Showing 101 items

matching stoke- on - trent

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

... Stoke-on-Trent, Staffordshire, UK ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

... Stoke-on-Trent, Staffordshire, UK ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Puffing Billy Railway

Puffing Billy RailwayVictorian Railways Saucer Plate, May 1954 "5-54" = "month-year"

... Tunstall, Stoke-on-Trent, , England ...Victorian Railways Saucer Plate - Red & White Supplier to Victorian railways : Loftus Moran, Melbourne: Mr Loftus Henry Moran was well known in the tea trade. Originally employed by Griffiths Bros Ltd, he started his own business, Loftus Moran Pty Ltd, in 1909 In 1913 he purchased the tea business of McIntyre Bros, and later, that of Steele Bros, and absorbed them in his own company. He had a wide business connection among hotels and guest houses for supplying crockery and other supplies. Ref: DEATH OF MR LOFTUS MORAN (1944, May 27). The Argus (Melbourne, Vic. : 1848 - 1957), p. 4. http://nla.gov.au/nla.news-article11809686 1st Advertisement of the Plates in the papers: CHIPPED CROCKERY. Nothing is more objectionable than chipped crockery--besides its use is illegal. DURALINE Plates, manufactured by The Grindley Hotel Ware Co., are tough as raw-hide. This is why they are used by practically every hotel and institution in Australia. Obtainable only from LOFTUS MORAN PTY. LTD., Hotel Supply Specialists, 131 Queen's Bridge Street, Melbourne South Advertising (29 March 1933, ). The Argus (Melbourne, Vic. ), p. 7. http://nla.gov.au/nla.news-article4726734Historic - Victorian Railways - Refreshment Services crockery - plateCeramic Victorian Railways Saucer Plate - Red & White Victorian Railways ( in Red on fount of plate ) "DURALINE" ( in Black on back of plate ) super Vitrified GRINDLEY HotelWare Co England Loftus Moran Pty Ld Melbourne 5 -54 puffing billy, victorian railways, crockery, plate -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPin Dish, Swinnertons, 1950's

... Hanley Stoke-on-Trent, Staffordshire, England ...Small dish with flutter edging with pink flowers.SWINNERTONS / STAFFORDSHIRE / MADE IN ENGLANDpin dish, swinnertons -

Anglesea and District Historical Society

Anglesea and District Historical SocietyBowl, Alfred Meakin (Tunstall) Ltd, Royal Albert & Newfield Potteries

... Tunstall, Stoke-on-Trent, Staffordshire, England ...Small bowl-dish with rim. Brown daisy pattern.Glo-White-Ironstone / crown symbol / Alfred Meakin / Englandplate, bowl, meakin -

Anglesea and District Historical Society

Anglesea and District Historical SocietySouvenir Plate, Estimated 1937

... Stoke on Trent, England ...Souvenir plate commemorating Coronation May 12, 1937 of King George 6th and Queen Elizabeth - crowned in Westminster Abbey. Cream china plate with British Coat of Arms. Names of King George 6th and Queen Elizabeth in red on gold background around edge with "Crowned May 12 1937'".Royal Crest - By appointment. A Perpetual Souvenir in Paragon China to commemorate the Coronation of their majesties King George 6th and Queen Elizabeth crowned in Westminster Abbey May 12 1937. Registered and copyright. Made in England.plate, coronation 1937 souvenir -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPlate, J & G Meakin, Eagle & Eastwood Pottery Works, 'LILAC' PLATE, 1912

... Hanley, Stoke-on-Trent, England, United Kingdom ...Basically square with indented corners. "Lilac" trees and sprigs. Green edging.Regd. SOL - 391413 / J & G MEAKIN ENGLAND / (Unreadable bottom line)meakin, plate -

Anglesea and District Historical Society

Anglesea and District Historical SocietyQueen Elizabeth II Coronation Souvenir Mugs, 1953

