Showing 71 items

matching treadle

-

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumMachine - "Jones" Treadle Sewing Machine, Jones Sewing Machine Co Ld, Around 1950

Made of metal and wood. Set in a cabinet with a drop down bench that can be rested on the open door to extend bench space. Metal treadle and what appears to be an electric treadle and and electric light. Accompanied by original sales docket and Instruction booklet“Jones” Cabinet model Sewing machine Made in England Medium CS (Cylinder shuttle). Engraved pattern around edge of metalmachine sewing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Mont De Lancey

Mont De LanceyFunctional object - Sewing Machine, Wertheim, early 1900's

Wedding gift to Mrs. and Mrs. Wandin Sebire in 1905. From their home in Sebire Avenue Wandin.An antique black painted cast iron treadle sewing machine with gold decoration on the front and mounted on a wooden base with one small drawer on each side and a foot operated treadle below. It has a wooden detachable cover. There are two cotton reels included.Plate reads "Deutsche Nahmaschinen Fabrik. Vormals. Jos. Werthheim : Frankfurt a/m".Stamped Hugo Werthheim.sewing machines, cabinet sewing machines, machines, sewing equipment -

Flagstaff Hill Maritime Museum and Village

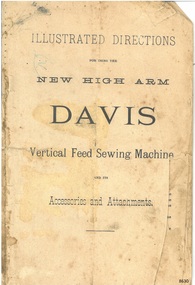

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumSewing Machine, Premier, 1902 - 1913

Used by grandmother (Mrs Medbury) and mother(Mrs Jerrett) of former local resident (Grace Jerrett).Vintage treadle type sewing machine includes drawers across front. Folds down to create small table.Premier. Made in USA. patented 11 February 1902 to 20 May 1913.premier sewing machine, treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, c1860s

Willcox and Gibbs: Serial No. 158679.|The Willcox& Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London .Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948.|A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox& Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment.|In addition to the domestic hand and treadle machines the company produced a wide range of industrial models.|The Company finally closed in 1973.|This Willcox& Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox& Gibbs badge is located on the rear of the base casting and it also has a deep wooden base.|The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846.|There are only two English patents one for J. E. A Gibbs and the other for James Willcox.Upright sewing machine. Machine is quite small and set on wooden table. Ornate metal sides and treadle feet. One drawer. Brass name medallion on back.Willcox & Gibb Sewing Machine co, New York.|Other inscriptions are :-|London, Paris|Measures|Thread type|Needle 12 stitches to inch|Brevettees G.D.G.|En France|Eten Delgique|Under Royal Letters|Patent|James Willcox|July 4 - 71 [1871]handcrafts, equipment -

Vision Australia

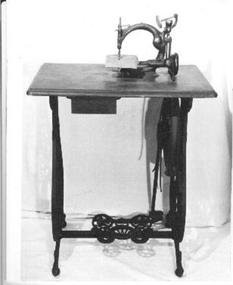

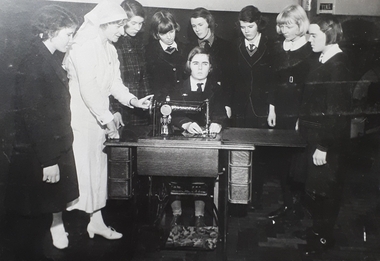

Vision AustraliaPhotograph (item) - Image, School girl using sewing machine

A schoolgirl uses a foot treadle Singer sewing machine, surrounded by classmates who listen to Matron give instructions.royal victorian institute for the blind, education, children -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine

Singer treadle sewing machine circa 1919. Singer Manufacturing Co. No Y2656052 Has 3 drawers down each side with a flip out drawer. Sewing machine folds down into body of machine.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Maldon Vintage Machinery Museum Inc

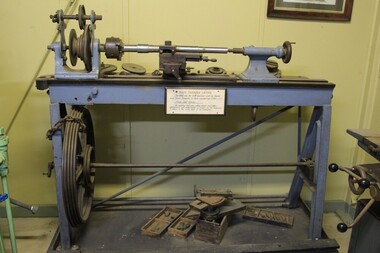

Maldon Vintage Machinery Museum IncTreadle Lathe, Post 1875

The first metal working machine used by David & James Thompson in 1878. Brought by ship by David Thompson who used it on the journey to make working models.The first machine used by David & James Thompson in their engineering section.Treadle lath for metal turning. Some brass accessories for metal working are laid out on a timber bench attached to the back of the lathe. Painted gunmetal grey and mounted on a black wooden platform for display purposes.Nonemachinery; tools; metalwork -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine

Inlayed case has box snibbed shut with parts for sewing machine. base also inlayed home sewing machine pre electric "treadle"Black Machine on wooden base with wooden cover. rusted missing parts. On to of the machine the remains of name "THE". Light wood case lid has inlayed wood around the top of the lid. -

Stratford and District Historical Society

Stratford and District Historical SocietySewing Machine

Used by Miss Alice Mitchell of Stratford. Purchased in 1909 by Miss Mitchell’s mother, and later used by Miss Mitchell who, for the duration of the war, made two pairs of socks, a flannel singlet / shirt and a pair of pyjamas (the last two on this machine), each week, for the entire war. Miss Mitchell lost three brothers and her fiancée in World War I, and was a member of the Red cross for the two world wars, and served the organisation for over 50 years.A Singer treadle sewing machine set in a large table with cast iron legs and stand with the words SINGER on it. There are two wooden drawers on either side. The machine is black and ornamented in gold. The head swings down into the stand, forming a table when not in use.world war 1914-1918 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Sewing Machine, c 1914-1930

Sewing Machine, Medium C S. (item has 10 parts), treadle operated, in wooden cabinet. Machine body is black with floral decals in gold, cream and red. Cabinet has wheels, 4 drawers containing cylinder shuttle, 2x bobbins, handle from a drawer and a bundle of horse hair. Drive belt is missing, cabinet has evidence of borer. Ironwork on right upright has 2 splits, name on plate of treadle is worn off. Decals include English Made and Approved to Her Majesty Queen Victoria. Machine has Serial Number.Pencilled inside machine support " 11/11/10 H M X" Serial Number "66389" Decals include "MEDIUM C.S / APPOINTED TO HER MAJESTY / QUEEN VICTORIA", "ENGLISH MADE".flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sewing machine, cylinder shuttle sewing machine, dressmaker's equipment, taylor, jones sewing machine, medium c.s. machine, medium cylinder shuttle machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Page Numbering Machine, EARLY 1900’S

Antique paging or page numbering machine, also referred to as a paginater. Machine prints six digit numbers consecutively. It was used in the printing industry to number consecutive pages of journals in the early 1900’s. Alex Cowan & Sons Ltd. of Melbourne, Sydney and Adelaide supplied printing equipment to other firms. The parent company, Alexander Cowan & Sons Ltd., manufactured fine paper in Valleyfield, Penicuik, Scotland from 1814-1937. This page numbering machine or paginater is an example of mechanical technology used in the printing industry in the early 1900's.Page numbering machine, also known as a paginater or paging machine. Printing machine with six digits for numbering pages consecutively. Steel frame, wooden treadle plate and bench. Inscription of maker's name on metal plate. Made by Alex Cowan & Sons Ltd.Inscribed on maker's plate, "Alex Cowan & Sons Ltd. / Printers Furnishers / Melbourne, Sydney, Adelaide". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, paging machine, treadle paging machine, printing machine, page numbering machine, paginater, alex cowan and sons ltd, australian printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, c1880

Machine used by Francesca Schwerkolt, August Schwerkolt daughter -in - law. She was the grandmother of the donor.Hand and foot operated transverse shuttle sewing machine with ornate foot treadle. Wooden top with mechanism in centre. Base of mechanism has mother of pearl inlay. Ornate iron supports. Two drawers on either side with ornate handles. Centre drawerOn Sewing Mechanism - ' Syst 182/Manufactured in Germany/Specially for/Hugo Wertheim'|On Base - 'Griffin' in ironwork|'Wertheim' in ornate ironwork on sides|S No. 6778165domestic items, sewing, textile machinery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine

Singer treadle sewing machine circa 1909 by The Singer Manufacturing Co. No F721292. Sewing machine folds down into body of machine. Machine has 3 drawers down each side. and a pull out drawer across the front. Thistles are carved on the wooden ends.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1871

