Showing 58 items matching "top - spinning"

-

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionLeisure object - Board Game and spinners, n.d

a) Green felt game board called 'TOTE'. Divided into 9 squares, nos. 1 - 8 and TOTE, painted in yellow. b) Bakelite spinners for use with a) Flat base, rounded top with 2 display holes, one showing odds, the other , horse number. Lever on right hand side, which spins the dialstoys, games, leisure -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Ledger Commercial, unknown, Circa 1920

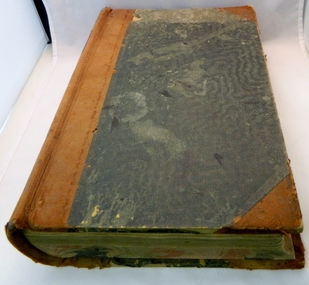

... Located on the top section of the spin (in gold print... transactions local kiewa valley commercial history Located on the top ...Historically(1920 to 1927), this ledger not only details the legible hand writing of this era but also the day to day commercial activity in the Kiewa Valley region. The neatness and the diligence of those who were required to pen the information into this ledger was a requirement by all who were involved in commercial trade be it in the city or in the rural area. Emphasis on neatness was ingrained in students at a young age. This era was well before general commercial stock computer based inventories. Generally all students of commerce required an accuracy in writing and arithmetic. Neatness and order were a "selection criteria" requirementThis item clearly identifies the Kiewa Valley as having a substantial financial hub to accommodate the various commercial enterprises within a rural environment Circa 1880's. Although Kiewa Valley had mining, agriculture, cattle and sheep it was also composed of a mixed society, encompassing all levels of society at that period. It identifies some the commercial activities(newsagency) undertaken by specific families farming in the Kiewa Valley and relates their history in the period of 1920 to 1927This ledger has a very thick cover of strong compressed cardboard. It has a cloth covering (Glued on) and is a faded blue colour. The corners of the opening side of the cover are reinforced by suede cloth,in a triangular shape, and enclose both the front and inside portions of the the ledger. The spin is reinforced by a suede section to provide increased strength and protection. The inside cover (both front and back) has an orange and brown bubbles and specks pattern. The grammage of the lined sheets (blue) is approximately 120g/m. The first twelve pages are indented and alphabetically marked with alternating red and black letters (two letters per page except for the last page which has three letters). The remaining pages are numbered in black print at the top outside edge of each page. There are 742 page numbers. Each page has thirty two blue horizontal lines and one double red line (second from top) Each page has thirteen vertical lines starting from the top horizontal double red lines and ending at the bottom of the page. These lines segregate the page into blocks for the date, the transaction and financial input. There are three double vertical red lines which designate the amount of money of each transaction (in pounds shillings,and pence).Located on the top section of the spin (in gold print on red background) "LEDGER" This is framed within a golden printed pattern of straight and squiggly lines.ledger, book keeping, 1920s commercial transactions, local kiewa valley commercial history -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySlicer Bean, early 1900's

This large bean slicer was first manufactured in the late 1800's in England and exported to Australia. Due to the transportation costs it was not used in many Domestic kitchens. This slicer would have been in a kitchen of a higher socio/economic family within the Kiewa Valley. In the 1930's the manufacturer traded this slicer as "domestic labour-saving slicers". This was the beginning of new generation of the kitchen "gadget". The introduction of the Asian "gadget" manufacturer from the late 1950's saw English export diminish by the cheaper Asian products.This item has great significance because it demonstrates that even "remote rural" locations, such as the Kiewa Valley in the early 1900s still were able to optain "state of the art" labour saving "kitchen" appliances. It was these English and European goods that were made "to last" which brought the mind set "British is best" This mindset was only altered by periods of Australian economic down turns and the cheap Asian product availabilityThis bean slicer is made from cast iron with a round body housing three rotating blades screwed into a riveted spinning base plate. The whole body of this slicer is green with a "natural coloured" handle. A "G" clamp is part of the main frame to fasten the slicer onto a table/counter top (when in use). On the side of the handle and along the top plate "SPONG & Co Ltd" and opposite "BEAN SLICER" below this "No 633"domestic kitchen time savers, food processors, bean slicers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBox Cuticle Soap, mid to late 1900's