... Keele Street, Stoke-on-Trent, England, United Kingdom ...Pair of Keele Street Pottery souvenir mugs of 1953 coronation of Queen Elizabeth 2. 1. One cream mug with gold trim. 2. One pale green mug with dark green trim.Marked "ENGLAND KSP" on base with "M" on base of cream mug.keele street pottery, coronation mug, queen elizabeth 2 -

Anglesea and District Historical Society

Anglesea and District Historical SocietyIronstone Mug, Ironstone Mug in celebration of HM Queen Elizabeth 2 - 1952-1977, Estimated 1977

... Stoke-on-Trent, England, United Kingdom ...Souvenir mug in white ironstone with black painting of London scenes headed "London Celebrations 1977" on one side and "The Queen's Silver Jubilee" on the other. Card attached with list of dates and occurrences in the Queen's life from 21 April 1925 to 14 November 1973.Stamp of "ADAMS - Real English Ironstone. Made in England. / Established 1657" - on bottom of mug.queen elizabeth 2, silver jubilee souvenir, ironstone mug -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Child's bowl

... Stoke on Trent, England ...White china feeding bowl for infants with black cats on border and base of bowl.domestic items, infants -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMemorabilia - China Bowl Ronan's Coffee Palace, Grindley Hotel Ware, C.1921 - 1930

... Stoke-on-Trent, Staffordshire, England ...Coffee Palaces were developed throughout Australia with the backing of the Temperance Movement as an alternative venue to pubs in the late 19th century. Two Coffee Palaces identified in Wodonga in the early days were the Railway Coffee Palace and the Wodonga Coffee Palace. In 1908 Wodonga Coffee Palace was advertised for sale, having 15 rooms, a 15 stall stable and feed-room. In 1921 Wodonga Coffee Palace was taken over by Julia Ronan who had successfully conducted the dining rooms at the Wodonga Sale-yards for 15 years. The building of the Hume Weir was in progress and many of the workers boarded at the Coffee Palace. In 1936 Wodonga Coffee Palace became “Glenburnie” Guest House. Mr. Loftus Henry Moran, born in Winchelsea, Victoria, was well-known in the tea trade, originally working with Griffiths Bros Ltd. He started his own business, Loftus Moran Pty Ltd in 1909. Loftus Moran's company imported chinaware from Britain and sold it into the Australian market. They specialised in supplying to hotels, businesses and institutions.This bowl is an excellent example of earthen ware items used throughout Australia in hotels, cafes and other institutions. Loftus Moran Pty Ltd, was a major distributor and successful Melbourne Company. Mrs. Ronan's Coffee Palace was an important business in Wodonga and an alternate food and accommodation venue for those who preferred not to stay in public houses or hotels.A small white bowl bearing the logo of Ronan's Coffee Palace in Wodonga printed in green.In a scroll at the top edge "RONAN'S COFFEE PALACE" Underneath the bowl in green writing below a green crown "GRINDLEY HOTEL WARE/ENGLAND/VITRIFIED/LOFTUS, MORAN/ MELBOURNE"coffee palace, wodonga business, wodonga, mrs. ronan wodonga, 1920s wodonga -

Mont De Lancey

Mont De LanceyDomestic object - Chamber Pot, Bridgwood & Son, c. 1800's

... Longton, Stoke on Trent, England, Great Britain ...This chamber pot came from the local Parker family. We take indoor flushing toilets pretty much for granted, but in the 18th century the chamber pot was the solution to answering a call of nature for most poorer households. Wealthier people also had chamber pots made from either earthenware or pewter. Prosperous travellers took their pot with them on journeys - public toilets did not exist. Some pots had lids. Bridgwood & Son were established in Lane End around 1795. Sampson Bridgwood took over the Anchor Pottery at the corner of Wharf Street (renamed Bridgwood Street in the 1950s) and Goddard Street in Longton in 1853.A white porcelain chamber pot decorated on two sides with large double pink roses and a blue floral leafed pattern. It has a fluted self pattern around the lower half of the pot, a gold line trim near the top and a decorative fluted handle. The wavy rim is also fluted.'Porcelain Opaque Bridgwood & Son.' is stamped in brown lettering around a manufacturer's shield on the base.bedpans, chamber pots, pots, sanitary equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Book, Tile catalogues, c. 1900