This 1871 coffin top Singer sewing machine was purchased third hand by a member of the Giles family in 1922. Its box-type lid was often used as a stool. It is now part of the Giles Collection. There are many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by Vera and Aurelin Giles. The items are associated with the Giles Family and are known as the “Giles Collection”. These items mostly came from the simple home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton), whose photos are in the parlour. They married in 1880. Henry Giles was born at Tower Hill in 1858. He was a labourer on the construction of the Breakwater before leaving in 1895 to build bridges in N.S.W. for about seven years. Mary Jane was born in 1860 at Cooramook. She attended Mailor’s Flat State School where she was also a student teacher before, as family legend has it, she became a governess at “Injemiara” where her grandfather, Francis Freckleton, once owned land. Henry and Mary’s family of six, some of whom were born at Mailor’s Flat and later children at Wangoom, lived with their parents at Wangoom and Purnim west, where Henry died in 1933 and Mary Jane in 1940. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established. Singer sewing machines with a rocket bobbin system are rare.Singer treadle sewing machine, "coffin top" circa1890'. Singer Manufacturing Co. made in 1871. Machine has one drawer each side and a pull out drawer across the front. It has a rare Rocket Bobbin. The cover is separate to the cabinet. It is part of the Giles Collection." Singer Manufacturing Co", "No. 9073814"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, singer manufacturing co., 1871 singer coffin top sewing machine, treadle sewing machine, dressmaking, sewing and mending, domestinc equipment, coffin top, 1871, 9073814, rocket bobbin -

Ithacan Historical Society

Ithacan Historical SocietyPhotograph, Sewing Class, Ithaca, c 1930s

This is a photo of a sewing class for young girls in Ithaca. The women are proud to show off their sewing machines as the acquisition of these items would allow them to make many personal and household items more quickly and efficiently than they could be made by hand. Sewing was considered an important skill for young women and dressmaking was also a means to earn money to help support their families. A black and white scanned photograph taken outdoors of fourteen women sitting behind their treadle machines and posing with their needlework. Three women and a man are standing behind the group and two boys and a girl are sitting in the front on stools. A building with four large security windows/entrances in the background. 29 pas 7 is written on the back -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia - Sewing Machine, Wertheim

Wedding present to Mr Clive Richard Harrison and his wife Margret Audrey in 1927. Buried to protect it from the 1939 Bushfires - Pomonal. Remained in use until the death of Mr. Harrison in 1982. Home sewing machine Treadle Pre-electricBlack, Rusted. Flywheel has wooden handle. IncompleteName on top in gold, case has a key hole. carving on sides knob on to - light wood -

Bendigo Historical Society Inc.

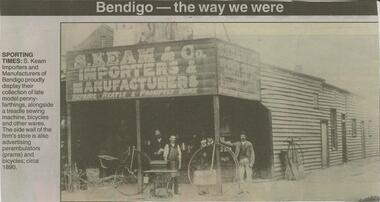

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: SPORTING TIMES

Samuel Keam (1851-1928) was the son of John Keam and Mary Truscott of Eaglehawk. He was a keen bike rider who challenged many other riders to races in the Bendigo area. He also rode in professional races. He eventually opened his bicycle shop in Williamson Street. He married Mary Jane Wheatley in 1873. They eventually moved to Spotswood where he died.Bendigo Advertiser ''The way we were'' from Thursday, February 12, 2004. Sporting times: S. Keam Importers and Manufacturers of Bendigo proudly display their collection of late model penny-farthings, alongside a treadle sewing machine, bicycles and other wares. The side wall of the firm's store is also advertising perambulators (prams) and bicycles, circa 1890. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Melbourne Tram Museum

Melbourne Tram MuseumManual, G D Peters & Co, "Pneumatic Door Apparatus", c1930

Book published by G D Peters & Co. of Caxton House Westminster London detailing the National Pneumatic door control systems. Provides an introduction, system types, door engines, folding door and step equipment, treadle plates, electrical and pneumatic fittings and location advice. This type of equipment was used on Melbourne tram and buses. Has the stamp of the Melbourne agents - Railways & Rolling Stock Equipment Ltd. throughout.Yields information about the pneumatic door control systems of G D Peters.Book - green paper covers containing approx 90 pages detailing the equipment offered with some coloured diagrams. Pages secured by two metal clips.tramways, tramcars, g d peters, electro pneumatic, door controls, buses -

