Showing 1231 items

matching clays

-

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, The Surrey Dive, 1910, 1910

The Dive, in Elgar Road Park was formed when water seeped into the hole from which clay had been quarried for brick-making. In 1905 the Surrey Swimming Club was formed and carnivals were held regularly. This was the venue for training Olympic swimmers prior to the Council constructing an Olympic sized pool.Black and white photo with a grassy foreground beyond which the apex of the roof only of the clubhouse is visible. Beyond this the far bank of the Surrey Dive can be seen with fencing along its perimeter.surrey dive, swimming, sports and recreation, quarries, box hill brick works, elgar road park, surrey swimming club -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Platters by Bern Emmerichs

Bern EMMERICHS (1961 - ) Bern Emmerichs is a trained painter who has adopted clay surface as her canvas. She completed a Diploma of Fine Art at Phillip Institute of Technology, Melbourne in 1982. She became interested in clay as a medium while renovating her house and now paints on tiles, vessels and platters, as well as working in mosaic. A founding member of 'Whitehall Enterprises', a group of about six artists who together rented an old factory in Whitehall Street, Footscray from 1987 to 1990. In 2000-2002, Bern spent two-years travelling, working and exhibiting in Europe, based for most of the time in Kamp-Lintfort, Germany. Recently she has been exploring imagery related to Australian colonial history. Her works are signed with a painted 'Bern Emmerichs'. Two platters decorated by Bern Emmerichsbern emmerichs -

Federation University Historical Collection

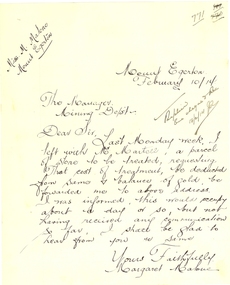

Federation University Historical CollectionLetter - Correspondence, Margaret Malone, Letter regarding gold assay from Mount Egerton Mine, 10/02/2014

Margaret Malone was associated with a kaolin mine at Mount Egerton. WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." (WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." (Adelaide Observer, 31 August 1929.)Hand written letter from Margaret Malone of the Mount Egerton Mine.Mount Egerton Mine February 10/14 The Manager Mining Dept Dear Sir, Last Monday week, I left with Mr Martell, a parcel of stone to be treated, requesting that cost of treatment, be deducted from some and balance of gold be forwarded me to above address. I was informed, this would occupy about a day or so, but not having received any communication so far, I shall be glad to hear from you are same. Yours faithfully Margaret Malonemargaret malone, female mine manager, kaolin, mount egerton, women -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Woodfired Lidded Jar by Stewart Scambler, c1986

Stewart SCAMBLER Stewart Scrambler is also a woodfirer, making ceramic forms inspired by the Western Australian landscape from local clays and glazes and a mix of native timbers from his York property. He used an incised or impressed 'Stewart' for his mark on early works but later started incising his full name.Wheelthrown and woodfired lidded jar. stewart scrambler, ceramics, jan feder memorial ceramics collection, gippsland campus, woodfire 86, bohemian ceramics, australian studio pottery -

Whitehorse Historical Society Inc.

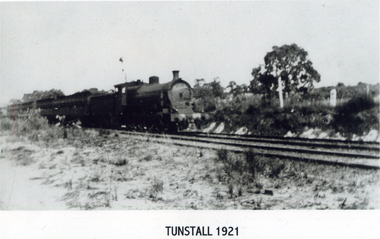

Whitehorse Historical Society Inc.Photograph, Tunstall 1921, 1921

Tunstall was named after a town in England of the same name because of the similarity of the clay. In 1945 Cr. Knox moved 'that the name of the district known as Tunstall be altered to Nunawading and the council requests that the Post Master General's Department, the Victorian Railway Commissioners and any other department concerned , give affect to such change'. This was seconded by Cr. Savage and carried unanimously.Black and white photograph of a train on lines near Tunstall. No buildings.tunstall 1921, railways -