... . Tichelaar Makkum, Holland; Mintons China Works, Stoke-upon-Trent... Works, Stoke-upon-Trent; Leeds Fireclay Company, Burmantofts..., Stoke-upon-Trent; Leeds Fireclay Company, Burmantofts Works ...Six catalogues used as references by the Australian Tesselated Tile Co. Pty Ltd:Six catalogues used as references by the Australian Tesselated Tile Co. Pty Ltd: Carter & Co., Poole, Dorset - Encaustic Tile Works; Gbrs. Tichelaar Makkum, Holland; Mintons China Works, Stoke-upon-Trent; Leeds Fireclay Company, Burmantofts Works, Leeds (building illustrations); Richards Tiles Ltd, Tunstall, Stoke-on-Trent - Tile fireplacesSix catalogues used as references by the Australian Tesselated Tile Co. Pty Ltd:richards tiles ltd, leeds fireclay company, mintons china works, tichelaar gebrs. makkum, carter & co., tiles, australian tesselated tile co. pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Container, Registration No indicate item was made between 1911-1912in the Stoke on Trent area of the UK

... made for domestic use in the Stoke-on-Trent area of England... the Stoke on Trent area of the UK... to have been made for domestic use in the Stoke-on-Trent area ...A mass produced utilitarian item believed to have been made for domestic use in the Stoke-on-Trent area of England, no history or manufacturing provenance currently available makers mark unable to be identified at this time. Over 1500 pottery firms have operated in Stoke-on-Trent since the early 1700's - Some lasted only a few years and some for well over 200 years. Some potters built and owned their own works. Many others were tenants in works built by others and a succession of potters occupied the same works. It was also a common practice for a works to be split between two different pottery companies or for a larger manufacturer to let out a smaller section of his works to a potter who would make wares which were not of interest to the pot works owner. Some potters purchased 'blanks' from other manufacturers and put their own decoration on them some items have two back stamps. All this adds to the confusion and frustration of trying to trace details of a particular manufacturer such as the subject item.Item at this time cannot be associated with an historical event, person or place, provenance is undetermined, item assessed as a collection asset given it was produced before 1950.Toilet article container base, porcelain with blue decoration on white backgroundRd No 58105 (year 1911) Orchid W.& W. on baseflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, toilet container base, toilet article, grooming article -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Souvenir - SOUVENIR OF WHITCHURCH

... Stoke On Trent Arcadian China... DOMESTIC EQUIPMENT Ornaments Souvenir Stoke On Trent Arcadian China ...Small white china ornament souvenir of Whitchurch with a loop for hanging, decorated with a blue shield with 3 lions faces and a gold banner with wording Floreat Salopia banded with gold.Date in gold on reverse 1836.Stoke On Trent Arcadian Chinadomestic equipment, ornaments, souvenir -

Orbost & District Historical Society

Orbost & District Historical Societyteapot, Untitled, 9.10.1871

... Bottom-Ridgeways, -Cenis, Stoke on Trent... Bottom-Ridgeways, -Cenis, Stoke on Trent Square-shaped china ...Square-shaped china teapot. White background with brown transfer images of pineapples. Spout and handle ornately designed. Manufactured by Ridgways, a Staffordshire Pottery in England, with the English registry mark dating its registration to 1871. In the pattern, “Cenis”. Bottom-Ridgeways, -Cenis, Stoke on Trentteapot domestic-items food-drink-consumption ridgways -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Tile, circa 1878