National Wool Museum

National Wool MuseumTextile - Quilt, Mrs Elizabeth Morton, c.1934

Made by Mrs Noel (Lizzie) Morton, the donor's mother on their farm "Wanera" at Benjeroop on the Murray River. It was stitched with a treadle machine. Her sister Flora MacDonald did the running stitch and provided the silk backing. The squares were sent as samples from a firm called "Fred Hesse" who advertised in the Melbourne papers "Be smart and dressy In a suit by Fred Hesse". The buyer chose a sample and then sent it back with measurements and received a "mail order" suit.A small knee rug made from suiting samples machine stitched together. It is backed with black silk fabric and finished with a running stitch of orange wool oversewn with black wool thread.farming quilting quilting - history, wanera benjeroop, farming, quilting, quilting - history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1903

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Wertheim sewing machine in carry case, hand operated with two spindles, handle with locking pin, which turns lever between spokes of main handle, hand brake. The machine is table-mounted with a Turkish walnut base. The base can be attached to a cast iron table with a foot treadle as an optional extra. The walnut base has marquetry to the front set out as a measure for material. There is also an accessory box inside the carry case containing 20 additional items for use with the machine. Wertheim brass trademark badge riveted to the body of the machine of a crouching dwarf with a hammer with the name of the company Wertheim and Frankfurt. Gold filigree decoration in gold paint adorns the main body of the machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated sewing machine, crank handle sewing machine, wertheim, dressmaking, taylor, domestic, clothing, hugo wertheim, joseph wertheim -

National Wool Museum

National Wool MuseumSpinning Wheel

Part of the Zakrzewski Collection of spinning wheels donated to the National Wool Museum by Mr Wlodzimierz Zakrzewski. For many years, Mr Zakrzewski collected, researched and repaired spinning wheels from all over the world. This wheel is from Yugoslavia and dates from the early 20th century. It is made from Poplar Alba. The treadle bar runs obliquely from beneath the right arm of the T-shaped base to beneath the stem of the T. The mounting of the wheel and the flyer mechanism are reversed. This is in order that flax may be spun with one hand or that plying may be done. It was purchased by Sobieski Galleries, Glen Iris.Part of the Zakrzewski Spinning Wheel collection.handicrafts - history flax, spinning wheels, highlights of the national wool museum: the zakrzewski spinning wheel collection - exhibition (28/07/2001 - 02/12/2001), zakrzewski, mr wlodzimierz, handicrafts - history, flax -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrinting Press, C. 1934

This small Adana letterpress was based on a larger press. It was intended for printing stationery such as business cards, visitor’s cards, shop price cards and notepaper headers, Used for letterpress printing, and advertised as “Virtually indestructible”. Used for hobby printing, schools, and similar uses. When donated to Flagstaff Hill the chase still had letter type in it, which was printed out "THE SHADOWS / apahc / the aauage / shaboogie ". Currently, the machine is used by the Flagstaff Hill "Examiner" office to make business cards for use by some of the Volunteers in the Village. HISTORY Donald Aspinall, born in London in 1899, suffered shell shock while serving in World War 1. During his recovery, while still a teenager, he worked his hobby, the design of a small flatbed printing press, then advertised it in The Model Engineer’ in 1918 and received an overwhelming response of orders. In 1922 Aspinall founded the Adana Agency, in Twickenham. His had great success in his sales of flatbed, self-inking wooden presses to hobby printing enthusiasts. Over the years Adana made a variety of machines; flatbed, lever, treadle and powered presses Adana cast its own type in 1925 and has a number of patents for press parts. In the 1980’s the company wound down, and was purchased by Caslon, who still service and supply part for the Adana machines. Printing press; hand operated small letterpress machine made by Adana. Tiny platen style. Model Five-Three (5 inch x 3 inch). Cast metal base and lever handle with rounded end, both painted dark red, rounded red metal lever handle. C. 1934 Marks on foot of stand " REG. NO. / ISIL 46 & S00575 / PATENTS PENDING" and "REG. TRADE MARK / ADANA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, adana letterpress, adana model three-five, mini letterpress, printing machine, donald aspinall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Chemise, Eliza Towns, Late Victorian era