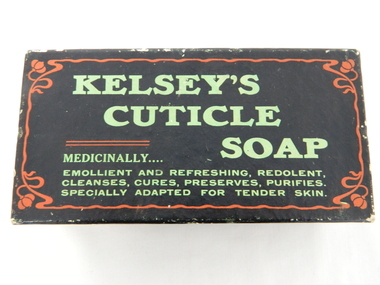

The mid 1900's provided the start of "the body beautiful" revolution. The cosmetic industry, with the help of quasi scientific selling advertising slant targeted those "customers" that needed the "extra care" factor that only their product could offer. At this period in time their advertising power was based on in store, radio and newspaper media channels with saturation levels relatively low. In the later years of the 1900's saturation levels and a wider range of products and increased competition further increased the product saturation levels available to the buying residents. With the introduction of television the advertisements become more elaborate and "catchy" words, phrases and comedy type situations helped boost the advertising "pitch" and subliminal undertones to effective levels required for a highly competitive health related market place. 'sellingThis subliminally,"medically" endorsed product was one of many during the great "spin" revolution of product marketing and selling. This item is significant in that it demonstrates that greater infusion of product awareness throughout rural areas was highly successful through a greater variety of advertising media. It also demonstrates that in a highly competitive marketplace there are no physical boundaries that impinge upon the distribution of products and services. The rural sector is a highly lucrative region for any product that helps protect the body from all the "nasty's" that become more noticeable in a rural environment. This rectangular box which had contained cuticle soap is constructed from cardboard and reinforced by a black nylon impregnated sheeting. This impregnation was required to keep the box from soaking up any water from the user's hands. The top section of the box(lid) has and in large print "KELSEY'S" top line followed by "CUTICLE" off to the right and underneath and to the right "SOAP". Below this and in smaller print is "MEDICINALLY..." below this and in smaller print "EMOLLIENT AND REFRESHING, REDOLENT, CLEANSES, CURES, PRESERVES, PURIFIES." and last line underneath "SPECIALLY ADAPTED FOR TENDER SKIN" On each of the sides of the top lid are, side 1 "INVALUABLE FOR THE NURSERY." underneath in smaller print "JOHN M. KELSEY CO." to the left of this and on a green backed highlighter "No. 1744 - Guaranteed under Pure Food Act, 1908, N.S.W. by John M. Kelsey Co. - No. 1744. Melbourne, Victoria." On the right side and in large print "KELSEY'S CUTICLE SOAP" on the next side and also a similar sign on the opposite side "SPECIALLY ADAPTED FOR TENDER SKIN." below this "JOHN M. KELSEY CO." "Registered" and on the other long side in large print "SPECIALLY ADAPTED FOR TENDER SKIN" underneath in smaller print JOHN M. KELSEY CO. Registered"specialised soap, toilet requisites, nursery health., bathroom, domestic -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTowel Tea CWA, circa mid to late 1900's