... colonial markets by the Milton Pottery at Stoke upon Trent were... “46” and the letters “Minton & Co Patent Stoke upon Trent”....Stoke upon Trent, Staffordshire, England... colonial markets by the Milton Pottery at Stoke upon Trent were ...This Minton floor tile is from the wreck of the LOCH ARD. Other examples of this manufacture have been recovered from the wreck site and form part of the collection at Flagstaff Hill. The iron-hulled clipper ship from the Loch Line was heading for Port Phillip from London when it ran into the cliffs of Mutton Bird Island near Port Campbell and was wrecked on the early morning of June 1, 1878. The LOCH ARD was laden with high-value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well-packed Minton porcelain peacock, a two-metre-high ceramic masterpiece of vivid glazed colours. The almost total loss of life and property from the LOCH ARD registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. The wealth generated from gold and wool was increasingly being spent on magnificent private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton Pottery at Stoke upon Trent were their new range of colourfully patterned but very durable floor tiles – ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These new floor tiles were “encaustic”, meaning that their designs and colours were encased within the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) that were poured into a deep pre-moulded casting. When fired, the resulting tile was colour-fast and design-fast.The Minton encaustic floor tile is significant for its method of manufacture which makes it durable as well as decorative. The shipwreck of the LOCH ARD is of State significance. Victorian Heritage Register S417. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best-known shipwrecks in Victoria’s history.A square Minton floor tile with a black and beige pattern against a white base. This encaustic floor tile was recovered from the shipwreck of the LOCH ARD. On the back, or base, of the tile is inscribed the number “46” and the letters “Minton & Co Patent Stoke upon Trent”.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, mutton bird island, loch ard gorge, minton floor tile, encaustic tile, melbourne international exhibition, floor tile -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Haeusler Collection Child's Ceramic Bowl

... (Ltd) in Stoke on Trent, Staffordshire, England. Empire... mould/ "EP.Co Stoke on Trent" is embossed on the bottom... (Ltd) in Stoke on Trent, Staffordshire, England. Empire ...The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This bowl is one of several objects in the Haeusler Collection concerning early childhood that provide insight into family and home life in early twentieth century Wodonga. The Hauseler Collection bowl was manufactured by Empire Porcelain Co (Ltd) in Stoke on Trent, Staffordshire, England. Empire Porcelain Co (Ltd) was established in 1896 and manufactured bone china and earthenware until the company's closure in 1967. It can be dated to the first half of the twentieth century, likely c.1910s-1920s. Staffordshire became a centre for ceramic production in the 17th century due to the local availability of pottery materials including clay, salt, lead and clay. This item has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history, social history, and women’s history.Child's ceramic bowl with black print. The print in the centre of the bowl features a child with a wind instrument and three dancing cats. The outer rim of the bowl features a black circular print of roosters, dogs, cats, geese, rabbits and squirrels. The bottom of the bowl is embossed with details of manufacture. "ENGLAND" is embossed on bottom of the bowl via ceramic mould/ "EP.Co Stoke on Trent" is embossed on the bottom of the bowl in black via print. tableware, haeusler collection, children, ceramic, social history, domestic, family -

Orbost & District Historical Society

Orbost & District Historical Societycruet set, 1913-1917

... Base of jug- S.F. & G. Stoke on Trent England ; a crown... pottery cruet-set Fielding Base of jug- S.F. & G. Stoke on Trent ...This cruet set reflects the style of tableware produced in Staffordshire, England, in the early 20th century. Staffordshire became the centre of pottery manufacture in England by 1730, and a century later it was established as an international centre, exporting its products around the world. Staffordshire pottery was widely used in homes and cafes throughout Australia.A cruet set on a silver plated stand. The jug and shaker are ceramic - violets on a cream background.The shaker has a silver-plated topBase of jug- S.F. & G. Stoke on Trent England ; a crown ; Crown Division Shaker - on lid -E.P.N.S. and on the base - S.F. & G. Stoke on Trent England ; a crown ; Crown Divisionporcelain pottery cruet-set fielding -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Tile, circa 1878

