Showing 135 items matching "steel manufacturer"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, Cut-throat razor ‘Sinfonie’, c1900 -1930

... gebruder ltd., Solingen germany, cutlers, steel manufacturers ...Gebrüder Stoll, Central-Stahlwarenfabrik Founded in 1889 . Solingen-Foche in 1900- 1930. Names: ‘Gallop’, ‘Pedecor’ (Dedecor?), ‘Sinfonie’, ‘Stoll’, ‘Stoll Brothers’. The parts of a straight razor and their function are described as follows: The narrow end of the blade rotates on a pin called the pivot, between two protective pieces called the scales or handle. The upward curved metal end of the narrow part of the blade beyond the pivot is called the tang and acts as a lever to help raise the blade from the handle. One or two fingers resting on the tang also help stabilize the blade while shaving. The narrow support piece between the tang and the main blade is called the shank, but this reference is often avoided because it can be confusing. The shank sometimes features decorations and the stamp of the country of origin. The top side and the underside of the shank can sometimes exhibit indentations known as fluting, or jimps for a more secure grip. The curved lower part of the main blade from the shank to the cutting edge is called the shoulder. The point where the shoulder joins the cutting edge is called the heel. A thick strip of metal running transversely at the junction where the main blade attaches to the shank is called the stabiliser. Although straight razors were once the principal method of manual shaving, they have been largely overshadowed by the safety razor, which incorporates a disposable blade. Electric razors of various types have also been an available alternative, especially since the 1950s. Straight razors require considerable skill to hone and strop, and require more care during shaving A man's cut-throat razor that folds to protect blade inside handle. with a caseon blade 'SINFONIE' on case; Stahlwaron / Fabrikcut-throat razors, straight razors, shaving equipment, steel blades, stoll gebruder ltd., solingen germany, cutlers, steel manufacturers, ‘sinfonie’ trade mark, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, mechanical hand whisk c1940, c1940

An eggbeater is a hand-held device with a crank on the side geared to one or more beaters. The user grips the handle with one hand and operates the crank with the other, creating the rotary action. A hand-turned rotary egg beater was patented by J.F. and E.P. Monroe in 1859 in the US. This egg beater patent was one of the earliest bought up by the Dover Stamping Company, whose Dover egg beaters became a classic American brand. The Monroe design was also manufactured in England. In 1870, Turner Williams of Providence, R.I., invented another Dover egg beater model. The Hobart Manufacturing Company was an early manufacturer of large commercial mixers. A mechanical egg beater with a wooden handle and steel gears and crank c1940cooking, kitchen equipment, dairy, cakes, housework, early settlers, pioneers, baking, nutrition, blacksmiths, market gardeners, cake mixers, moorabbin, cheltenham, bentleigh, brighton, monroe e.p., monroe j.f., egg beaters, williams turner, dover stamping compant ltd., hobart manufacturing company ltd. -

Kiewa Valley Historical Society

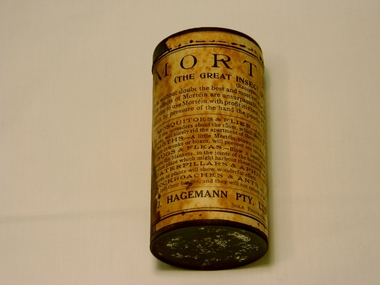

Kiewa Valley Historical SocietyCan Mortein Powder, late 1870s to early 1920s

The can(product) of powdered Mortein was used throughout Australia and especially in rural regions where environmental conditions of crops, cattle and other livestock resulted in greater amount of "invasions" from insects. The eradication of unwanted invaders into the homestead required either manual extermination or a relevant poison which in low doses would not affect humans. Fly squats were still a good measure of eradication of flying pests however those lurking in cupboards or "hard to get at" locations needed a method, such as the Mortein powder to do the deed. This product and especially this can was used at the fore front of pest eradication. Powders and pellets are still in use 100 years later and the core ingredient is still environmental friendly and meets health conscious modern Australians. The basic product has survived the passage of time and was invented by a German immigrant to Australia in the late 1800s.This can and what it represents to rural households and outhouses, is in some ways immeasurable to the peace, health and tranquility within the household of all the families within the Kiewa Valley. Although small in size the relief of those within the sanctity of the home from annoying pests is enormous. The relief not only physical but also mentally to those residents, from the sometimes grueling and painful rural existence in a "sunburnt" countryside cannot be truly expressed in words. Kiewa Valley residents are part of the sometimes harsh rural environment where the introduction of helpful products such as this powder are noticed and used more prolifically. Any product, especially invented within Australia, which allows for a easier existence is of a great significance.This small cylindrical can contains powder of crushed the chrysanthemum flowers(pyrethrum extract) and has two circles of small circular perforations in the lid (to allow contents to be sprinkled onto other surfaces). It is constructed of mild steel with both ends crimped onto the main cylinder. A paper information label has been adhered to the outside of the cylinder.Printed on the outside label is: 1st line "MORTEIN!" 2nd line "THE GREAT INSECT DESTROYER" underneath "(Registered)" and underneath "It is without doubt the best and most reliable Insect powder in the World" underneath this line "In order to use Mortein with profit it is best to get a Mortein spreader through", next line "which by pressure of the hand the powder is ejected and well diffused." An inflection mark appears over the e in "Mortein" as to signify that the word "mort" is french for (dead) and the "ein" is german for "one". The word "mortein" therefore is diffused and translated into "dead one". A thin line separates the above from the list of insects which the powdered contents will kill together with the suggested application targets. T the bottom of the instructions is printed the manufacturer "J. HAGEMANN PTY. LTD., MELBOURNE," Below is "Sole Proprietors"natural insecticide products, environmentally friendly products, household pest dispensers, australian inventions -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTester Direct Current, mid 1900's