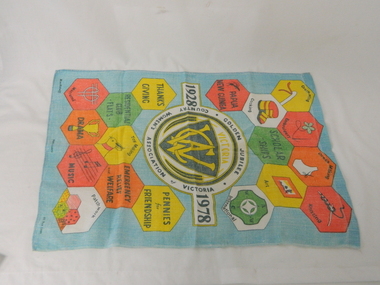

This tea towel was manufactured in 1978 in Ireland and shipped to Australia. This was in a period when the C.W.A. was the major women's organisation which had the greatest influence amongst rural women (especially in isolated areas). This was a period when broad based communications were mainly by radio,women orientated magazines and the telephone. The relay of television to "remote" rural areas was not yet established. The CWA was therefore a very important organisation that catered exclusively to women's needs. The C.W.A. motto "Honour our God, Loyalty to the throne, Service to the country, Through country women, For country women, By country women." The atmosphere was one of "sisterhood" and covered nearly all the needs of rural based women. This one organisation incorporated knowledge and learning targeting women who physically may be isolated but not mentally. On the tea towel are portrayed all the activities that would be beneficial to rural women.This tea towel with its respective motifs is very significant to the Kiewa Valley as it related especially to women who felt the limitations of social interactions within a rural area. This tea towel represents a era where communications was relatively based on radio, magazines, books and limited telephone access. Within these restrictive interactive communication levels, the isolation of a "back o' Bourke" location applied tremendous mental fatigue on women more than on men.This CWA Victoria Golden Jubilee (1928-1978) tea towel is made from Irish flax at the Blackstaff Flax Spinning and Weaving factory. It is therefore of high quality and very durable. The major colours projecting from a light blue background are red, yellow, green, orange and black. The motives portrayed the activities of the CWA in 1978. These activities are embroidery, crocheting, dress making, knitting, cooking, art, macrame, drama, music, patchwork, toy making and community relief, pennies for friendship, emergency relief and welfare, residential club flats, the thanks giving and Papua New Guinea.The main or central theme of this tea towel is presented in the central area within three rings. "1928" on the left and "1978" on the right. On the top part "GOLDEN JUBILEE" and at the bottom "COUNTRY WOMEN'S ASSOCIATION OF VICTORIA" There are various shapes representing the activities listed above.cwa promotional material, cwa golden jubilee, women only organisations, country women's association -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchJumper, Calcoup Knitwear, C 2015

This jumper is part of a General Purpose Uniform issued by the Australian Airforce to Bernard Farley during service. This uniform type was developed in 2014 and replaced camouflage as the uniform worn during general base duties and in non-warlike environments. Although a camouflage pattern, this design is not intended for use as camouflage. This woolen jumper was presumably a winter addition to the GPU.This item has social significance, as an item of uniform worn by Warrnambool RSL community member and Secretary (2019), Bernard Farley during service with the Australian Airforce. The item is a representative example of current Airforce General Purpose Uniform and is in excellent condition. As a set, the uniform has aesthetic significance in it’s design, incorporating GPU uniform design from the Army alongside the colours and motifs of the Australian Airforce. Navy blue ribbed knitted jumper with stitched navy cotton elbow patches, rectangular in shape. Similar rectangular shaped patches on the left and right shoulder, bearing two epaulettes, stiched at one end and fastened with velcro and the other. The left shoulder carries an Airforce embroidered patch at the top of the arm. Arm cuffs have external seam for approximately 100 mm from the end, indicating that the jumper may have been worn with cuffs folded over. Synthetic strip of black fabric on the interior collar behind a cream coloured label.Label on interior of collar reads: “CALCOUP KNITWEAR/291083/ 06/01 / 8405/661468799 / SIZE: 115cm-125cm/SERVICE No........./ NAME........../MACHINE WASHABLE GENTLE CYCLE/Fasten shoulder straps before/washing. Warm machine wash,/inside out on medium cycle./Do not bleach./Warm rinse. Normal spin./Doi not tumble dry./Dry in shade. Warm iron./ Dry Cleanable A/80% Wool 20% Nylon”camouflage, general purpose uniform, airforce, uniform, australian defence force -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Federation University Historical Collection

Federation University Historical CollectionBook, The Year Book and Diary 1914, 1914

Sixtth year of issueBlack hard covered book of 592 pageswool, carding, weaving, spinning, sizing, dyeing, worsteds, waterproofing, factory, trade, associations, unions -

Federation University Historical Collection

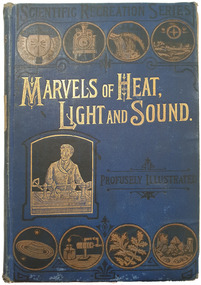

Federation University Historical CollectionBook, Marvels of Heat, Light and Sound

Blue hard covered book with gold writing and illustrations on front cover, illustrations, 196 pages. Targetted to the general reader of the scientific principles of heat, light and sound topics include heat; light (including reflection and refraction); vision (including vision and optical illusions, the eye, chromatic aberration, spinning tops); optical illusions (including occular estimation, zollner's designs, the thaumatrope, phenakistoscope, zootrope, praxinoscope, the dazzling top); optical illusions cont. (including the talking head, ghost illusions); optical apparatus (including the eye, the streoscope, spectrum analysis, the spectroscope, the telescope and microscope, photography, dissolving views, luminous paint); spectral illusions (including a spectre, ghosts); acoustics (including the harmonograph); acoustics cont (including the topophone, the megaphone, the autophone, the audiphone, the telephone, the phonograph, the microphone). non-fictionscience, science class, scientific recreation series, light, heat, sound, ballarat ironworkers & polytechnic association -