... by the Milton Pottery at Stoke upon Trent, were their new range... “46” and the letters “Minton & Co Patent Stoke upon Trent”....Stoke upon Trent, Staffordshire, England... by the Milton Pottery at Stoke upon Trent, were their new range ...This Minton floor tile is from the wreck of the LOCH ARD along with other examples of this manufacture recovered from the wreck site and form part of the collection at Flagstaff Hill. The iron-hulled clipper ship from the Loch Line was heading for Port Phillip from London when it ran into the cliffs of Mutton Bird Island near Port Campbell and was wrecked on June 1st, 1878. The LOCH ARD was laden with high-value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well-packed Minton porcelain peacock, a two-metre-high ceramic masterpiece of vivid glazed colours. The almost total loss of life and property from the LOCH ARD registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. The wealth generated from Gold and Wool was increasingly being spent on grandiose private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton Pottery at Stoke upon Trent, were their new range of colourfully patterned but very durable floor tiles – ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These new floor tiles were “encaustic”, meaning that their designs and colours were encased “within” the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) were poured into a deep pre-moulded casting. When fired, the resulting tile was colour-fast and design-fast. A brief history of the Loch Ard (1873-1878): - The sailing ship Loch Ard was one of the famous Loch Line ships that sailed from England to Australia. Barclay, Curdle and Co. built the three-masted iron vessel in Glasgow in 1873. It had sailed three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of recently married, 29-year-old Captain Gibbs. It was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, and a heavier load of railway irons, cement, lead and copper. Other cargo included items intended for display in the Melbourne International Exhibition of 1880. The Loch Ard had been sailing for three months and was close to its destination on June 1, 1878. Captain Gibbs had expected to see land at about 3 am but the Loch Ard ran into a fog that greatly reduced visibility and there was no sign of land or the Cape Otway lighthouse. The fog lifted at 4 am and the sheer cliffs of Victoria's west coast were much closer to them than Captain Gibbs expected. He tried to manage the vessel but failed and the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. The top deck loosened from the hull, and the masts and rigging crashed down, knocking passengers and crew overboard. The lifeboat was launched by Tom Pearce but crashed into the side of Loch Ard and capsized. He clung onto its overturned hull and sheltered under it. He drifted out to sea and the tide brought him back to what is now called Loch Ard Gorge. He swam to shore and found a cave for shelter. A passenger, Eva Carmichael, had raced onto the deck to find out what was happening and was confronted by towering cliffs above the ship. She was soon swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He swam out and dragged her to the shelter of the cave. He revived her with a bottle of brandy from a case that had washed up on the beach. Tom scaled a cliff in search of help and followed some horse hoof prints. He came from two men from Glenample Station, three and a half miles away. He told the men of the tragedy and then returned to the gorge while the two men rode back to the station to get help. They reached Loch Ard Gorge and took the two shipwreck survivors to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome and was presented with a medal and some money. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton porcelain peacock - one of only nine in the world. The peacock was destined for the Melbourne International Exhibition in 1880. It had been well packed, which gave it adequate protection during the violent storm. Today, the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck, it has now become Australia's most valuable shipwreck artefact and is one of very few 'objects' on the Victorian State Heritage Register. The Minton floor tile is significant for its hard-wearing yet attractive design. The shipwreck of the LOCH ARD is of State significance. Victorian Heritage Register S417. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best-known shipwrecks in Victoria’s history. A square Minton floor tile with a black and apricot pattern against a chocolate brown background. There is a large chip missing. This decorative floor tile was recovered from the shipwreck of the LOCH ARD. On the back, or base, of the tile is inscribed the number “46” and the letters “Minton & Co Patent Stoke upon Trent”.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, encaustic tile, melbourne international exhibition, floor tile, minton floor tile -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Earthenware Biscuit Barrel, S. F. & Co, c1903