Federation University Historical Collection

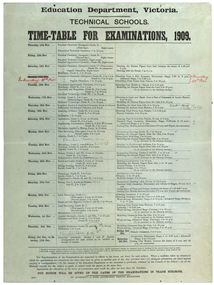

Federation University Historical Collectionposter, J. Kemp, Education Department Victoria Technical School Timetable for Examinations, 1910, 1910

Large printed timetable for Technical School examinations in 1901. Subjects included Chemistry, Geology, Asssaying, Hydraulics, Agriculture, Engineering , Mine Surveying, Algebra, Mineralogy, petrology, Botany, Trigonometry, Euclid, Land Surveying, Steam and gas Engines, Applied Mechanics, Drawing, painting, engineering drawing, building construction, architecture, drapery, modelled design, casting clay models, composition of form and colour, Lettering, Wood Carving, historic ornament, Wood Carving. .1) Trade Subjects .2) Other subjects, including artexaminations, technical schools, trades, art, technical art school, timetable, clay modelling, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Reference, John Perry, The Steam Engine and Gas and Oil Engines, 1899

This is the first edition of the book, printed in 1899. It has since been reprinted with slight corrections in January 1900 and with correction in 1902. It is a text book and reference book based on the study of steam, gas and oil driven machinery of the late 19th and early 20th century. The author, John Perry D. Sc., F.R.S., was born in 1850 and passed away in 1920. He was a Professor of Mechanics and Mathematics in the Royal College of Science, Vice-President of the Institution of Electrical Engineers, and Vice-President of the Physical Society. This book has significance as the First Edition of the book, published in 1899. The book is significant to the history, understanding and evolution of power driven machines. The principles apply to the machinery of the late 19th to early 20th centuries. The Steam Engine and Gas and Oil Engines: a book for the use of students who have time to make experiments and calculations Author: John Perry D.Sc., F.R.S. Publisher: Macmillan & Co Ltd, London Printed by Richard Clay and Sons, Limited, London and Bungay This is the First Edition of the book, printed in 1899 A hard cover book, red linen with black print. The Preface is written by the aughor on 22nd February 1899. The book contains many diagrams and tables as well as having reference numbers on many paragraphs in the chapters.Pencil on front endsheets "SJ 9""Rec. 371 a" Stamped in purple , front endsheet "F. ST. G. D. HOLYMAN" "L.4." Handwritten in ink "Richard G ---- / Liverpool --- P---ye"warrnambool, shipwrecked-coast, flagstaff-hill, maritime-museum, shipwreck-coast, book, the steam engine and gas and oil engines, john perry, reference book, scientific book, steam engines, gas engines, oil engines, combustion engines -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - DIGGERS & MINING: THE DIGGINGS - THE DIGGERS

Diggers & Mining: The Digging - The Diggers. Slide reads: Contemporary writers liked to compare a diggings to a great ants' nest; in many ways the scene must have been colourful and exciting. But to some observers, the general picture was an unattractive one. They saw the unsightly heaps of clay, the trees felled, the dust everywhere in summer and the mud in winter; the flies and the mice. The next two frames contain a description of the Forest Creek diggings taken from the Argus of March 22, 1852. Markings: 24 994.LIF:6. Used as a teaching aid.hanimounteducation, tertiary, goldfields -

Melbourne Tram Museum

Melbourne Tram MuseumNewspaper, The Age, “Probes on dirty trams, 'underpaid cleaners'”, 23/12/2020 12:00:00 AM

Newspaper clippings titled: “Probes on dirty trams, 'underpaid cleaners'” by Timna Jacks, Clay Lucas Newspaper clipping from the Age 23/12/2020 Leaked emails from company contracted to clean Melbourne's tram network suggest cleaning standards were impossible to maintain and staff were underpaid and risked injury. Fair Work Ombudsman and Yarra Trams are investigating cleaning contractor GJK Facility Services. Trams, depots and tram stops have all cleaned by the contractor with some not cleaned in accordance with contractual requirements.trams, tramways, yarra trams, tram depot, rolling stock, tram stops, cleaners, cleaning -

