Showing 108 items matching "spinning machinery"

-

National Wool Museum

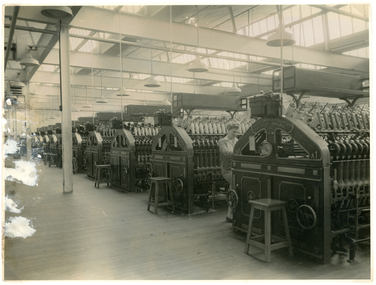

National Wool MuseumPhotograph, R S & S worsted spinning

... spinning machinery...-and-the-bellarine-peninsula Worsted spinning department, R S & S mill ...Worsted spinning department, R S & S mill.R S & S worsted spinning AUSTRALIAN OFFICIAL PHOTOGRAPH/ DEPT OF INFORMATIONtextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, spinning machinery, yarn - worsted, textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

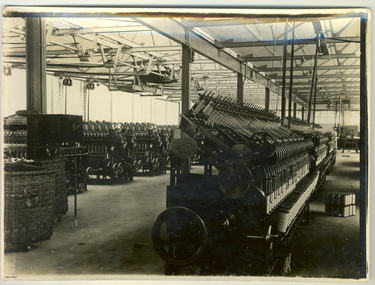

National Wool MuseumPhotograph

... Spinning Machinery... Collins Bros Mill Pty Ltd Spinning Machinery Murgatroyd Mr Fred ...James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, spinning machinery, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

... Spinning Machinery... Collins Bros Mill Pty Ltd Spinning Machinery Murgatroyd Mr Fred ...James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, spinning machinery, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

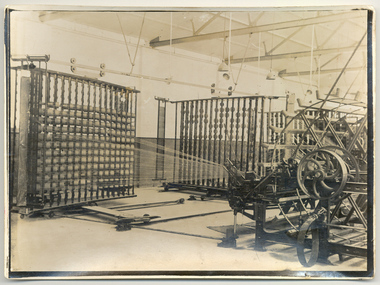

National Wool MuseumPhotograph

... Spinning Machinery... Collins Bros Mill Pty Ltd Spinning Machinery Spinning Murgatroyd ...James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.The Murgatroyd CollectionF Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, spinning machinery, spinning, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

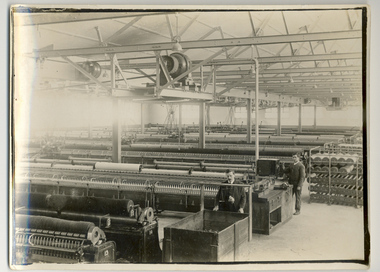

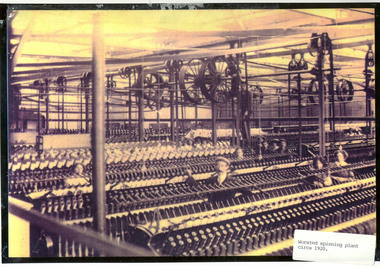

National Wool MuseumPhotograph, Worsted spinning plant circa 1920

... Spinning Machinery... Classweave Industries Pty Ltd Federal Woollen Mills Ltd Spinning ...Acquired when "Classweave Industries" closed down.Worsted spinning plant circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

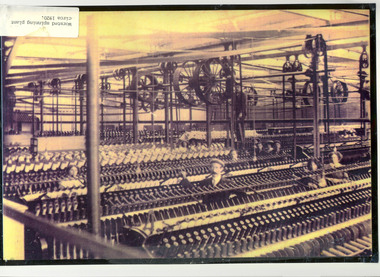

National Wool MuseumPhotograph, Worsted spinning plant circa 1920

... Spinning Machinery... Federal Woollen Mills Ltd Spinning Machinery Textile Mills Woollen ...Acquired when "Classweave Industries" closed down.Worsted spinning plant circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills -

National Wool Museum

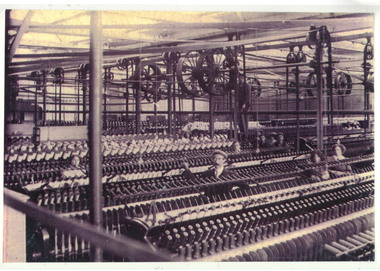

National Wool MuseumPhotograph

... Spinning Machinery... Classweave Industries Pty Ltd Federal Woollen Mills Ltd Spinning ...Acquired when "Classweave Industries" closed down.H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

