Showing 175 items

matching trent

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Plate, Criterion Hotel Warrnambool, Early 20th century

This plate has been made by the Globe Pottery Company in England and supplied by the china merchant firm of John Dynon and Sons of Lonsdale Street, Melbourne. As it has the mark ‘Cobridge’ on the back of the plate, it was made before 1934. It was used at the Warrnambool Criterion Hotel which was on the western side of Kepler Street near Lava Street. This hotel was established in 1872 with the first licensee being John Tate. It closed in 2008, was partially destroyed by fire in 2010 and was demolished in 2013. During the first 30 years of the 20th century licensees at the Criterion Hotel included members of the Humm family, Theresa Lynch and Henry and Margaret McGennan. The plate could have been used for all or part of these times and even at a later date. This plate is of considerable interest because it came from the Cruterion Hotel, a prominent hotel in Warrnambool for over 130 years.This is a circular white china plate with a shallow base probably used as a soup plate. It has a red embedded stamp in the shape of a belt on the front edge and on the back it has the grey markings of the maker.‘Criterion Hotel Warrnambool’ ‘Globe Pottery Co. Ltd. Cobridge, England, Vitrified, John Dynon &Sons, Melbourne’ criterion hotel, history of warrnambool, humm family, woodford, theresa lynch, mcgennan family -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Plate, Criterion Hotel Warrnambool, Early 20th Century

This plate has been made by the Globe Pottery Company of England and supplied by the china merchant firm of John Dynon and Sons of Lonsdale Street, Melbourne. It was used at the Criterion Hotel in Warrnambool. The Criterion Hotel, situated on the western side of Kepler Street near Lava Street, was established in 1872 with the first licensee being John Tate. The hotel closed in 2008, was partially destroyed by fire in 2010 and was demolished in 2010. This plate, being marked with the name ‘Cobridge’, was made before 1934. In the first three decades of the 20th century the licensees at the Criterion Hotel were members of the Humm family, Theresa Lynch, Henry McGennan and Margaret McGennan. The dinner plate could have been used for all or part of these years and could have been used later as well. This plate is of considerable interest as it was used at the Criterion Hotel, a prominent hotel in Warrnambool for over 130 years. This is a circular white china plate with a rim and a slight indentation at the base. There is a red embedded stamp in the shape of a belt on the top edge and the grey stamp of the maker on the bottom of the plate. This plate was probably used as a small dinner plate. There are a few small imperfections and stains on this plate.‘Criterion Hotel Warrnambool’ ‘Globe Pottery Co. Ltd. Cobridge England Vitrified, John Dynon & Sons, Melbourne’ humm family, mcgennan family, theresa lynch, criterion hotel, history of warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Plate, Rolfe dinner plates x 4, 1864

These dishes were part of a crockery set used in the George Rolfe household at Lyndoch, Warrnambool. George Rolfe (1836-1919) was a Melbourne tea merchant who acquired land at the mouth of the Hopkins River in Warrnambool from the 1880s on as a holiday home. He developed the property over the years, adding a windmill and reservoir, bone and chaff sheds, a stable, jetty and boathouse and an extensive garden. In 1891 he married Mrs Annie Lake and it was his stepdaughter, Florence Lake who built the house, Lyndoch in the 1920s. This building today forms part of an Aged Care Facility. This item is part of the larger Rolfe dinner set as described on Victorian Collections at VC001421 and VC001422These dishes are of importance as they belonged to the George Rolfe family of Lyndoch, Warrnambool. They demonstrate the quality of the household goods used by more affluent families in the second half of the 19th century. These are four china serving dishes or plates which are part of a set of crockery used in the Rolfe Lyndoch household in Warrnambool. The dishes have a circular base with a circular dish resting on the base. The dishes have or had two handles with these handles and the edges of the dishes being gold trimmed. Around the rim of the dishes is a pattern of loops and dots etc of teal and gold. One dish (.1) has no handles, one dish (.4) has one handle only and two dishes are cracked (.3 & .4) . Two dishes are stained, one severely (.2 & .4) ‘Minton’ george rolfe, florence lake -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Plates, Rolfe Saucers x 6, 1864