Orbost & District Historical Society

Orbost & District Historical Societybrick

There is a slight ridge ridge along the side where the wet clay has been pushed up between the bricks as they have been stacked. Wooden press moulds were used to form the brick and lead shaped markers were used to brand a frog in the brick. The frog is the hollow in the centre of the face of the brick. This centre helps the bricks to adhere in construction.A hand-made brick. There is a slight ridge along the top side where it has been pushed up between the bricks as they dried. The frog (hollow in the centre) is an unusual elliptical shape. brick building construction -

Federation University Art Collection

Federation University Art CollectionCeramic, Two Pottery Vases by Mark Reid

Mark REID Mark Reid began working in clay in the early 1980. He was working for a time at Kairi Pottery in North Queensland. In 1985, Mark and Robyn Reid established Torvil Pottery at Buninyong, Victoria. In 1991 he relocated to a 10 acre property in nearby Magpie and set up the Ballarat Clayfire Gallery. In 2005, Clayfire Gallery relocated to Daylesford. Two pottery vases by Mark Reid. He signs his work with an incised 'Mark Reid' or 'MR'.ceramics, mark reid, torvil pottery, clayfire gallery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1904-1930s

This Sharpe Bros. one gallon stoneware Demijohn is in excellent condition and includes its original stopper. It was made between 1904 and 1930, the date from the patent of the handle until the time that the factory no long produced returnable items. The bottle was once part of Dr W.R. Angus' household and is part of the W.R. Angus Collection and could have been purchased from Warrnambool's Sharpe Bros. factory. SHARPE BROS. 1903-1972- The first Sharpe Bros. cordial factory was opened in Dunedin, New Zealand, in 1903 by English prohibition brothers John and Percy Sharpe. Sharpe Bros. made ‘health’ beverages that were non-alcoholic drinks such as ginger beer, ginger ale, lime juice, soda and cordials. The containers of these drinks were not sold with the drinks but were marked as returnable items, to be cleaned and re-used, until this practice ceased in the 1930s. Sharpe Bros. made a niche in the soft drink market by delivering drinks by horse and cart to its customers’ homes. John Sharpe patented the unique wire spiral handle in 1904. By 1905 the New Zealand company also had factories in Australia. By 1910 the company had over 20 factories including Wanganui, New Zealand; Adelaide, Albury, Ballarat, Bathurst, Forbes, Geelong, Goulburn, Lithgow, Melbourne, Newcastle, Orange, Sydney, Tamworth, Warrnambool and Wollongong. The Warrnambool factory was established in 1919 and existed until 1951. The company won awards at Australian exhibitions for its carbonated drinks, including First Prize for its ginger beer made in the Brisbane factory. The company was taken over in 1962 by Tarax Drinks Holdings Ltd, which was in turn taken over by Cadbury Schweppes in 1972. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This stoneware Demijohn is connected to the history of Warrnambool, as it was owned by the daughter of Dr W. R. Angus and his wife Gladys. It is part of the W.R. Angus Collection, which is notable for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. It is also connected through its manufacturer Sharpe Bros. which had a branch in Warrnambool from 1919 to 1951, overlapping the time when the Angus family resided there from 1939 to the 1970s. The bottle is also significant as an example of the early-20th-century beverages found in local households and could have been purchased from the local Sharpe Bros. factory.This stoneware Demijohn is glazed, with a brown neck with internal thread and shoulders and a cylindrical cream base. The one gallon bottle has a flat, black stopper with a cork stem and a rubber, threaded tip. The ‘U’ shaped wire carry handle has a spiral of wire around the handpiece. An overhanging lip is on top of the bottle’s short neck above its rounded shoulder. The clay has been joined at the base of the neck, shoulder and body. The underneath is unglazed. The brown glazing on the shoulder has a run mark. Inscriptions are on the stopper and bottle. This container is part of the W.R. Angus Collection.Stamped in black on the shoulder: “KEEP THE / STOPPER TIGHT” Stamped in black on the body: “THIS JAR IS THE ABSOLUTE PROPERTY OF AND MUST BE RETURNED TO SHARPE BROS. AUSTRALIA / & NEW ZEALAND. ORIGINAL & LARGEST HYGIENIC BREWERY. CAUTION Persons Damaging, Willfully Retaining, Trading with or Misappropriating the Use of this Jar WILL BE PROSECUTED “ Stamped in script writing: “Sharpe Bros. TRADE - - - ED “ Embossed on the stopper: “AUSTRALIA AND NEW ZEALAND, SHARPE BROS.”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, sharpe bros., bendigo pottery, bottle, stoneware bottle, demihohn, one gallone bottle, soft drink, non-alcoholic drink, drink container, jar, jug, warrnambool soft drink, hygienic brewery, cordial factory, new zealand, australia, john sharpe, percy sharpe, non-alcoholic, spiral wire handle, ginger beer, w.r. angus collection, demijohn -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionPhotograph

The 8th/13th Victorian Mounted Rifles was raised as a regiment of the Royal Australian Armoured Corps on 1 May 1948 with Headquarters in Melbourne and squadrons in Sale, Benalla/Wangaratta and Albury. In 1955 Regimental Headquarters moved to Wangaratta and a second squadron was located at Albury. The Sale squadron transferred to 4th/19th Prince of Wales’s Light Horse. In 1977 8/13 VMR Regiment was reduced to an independent squadron A Squadron 8th/13th Victorian Mounted Rifles and in 1991 was linked with 4th/19th Prince of Wales’s Light Horse forming the VMR Squadron of that regiment.Colour photograph of a group of 8/13 Victorian Mounted Rifles 0fficers at Dining In function 22 April 1989. Standing from left : Lt. J. Burke, Capt. C. Carrington, Lt. Marshall, Maj. R. Morrison, Lt. Mathews, Capt S Whitehead, Lt. J. Clay, Maj. I. Docking, Maj. G. Cole, Lt. Col J. Allard, Maj. R. McDermott, Col J. Neale, Seated: Capt. P.Hartung, Maj. M. Oates, Capt. P. Martin, Capt. J. McLean, Capt. L. Jackel. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - Box of collected items

Items found by Barry Maggs in the Whipstick National Park with a metal detector. A purple plastic display box with a clear plastic lid. it has ten compartments containing items made from metal, wood and ceramics. a: Five pieces of pipes made from clay wood and metal decoration. b: Clay pipe with a metal decoration. c: Four pieces of metal jewelry one to two centimeters in diameter Including a ring, a flower brooch, a pendant and a button. d: Metal button two in diameter with an inscription Warranted Superior and a coat of arms. e: Two metal badges both have ship's anchors on them, one is three centimeters round the other is five centimeters by four centimeters. g: small piece of jewelry made of metal and glass five centimeters long and two centimeters wide. h: Four pieces of hollow metal five to eight centimeters long and one centimeter diameter. i: A piece of hollow metal tube five centimeters long and one centimeter in diameter. It had a small piece of wood and some pieces of paper with printed text inside. j: a metal nail seven centimeters long and one centimeter diameter head. k: pottery, part of a gold crucible three centimeters high and three centimeters in diameter. barry maggs, whipstick national park, metal detection -

Orbost & District Historical Society

Orbost & District Historical Societypipe, 19th Century

The first recorded use of meerschaum for making pipes was around 1723 and quickly became prized as the perfect material for providing a cool, dry, flavorful smoke. The porous nature of meerschaum draws moisture and tobacco tar into the stone. Meerschaum became a premium substitute for the clay pipes of the day and remains prized to this day, though briar pipes have become the most common pipes starting in the mid-1800s.A pipe made in the shape of a ram's head, coloured white or bone. It fits snugly into a shaped leather case which is hinged and closes to protect the pipe.pipe smoking tobacco -

Duldig Studio museum + sculpture garden

Duldig Studio museum + sculpture gardenCeramic, Karl Duldig, Gumnut Bowl by Karl Duldig c.1948, c. 1948