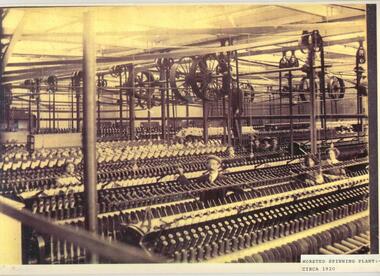

National Wool MuseumPhotograph, Worsted spining plant circa 1920

... Spinning Machinery... Classweave Industries Pty Ltd Federal Woollen Mills Ltd Spinning ...Acquired when "Classweave Industries" closed down.Worsted spining plant circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

... Spinning Machinery... Classweave Industries Pty Ltd Federal Woollen Mills Ltd Spinning ...Acquired when "Classweave Industries" closed down.H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

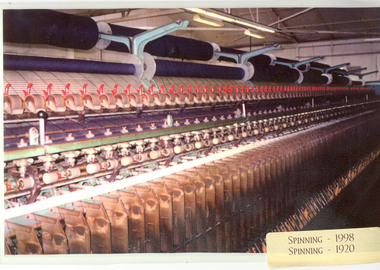

National Wool MuseumPhotograph, SPINNING 1998 - SPINNING 1920

... Spinning Machinery... Machinery Textile Mills Woollen Mills Textile Mills - staff SPINNING ...Acquired when "Classweave Industries" closed down.SPINNING 1998 / SPINNING 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

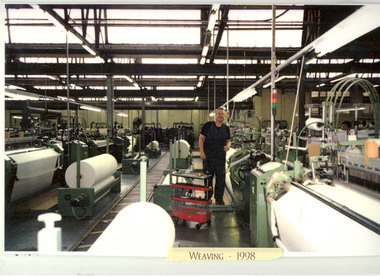

National Wool MuseumPhotograph, Weaving 1998

... Spinning Machinery... Classweave Industries Pty Ltd Federal Woollen Mills Ltd Spinning ...Acquired when "Classweave Industries" closed down.WEAVING 1998 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

National Wool MuseumPamphlet, PG-4 Ring Spinning Frame

... Spinning Machinery... Machinery Works Spinning Machinery Pamphlet for a PG-4 Ring Spinning ..."PG-4 Ring Spinning Frame" - Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.Pamphlet for a PG-4 Ring Spinning Frame by Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.textile machinery, metalexport bielsko textile machinery works, spinning machinery -

National Wool Museum

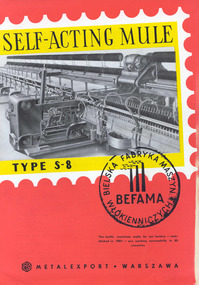

National Wool MuseumPamphlet, Self-Acting Mule Type S-8

... Spinning Machinery... Machinery Works Spinning Machinery Spinning Pamphlet for a Self ..."Self-Acting Mule Type S-8" - Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.Pamphlet for a Self-Acting Mule Type S-8 by Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.textile machinery, metalexport bielsko textile machinery works, spinning machinery, spinning -

National Wool Museum

National Wool MuseumBook, Catalogue of Improved Machinery for Preparing, Carding and Spinning Wool

... Spinning Machinery...: "Catalogue of Improved Machinery for Preparing, Carding and Spinning ..."Catalogue of Improved Machinery for Preparing, Carding and Spinning Wool" - John Hetherington and Sons Limited, proprietors of Curtis, Sons and Co., c.1930.Book: "Catalogue of Improved Machinery for Preparing, Carding and Spinning Wool" - John Hetherington & Sons Limited, Manchester, c.1930.textile machinery, john hetherington and sons limited curtis, sons and co., carding, spinning machinery, scribbling, cloth - woollen, cloth - worsted -

National Wool Museum

National Wool MuseumBook, Australian Inventions and Innovations

... Spinning Machinery... Shearing Spinning Spinning Machinery Wool staple - measurement ..."Australian Inventions and Innovations" - Robert Ingpen, 1982merino sheep - history sheep breeding - history shearing, spinning, spinning machinery, wool staple - measurement, merino sheep - history, sheep breeding - history, shearing -