These saucers are part of a crockery set that belonged to George Rolfe and his family. George Rolfe (1836-1919) was a tea merchant in Melbourne who bought land at the mouth of the Hopkins River in Warrnambool in the 1880s. He had adjoining land and the properties of ‘Shipley’ and ‘Fairy Hill’ and developed ‘Lyndoch’, adding stables, jetty, boat house, windmill and reservoir, chaff and bone sheds and an extensive garden. In 1891 he married Annie Lake and it was his stepdaughter, Florence Lake who built the ‘Lyndoch’ house still standing today. ‘Lyndoch’ today is now the site of an Aged Care Facility. This item is part of the Rolfe Dinnerset as described on Victorian Collections at VC001420 and VC001422.These saucers, part of a crockery set, are kept because they belonged to George Rolfe, a prominent property owner and farmer in Warrnambool in the late 19th century and early 20th century. The items, dating from 1864, have social significance showing the type of crockery used by a more affluent family in the 19th century. These are six circular china saucers with a gold rim and ornamentation in a scallop design in gold and teal around the rim and the outer edges. The base of the saucers has a gold rim. One of the saucers has a chip on the edge and four show significant wearing of the inner gold circle. Some of the outside gold edging also shows wear. The maker’s marks and name are indented on the bottom of the saucers ‘Minton’ lyndoch, warrnambool, rolfe and co., george rolfe, history of warrnambool, florence lake -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.China, Cups x 4, 1864

These dishes were part of a crockery set used in the George Rolfe household at Lyndoch, Warrnambool. George Rolfe (1836-1919) was a Melbourne tea merchant who acquired land at the mouth of the Hopkins River in Warrnambool from the 1880s on as a holiday home. He developed the property over the years, adding a windmill and reservoir, bone and chaff sheds, a stable, jetty and boathouse and an extensive garden. In 1891 he married Mrs Annie Lake and it was his stepdaughter, Florence Lake who built the house, Lyndoch in the 1920s. This building today forms part of an Aged Care Facility. This item is part of the larger Rolfe dinner set as described on Victorian Collections at VC001421 and VC001422These cups are part of a crockery set, and are kept because they belonged to George Rolfe, a prominent property owner and farmer in Warrnambool in the late 19th century and early 20th century. The items, dating from 1864, have social significance showing the type of crockery used by a more affluent family in the 19th century.Four small white cups decorated with aqua band around the top of each cup . A scalloped pattern of dots are suspended from the solid band which is decorated with a row of gold dots. There is a gold rim at the base of the cup.Mintonrolfe, lyndoch, warrnambool, minton cups, mrs annie lake -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Crockery, Serving dish x 2, Between 1900 and 1920

These two serving dishes or tureens have been made by the English firm of Myott, Son & Co. early in the 20th century (Art Nouveau design). Ashley Myott established the business in 1898 and later his brother joined the business. In 1976 the firm merged with the Alfred Meakin Company but today it is owned by the Churchill Pottery Group. The dishes have no known local provenance. These dishes are kept because they are attractive items in good order and examples of the type of dishes bought for use in the more affluent households early in the 20th century They will be useful for display purposes These are two identical china serving dishes with lids. The bases of the dishes are circular with the bowl section having twelve-sided edges and two handles with black patterns. The tops of the bowl have two black lines around the edges with two ornamental patterns in red, grey and black on the top edges. The lids also have twelve sided edges and have the same black lines, four of the coloured designs and handles with black patterning. On the bases are a gold-coloured crown with the maker’s details. ‘Myott, Son & Co. Ltd.’ myott & co, art nouveau, warrnambool, art nouveau serving dishes -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Plate, Humms Criterion Hotel, Early 20th century

