)Photographic portrait of John Brooksbank from a photographic montage held by the Ballarat Old Colonists' Association.john brooksbank, ballarat old colonists' association, ballarat old colonists' club, old colonists' association -

Royal District Nursing Service (now known as Bolton Clarke)

Royal District Nursing Service (now known as Bolton Clarke)Photograph - Photograph, black and white, 1967

... to their own hygiene safely, and, working towards independence where ...This photograph shows Royal District Nursing Service (RDNS) Sister Meissen observing Mrs Lata as she transferred from her wheelchair onto a shower chair in the bathroom at her home. Sr. Meissen is based at the RDNS Moorabbin Centre. Patients were taught, and then supervised, by RDNS visiting Sisters in the use of safe transferring techniques. From the founding of the Melbourne District Nursing Society (MDNS) in 1885, known as the Royal District Nursing Service (RDNS), from 1966, their Trained nurses cared for patients in their own homes who required to be taught safe transferring techniques, e.g. from bed to wheelchair or from chair to walking frame etc. Their family members also needed to learn safe transferring techniques to enable them to care for their loved ones. RDNS employed a Physiotherapist who taught staff the correct techniques, not only for safety of the patient, but to reduce physical strain on RDNS nursing staff and patient’s family members. Sisters carried out General Care to those patients unable to care to their own hygiene safely, and, working towards independence where possible, the Sisters taught them safe transferring techniques using equipment such rails, shower seats, and hand showers.On the right of this black and white photograph is Royal District Nursing Service (RDNS) Sister Meissen standing and observing Mrs. Lata in the bathroom of her home. Sr. Meissen has short dark hair; is wearing a white gown over her uniform and wears a grey peaked uniform hat. She has a towel draped over her left arm, and is smiling at Mrs. Lata who is on her left and is sitting on a shower chair. Mrs. Lata, who is wearing a light coloured nightgown with flower motifs, is smiling up at Sr. Meissen and has her right arm raised with her hand gripping a rope pulley. Part of a wheelchair with the left arm removed is seen in the foreground; the seat of the chair is in line with the seat of the shower chair. A hand shower, taps and glass screen can be seen in the background of the photograph.rdns, royal district nursing service, rdns uniform, patient care, moorabbin centre, sister m. meissen, mrs lata -

Royal District Nursing Service (now known as Bolton Clarke)

Royal District Nursing Service (now known as Bolton Clarke)Photograph - Photograph, black and white, 09 05 1967

This Sister is working at the Control Centre at RDNS Headquarters, 452 St. Kilda Road, Melbourne where she is receiving a phone call which she will transfer to the appropriate staff member in Headquarters, or if appropriate pass the message onto an RDNS Centre to take action. Central Control was based in the Royal District Nursing Service (RDNS), Headquarters and the Sister working there took and directed all incoming telephone calls to persons in Headquarters or to the appropriate RDNS Centre. Each Centre contacted the Control Sister each morning for any messages received over night. She remained in contact with each RDNS Centre during the day, and in contact with Evening staff after each Centre was closed at 6 p.m. Evening staff contacted Central Control after completing their evening visits, and book work, so the Sister in Central Control knew they were safe and had completed their shift before leaving the RDNS premises. Of a weekend, when reduced staff numbers were working, the same procedure was carried out by the Sister working in each Center's office. In the centre of this black and white photograph is a Royal District Nursing Service, (RDNS), Sister, who wears glasses and has short curly hair, is wearing a watch on her left wrist and is wearing her grey short sleeved uniform with an RDNS cotton badge applied to the top of the sleeve. She is sitting behind a desk and is holding a telephone to her right ear; she has a pen in her left hand and is ready to write in an open white paged book. A typewriter is on the left hand side of the desk and a black telephone can be seen on a shelf adjacent to the desk, A framed rectangular mirror can be seen on the left hand side wall. A shelf, with several books on the left hand side, can be seen attached to the upper part of the wall behind the Sister. Below this a large chart is on the wall and a wooden shelf below itPhotographers Stamp. 'Quote No. GE 14rdns, royal district nursing service, rdns administration -