Federation University Historical Collection

Federation University Historical CollectionScientific Instrument, Optics: Nipkow Disc

When glass disc spins the line visible through the front slit shows the movement of waves - sound , lightWooden frame - solid front with window slit. Open back with wooden cross bar. Spinning glass disc with a continuous black circular line - varying widths. One red line in one section. Metal plate on front " MADE SPECIALLY FOR H.B.SILBERBERG & CO MELBOURNE"optics, nipkow disc, glass disc, wave movement, scientific instrument -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Machine - Dairy, Milk Separator manual, c1900

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past where farmers milked a few cows, usually by hand, and separated by letting milk sit in a container until the cream floated to the top when it could be skimmed off by hand. Some of the skimmed milk was consumed while the rest was used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. Manual rotation of the separator handle turns a mechanism which causes the separator bowl to spin at thousands of revolutions per minute. When spun, the heavier milk is pulled outward against the walls of the separator and the cream, which is lighter, collects in the middle. The cream and milk then flow out of separate spouts. Montgomery Ward was founded by Aaron Montgomery Ward in 1872.as a mail-order business in Chicago, Illinois USA. Rural customers were attracted by the wide selection of items that were unavailable to them locally and were also inspired by the innovative company policy of "satisfaction guaranteed or your money back".This milk separator is typical of the type used by early settlers in Moorabbin Shire where every family owned a 'house cow' to supply their dairy needs. Households also kept a few chickens for eggs and developed a vegetable garden with additional fruit trees. A 'primrose' manual milk separator 'Montgomery Ward', Chicago USA c1900'primrose ' / SATTLEY / MONTGOMERY WARD/ CHICAGOearly settlers, dairy farmers, milk products, dairies, market gardeners, blacksmiths, tools, moorabbin shire, bentleigh, mckinnon, highett, cheltenham, moorabbin -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Leisure object - TOYS AND GAMES COLLECTION: SPINNING TOPS, early 1900s

Toys and Games Collection. Three children's wooden spinning tops with metal tips. 1. Light coloured wooden top. Machine turned. 2. Red painted wooden top. Machine turned. 3. Wooden top. Possibly hand-made, with uneven shape and surface.toys, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWool winder, 1940's

Made by Internee at Camp 3Superb hand tooled red gum wool winder on a base of 2 hexagonal pieces, 2 small hexagonals on the top piece of wood support one fixed position spool whilst the upper spool is adjustable up or downwool, hoefer r, wood, camp 3, tatura, ww2 camp 3, textile, machinery, spinning, handcrafts, woodwork -

Inglewood & District Historical Society

Inglewood & District Historical SocietyFunctional object - Lamp - Kerosene, TABLE LAMP, Circa 1930

Used by the Wodetzki family (Mrs A.) of Bridgewater for household lighting - circa 1930 to 1950Table Lamp. Kerosene.Brass Nickel plated Base and Bowl. Tall Glass Aladdin Chimney. Glass shade - clear glass bottom with milk glass top.Moulded base, blown shade. Metal spinning. Manufactured in USA by Aladdin Industries. lamp, wodetzki -

National Wool Museum

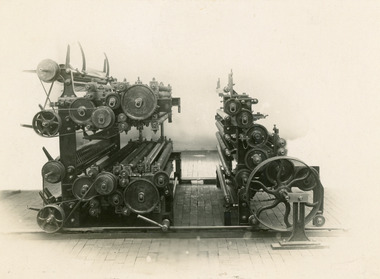

National Wool MuseumPhotograph, Carding Machine, Unknown

... established in 1899. textile machinery wool manufacture wool spinning ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Black and white photograph of a carding machine.Rear handwritten top edge - Chadwickstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph, Geelong Wool Brokers, Geelong Wool Brokers Float, 1938