This chemise is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes as well as clothes for her children - adding her own handmade embroidered or crocheted decorative trim. This chemise is machine sewn by Eliza Towns and she has added pintucks and broderie anglaise lace as a decorative element. A chemise was usually a sleeveless garment made of linen or cotton (so they could be easily washed) and its shape was much like a modern day nightgown. The name comes from the French word for "shirt" or "shift". Women wore chemises next to the skin (under the corset) to keep stains and odors away from the less washable corset and gown.This item is an example of the needlework skills of women in the mid to late 19th century - combining machine stitching with hand embroidery to personlise and embellish an item of clothing. It is also significant as an example of a practical solution to the difficulties of needing to regularly hand wash a bulky outer garment or gown in the Victorian era.A white cotton, short sleeved, knee length chemise. The fabric at the front is gathered on a yoke which is decorated with bands of five pintucks alternating with broderie anglaise lace and embroidered strips lined with pink ribbon. A different broderie anglaise design decorates the sleeve edges, neckline and center broderie anglaise strip. The back of the chemise is gathered on to the neckline. There are two bands of pintucks on each sleeve. The fabric around each armhole has been strengthened with another layer of cotton and a length of cotton has been added (from the left shoulder to the hem) to increase the width of chemise.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, great ocean road, south west victoria, victorian era, victorian era undergarments, chemise, victorian era chemise, undergarments, pintucks, victorian chemise, eliza towns, nhill, wimmera, home sewing, machine sewn, hand made -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing Machine, Melber, Early 20th Century

Melber sewing machines were first sold in Australia in the late 1870s. The 'Box Cottage' Melber Treadle Sewing Machine was owned by Mary Box, nee Kloster / Closter, wife of Alonzo Box , the nephew of William and Elizabeth Box who purchased 'Box Cottage' in 1865 from a pioneer settler The machine was bought in 1909, and is a good example of its kind. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm.”, and clothes were mended, or ‘re-made’ into another garment. The cottage has both the Receipt, cat 00004.1 and Guarantee, cat 00004.2, for the sewing machine. This machine was possibly built by Wertheim Pty Ltd Hugo Wertheim (1854 – 1919) arrived in Melbourne in 1875. He became a successful agent for sewing machines manufactured by his father’s cousin Joseph Wertheim in Frankfurt, Germany. Hugo married Joseph’s daughter Sophie Emilie and they settled in Richmond Melbourne Australia. Hugo made many trips back to the main factory in Germany and, with extensive advertising, established a thriving business for sewing machines, bicycles, pianos under various ‘brand names’ - Wertheim, Electra, Planet, Griffin, Hapsburg. It has been said that Dame Nellie Melba preferred a Wertheim piano for her performances. In 1908 Hugo opened a large piano factory in Bendigo St Richmond, Victoria and his son Herbert maintained the business until 1935 The sewing machine was donated in 1985 by, a descendant of the Box family. The machine is complete, and in good condition. William and Elizabeth Box purchased 'Box Cottage' in 1865 from a pioneer settler who had bought part of the land noted in Dendy's Special Survey 1841 Brighton. They raised their family there and established a market garden to supply produce to the population of Melbourne. Their nephew Alonzo married Mary Kloster/ Closter in 1918 and she brought with her this 'Melber' sewing machine that she used to provide clothing for the family. 'Melber'Treadle Sewing Machine that was owned by Mary Box, nee Kloster/ Closter. It was bought in 1909, and it is a good example of its kind. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm.”, and clothes were mended, or ‘re-made’ into another garment. The Box Cottage Museum has both the Receipt, and Guarantee for the sewing machine. 'MELBER' stamped on sewing machine.dendys special survey, treadle sewing machine, box cottage, mary kloster, alonzo box, melber, wertheim hugo, wertheim sewing machine manufacturer, richmond melbourne victoria,