Wodonga & District Historical Society Inc

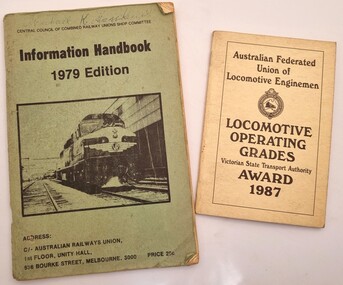

Wodonga & District Historical Society IncManual - Railways Union Booklets, Australian Railways Union, 1979 & 1987

... This item illustrates the regulations put in place to ensure safe ...These handbooks document changes in industrial awards put in place to regulate the work conditions and safety in the railways. The 1979 Information Handbook was issued by the Central Council of Combined Railway Unions. The 1987 publication by the Australian Federated Union of Locomotive Enginemen outlined the Locomotive Operating Grades Award as implemented by the Victorian State Transport Authority.2 booklets documenting Union regulations for railway employees, the 1979 publication on green paper and the 1987 publication on buff coloured paper. Both have staple binding on the spine.fictionThese handbooks document changes in industrial awards put in place to regulate the work conditions and safety in the railways. The 1979 Information Handbook was issued by the Central Council of Combined Railway Unions. The 1987 publication by the Australian Federated Union of Locomotive Enginemen outlined the Locomotive Operating Grades Award as implemented by the Victorian State Transport Authority.vline safety, vline training, railways victoria, australian federated union of locomotive enginemen -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncManual - Public Transport Corporation Guides, Public Transport Corporation Victoria, 1990s

... in place to ensure safer working conditions for all public ...These booklets outline changes to regulations governing rules and operational procedures of Victorian Railways. The white booklet outlines Supplementary Rules and regulations Amendments for the operation of locomotive hauled driver only passenger trains in 1992. The pink booklet is a guide to the 1994 book of rules and operating procedures. It included major changes with respect to existing safe working policy so was a critical document issued to all staff to be read in conjunction with the full book of rules.2 small publications outlining changes to existing regulations. Both bear the logo of the Victorian Public Transport Corporation and are printed in black ink.fiction These booklets outline changes to regulations governing rules and operational procedures of Victorian Railways. The white booklet outlines Supplementary Rules and regulations Amendments for the operation of locomotive hauled driver only passenger trains in 1992. The pink booklet is a guide to the 1994 book of rules and operating procedures. It included major changes with respect to existing safe working policy so was a critical document issued to all staff to be read in conjunction with the full book of rules. vline safety, vline training, railways victoria, public transport corporation victoria -

Vision Australia

Vision AustraliaEducation kit - Object, Clear Direction: a guide to communicating with people who are blind and vision impaired, 2000

In order to expand the understanding of the general public, Vision Works - a division of RBS - produced this CD designed to offer sighted users the experiences that people had when undertaking a sighted guide course and when working with blind or vision impaired colleagues. "The information contained in this module will enable you to assist people who are blind and vision impaired whether they be customers, friends, relatives or anyone else you may come in contact with. This interactive educational package encourages users to work at their own pace to learn practical communication techniques; methods of providing effective customer service; and ways of developing the skills needed to safely guide a person who is blind or vision impaired. It also includes a game based on sighted guide techniques and evaluation questions designed for in-house training. This CD has been designed, based on the work of professional service providers at Royal Blind Society, a major blindness agency in Australia."1 CD-ROM with text and imagesPC CD-ROM: Windows 95/98/2000 The information contained in this module will enable you to assist people who are blind and vision impaired whether they be customers, friends, relatives or anyone else you may come in contact with. This interactive educational package encourages users to work at their own pace to learn practical communication techniques; methods of providing effective customer service; and ways of developing the skills needed to safely guide a person who is blind or vision impaired. It also includes a game based on sighted guide techniques and evaluation questions designed for in-house training. This CD has been designed, based on the work of professional service providers at Royal Blind Society, a major blindness agency in Australia.royal blind society of new south wales, education -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPostcard - Dredge Pioneer, Segerberg and Bulmer, 1910 c