Geelong Wool Brokers float for the 1938 Gala Day in Geelong. For over 20 years Geelong held a Gala Day to raise money for the Hospital. Many organisations created floats and paraded them in Geelong. In 1938 the day raised more than 10,000 pounds for the Hospital.Sepia photo of the Geelong Wool Brokers float in landscape format. The base of the float is made of flowers, on top is a taxidermy sheep with a large wool bale filled with wool. Three woman are are sat on the bottom third of the float spinning wool.On Float - Grower Manufacturer Geelong Wool Brokers The Link G.W.B.A Super Fleece 1938wool, woollen mills, wool manufacture, federal woollen mills, geelong, gala day -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

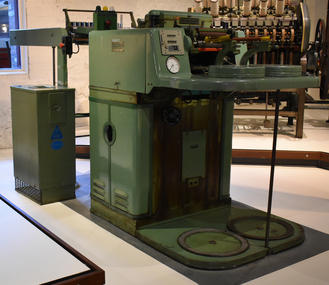

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

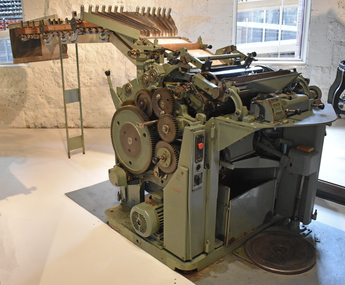

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

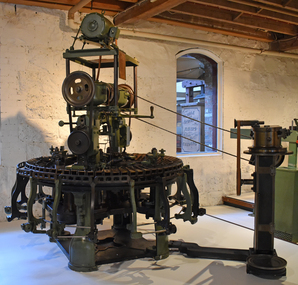

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

National Wool MuseumT-shirt

Australian womens top/t-shirt from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Blossom Road Pty Ltd from Colana yarn (a wool/cotton blend) from Rocklea Spinning Mills Pty Ltd.fashion, woolmark company blossom road pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Lawn sprinkler

Lawn sprinkler with two splayed legs acting as a stand. Hose fixture on one side. Top shaft with nozzle at either end. Shaft on wheel to allow it to spin.Rain King Pat Fan 1956 P2056 Chicago Flexible Shaft Co Chicago.domestic items, gardening -

Tennis Australia

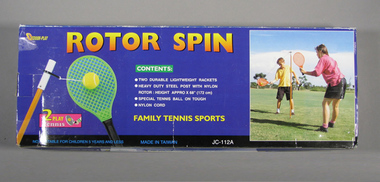

Tennis AustraliaPole tennis set, Circa 1990

'Rotor Spin' pole tennis game. Contains two plastic bats, a three-piece metal pole with stake base and plastic threaded component at top, and a tennis ball attached to string. Complete set. Materials: Cardboard, Ink, Metal, String, Felt, Nylon, Plastictennis -

National Wool Museum

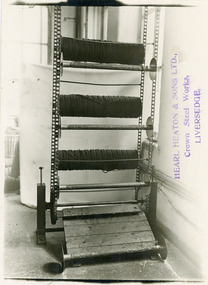

National Wool MuseumPhotograph, Yarn Spinning Machine, Unknown

Photographs most likely used for promotional purposes. The photographs are of a yarn spinning machine used to place yarn onto bobbins. The machine was made by Hearl Heaton and Sons Ltd, founded in 1809. The company played an important part in Britain’s Industrial Revolution, providing bobbins to the textile mills across the North of England.Four black and white photographs of a yarn spinning machine. The first two photos show the machine in the lower floor of the building and the last two are on the upper floor. The are connected by the two chains working the machine.8053.1 - Front right edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.2 - Rear middle - No.1 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.3 - Front top edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.4 - No. 2 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge.textile machinery, wool manufacture, wool, spinning -

National Wool Museum

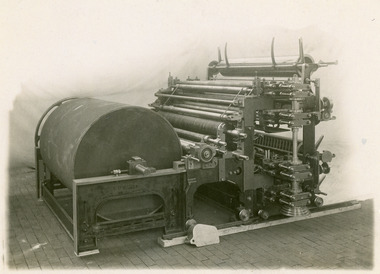

National Wool MuseumPhotograph, Carding Machine, Unknown

... established in 1899. textile machinery wool manufacture wool spinning ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Two black and white photographs of a carding machine. The first photo is of the rear of the machine, the second the front.8054.1 - rear handwritten top edge - Chadwicks left edge - unknown 8054.2 - a calculation of numberstextile machinery, wool manufacture, wool, spinning -