National Wool Museum

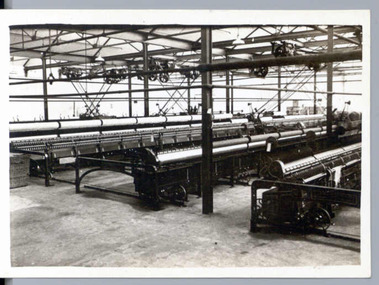

National Wool MuseumPhotograph

... Spinning Machinery... Worsted Mill Spinning Machinery Yarn - woollen Interior of Valley ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning mule for woollen threads. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - woollen -

National Wool Museum

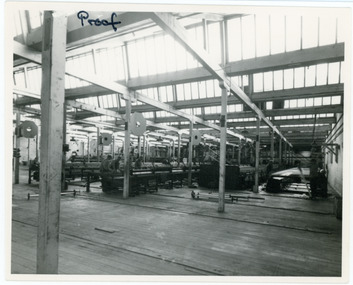

National Wool MuseumPhotograph

... spinning machinery... of the takeover. godfrey hirst and co. pty ltd spinning spinning machinery ...Depicts the woollen spinning room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, spinning, spinning machinery -

National Wool Museum

National Wool MuseumSpindle

... Spinning Machinery.... Collins Bros Mill Pty Ltd Deakin University Spinning Machinery ...Spindle originally from Collins Bros Mill.collins bros mill pty ltd deakin university, spinning machinery -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWool winder, 1940's

... camp 3 tatura ww2 camp 3 textile machinery spinning handcrafts ...Made by Internee at Camp 3Superb hand tooled red gum wool winder on a base of 2 hexagonal pieces, 2 small hexagonals on the top piece of wood support one fixed position spool whilst the upper spool is adjustable up or downwool, hoefer r, wood, camp 3, tatura, ww2 camp 3, textile, machinery, spinning, handcrafts, woodwork -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCarder, Not known

... textile machinery; spinning; wool carding; metalcraft; cast... goldfields textile machinery; spinning; wool carding; metalcraft ...Green painted, hand operated, floor standing drum carder. Metal guard badly corroded. Four legs. Three meshing gearwheels. Large spikes on drum. Wooden roller to feed fleece.Ruben Sutcliffe / Maker / Manchester. In relief on topside of frame.textile machinery; spinning; wool carding; metalcraft; cast iron -

Clunes Museum

Clunes MuseumPhotograph

... MACHINE CLUNES KNITTING MILL STAFF MACHINERY SPINNING .1 B/W ...STAFF OF THE CLUNES KNITTING MILL 1923. INTERKNIT SPINNING MACHINE.1 B/W PHOTOGRAPH SHOWING STAFF IN FRONT OF THE CLUNES KNITTING & MFG CO. LTD. (INCLUDES SOME CHILDEN) 1923. RECEIPT ATTACHED 1992. .2 B/W PHOTOGRAPH OF SPINNING MACHINE IN THE FACTORYclunes knitting mill staff, machinery, spinning -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Hand-cranked separating maching, made in Sweden for Melbourne Crown Separator Co. Pty Ltd. Machine is used for separating cream from milk, with the machine speed being 70 revs per minute.Separator machine. Hand-crank operated milk separator, small, painted red, Crown Separator Co Pty Ltd. Base and spinning mechanism only (mechanism spins very rettly). Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, cream separator, dairy machinery, farming machinery, crown separator co pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book, Worsted Preparing & Spinning, 1923