... Underneath barrel" Hallmark of S. F. & Co., STOKE ON TRENT... barrel" Hallmark of S. F. & Co., STOKE ON TRENT above number 0279 ...This item is from a collection donated by descendants of John Francis Turner of Wodonga. Mr. Turner was born on 6 June 1885. He completed all of his schooling at Scotts Boarding School in Albury, New South Wales. On leaving school, he was employed at Dalgety’s, Albury as an auctioneer. In 1924 John was promoted to Manager of the Wodonga Branch of Dalgety’s. On 15/03/1900 he married Beatrice Neal (born 7/12/1887 and died 7/2/1953) from Collingwood, Victoria. They had 4 daughters – Francis (Nancy), Heather, Jessie and Mary. In 1920, the family moved From Albury to Wodonga, purchasing their family home “Locherbie” at 169 High Street, Wodonga. "Locherbie" still stands in Wodonga in 2022. The collection contains items used by the Turner family during their life in Wodonga.This item comes from a collection used by a prominent citizen of Wodonga. It is also an excellent example of British earthenware of the early 20th century.An earthenware biscuit barrel with a metal lid and handle. Underneath barrel" Hallmark of S. F. & Co., STOKE ON TRENT above number 0279domestic items, silver cutlery -

Melbourne Legacy

Melbourne LegacyPhotograph, Legatee function

... , Photographers, 20 Lonsdale St, Stoke-on-Trent, Staffs." in purple ink...., Stoke-on-Trent, Staffs." in purple ink. Black and white photo ...The photo shows a group of people at a dinner table, the menus on the table indicate an official event. Sir Stan Savige is on the far left. The venue, date and names are unknown - there appears to be a cricketer on the menu and may read ' A Toast to England'. The event may be in England due to the photographer's mark.Legatees supported each other by coming together for various events throughout the year. Black and white photo of a people at a function.Stamped with the studio mark for "A & E Bradbury, Photographers, 20 Lonsdale St, Stoke-on-Trent, Staffs." in purple ink.legatee event, comradeship -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumDomestic object - Dinner Setting

... Bottom of items: Dudson/Fine China/Made in/Stoke-on-Trent/England... of Bulla Bottom of items: Dudson/Fine China/Made in/Stoke-on-Trent ...The councillors of the Broadmeadows Shire used this white four-piece dinner setting at functions, which included a teacup, saucer, tea plate, and dinner plate.The white four-piece dinner setting used at Broadmeadows Shire functions, including a teacup, saucer, tea plate, and dinner plate, holds historical significance. Made by Dudson Fine China, it reflects the Shire's formal dining traditions White 4-piece dinner setting used by Shire of Bulla. Include 2 x teacup, 2 x saucer, 14 x tea plate, 2 x dinner plate, 2 x oval plateThe Mayor, Councillors and Citizens of/Shire of Bulla Bottom of items: Dudson/Fine China/Made in/Stoke-on-Trent/Englandshire of bulla, china, dinner setting -

Orbost & District Historical Society

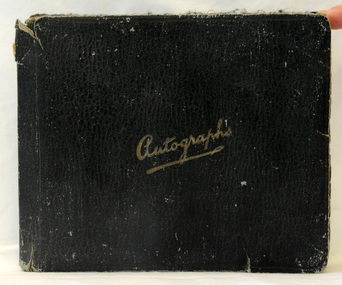

Orbost & District Historical Societybook, Autographs, 1920's

... Stoke-on-Trent N. Staffs... Stoke-on-Trent N. Staffs England autographs Orbost album ...Possibly owned by Joseph H. Keightly Heath St Gildenhall Stoke-on-Trent N. Staffs EnglandA rectangular book with a dark grey/green cover which is padded. The word AUTOGRAPHS is stamped in gold on the ront cover. The inside covers are marbled and the pages are gold edged. Inside are autographs of early Orbost residents, sketches and comments.autographs orbost album -