Mont De Lancey

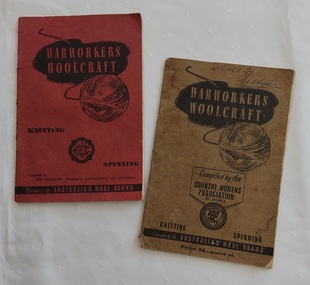

Mont De LanceyBooklet - Knitting Patterns, The Country Womens Associaotion of Victoria, War Workers' Woolcraft, c.1940's

The red covered book is compiled by The Country Women's Association of Victoria and sponsored by the Australian Wool Board. On the back of the front cover is an Introduction by the Chairman of the Australian Wool Board, Sir Dalziel Kelly, K.B., L.L.B. explaining the reason for these books encouraging the use of Australian wool to support the Empire Forces. The Foreward promotes the CWA in a similar vein. The book has knitting hints, patterns useful for war service members in the navy, army and air force patterns for clothing.The khaki covered book is similar, but is compiled by the Country Women's Association of Victoria. It is a Third Edition.Two small copies of War Workers' Woolcraft - Knitting and Spinning books: one with a red paper cover and the other with a faded khaki coloured paper cover. 1. The red front cover book shows the title printed inside a black cloud shape with a black lined illustration of a ball of wool underneath. The Country Women's Assoc. South Aust. is printed on the cover inside a round shaped black crest. It is compiled by The Country Women's Association of Victoria and sponsored by the Australian Wool Board. Inside on the back of the front cover is an Introduction by the Chairman of the Australian Wool Board, Sir Dalziel Kelly, K.B., L.L.B. explaining the reason for these books encouraging the use of Australian wool to support the Empire Forces. The Foreward promotes the CWA in a similar vein. The book has knitting hints, patterns useful for war service members in the navy, army and air force patterns for clothing - caps, sleeveless pullover, waistcoat muffler, armlets, man's socks and mittens, kneecaps, hot water bottle covers and scarves. Inside the back cover is advice on checking your tape measure against the 6 Inch one printed on the page. 2. The khaki covered book is similar, but is compiled by the Country Women's Association of Victoria with Price 3d.- posted 4d. at the bottom of the cover. It is a Third Edition. Both have advertising on the last few pages.non-fictionThe red covered book is compiled by The Country Women's Association of Victoria and sponsored by the Australian Wool Board. On the back of the front cover is an Introduction by the Chairman of the Australian Wool Board, Sir Dalziel Kelly, K.B., L.L.B. explaining the reason for these books encouraging the use of Australian wool to support the Empire Forces. The Foreward promotes the CWA in a similar vein. The book has knitting hints, patterns useful for war service members in the navy, army and air force patterns for clothing.The khaki covered book is similar, but is compiled by the Country Women's Association of Victoria. It is a Third Edition. knitting, knitting patterns, knitting equipment -

Melbourne Tram Museum

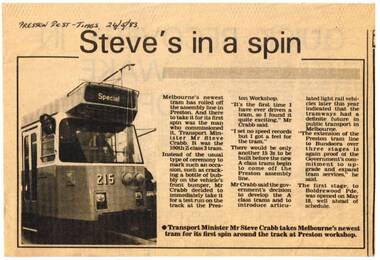

Melbourne Tram MuseumNewspaper, Preston Post Times, "Steve's in a spin", 24/05/1983 12:00:00 AM

Newspaper clipping from Preston Post Times, 24/5/1983, titled "Steve's in a spin" of the launch of the 100th Z3 class tramcar at Preston Workshops. Newspaper clipping notes that there are 15 more Z3's to go, then the A class and also the introduction of the articulated trams and extension to Bolderwood Parade opened in May. Has a photo of the Transport Minister, Steve Crabb with his head out of the window of Z3 215.In ink on top edge "Preston Post Times 24/5/83"trams, tramways, preston workshops, z3 class, launch, tram 215