Message on back Arrived safe 25th have a good time hoping you are well from FCG Addressed to Mrs FC Gason, Jessops Hill, Lower NicholsonBlack and white postcard showing dredge Pioneer working below Jemmys Point facing entrance rock groynes on west of Bullock Island calm entrance in distance steamer JCD heading across Reeves Channel after leaving Lakes Entrance VictoriaLakes Entrance waterways, dredges, correspondence -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Cylinder, Oxygen

In Australia, the wholesale druggists Fenton, Grimwade and Company, established in 1876, were producing small quantities of oxygen for medical and industrial purposes(11,11). In 1910, they produced a booklet promoting the therapeutic use of oxygen, suggesting it's use in pulmonary and cardiac affections, asphyxia, and morphine poisoning(9). Eventually, oxygen was to play a more significant role in medicine following two significant events. In 1895, Karl Von Linde succeeded in liquefying air, and then fractionally distilling its individual components, including oxygen. This new technique for the production of oxygen from air was revolutionary, but large demand for it did not develop in the wider community until Claude and Hess managed to compress acetylene into cylinders safely in 1897, keeping the highly explosive fuel stable by dissolving it in acetone. By 1900, the oxy-acetylene welding technique was born, and the demand for oxygen for industrial purposes accelerated worldwide. In Australia, Russell Grimwade, working for his father's company, ordered the first oxygen plant to be built in Australia in 1910. (George Kantianis, 2013)Medium sized black coloured cylinder with rounded base once containing oxygen with a large black on white diamond shaped manufacturer's label adhered to the front. Much of the label has been degraded with missing bits, and rust stains.Printed on to manufacturer's label: OFFICIALLY PREPARED FOR MED? / AUSTOX [in logo] / COMPRESSED / OXYGEN / CONTENTS / 33 [handwritten in pencil] Imperial Gallons / KEEP COOL / Australiand Oxygen and Industrial ? / Pty. Ltd. / MELBOURNEoxygen, cylinder, therapeutic, russell grimwade -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1997

This photograph contains an array of different musical instruments being used by a band in a performance. The instruments visible in the photo include the Cymbals, Double bass, Trumpets, Trumbones, Tuba and Clarinets. Given the assortment of instruments present it is clear that this ensemble is an orchestral band. All of these instruments require the musician to be sitting while performing as depicted in the photograph. This photo was taken in 1997 and highlights the diversity of the band members, which includes both young and old men and women all working together to deliver a performance. While the details of the event are still unknown, it is safe to assume that this was taken during a formal performance due to the formal attire worn by the band members. This photo captures a specific time and event in amazing detail while showcasing the historic use of these intruments in a social setting. This photograph carries great historic significance as it depicts the historic use of these instruments within the context of an orchestral band performance. With this knowledge, one can track the importance and use of these instruments across time as well as understand the type of events and activities associated with the people and communities that attended these gatherings, as both performers and audience members. Black and white rectangular photograph printed on matte photographic paper, unmounted.reverse: 2671 / 1997.00007 / Agfo [watermark]band, band members, instruments, musical instruments, trumpet, black and white, formal attire, musical performance, 1997, brass instruments, percussion instruments, woodwind instruments, orchestra -