This tester was used between 1950 and 1980's. As part of the Occupation, Health and Safety requirements, equipment used to monitor the performance of electricity producing generators, regularly, hand held testers were used to check the insulation and the "earth" pin were up the the required operational levels. As the generators and their ancillary monitoring equipment was spread over a large area and cumbersome to service small hand held devices were required. These had to always be safe for the user to operate. A selected range of high quality meters were recalibrated every two years in the Meter and Calibration Laboratory at Yarraville(near Melbourne) This meter is very significant to The Kiewa Hydro Electricity Scheme because it was an integral part of maintaining the electricity producing water driven generators of the power stations. The reason why this meter was so essential is that provided the safety check on equipment used to monitor each Hydro Generator that they were complying within the grid network parameters. Grid parameters are set so that if there is an electrical fault on the system, that fault can be attended to with a very small change in the output stability of each generator. It is essential that the voltage of the network remain within the set limits. Generators are at Dartmouth, Mackay, Clover, West Kiewa, Yarrawonga, Cain Curran and three Power Stations in the Thornton area.This hand driven current generator produces 500 volts by winding the handle(on funnel curved side) to keep the voltage constant(one minute per test). The whole body is made from caste aluminium. One of the functions of this meter is to test the isolation resistance of any equipment being tested. This is to see if that equipment is safe to handle(no electrical shocks). The second function is to test the earth pin of any portable electrical equipment. The turn key on one side can direct which function is required(marked insulation or continuity). On the top side(enclosed in a glass fronted marked scale) is a continuity scale(top) and an insulation scale(bottom). This is covered , when not in use by "flip up" lid with manufacturer's details and name of the instrument. Opposite the winder are two screw tight knobs. One marked earth(left side) and one marked line(right side). On the top and next to the glass windowed scales in a post manufacture SEC Vic equipment equipment ID number. For carrying purposes there is chromed steel (fold together) handle.The bottom of the unit has two metal "feet" 150mm long by 114mm wideManufacturer's details on top side "MEG" underneath "INSULATION AND CONTINUITY TESTER" below this "constant 500 VOLT pressure" below this "REGISTERED MEG MEGGER TRADE MARK" below this "REG DESIGN NO. 690326" below this "UNITED KINGDOM PATENT Nos. 193746, 197178, 198182, 202062, 202398, 204649, 350715" below this "SUPPLIED BY THE GENERAL ELECTRIC Co. Ltd OF ENGLAND" below this "MAGNET HOUSE, KINGSWAY LONDON W.C.2" 'sec vic kiewa hydro scheme, alternate energy supplies, alpine feasibility studies temperature, rainfall -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomWater bottle

Standard Army issue item. Original owner not knownArmy issue water bottle. Steel construction with blue baked enamel finish. Housed in khaki felt jacket. In leather carrier. No strap.Leather has manufacturer's stamp; "WHITEHOUSE & HARTLEY WALSALL 3038" Stopper marked "DD", Defence arrow and "QP"water bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyOrgan

Bill Sutton Collection Jacob Estey founded te Estey Organ Company Battleboro in the late 1800s. One of the largest manufacturers of reed organs in the world. The company closed in the 1960s. This organ possibly 1923Used by a resident of the Kiewa ValleyMade of white Oak this small organ has a lid on 2 hinges at the sides and has 2 steel clips, each side, to keep it closed. At each end is attached a leather handle to move the organ.Next to the right-hand side of the keyboard is a movable silver knob. It has 2 wooden pedals each with a piece of non-slip material 'glued?' on. Each pedal is attached to the keyboard area with a leather strap. See "Reed Organ Society" La Vernia Tx, USA"Estey Organ Co. Brattleboro Vt USA" on the lid. (Note: Vt = Vermont) "Allan and Co. Ltd / Melbourne / Sole agents for Victoria" on the lid.reed organ, music, estey organs -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWhistle Penny, circa 1950s

This item is a cheap Penny Whistle made in Thailand Circa 1955. The item was one of the first wave of imports from the growing Asian steel producers. This was an era where cheaper Asia based steel companies did not compete against the stronger, and well established Australian ones. This Penny Whistle was "roughly" made and possibly purchased by the Victorian Education Department for use in school bands and music classes. Schools within the Kiewa Valley would have used them to integrate students the fundamentals of reading music and playing basic musical scores. Later conversion from steel to plastics would have been more conducive to multiple users in a classroom environment (more hygienic and rust proof.This item shows how the "cheaper" invasion of all types of manufactured goods from the Asian regions have altered the purchasing patterns of rural Australians(the more traditional consumer). The cost imbalance of purchasing from "The Mother Country (England)" or European supply versus the Asian manufacturers was due to not only the financial pressures post World War II but also in the elimination of Tariff restrictions placed on non favoured suppliers.This tin Penny Whistle is made from rolled tin(steel), cylindrical in shape, with a wooden Fipple plug at the mouth end and six note holes starting half way down the front side evenly spaced and ending 35mm from the bottom. This whistle is in the key of D"G steel & Co. D"music, wind instruments, whistle, celtic music -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tobacco / Cigarette, Circa 1900s