Orbost & District Historical Society

Orbost & District Historical Societybowl and cups

... Josiah Spode I (1733-1797) founded the Stoke-on-Trent based... gippsland Josiah Spode I (1733-1797) founded the Stoke-on-Trent ...Josiah Spode I (1733-1797) founded the Stoke-on-Trent based pottery company, Spode, in 1770.Three small coffee cups in white china patterned with blue flowers. One small white china bowl with blue stencil pattern.Back of bowl - S.H. Back of one cup - Spode crockery domestic-items-spode bowl cups-coffee china -

Mont De Lancey

Mont De LanceyDomestic object - Dessert Plate, Burleigh ware, c 1930's

... at Middleport Pottery in Stoke-on-Trent, England.... at Middleport Pottery in Stoke-on-Trent, England. Side plates Serving ...Burleigh Ware have been making their products since 1851 at Middleport Pottery in Stoke-on-Trent, England.A blue and white Willow Pattern scalloped edged dessert plate with the traditional oriental landscape scene on the front with a highly decorative blue and white floral raised edge and fine gold line trim around the outer edge.'Burleigh Ware, willow, made in England, 1'. This is stamped on the base of the plate on a blue leaf pattern.side plates, serving plate, butter plates -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Ephemera - LYDIA CHANCELLOR COLLECTION: GUARANTEE ''CROWN DEVON'' POTTERY

... in Stoke-on-Trent. It is in the form of a scroll with a decorative... and produced at the factory in Stoke-on-Trent. It is in the form ...A guarantee in the form of a wall hanging which would have been issued with a special piece of 'Crown Devon' musical pottery designed by Beresford Hopkins and produced at the factory in Stoke-on-Trent. It is in the form of a scroll with a decorative red and black design. Produced for the Coronation of King Edward VIII who abdicated in 1936.handcrafts, ceramics, lydia chancellor, collection, scroll, guarantee, 'crown devon musical pottery, king edward viii, royalty, royal coronation, ceramics, pottery -

Mont De Lancey

Mont De LanceyPlate, Paragon China Company, 1950

... of bone china from 1919 to 1960, based in Longton, Stoke-on-Trent... manufacturer of bone china from 1919 to 1960, based in Longton, Stoke ...The Paragon China Company was a British manufacturer of bone china from 1919 to 1960, based in Longton, Stoke-on-Trent, and more recently part of the Royal Doulton group.Green display wall plate with multicoloured central floral design and gold patterned fluted edge.plates, china -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSouvenir - Souvenir Plate - Casterton, Victoria, n.d

... in Stoke on Trent England'... in Stoke on Trent England' Souvenir dish, white china, fluted edge ...Souvenir dish, white china, fluted edge, gold rimmed; view of Casterton, Victoria, colouredFront: 'Greetings from' - gold lettering above view 'View at Casterton Vic.' below view Back: 'WILLOW', maker's mark, 'Made in Stoke on Trent England'souvenir, casterton, victoria -

Ballarat Tramway Museum

Ballarat Tramway MuseumDomestic Object - China Vase, Devon Ware Fieldings, c1910

... by Devon Ware Fieldings, Stoke on Trent England - marked... Fieldings, Stoke on Trent England - marked on the base of the object ...Yields information about the appearance through a drawing of Sturt St in the mid 1920's and yields information about the manufacture of china items with images on the outside of the vase.Black colour external china vase with handles, white interior with a gold rim, three small legs at base with a transferred image of Sturt St from Grenville St early 1910's with an ESCo tram arriving at the Grenville St terminus and with another tram in the view. Looks west along Sturt St. Produced by Devon Ware Fieldings, Stoke on Trent England - marked on the base of the object. tramways, trams, crockery, sturt st, esco