Karl Duldig’s ceramic bowl is a particularly interesting example of Karl’s ability to creatively respond to a new environment with a fresh visual repertoire, in this case, the flowering Eucalyptus in a design reminiscent of traditional European folk art. The bowl is an excellent example of the utilitarian and decorative studio pottery produced by Karl and his wife Slawa Horowitz-Duldig between 1944 and 1960. Clay was an important medium for Karl. When he was forced to flee Austria for Switzerland, working with clay became a convenient medium; and he continued to expand his use of clay in Singapore. In Australia his work in clay extended from domestic hand-made pottery to public sculptures and architectural reliefs. In 1944 Duldig purchased a kiln, which was installed in the garage of the family’s St. Kilda flat, soon after a pottery wheel was acquired. It was the beginning of a cottage industry that supplemented the family income during the war years and beyond. Duldig initially sold his decorative ceramic wares through a local florist in St. Kilda, and subsequently through shops such as the Chez Nous French Art Shop (Howey Place) and Light and Shade (Royal Arcade), and the Primrose Pottery shop in Collins Street. The Primrose Pottery shop was an extremely important commercial outlet, and hub, for emerging artists, potters and designers from 1929 until 1974. Its proprietors Edith and Betty MacMillan worked closely with their suppliers, commissioning and taking items on consignment. In the post war period important Melbourne studio potters such as Allan Lowe, Arthur Boyd, John Perceval and Neil Douglas exhibited and sold domestic wares in the Primrose Pottery shop. The Duldigs studio pottery provides a counterpoint to the ceramics produced at Arthur Merric Boyd Pottery in Murrumbeena, which was established in 1944 by Arthur Boyd, John Perceval and Peter Herbst. The emphasis on painterly decoration was important and the AMB potters also produced simple household wares decorated with Australian flora and wildlife, for example Neil Douglas also made small bowls decorated with the fairy wrens, lyrebirds, gumnuts and eucalypts. Ann Carew 2016The Duldig Studio’s collection of ceramics has national aesthetic and historic significance. It contains a representative sample of works of art in ceramics created by Karl Duldig during his lifetime, including small sculptures, as well as functional and novelty items for the tourist market during the 1956 Melbourne Olympic Games. The artist’s working methods and the development of his practice are comprehensively demonstrated in the collection. This in-situ collection demonstrates the philosophy of the Vienna Secession and its inheritors that handcrafted, simple functional domestic wares might enrich both the lives of the maker and the user. This bowl is part of a collection of ceramics that has national historic significance in providing a rich illustration of an immigrant and artistic experience, and touching on the themes of settlement adaptation of artistic practice. The collection is also associated with places of cultural and historical significance in Melbourne such as the Primrose Pottery Shop, and the story of Australian studio ceramics in the post-war years. Ann Carew 2016Cream earthenware bowl with flowering gum motif and sponged green background.Duldig in script incised under. -

Clunes Museum

Clunes MuseumTool - GOLD CRADLE & PANNING DISH, JAMES ESMOND, CIRCA 1850

USED TO OBTAIN ALLUVIAL GOLD THE DESIGN OF THIS EQUIPMENT IS MOSTLY BASED ON THE PRINCIPLE OF THE WAY HEAVY MINERALS ARE CONCENTRATED IN ALLUVIAL DEPOSITS. THE PROSPECTING DISH IS USED WHEN WORKING WITH SMALL AMOUNTS OF STONES & CLAY WHILE BIGGER JOBS THE CRADLE OR BANJO IS MORE EFFICIENT. THE GAUZE OF MESH IN THE SIEVE IS VARIABLE. THE CRADLE OR BANJO IS USUALLY SET UP AT RIGHT ANGLES TO A SHALLOW CREEK OR WATERHOLE WITH THE OPEN ENDS TOWARDS THE WATER.1 WOODEN CONSTRUCTION MADE BY HAND WITH GAUZE FILTER IN UPPER SECTION TO SEPARATE QUARTZ ROCKS, SAND AND SOIL. A HANDLE ON BOX LIKE CONSTRUCTION IS USED TO ROCK THE CRADLE WHICH IS MOUNTED WITH ITS ROCKERS RESTING ON WOODEN BEARERS. .2 PANlocal history, mining equipment, mining -