This particular brand of tobacco (State Express 555) was first made in 1915, and was most popular in Asia and China. The number triple 5 was mooted as a sacred number, and may have contributed to its high level of demand by Asian smokers. This would have been a favourite "smoke" for the Chinese emigrants, and especially those who settled in rural areas of Australia. In the era where 'male' type of activities such as motor racing, were sponsored by tobacco companies, roll your own cigarettes was ingrained as a macho male requirement. It was only in the early 2000s, when cigarette advertising had greater restrictions attached to the product, that the roll your own, and cigarettes in general, became less "cool". This particular cigarette tin would have also been useful for roll your own (ready rub tobacco)The significance of this particular Qantas cigarette tin to this rural region is that it demonstrates that overseas travel by plane was not only for the affluent city dweller but also available, and not impossible to the inhabitants of the Kiewa Valley. This cigarette tin also may hint that the influx of Asian immigrants into this region where able to visit relatives back in Asia without too much effort. The use of a Qantas cigarette tin in the Kiewa Valley also suggests a degree of affluent there or tourists from elsewhere. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries.This tobacco/cigarette tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method.The outside lid and frame has a yellow colour anodised to the metal.On the front of the lid are the following printed: "STATE EXPRESS" ,in yellow print, and below this are two horizontal lines in brown and central to these are the numbers "555" . Below this appears and within a 'royal' crest, in yellow writing on a brown circular background "STATE EXPRESS". Below this, in brown print, "PICCADILLY, LONDON". On each side of the tin are printed in brown colour: front side" ARDATH TOBACCO CO. LTD. PICCADILLY, LONDON" . On the left and right sides are printed in brown colour "20 STATE EXPRESS 555". On the rear side is with smaller print "MANUFACTURED UNDER ARRANGEMENTS WITH THE POPRIETORS". On the inside of the lid printed in red colour, are the following words, the royal crest and sketch of the winged kangaroo(symbol of the QANTAS logo). Within a red elongated square border, are the Royal Crest and in very small red print "BY APPOINTMENT TO HER MAJESTY THE QUEEN" underneath in slightly larger print "STATE EXPRESS" The print underneath this and in smaller print is "CIGARETTE MANUFACTURERS ARDARTH TOBACCO CO. LTD." Next to the royal crest and in much larger print is "STATE EXPRESS" and underneath this ,the numerals 555 with the words "CIGARETTES" below. The lower half of the inside lid has the following words and the "flying" kangaroo(winged). These words in written (running free hand) style "Specially packed for QANTAS(in red print). Underneath and in smaller print is "AUSTRALIA'S OVERSEAS AIRLINE". On the bottom of this tobacco tin is stamped into the metal surface, the number"704"qantas supplied cigarettes, roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers, tobacco -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tools, Saws, Early 20th century

These handsaws belonged to a Warrnambool furniture maker and dealer, Ernest Brighton Phillips (1875-1924). He learned cabinet making at the Warrnambool Box Works and established a furniture warehouse at the corner of Liebig and Koroit Streets in the late 1890s. By the early 20th century he had the largest furniture warehouse and factory in Victoria outside Melbourne and his furniture was sold all over Australia. He and his family lived at ‘Heatherlie’ in Koroit Street and today the site of this family home houses the retirement village complex known as ‘Heatherlie’. The makers of these saws was Robert Sorby of the Kangaroo Works in Sheffield, England. This business was established in 1928 and is one of the world’s premier manufacturers of specialist woodworking tools. These two tools are of some significance as they belonged to Ernest Phillips, a prominent businessman in Warrnambool at the end of the 19th and the beginning of the 20th centuries. These are also a good example of the type of tools used in the woodworking trade 100 years ago. These are two handsaws which belonged to Ernest Phillips. They have wooden handles attached to the blade by metal screws. One screw is missing on the larger saw. The blades are made of steel with serrated edges and they are inserted into a fold of steel along the top edge. The handles are well-worn and the blades are a little rusty. ‘Robt. Sorby Sheffield Cast Steel’ ‘E. Phillips’ ernest phillips, robert sorby, history of warrnambool -

Warrnambool and District Historical Society Inc.

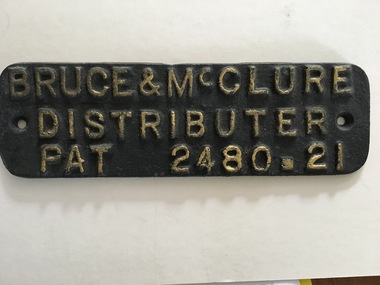

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Orbost & District Historical Society