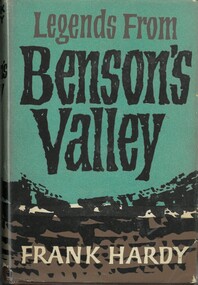

Bacchus Marsh & District Historical Society

Bacchus Marsh & District Historical SocietyBook, Legends from Bensons Valley

The writer and novelist Frank Hardy spent most of his childhood and early adulthood in Bacchus Marsh. This collection of short stories is inspired by his early years in the town of Bacchus Marsh in the 1930s. The collection contains 13 stories. Many of the these stories depict the poverty and struggles of working class people during the great economic depression of the 1930s. The setting is fictionalized as 'Benson's Valley' but to anyone familiar with the town Bacchus Marsh this location is clearly the setting for these stories and some of the characters are based upon Bacchus Marsh people Hardy knew at the time.Printed book. Hardback. 248 pages. Citation: Hardy, Frank, London, T. Werner Laurie, 1963. BDMHS Location: AR/SU62/SafefictionThe writer and novelist Frank Hardy spent most of his childhood and early adulthood in Bacchus Marsh. This collection of short stories is inspired by his early years in the town of Bacchus Marsh in the 1930s. The collection contains 13 stories. Many of the these stories depict the poverty and struggles of working class people during the great economic depression of the 1930s. The setting is fictionalized as 'Benson's Valley' but to anyone familiar with the town Bacchus Marsh this location is clearly the setting for these stories and some of the characters are based upon Bacchus Marsh people Hardy knew at the time.frank hardy 1917-1994, bacchus marsh writers -

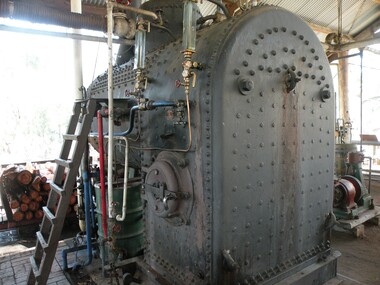

Port of Echuca

Port of EchucaFunctional object - Locomotive Type Fire Tube Boiler, 1927

This Johnson Bros. (USA) Locomotive Type Boiler was from a steam shovel (that moved on rails) that excavated rock and soil during the construction of Stevens Weir near Deniliquin NSW in 1934. It has a working pressure of 100psi. This is an example of a fire tube boiler where the fire from the fire box heats the water surrounding the fire tubes running through the boiler, smoke escapes out the smoke stack and the steam is captured in the dome and sent through pipes toward other engines in the Port of Echuca Steam Display. Two glass gauges are fitted on the side of the firebox. Two safety valves are fitted at the top of the boiler to maintain the correct and safe pressure. It still functions today for visitors most days of the week.A good example of the technology and industrial history of the Riverina region of southern NSW and northern Victoria. It is an integral part of the Port of Echuca Steam Display running secondary engines off the steam produced within this boiler. Large cast iron, fire tube boiler with 124 fire tubes, fire box, steam dome and exhaust chimney. boiler, johnson bros, steam display, kevin hutchinson steam shed -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1962-1966