This plate has been produced by the English firm of W.H.Grindley for use at the Criterion Hotel in Warrnambool. The Criterion Hotel was on the western side of Kepler Street near Lava Street and was established in 1872 with the first licensee being John Tate. The hotel closed in 2008, was partially destroyed by fire in 2010 and was demolished in 2013. The Humm family had a long association with the Criterion Hotel with George Humm of Woodford taking over as licensee in 1882, buying the hotel in 1887 and remaining there until his death in 1894. George Humm’s widow, Elizabeth, was the licensee from 1894 to 1907, her son, John, was the licensee from 1907 to 1916 and his widow, Bridget, was the licensee from 1916 to 1919. The plate could have been in use for all or part of these years but is most likely to have been bought early in the 20th century. This plate is of considerable interest because it came from the Criterion Hotel, a prominent hotel in Warrnambool for over 130 years. This is a white china plate which has been broken into three pieces and inexpertly mended. The plate is much stained. It has a red embedded stamp in the shape of a belt (the maker’s trademark) on the front and on the back it has the blue markings of the maker with an image of a crown. The bowl has a shallow curved base and was perhaps used for soup. ‘Humms Criterion Hotel Warrnambool’ ‘Grindley Hotel Ware England Vitrified’ criterion hotel, humm family of woodford, history of warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.China, Saucer, Mid 20th century

This is a dish or pin tray sold in Warrnambool as a souvenir of the city. It features Shelly Beach, one of the popular picnic spots, especially in the first half of the 20th century. This dish was made by Royal Stafford China and was presumably produced with a plain centre so that an illustration of a tourist spot in Australia could be reproduced on the dish. There were many similar items produced by Royal Stafford China that featured Warrnambool scenes and were selling in Warrnambool in the 1930s, 40s and 50s. They were all good quality items and so many have survived today. They were useful as well as decorative – vases, plates, cups and saucers etc. Some business houses in Warrnambool also had Royal Stafford China souvenir items featuring the business name to sell or give away to customers. Tourism in Warrnambool has always been an important aspect of the city and this souvenir dish is a good example of the souvenir items on sale in the first five or six decades of the 20th century. It will be useful for display. This is a small white china dish or pin tray with a colour sketch (taken from a photograph?) of Shelly Beach in Warrnambool. The illustration covers most of the dish which has a gold edging. The bottom of the dish has the name and symbol of its maker. ‘Royal Stafford China Made in England’ tourism in warrnambool, royal stafford china -

Warrnambool and District Historical Society Inc.

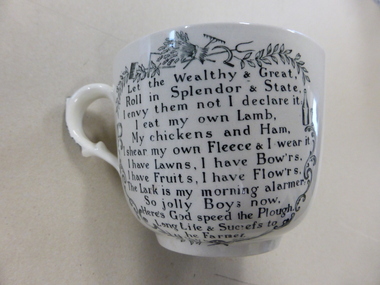

Warrnambool and District Historical Society Inc.China, Cup & Saucer, Eary 20th century

This is a porridge set which probably dates from the early years of the 20th century. Porridge bowls and cups were particularly popular in Scotland at that time and would have been used in households in Australia throughout the 19th and early 20th centuries. These items have no known local provenance but are of interest as an example of the household china that was in use 100 years ago and was still being used for many decades after that time. They are attractive items and will be useful for display. These two items are a large cup and saucer made of china and used for porridge. The cup has colour floral and leaf scroll decorations inside the top rim, a piece of verse extolling the farmer and surrounded by black and white patterns, including farming implements, on one side of the cup and coloured farming implements in circles with the same verses in larger circles with a colour wheat sheaf in the centre on the other side of the cup. The saucer, more in the shape of a soup bowl, has the same colour floral and leaf decorations around the rim and the same farming patterns and verses in the centre. The handle has a black and white floral decoration The maker’s mark and name are on the bottom of the cup and saucer. ‘In God is Our Trust’ ‘The Farmers Arms’ history of warrnambool, porridge bowls -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.China, The Federation Parliament HRH Duke of York, 1920s

This cup and saucer set was issued as a souvenir of the opening of the Federal Parliament in Canberra in 1927. The building was opened by Prince Albert, the Duke of York who was accompanied by Elizabeth, the Duchess of York. The Duke of York later became King George VI of England. The colonies in Australia became Federated States in 1901 and from that date to 1927 the Australian Federal Parliament sat in Melbourne. When Canberra became the capital of Australia a Parliament House building was erected at a cost of £600,000 but it is now known as Old Parliament House as the present Parliament House was opened in 1988. This cup and saucer set is of interest as a memento of an important event in Australia’s history – the creation of a capital city and the opening of the first Federal Parliament House. It will be useful for display. This is a white china cup and saucer set. Both the cup and saucer have two gold bands around the rims and are decorated with black ornamentation and the portraits of the Duke and Duchess of York contained within gold oval patterns. There is also black lettering on both objects. The name of the maker is printed on the bottoms of both objects. On both objects: ‘The Federal Parliament opened by H.R.H. The Duke of York at Canberra 1927’ ‘Foley China E.B. & Co. Made in England’ opening of federal parliament 1927, history of warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.China, Dish with pink lid, Early 20th century