Orbost & District Historical Societyboard game, 1930-1950

The National Bicycle Game is an Australian-made and designed board game for 2, 3 or 4 players made by The National Game Company of Ballarat and Melbourne between 1930 and 1950. The earliest board games date from the mid-18th century and were printed on copper or steel plates and coloured by hand. By 1839 lithography was first used, making it possible for publishers to produce larger quantities of all types of toys. By the 1890s the games were mounted on to a folded board. Popular subjects were of an historical or geographical nature, as well as transport including motoring, aviation and railways and various sports. The board game 'A Motor Ride' ,made by The National Game Company, was possibly the first large-scale manufacturer of locally-designed board games in Australia. The firm was established in Ballarat, Victoria, at the beginning of the twentieth century by W. Owen. Other board games made by National include the 'Victory-United Nations" game, 'Fairyland', 'Yacht Race', 'Golf Game', 'Bicycle Game', Steeple Chase', 'Our Great Game' about football, 'Courtship and Marriage', 'Around the Commonwealth by Aeroplane', and 'Dugouts and Trenches' as well as the more traditional games such as Ludo, Snakes and Ladders, and Noughts and Crosses. This game board has been well-used. The game is significant because it uses scenarios familiar to Australian children in the first half of the twentieth century. This game board reflects the experience of being a child in the twentieth century. Toys were how children were socialised and taught. Most toys mimic the adult world, and looking at them can tell us something about how the world has changed. A folding game board for The national Bicycle Game for 2,3 or 4 players. It has a yellow spiral track on which the player progresses at the throw of the die, starting at the clubhouse until reaching home. In the background are pictures of rural scenes.board-games recreation cycling national-game-company -

Orbost & District Historical Society

Orbost & District Historical Societydoll's pram, first half 20th century

It was inevitable that once children began to play with dolls and to create their own accessories for these toys, opportunistic manufacturers would begin to market products to cater for them. Toys made especially for little girls were designed to imitate the life and the society around them and to prepare them for their adult life as mothers. In the 21st century toys are less recognisable as miniature playthings. This item reflects the type of toys likely to be used by young girls.This is a cane pram for a doll. It has a wire handle which was probably once covered with cane. There are 4 steel wheels with solid rubber tyres. The cane has been woven around wire attached to the base. the hood is part of the basket. toys pram-dolls -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Cooper’s Hollowing /Jigger Knife, William Greaves & Sons, 1823 -1850

William Greaves was once a prolific company that highly prospered in the 19th century during the boom of the tool and cutlery trades in Sheffield England as steel became more commercially available. William Greaves's works were situated at the Sheaf Works in the heart of Sheffield, at Maltravers Street, opening in 1823 and was known to be the largest business in this area at this time. The Sheaf Works made a range of tools and saws including cutlery, penknives and razors and also even made its steel in-house. The factory used its perfect position for water power being built on the edge of the Sheffield canal and also used the railway line nearby giving them the perfect opportunities for transporting its goods. The factory itself was also a revolution because it attempted to bring together as many cutlery manufacturing processes as possible together in one place, something that had not been attempted before. The money to build these huge works came from Greaves' trade with America, where they sent razors, table cutlery and sturdy Bowie knives. This allowed the Greaves’ to build the factory and expand their production, which made them even more money. This made William Greaves very rich indeed, and it was reported that when he died in 1830 he left each of his five surviving daughters £30,000 each, an astronomical sum at the time. In today’s money that is approximately £2.3 million. The firm finally dissolved in 1850, but Sheaf Works continued to be used by many cutlery manufacturers until the 1980s. With most of the buildings still standing today.A significant item made by a successful cutlery manufacturer in England during the first half of the 19th century. This company undertook many new processes to streamline cutlery production and introduced innervations regards working with steel that are still in use today. This item is now regarded as a collector's item given the company ceased trading in 1850. jigger/hollowing knife with internal bevel, Electro Boracic Steel. Stamped 3.1/2″ William Greaves, Sheaf Works, Sheffield flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cooper's jigger, howeling knife, wm greaves & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, Ward & Payne Ltd, Late 19th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. The subject item was made by Ward & Payne of the Limbrick Works at Hillsborough, Sheffield England manufacturers of hand-forged tools. Their trademark registered in 1850 was a Letter "W" & "P" stamped into the steel. The firm was established by David Ward (1767-1822) in 1803 the company became David Ward & Sons, in 1837 after Ward's son Edward joined the firm. In 1845 Henry Payne the founder's son-in-law became a partner but died in 1850 after which the company reverted to the Ward family. The business then concentrated on making carving tools, chisels and gouges. In 1882 David Ward's grandson David Ward Jr. (1835-1889) purchased land and built a factory at Sheffield North known as the "Limerick Wheel". For a time Wards operated from both 106-114 West Street Sheffield and at Limbrick Road, Hillsborough on the river Loxley. By 1911 they had expanded into making spades, forks, sheep shears and many other types of edged tools including drills and wood planes. In 1967 Wilkinson Sword purchased all the company's share capital and continued to sell Ward & Payne tools until 1970 when a fire burned the factory down and housing development was built on the site. The subject item is significant as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Caulking tool with square end"WARD Sheffield"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, james s steele, caulking iron, caulking tool, shipwright tools, ward & payne sheffield, forged tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Pot, T & C Clark, Late 19th Century

T. & C. Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enameled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councillor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enameled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enameled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enameled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.An item that was made by a British foundry that was a pioneer and innervated many new processes in the manufacture of enamel ware, producing many items for every day use.Glue pot with inner pot, metal, corroded, both pots have handles."T & C CLARK & Co Ltd, ENGLAND, 55279 RD" and "FIRST QUALITY No. 4/0"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t& c clarke, cast iron, foundry, sanitary ware, ironware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Adze, Ward & Payne Ltd, Between 1843 to Mid 20th Century