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. The colourwork dogs from this design are a very popular motif, and were available in both wool and Orlon in multiple styles from at least 1961-1972, including a cardigan and a pullover, selling 4346 of these in winter 1961. This example most likely dates from 1962-1966. An Illustration depicting this style is catalogued under NWM-09026. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children’s machine-knit jumper with white dog motif and green grass colourwork, closes with three red plastic buttons at left shoulder .2 and .3 are sample tags with manufacturing information, including sizes and colours available .4 is a swing tag with manufacturer care instructions.1) [label stitched at back neck] KATHRYN REGD. / 100% ORLON / 24 .2) STYLE: 44/OP – ORLON PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. WHITE. / 20” – 24” SKY BLUE. LEMON. WHITE. REDCOAT. BOTANY BLUE. SULTRY GREEN. NUTTY BROWN. OATMEAL .3) STYLE: 44/PW – WOOL PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. / 20” – 24” SKY BLUE. LEMON. REDCOAT. BOTANY BLUE. / SULTRY GREEN. NUTTY BROWN. NED KELLY GREEN. / .4) Obverse: [handwritten] 5/10 (unintelligible) Kathryn / ORLON KNITWEAR / Style : 44/OP / DESIGNED & MANUFACTURED BY / Robert Blake / MELBOURNE Reverse: STANDARD MEASUREMENTS / FIT EXACTLY / LAUNDER PERFECTLY / HOT WATER WILL DAMAGE / THIS GARMENT / WASHING INSTRUCTIONS / 1. Use lukewarm water and mild soap. / 2. Squeeze water out by hand – DO / NOT WRING. / 3. DO NOT ROLL. Hang on / Clothes hanger to dry. / To keep brushed garments like / new, brush frequently with / Nylon brush. / IRONING [m (handwritten)] ORLON garments require little / or no ironing if drip-dried. If / ironing is necessary, it may be done damp or dry, using / a warm iron. / DO NOT USE / STEAM IRON /knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, dog motif, animal motif, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1953-1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children's wool jumper with green and white geometric tartan/plaid pattern on front. Has long sleeves with ribbed cuffs and ribbed crew neck and closes with four red plastic buttons at back neck. Coloured pattern is worked in lines on top of finished fabric in surface crochet in pattern of green, white, green[white label at back neck with blue stitching] ALL WOOLknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Grey wool Jumper with Blue and grey cable design on front. Vertical cable pattern is two sets of intertwining grey blue cable pairs on a purl stitch background in alternating rows of blue and grey. Front panel of jumper has five cable panels separated by smooth stocking stitch panels. Jumper has long sleeves and crew neck with thick ribbed collar and cuffs. Style B/110, Colourway Silver/Denim, Size 8 .2) 2 Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Brown/Woodgrain, Denim/Blue Shadow and Pebble/Oyster.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2) [blue sample label] STYLE B/110 Crew Neck Wool Pullover SIZES: 2 4 6 8 10 PRICE: $10 [amended to $11 in blue pen] $[written over in blue pen so as to be illegible] [handwritten in blue pen] $12.55 SIZES: 12 14 PRICE: [printed] $12.30 [handwritten over top in blue pen] $13.15 COLORS: Silver/Denim, Brown/Woodgrain, Denim/Blue Shadow, Pebble/Oyster. Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Brown and Grey children’s jacket with brown accents at pockets and shoulder, centre front zip, curved pocket detail.Style B/117, Colourway Woodgrain/Pebble, Size 8 .2) Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Green/Silver, Burgundy/Denim, Navy/Denim, and Rust/Pebble.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2 [blue sample label] STYLE B/117 Jacket. Zip. Birdseye. Wool. SIZES: 2 4 6 8 10 PRICE: $11.75 [amended to $12.80 in blue pen] $13.85 [amended to $15.05 in blue pen] SIZES: 12 14 PRICE: [printed] $14.95 [amended to $16.15 in blue pen] COLORS: Woodgrain/Pebble Green/Silver [drawn through in black pen] Burgundy/Denim, Navy/Denim, Rust/Pebble Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, children's knitwear -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. In a world where wool garments all had to be washed by hand, the invention of machine-washable acrylic fibres and widespread adoption of washing machines in ordinary Australian homes in the 1950s and 60s posed a major risk to the wool industry, and by extension the entire Australian economy. With the price of wool falling, the CSIRO and the Australian Wool Board worked together from the 1950s on a number of developments to keep Australian wool competitive and desirable to the public, many of which came out of the Geelong research labs. While progress had been made in the preceding decades, 1970 saw a major breakthrough; the invention of a new method of making wool washable and shrink-proof, most commonly known as ‘Superwash’. It is a technology that is still highly used to this day, and is very recognisable to those who use commercial wool yarn to knit or crochet. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Blue wool turtleneck ‘skivvy’ jumper in all over rib pattern with long sleeves. .2) swing tag with woolmark logo for ‘Superwash Wool’1.)[white label at back neck with blue writing] KATHRYN REGD. (Woolmark Logo) PURE NEW WOOL Superwash SIZE 2 HGT. 92cm MADE IN AUSTRALIA 2.)[retail swing tag for ‘Superwash Wool’] [OBVERSE] [woolmark logo] [handwritten in blue pen] 314 [printed] PURE NEW WOOL [handwritten] 2 Superwash Wool Machine Washable [INTERNAL] [woolmark logo] PURE NEW WOOL YOU ARE NOW THE OWNER OF A SUPERWASH WOOL GARMENT That has been specially treated to withstand a lifetime of machine washing. SUPERWASH WOOL has all the desirable qualities of wool – soft handle, comfort, warmth and style. Not all wool knitwear has the SUPERWASH treatment so remember always to look for the special “SUPERWASH” label and swing ticket. To was SUPERWASH WOOL just follow the instructions of the garment label. [woolmark logo] PURE NEW WOOL SUPERWASH WOOL THE WOOL YOU WASH IN THE MACHINE.knitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, csiro, national wool board, superwash, australian wool innovation -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1965