This dish would have been used in the home either as a dish for some sort of food (perhaps jam) or in the bedroom as a container for small items such as hair clips or pins or even as a powder bowl. It is an attractive item and has been bought for its ornamental qualities. This item has no known local provenance but is retained for display as an attractive and high-quality item in use in households in the past. This is a pink china dish or bowl with a lid. The bowl is round with a black edging around the rim. There is a small crack on the side. The lid is circular with a raised top and a black line around the rim and a wide circular band of patterning of flowers, leaves and scrolls around the outer edge. The pink handle has a black edging. 'F & Sons Burslem England'warrnambool, china bowl -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Dish, Souvenir Dish, Mid 20th century

This item is one that was sold to tourists in Warrnambool in the mid to late 20th century. The dish has been mass produced in England and the image of Shelly Beach in Warrnambool added later, probably in Australia. As it is a Royal Stafford china piece it would have been a relatively costly item. It could have been bought for use in the buyer’s home or as a present for another person. Souvenir dishes such as this one have been popular souvenir items for tourists for over 100 years. Warrnambool, as a coastal location, has always been a tourist town and it remains today an important industry for the city. This dish is of interest as an example of the items sold to tourists in the mid 20th century. It will be useful for display.This is an oval-shaped china dish with fluted sides and a fluted edge and gold paint around the edge. The gold edging is partly worn off. The dish is white with a multi-coloured image set into the base of the dish. There is a crack on one side of the dish. On the base of the dish is a crown symbol and details of the manufacturer. ‘Shelly Beach, Warrnambool, Victoria’ “Royal Stafford China Made in England” tourism in warrnambool, history of warrnambool -

Flagstaff Hill Maritime Museum and Village

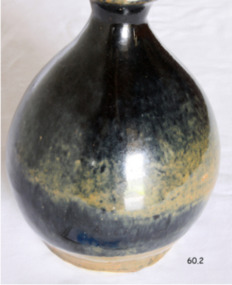

Flagstaff Hill Maritime Museum and VillageContainer - Ceramic Bottle (Chinese Style), Minton Potteries, Late 19th century

The subject item is believed to be a "Chinese style stoneware liquor bottle used to store "Tiger Whiskey" (rice wine). These Chinese liquor bottles are made of glazed pottery known as brown stoneware and have been made throughout the centuries by many makers until well after American Prohibition. Later varieties from the mid 20th century are commonly found in the USA with the raised lettering "Federal Law Forbids Sale Or Re-use of this bottle" a sure sign of post-1934 manufacture. This example is interesting as it has a British Minton mark of two triangles on the base indicating a date of 1879 and was likely exported to Australia by Minton. These ceramic bottles virtually always have irregularities and flaws which indicate a product has been hastily manufactured, in any event, this is a fine example of a relatively common item that may have been copied by Minton and sold as a decorative domestic item for display or mass produced for storing liquor. Giles Family: The pair of ceramic bottles were given to Vera Giles by Jim Thompson and are just many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with Warrnambool and the Giles Family history. Items donated by the family have come to be known as the “Giles Collection”. Many items in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) who married in 1880 and whose photos are on display in the parlour. Henry was born at Tower Hill in 1858, and was a labourer on the construction of the Warrnambool Breakwater before leaving in 1895 for around seven years to build bridges in NSW. Mary Jane was born in 1860 at Cooramook and she attended Mailor’s Flat State School and where she eventually was to become a student teacher. After which she became a governess at “Injemiara” where her grandfather, Francis Freckleton, had once owned land. Henry and Mary’s family consisted of six, some of the children were born at Mailor’s Flat and later some children at Wangoom. They lived with their parents at Wangoom and Purnim west, and this is where Henry died in 1933 and Mary Jane in 1940. A significant item of lead-glazed ceramic with the possibility it was made by the Minton potteries in England who were renowned for making quality pottery. The item style is in all probability a copy of a Chinese liquor bottle that was in common use throughout the British colonies and America up until the mid 20th Century. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established.Chinese liquor bottle one of a pair, lead glazed ceramic, dark brown and blue/black. Part of the Giles Collection.Mark of a double triangle, apex touching, on base, (Minton mark for 1879).flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, vase, pottery, ceramic ornament, domestic ware, late 19th - early 20th centuy ornament, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, 19th century household goods -