An adze is an ancient and versatile cutting tool and has been in use for thousands of years. Adze are similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. They have been used since the Stone Age. Adzes are hand tools used for smoothing or carving wood. The subject item was made by Ward & Payne of the Limbrick Works at Hillsborough, Sheffield England manufacturers of hand-forged tools. Their trademark registered in 1850 was a Letter "W" & "P" stamped into the steel. The firm was established by David Ward (1767-1822) in 1803 the company became David Ward & Sons, in 1837 after Ward's son Edward joined the firm. In 1845 Henry Payne the founder's son-in-law became a partner but died in 1850 after which the company reverted to the Ward family. The business then concentrated on making carving tools, chisels and gouges. In 1882 David Ward's grandson David Ward Jr. (1835-1889) purchased land and built a factory at Sheffield North known as the "Limerick Wheel". For a time Wards operated from both 106-114 West Street Sheffield and at Limbrick Road, Hillsborough on the river Loxley. By 1911 they had expanded into making spades, forks, sheep shears and many other types of edged tools including drills and wood planes. In 1967 Wilkinson Sword purchased all the company's share capital and continued to sell Ward & Payne tools until 1970 when a fire burned the factory down and housing development was built on the site.The subject item is significant as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Adze with wooden handle curved painted green with patent number and maker's name inscribed on inside curve of blade. Inscribed "Patd 561 Ward" "2w". flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, smoothing tool, hand tool, carpenders tool, adze, coopers tool, woodworking tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Robert Sorby, First half of the 20th Century

A scotch eye auger is perfect for quickly making holes in dry or wet wood for making chairs, stools, and any number of woodworking projects. The scotch eye serves as a peg gauge and whatever peg you make to go into the hole should fit into the augers eye. Robert Sorby & Sons: The forbearer's of Robert Sorby had been cutlers in the Sheffield region of England, dating from the mid 17th century. Robert Sorby and Sons were registered in Sheffield in 1828 as a manufacturer of edge tools, saws, scythes and hay knives. In addition to manufacturing tools, they also diversified into the manufacture of crucible steel for tool manufacture. From circa 1860-1967, the Sorby factory in Sheffield was known as the “Kangaroo Works”. The Kangaroo Brand of tools was made by Robert Sorby & Sons. During the 19th century, they had a large trade in Australasia. By the early 20th century, they were manufacturing carving tools, planes and plane irons, circular saws, wood saws, butchers saws and cleavers, garden tools, pruning knives, coopers’ knives, bricklayers tools and joiners tools. In 1923 Robert Sorby & Sons was bought by Sheffield company Hattersley and Davidson. They are today one of the few remaining British tool manufacturers.The company has a long tradition of making edged tools for various uses and exporting them to Australia, however the subject item was probably made from the early 20th century up until 1967 when the company stopped exporting to Australia.Scotch Eye Auger, Double Twist with Lead Screw, square shaft, socket set at right angleRob Sorbey Sheffield stamped on shaft with Kangaroo trade markflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ring auger, carpenders tools, hole drilling, rob sorby & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1952

Mr John Wilson Gillie was born on the 31st of March 1864. On the 31st of July 1880 he was apprenticed for four years to J.J. Wilson and Sons, Nautical Instrument Makers of Sunderland. Following the apprenticeship he spent six months to a year as an ‘improver’ in Glasgow, and then started a new company ‘Wilson and Gillie’ in North Shields. At this time sail had just given way to steam and wooden ships to steel, and the railways were competing with colliers for the carrying of coal from the North East of England to London and the South. In 1858 only seven out of 44 shipyards on the Tyne were using iron, but by 1862 there were ten, employing around 4,000 men. These changes had a significant effect on nautical instrument manufacturers, as the magnetic compass for a wooden sailing vessel was very simple and required little in the way of compensation. For steel vessels much more was required and this was a period of great development, both in the compass bowl and the binnacle in which it was housed. In 1870 Sir William Thomson (later Lord Kelvin) designed his dry card standard compass, which completely replaced all previous designs. Wilson and Gillie started as agents for the Thomson compass, but later J.W. Gillie, using similar principles, redesigned the compass suspension and patented the ‘UNIT’ standard compass. It became popular with local shipowners and shipbuilders. In 1910 the firm of John Lilley and Son (which had been established in London in 1812), found themselves in financial difficulties and were saved with the help of John Wilson Gillie, who established, on the 8th of August 1911, a new firm of John Lilley and Son Limited. John Lilley and Son had been the sole London agents for Sir William Thomson, a very enviable position during this period, when the Thomson compass led the field. Unfortunately, Mr. Lilley had quarreled with the Glasgow company, who withdrew the agency and established their own branch in London (later to become Kelvin White and Hutton). On November 7th 1913, the firm of John Lilley and Son Limited of London amalgamated with Wilson and Gillie of North Shields, and after this date instruments manufactured by the two companies bore the name John Lilley and Son Limited of London and North Shields. During the 1930s many of the London nautical instrument makers were in difficulties, including John Lilley and Son Limited and Reynolds and Son, Dobbie and Clyde Limited, and Mr. J.W. Gillie arranged an amalgamation between these two companies. The new firm became Lilley and Reynolds Limited. In 1943, with estate duties in mind, the North Shields company was reconstituted and took the name of John Lilley and Gillie Limited, although the shareholders, directors and personnel remained unchanged In the early 1970s Lilley and Gillie developed close links with Observator in Rotterdam, who manufactured one of the first fully reliable transmitting magnetic compass systems. The Observator shareholders, Holland America Line, bought the share capital of John Lilley and Gillie Limited., but retained all the personnel and the directors. Tug Melbourne: The barometer was salvaged from a 496-ton tug that had been built in 1952 and had sunk in Port Philip Bay on the 9th of August 1972 after a collision with the SS Nieuw Holland, in 1973 it had been raised and scraped at this time the barometer was salvaged. The tug had been renamed from the Howard Smith to the “Melbourne” after the Adelaide Steamship Co was taken over by Howard Smith& Co, who were heavily involved in towage, salvage and the stevedoring industries in 1961.The significance is that the item was on a vessel that was evolved in a serious collision in Port Philip Bay in 1972. It is linked with the activities of the Port at that time and helps to form a picture of what the maritime industries that operated from Port Melbourne were like and the activities that stevedore and towage companies underwent.Ship Barometer, in brass caseInscribed "Compensated" , "John Lilley & Gillie Ltd London & North Shields." and "Millibars".flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, barometer, ship's barometer, weather instrument, john lilley & gillie ltd, shipwreck artefact, the tigboat melbourne, north shields, howard smith, the melbourne, salvage -