This book is a technical book that was originally from the Wendouree Woollen Mills but latterly was part of a collection of books owned by the Warrnambool Woollen Mill. The Wendouree Woollen Mills in Ballarat began in 1870 as a flour mill and became the Doveton Woollen Mill in 1877. In 1918 it became the Myer Woollen Mill (Myer Emporium ownership) and in the 1920s it was a knitting mill. After Myer sold the mill it was known as Wendouree Woollen Mill but it closed in 1975. The Warrnambool Woollen Mill in Harris Street, Warrnambool was established in 1910 on the site of an earlier woollen mill destroyed by fire in 1882. It was a successful business for many years and closed in 2000 after 90 years of operations but by that time it had been bought by successive companies including the multinational company Dunlop. In 1968 the Warrnambool Woollen Mills (Dunlop era) purchased Wendouree Woollen Mills and transferred much of its operations to Warrnambool until the Ballarat mill was closed in 1975. This explains why a Wendouree Woollen Mill book was in the Warrnambool Woollen Mill building when it closed. This book is of some interest as a good example of technical books produced in the early 1920s. It would have been well-used by woollen mills workers and foremen at the time. It is also of interest as it comes from the Warrnambool Woollen Mill and so it is a memento of a most important and influential business in Warrnambool in the 20th century. A great number of local people were employed at this mill over the years and it enjoyed for many years a national reputation for quality products. This is a hard cover book with a dark blue cover and gold lettering on the front cover and the spine. The title of the book is printed in an ornate script and is underlined with two gold lines. The book has 277 pages commencing with page 273 as the book is Volume Two of this title. The book, about wool combing was written by Fred Bradbury. It has a Preface, a Contents page and fifteen chapters commencing with Chapter 21 and ending with Chapter 35, an Index and several pages of advertisements for other technical books. The book has several black and white photographs of machinery and illustrations and sketches demonstrating mechanical and technical processes. The book has some small stains on the front cover.Front Cover: ‘Worsted Preparing and Spinning (Wool Combing) by Fred Bradbury’ Spine: ‘Worsted Preparing and Spinning, Vol11- Bradbury – F.King & Sons Ld., Halifax, England’. Inside in two places: stamp of Wendouree Woollen Mills Pty Ltd wendouree woollen mills, warrnambool woollen mill, history of warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Company seal embosser, Unknown

The former Albion (West) Woollen and Worsted Mills is a functional structure which has been built in stages, possibly dating from the 1880s, with the earliest sections near to the Barwon River.The Worsted mill operated for about 50 years and at its peak employed around 500 people. In 1973 the mill merged with the British John Foster and Sons Company under some controversial stock and shareholding issues. The mill continued for a short period before closing at a time when much of the Australian textile industry was finding it difficult to compete with overseas operations. In the 30 plus years after the closure, the site was used for several ventures, including the Mill Vintage Markets and a vehicle trim manufacturing operation. In 2011 the site was purchased by Little Creatures of Western Australia to become their main brewery for the eastern states of Australia. Now owned by the Lion Group, Little Creatures started their 60 million dollar transformation of the old mill in 2012. Finally, in 2013 these former walls of industry were soon rattling away to the sounds of a different type of industry, as the first bottles of beer made their way out of the Geelong Little Creatures Brewery. The remaining building of the former Albion Woollen and Worsted Mills has historical significance as one of Geelong's major woollen mills. The venture has operated on the same site for more than a century. The Albion Woollen Mill was one of the four key sites along with Victoria, Barwon and Union Mills that was established in the late 1860s to mid-1870s. These mills were in constant operation on the west side of the Barwon Bridge over the last century and led to Geelong's fame as milling and scouring locality. The Albion Mill was probably the most successful survivor of the early private company operations. It was regarded as a model mill in the late 1880s and was, from all accounts, well-planned and organised with machinery on a par with the great mills of England. It produced high-quality tweeds. Together with the (now demolished) Union Mill it was regarded as the borough's principal industry over the 1870-1900 period and was one of Australia's most significant producers of tweed by 1900. These two mills were more successful, competitive and long-lived than the Barwon and Victoria Mills. The remaining building form is an important reminder of the private ventures of both the Albion and Union Mills and represents a key site of spinning, carding and finishing as well as scouring and dying that occurred in the lower section near to the river. The loss of the adjacent former Union Mill is unfortunate because the complex, together with the former Collins Union Mill office building, was an important reminder of the success of these industries and the reputation they earned for the Geelong region as a centre for quality textile products. Company seal embosser hand operated matte black & brass colour Western District Worsted Mills emblem on frontflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

![Photograph, Carding machinery [R S & S]](/media/collectors/510b3f7f023fd725b4cd52cc/items/5406605b9821f50e3cc9feee/item-media/5406605b9821f50e3cc9feef/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, Carding machinery [R S & S]

Carding department, R S & S mill.2/ end of carding as carded yarn comes/ off machine for spinning/ R S & Stextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, carding, textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumPhotograph, Sellers 1940

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd Sellers 1940 83-5 KODAK PRINTtextile machinery textile mills textile mills - staff textile mills, collins bros mill pty ltd yarra falls mill tweedside woollen mills, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd KODAK PRINTtextile machinery textile mills textile mills - staff textile mills, collins bros mill pty ltd yarra falls mill tweedside woollen mills, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd KODAK PRINTtextile machinery textile mills textile mills - staff textile mills, collins bros mill pty ltd yarra falls mill tweedside woollen mills, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, textile mills - staff