Orbost & District Historical Society

Orbost & District Historical Societygravy boat, Early 20th century

This item is an example of an item of domestic tableware commonly used in the first half of the 20th century.A white porcelain gravy boat with a pouring lip. It has a raised pattern. The handle is ear-shaped.On bottom -Ridgeways ENGLAND Royal Semi-Porcelain Guaranteed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ceramic Bottle (Chinese Style), Minton Potteries, Late 19th century

The subject item is believed to be a "Chinese style stoneware liquor bottle used to store "Tiger Whiskey" (rice wine). These Chinese liquor jugs are made of glazed pottery known as brown stoneware and have been made throughout the centuries by many makers until well after American Prohibition. Later varieties from the mid 20th century are commonly found in the USA with the raised lettering "Federal Law Forbids Sale Or Re-use of this bottle" a sure sign of post-1934 manufacture. This example is interesting as it has a British Minton mark of two triangles on the base indicating a date of 1879 and was likely exported to Australia by Minton. These ceramic bottles virtually always have irregularities and flaws which indicate a product has been hastily manufactured, in any event, this is a fine example of a relatively common item that may have been copied by Minton and sold as a decorative domestic item for display or mass produced for storing liquor. Giles Family: The pair of ceramic bottles were given to Vera Giles by Jim Thompson and are just many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with Warrnambool and the Giles Family history. Items donated by the family have come to be known as the “Giles Collection”. Many items in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) who married in 1880 and whose photos are on display in the parlour. Henry was born at Tower Hill in 1858, and was a labourer on the construction of the Warrnambool Breakwater before leaving in 1895 for around seven years to build bridges in NSW. Mary Jane was born in 1860 at Cooramook and she attended Mailor’s Flat State School and where she eventually was to become a student teacher. After which she became a governess at “Injemiara” where her grandfather, Francis Freckleton, had once owned land. Henry and Mary’s family consisted of six, some of the children were born at Mailor’s Flat and later some children at Wangoom. They lived with their parents at Wangoom and Purnim west, and this is where Henry died in 1933 and Mary Jane in 1940. A significant item of lead-glazed ceramic with the possibility it was made by the Minton potteries in England who were renowned for making quality pottery. The item style is in all probability a copy of a Chinese liquor bottle that was in common use throughout the British colonies and America up until the mid 20th Century. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established.Chinese liquor bottle one of a pair, lead glazed ceramic, dark brown and blue/black. Part of the Giles Collection.Mark of a double triangle, apex touching, on base, (Minton mark for 1879).flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, vase, pottery, ceramic ornament, domestic ware, late 19th - early 20th centuy ornament, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, 19th century household goods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumWater Jug, E & C Challinor Fenton Potteries, 1862 - 1891

Reconstructed, but incomplete, ceramic water jug. Design of three urns on each side of the jug in green. Ornate pattern in green around the rim.Portland; E & C Challinorwater jug, dunphy's hotel, buckland valley, ceramics, aldo gios, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Plate, Minton Potteries, ca 1878