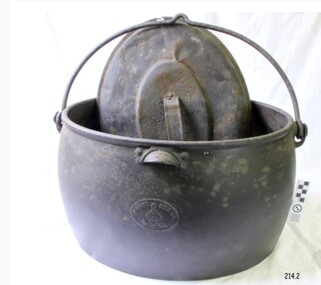

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

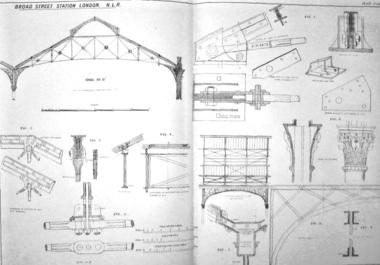

Federation University Historical Collection

Federation University Historical CollectionBook, Iron Roofs: examples of design, 1884 (exact)

Book. Large brown hard cover. Title written in gold on front cover and on spine. Manufacturer name also written in gold on spine. Illustrations, plates (black & white). 37 p. + plates.civil engineering, design, roofing, iron and steel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw Vice and Spanner, Henry Disston & Sons, Early 20th century

Henry Disston (1819-1878) was born in England and later moved to America. He has been noted in a biography as a "Pioneer Industrialist Inventor". In 1840 he began making and selling his own saws in Philadelphia, USA, growing to become the world's largest saw manufacturer. Tools made by Henry Disston and his company have the reputation of being the finest tools money can buy.The saw sharpening vice and its shifting spanner are significant for their connection with Henry Distton & Sons, renowned for high quality hand saws and associated tools. In 1855 Henry Disston cast a crucible saw sharpening steel, the first person to ever do so in America. The hand tools are also important for their association with the early building industry. Saw sharpening vice with accompanying saw tooth shifting spanner. The vice has a ball and socket clamp. The top of the vice has a saw clamp with wide jaws. The metal surface has remnants of black paint. Inscription is cast into the jaws of the vice. It was made by Henry Disston & Sons"HENRY DISSTON & SONS"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, vice, saw sharpening vice, saw sharpening tool, saw tooth, shifting spanner, woodworking tool, henry disston, disston & co, hand saw, handsaw, hand tools, carpentry, boat building -

Flagstaff Hill Maritime Museum and Village

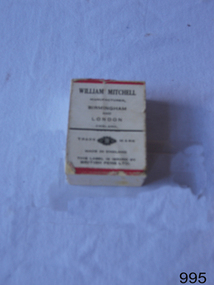

Flagstaff Hill Maritime Museum and VillageNibs & box, late 19th to early 20th century

Box of dip pen nibs made by William Mitchell Calligraphy dating back to late 19th or early 20th century when dip pens with steel nibs were the main writing instruments. The pen nibs are shaped to fit into a slot in the base of a wooden or Bakelite pen holder. The hole at the front of the nib is for collecting ink from a well, which is then stored in a reservoir at the back of the nib. The nibs are stamped with their nib size and Pedigree (what type of nib it is) and maker’s details. William Mitchell Calligraphy still makes these nibs today with a slightly difference finish. (ref: Sales and Marketing Director of William Mitchell Calligraphy in 2016). HISTORY of the Ink Pen Quills and ink were common writing tools until the early 19th century when the pen trade began mass producing steel nibs and pens. The steel nibs each have a hole in the middle that acts like a well for the ink. When the nib is dipped into the ink well the writer needs to ensure that it is dipped to only just past that well. India Ink was one of the most popular inks used with the nib pens, notable for its satin-like smooth flow. This ink is composed of a particularly fine carbon mixed with water; it can also be obtained as a dry stick that is then crushed and mixed with water as required. The Jewellery Quarter of Birmingham had the largest concentration of independent jewellers in Europe. Birmingham became the centre of the world’s pen trade for many years -, during the 1800’s over 100 factories, employing 1000s of skilled workers, manufactured the ‘Birmingham Pen’. ABOUT WILLIAM MITCHELL CALLIGRAPHY LTD.* (*The following text is quoted from the William Mitchell Calligraphy website) British based William Mitchell Calligraphy has been designing and manufacturing exceptional pens for almost 200 years. The William Mitchell heritage in making pen nibs began whilst working with his brother John Mitchell in the early 1820s. William Mitchell established his own business in 1825 to become one of the leading nib manufacturers and famous for lettering pens. Almost 100 years later William Mitchell merged with Hinks, Wells & Co, another pen manufacturer, to form British Pens, employing around 1000 people in the Bearwood Road area of Birmingham. During the early 1960s British Pens acquired the pen business of other pen manufacturers Perry & Co and John Mitchell, once again reuniting the two brothers. Joseph Gillott, who were famous for their artist drawing and mapping nibs, amalgamated with British pens in 1969. William Mitchell and Joseph Gillott established in Birmingham during the early part of the nineteenth century and [their products] are still proudly made here. British Pens were subsequently purchased by its current owner Byron Head, the owner of William Mitchell (Sinkers) in 1982, and was subsequently renamed William Mitchell (calligraphy) Ltd. Established in 1827 Joseph Gillott was one of the pioneers of mass steel pen nib manufacturing. The company was particularly strong in the American market, prompting Elihu Burrit, the American consul, to write “In ten thousand school houses across the American continent between two oceans, a million children are as familiarly acquainted with Joseph Gillott as with Noah Webster” (The compiler of the famous American dictionary). The company consequently received visits from many notable Americans, including president Ulysses S Grant. Email on file, from Mike Chappell, Sales and Marketing Manager, William Mitchell Calligraphy, “20161122 - William Mitchell re pen nibs” How to use a dip pen to create modern calligraphy, https://thepostmansknock.com/how-to-use-a-dip-pen-to-create-modern-calligraphy/ India Ink, Wikipedia https://en.wikipedia.org/wiki/India_ink birmingham Pen Trade, Wikipedia, https://en.wikipedia.org/wiki/Birmingham_pen_trade The Pen Museum, http://penmuseum.org.uk/ The early 19th century invention and later mass production of pen nibs such these in our collection had a large impact on education and literacy because the nibs could be produced in great numbers and affordable prices.Box of patent Mitchell nibs containing 48 "Pedigree" nibs. Box depicts picture of William Mitchell on lid, and picture of nib pen on lid and side. Made in Birmingham, England. Nib “0505 Wm MITCHELLS PEDIGREE ENGLAND” Box “PEDIGREE / MAINFOLD SLIP”, “WILLIAM MITCHELL / BIRM - - - - - - LOND” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, william mitchell calligraphy ltd, pen nib, writing implement, writing accessories, dip pen, birmingham manufacturer, communication in writing, mass produced pen nibs -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Concertina, Lachenal and Co, 1879-1933

Louis Lachenal manufactured concertinas for C Wheatstone & Co. from around 1848-1858 in a combined home and manufactory in Cheswick, England. He then establish up his own business 'Lachenal's' at 8 Little James Street in London. In 1863 the firm began advertising both 'Anglo and English concertinas, which were more expensive. Lachenal passed away in 1861, so his wife Elizabeth took over the business. The firm was sold to a group of five businessmen in about 1873 and in 1874 the firm became ‘Lachenal & Co.’ A Trade Mark application was made by Richard Ballinger on behalf of Lachenal & Co. on 31st August 1878 and the Number 19,555 was published in the Trade Mark Journal January 8, 1879. The symbol was an English-style reed-shoe with the words 'Trade Mark' and 'English Make'. It was stamped on the right-hand rail (handle) of the Lachenal Anglos, to distinguish them from the German-made ones. It seems that the company ceased business in 1933.This concertina, made in the late 19th to early 20th century, represents the portable musical entertainment of the early settlers in the colony of Australia. Concertina, six sided, 21 buttons, with fitted case. Wooden ends have carved cut-outs and leather straps attached to brass buttons. Five-fold bellows have light coloured sides with reinforced edges and corners. Constructed with steel reeds and bone key-buttons. Wooden, black fabric-covered hexagonal case with triangular metal catch, two brass hinges, leather handle and faded red lining. Inscriptions on label inside lid and on wooden ends of bellows. Lachenal, Anglo design, made by Lachenal & Co. of London. Label within oval cut-out "LACHENAL & Co / PATENT CONCERTINA / MANUFACTURERS / LONDON", Label inside lid " - CHENAL -", Impressed into wood STEEL REEDS", "ENGLAND", "TRADE MARK ENGLISH MAKE [reed-shoe symbol]" , (originally marked with Number "98030" )flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, concertina, squeeze box, musical instrument, london, english make, trade mark 15222, english-style reed, richard ballinger, louis lachenal, concertina manufacturer, reed-shoe, lachenal anglo, lachenal & co, lachenal -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers' Equipment, hair clippers 'BURMAN", c1950

Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. Burman & Sons Ltd, of Ryland Road, Birmingham, West Midlands, manufactured Burman-Douglas steering gear. Their recirculating worm and ball design of steering gear was fitted to pre-war vehicles such as the Ford Eight and the Ford Prefect, the Bedford CA, plus heavy trucks and off-road vehicles - both pre and post-war. In its day, Burman-Douglas steering-gear was regarded as.... a "quality" feature of a car chassis specification, but the worm and ball design was eventually surpassed by the cheaper rack and pinion design that dominates today. The company also manufactured motorcycle gearboxes, horse clippers and barbers’ clippers. 1871 Company founded. 1897 Private company. 1930s Gearbox for Ariel Square-four motorcycle. (Exhibit at Birmingham Thinktank museum) 1933 Burman and Sons Limited, manufacturers of horse and barbers' clippers, sheep shearers, motor cycle gear boxes and steering gears, Ryland road, Edgebaston 1953 S. F. Burman, M.B.E., Managing Director, Burman and Sons, Ltd 1955 Acquired by Vono Industrial Products. 1961 Manufacturers of motor and motorcycle accessories. 1,500 employees. 1968 Supplied rack and pinion steering units to Ford 1978 Adwest Group acquired Burman and Sons, the steering gear part of Duport. 1986 Major reduction in staffing at Burman due to fall in demand for its products and delivery problems. A set of hand held barbers’ hair clippers with an adjustable screw, from Burman and Sons Ltd of Birmingham, England. Chrome plated, in good condition, c1950. On left arm ; BURMAN On right arm ; MADE IN ENGLANDbarbers, hairdressing, hair clippers, grooming, horse clippers, cars, motor cycles, gear boxes, rack and pinion , worm and ball, steering gears, steel manufacture, birmingham england, burman and sons ltd, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Education, Pen Nibs ' R. Esternbrook Co. Ltd, 20thC

Dip pens emerged in the early 19th century, when they replaced quill pens. They were generally used prior to the development of fountain pens in the later 19th century, and are now mainly used in illustration, calligraphy, and comics. A nib pen usually consists of a metal nib with capillary channels like those of fountain pen nibs, mounted on a handle or holder, often made of wood. Other materials can be used for the holder, including bone, metal and plastic. Generally speaking, dip pens have no ink reservoir; therefore the user has to recharge the ink from an ink bowl or bottle in order to continue drawing or writing. Birmingham, England was home to many of the first dip pen manufacturers. John Mitchell pioneered mass production of steel pens in 1822; prior to that the quill pen had been the most common form of writing instrument. His brother William Mitchell later set up his own pen making business in St Paul's square. The Mitchell family is credited as being the first manufacturers to use machines to cut pen nibs, which greatly sped up the process. Germany 1842 began at the factory of Heintze & Blanckertz in Berlin By 1860 there were about 100 companies making steel nibs in Birmingham, but 12 large firms dominated the trade. Dip pens are rarely used now for regular writing, most commonly having been replaced by fountain pens, rollerball pens, or ballpoint pens. However, dip pens are still appreciated by artists, as they can make great differences between thick and thin lines, and generally write more smoothly than other types of pens. Dip pens are also preferred by calligraphers for fine writing. Richard Esterbrook was a Cornish Quaker from England who saw an opportunity in the United States to manufacture Steel Pens. In 1856 R.Esterbrook traveled to the US to set up shop as 'The Steel Pen Manufacturing Company' where Richard made these steel pens by hand using special tools and machines (mostly that Richard had to invent). In 1858 he was able to establish himself as the sole pen manufacturer in the USA and he changed the company name to 'The Esterbrook Steel Pen Mfg. Co.' The company settled down in Camden, New Jersey. Quality was a key factor in his success. His steel pens were versatile, long lasting, and came in many different styles to fit the varied writing styles of the public. Sadly, Richard Esterbrook didn't see the 'empire' his company was to become as he passed away in Atlanta on October 12th 1895 . in 1896 they started an Esterbrook branch in England to join the ranks of the other main pen manufactures in Birmingham . In 1912 the company had gotten so large that they erected a 5 story building, just to continue manufacturing pens. By 1920 the fountain pen was fast becoming more popular amongst people who were tired of 'dipping.' To meet this demand the company manufactured its first fountain pen. In 1930 the company sought less expensive means of manufacturing pens because gold and 'jewel' tips were too expensive and in this same year they began selling fountain pens in England . The Esterbrook Company began using the metal Iridium which they called 'Durachrome.' To meet the fountain pen demand the company reformed as 'The Esterbrook Hazel Pens Ltd.' In 1940 war had come to strike a blow at the Esterbrook company. On November 19th 1940 their England location was hit by an incendiary bomb destroying half of the location! To make matters worse, when putting out the fire using a human water bucket chain, someone accidentally grabbed a bucket of paraffin and set the place further ablaze. Oddly enough, the company was able to rebuild the structure during the war. However, the government had placed a stipulation that 50% of its capacity was to be used for government related purposes. In 1947 the company bought out John Mitchell and the American branch had already acquired Hazel Pen Co. The company re-formed again as 'The Esterbrook Pen Company.' This is the last company name the dip pen nibs were manufactured under. A box of Steel dipping nibs for writing pensOn Box; Photo of man / R. Esternbrook Co. / PENS / PROBATEsteel nibs, writing pens, education, schools, writing, caligraphy, artists, moorabbin, bentleigh, cheltenham, dip pens, inkwells, fountain pens, mitchell john, birmingham england, esternbrook richard, maple barbara