This plate is one of a collection of plates with the Asiatic Pheasant design from recovered from the wreck o the Loch Ard. A brief history of the Loch Ard (1873-1878): - The sailing ship Loch Ard was one of the famous Loch Line ships that sailed from England to Australia. Barclay, Curdle and Co. built the three-masted iron vessel in Glasgow in 1873. It had sailed three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of recently married, 29-year-old Captain Gibbs. It was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, and a heavier load of railway irons, cement, lead and copper. Other cargo included items intended for display in the Melbourne International Exhibition of 1880. The Loch Ard had been sailing for three months and was close to its destination on June 1, 1878. Captain Gibbs had expected to see land at about 3 am but the Loch Ard ran into a fog that greatly reduced visibility and there was no sign of land or the Cape Otway lighthouse. The fog lifted at 4 am and the sheer cliffs of Victoria's west coast were much closer to them than Captain Gibbs expected. He tried to manage the vessel but failed and the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. The top deck loosened from the hull, and the masts and rigging crashed down, knocking passengers and crew overboard. The lifeboat was launched by Tom Pearce but crashed into the side of Loch Ard and capsized. He clung onto its overturned hull and sheltered under it. He drifted out to sea and the tide brought him back to what is now called Loch Ard Gorge. He swam to shore and found a cave for shelter. A passenger, Eva Carmichael, had raced onto the deck to find out what was happening and was confronted by towering cliffs above the ship. She was soon swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He swam out and dragged her to the shelter of the cave. He revived her with a bottle of brandy from a case that had washed up on the beach. Tom scaled a cliff in search of help and followed some horse hoof prints. He came from two men from Glenample Station, three and a half miles away. He told the men of the tragedy and then returned to the gorge while the two men rode back to the station to get help. They reached Loch Ard Gorge and took the two shipwreck survivors to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome and was presented with a medal and some money. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. This plate is significant for its connection to the potters Minton. It is also significant for its connection with the wreck of the sailing ship Loch Ard. The Loch Ard shipwreck is significant for Victoria and is registered on the Victorian Heritage Register (S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck. The group gives a snapshot of history, enabling us to interpret the story of this tragic event and the lives of the people involved. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allow us to interpret Victoria's social and historical themes of the time. The collection's historical significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history.China dinner plate, scalloped rim. Floral arrangement with Asiatic Pheasant design, made by Middleport Pottery. Recovered from the wreck of the Loch Ard. Within cartouche "B & L / MIDDLEPORT POTTERY" and an 'L" handwritten in black pen.flagstaff hill, warrnambool, flagstaff hill maritime museum and village, shipwreck coast, great ocean road, plate, minton, loch ard, asiatic pheasant design -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Puffing Billy Railway

Puffing Billy RailwayVictorian Railways Saucer Plate, May 1954 "5-54" = "month-year"

Victorian Railways Saucer Plate - Red & White Supplier to Victorian railways : Loftus Moran, Melbourne: Mr Loftus Henry Moran was well known in the tea trade. Originally employed by Griffiths Bros Ltd, he started his own business, Loftus Moran Pty Ltd, in 1909 In 1913 he purchased the tea business of McIntyre Bros, and later, that of Steele Bros, and absorbed them in his own company. He had a wide business connection among hotels and guest houses for supplying crockery and other supplies. Ref: DEATH OF MR LOFTUS MORAN (1944, May 27). The Argus (Melbourne, Vic. : 1848 - 1957), p. 4. http://nla.gov.au/nla.news-article11809686 1st Advertisement of the Plates in the papers: CHIPPED CROCKERY. Nothing is more objectionable than chipped crockery--besides its use is illegal. DURALINE Plates, manufactured by The Grindley Hotel Ware Co., are tough as raw-hide. This is why they are used by practically every hotel and institution in Australia. Obtainable only from LOFTUS MORAN PTY. LTD., Hotel Supply Specialists, 131 Queen's Bridge Street, Melbourne South Advertising (29 March 1933, ). The Argus (Melbourne, Vic. ), p. 7. http://nla.gov.au/nla.news-article4726734Historic - Victorian Railways - Refreshment Services crockery - plateCeramic Victorian Railways Saucer Plate - Red & White Victorian Railways ( in Red on fount of plate ) "DURALINE" ( in Black on back of plate ) super Vitrified GRINDLEY HotelWare Co England Loftus Moran Pty Ld Melbourne 5 -54 puffing billy, victorian railways, crockery, plate -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPin Dish, Swinnertons, 1950's

Small dish with flutter edging with pink flowers.SWINNERTONS / STAFFORDSHIRE / MADE IN ENGLANDpin dish, swinnertons -

Anglesea and District Historical Society

Anglesea and District Historical SocietyBowl, Alfred Meakin (Tunstall) Ltd, Royal Albert & Newfield Potteries

Small bowl-dish with rim. Brown daisy pattern.Glo-White-Ironstone / crown symbol / Alfred Meakin / Englandplate, bowl, meakin -

Anglesea and District Historical Society

Anglesea and District Historical SocietySouvenir Plate, Estimated 1937

Souvenir plate commemorating Coronation May 12, 1937 of King George 6th and Queen Elizabeth - crowned in Westminster Abbey. Cream china plate with British Coat of Arms. Names of King George 6th and Queen Elizabeth in red on gold background around edge with "Crowned May 12 1937'".Royal Crest - By appointment. A Perpetual Souvenir in Paragon China to commemorate the Coronation of their majesties King George 6th and Queen Elizabeth crowned in Westminster Abbey May 12 1937. Registered and copyright. Made in England.plate, coronation 1937 souvenir -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPlate, J & G Meakin, Eagle & Eastwood Pottery Works, 'LILAC' PLATE, 1912

Basically square with indented corners. "Lilac" trees and sprigs. Green edging.Regd. SOL - 391413 / J & G MEAKIN ENGLAND / (Unreadable bottom line)meakin, plate -

Anglesea and District Historical Society

Anglesea and District Historical SocietyQueen Elizabeth II Coronation Souvenir Mugs, 1953

Pair of Keele Street Pottery souvenir mugs of 1953 coronation of Queen Elizabeth 2. 1. One cream mug with gold trim. 2. One pale green mug with dark green trim.Marked "ENGLAND KSP" on base with "M" on base of cream mug.keele street pottery, coronation mug, queen elizabeth 2 -

Anglesea and District Historical Society

Anglesea and District Historical SocietyIronstone Mug, Ironstone Mug in celebration of HM Queen Elizabeth 2 - 1952-1977, Estimated 1977

Souvenir mug in white ironstone with black painting of London scenes headed "London Celebrations 1977" on one side and "The Queen's Silver Jubilee" on the other. Card attached with list of dates and occurrences in the Queen's life from 21 April 1925 to 14 November 1973.Stamp of "ADAMS - Real English Ironstone. Made in England. / Established 1657" - on bottom of mug.queen elizabeth 2, silver jubilee souvenir, ironstone mug -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Child's bowl

White china feeding bowl for infants with black cats on border and base of bowl.domestic items, infants -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMemorabilia - China Bowl Ronan's Coffee Palace, Grindley Hotel Ware, C.1921 - 1930

Coffee Palaces were developed throughout Australia with the backing of the Temperance Movement as an alternative venue to pubs in the late 19th century. Two Coffee Palaces identified in Wodonga in the early days were the Railway Coffee Palace and the Wodonga Coffee Palace. In 1908 Wodonga Coffee Palace was advertised for sale, having 15 rooms, a 15 stall stable and feed-room. In 1921 Wodonga Coffee Palace was taken over by Julia Ronan who had successfully conducted the dining rooms at the Wodonga Sale-yards for 15 years. The building of the Hume Weir was in progress and many of the workers boarded at the Coffee Palace. In 1936 Wodonga Coffee Palace became “Glenburnie” Guest House. Mr. Loftus Henry Moran, born in Winchelsea, Victoria, was well-known in the tea trade, originally working with Griffiths Bros Ltd. He started his own business, Loftus Moran Pty Ltd in 1909. Loftus Moran's company imported chinaware from Britain and sold it into the Australian market. They specialised in supplying to hotels, businesses and institutions.This bowl is an excellent example of earthen ware items used throughout Australia in hotels, cafes and other institutions. Loftus Moran Pty Ltd, was a major distributor and successful Melbourne Company. Mrs. Ronan's Coffee Palace was an important business in Wodonga and an alternate food and accommodation venue for those who preferred not to stay in public houses or hotels.A small white bowl bearing the logo of Ronan's Coffee Palace in Wodonga printed in green.In a scroll at the top edge "RONAN'S COFFEE PALACE" Underneath the bowl in green writing below a green crown "GRINDLEY HOTEL WARE/ENGLAND/VITRIFIED/LOFTUS, MORAN/ MELBOURNE"coffee palace, wodonga business, wodonga, mrs. ronan wodonga, 1920s wodonga