City of Kingston

City of KingstonPhotograph - Black and white, c. 1958

This photograph depicts flooding of Ozone Avenue in Beaumaris, located off Balcombe Road. Roads in the Beaumaris area lacked sufficient drains to clear surface water. In many cases streets were unsealed and without footpaths and some were dirt tracks. Gutters and road surfaces were made of clay and in the wetter months of winter, unsealed roads and tracks became impossible quagmires that were unnavigable for vehicles and pedestrians. In the first decade after World War II there was rapid expansion in construction of new houses in the suburb of Beaumaris. Utilities and infrastructure to support the growth of housing was inadequate and not provided for prior to the development of the area. Without rudimentary drainage, flooding was frequent. Storm water runoff, domestic sullage and septic tank overflow would form large pools and families were sometimes marooned within their homes. The frequent flooding caused isolation and hardship and residents endured difficulties with accessibility to facilities. These disadvantages had the potential to cause social issues for the new residents.Black and white photograph of flooding in Ozone Avenue, Beaumaris. The image shows floodwaters with boggy and rough terrain on an unsealed road with housing in the distance.Handwritten in blue ink: 2124 circled Handwritten in red ink: 80% Handwritten in blue ink on yellow Post-It note: Chap 6. underlined, 2194 Ozone Ave Beaumaris 1958beaumaris, ozone avenue, balcombe road, flooding, roads, infrastructure -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Ray Hearn, 'End Game' by Ray Hearn

Dr Ray HEARN (1943- ) Born Stawell, Victoria Ray Hearn graduated from the Ballarat School of Mines Technical Art School with a Diploma of Art (Ceramics) in 1970, followed by an Master of Fine Art from Regina Canada in 1976. He holds a PhD in Anthropology from Northern Territory, Darwin in 2003, with field work, exhibitions and teaching in Thailand since 1996. He has completed his MA in art curatorship from the University of Melbourne, with a thesis on Sidney Nolan and Ned Kelly.From Above and beyond function: Ray Hearn explains the reasons behind his useless ceramics:- "End Game suggests a climax of a tactical and intellectual struggle, in ceramics or chess, but it is also about beginnings and endings, for in chess the king can never be captured--one game ends and the board is reset so the next can begin. I made this piece at the start of my PhD work, acknowledging then that as there were once potters so too there are potters today--and tomorrow. The ceramic pieces were all collected in Tanon Suthep, one of Chiang Mai's streets. The board is a fragment of white tiles from a pharmacy building being remodelled, the bowl is a broken fast food noodle bowl from the ubiquitous street stalls, and the new small blue and white jars purchased from a market stall. Typical of my work, the objects are familiar--they might be just like ones we have at home today, had but threw away only yesterday, or objects we might purchase tomorrow. Clay lives on, and the ceramic 'game' starts again too. As it transpires End Game is about my own work too. All research degrees require an end--a thesis must reach a conclusion, and like a game of chess, start again. The sculptural potential of clay is unlimited, and in theory functional clay wares' aesthetic potential unlimited too, from a classic Song celadon to Arneson's genital encrusted teapots (which I first saw illustrated in Craft Horizons 1971). West Coast funk with its kitschy teapots and cups were vehicles for sculptural objects never meant to be drunk from, and a genre of useless functional wares emerged. Nothing could be more useless in a practical sense than a work of art, especially a painting--yet most craftwork has a passing reference at least to function." ( https://www.thefreelibrary.com/Above+and+beyond+function%3A+Ray+Hearn+explains+the+reasons+behind+his...-a0172598257, accessed 07 February 2018:)ray hearn, ballarat school of mines, ballarat technical art school, alumni, ceramics -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - DIGGERS & MINING. GETTING THE GOLD, c1850s

Diggers & Mining. Getting the Gold. Slide: (Continued) The scene at the Gravel Pits was especially animated, and would have made a capital sketch. The crowded assemblage of white awnings on these clay heaps, which the diggers had raised to protect them at their work on rainy weather, these standing at different elevations; the diggers turning their windlasses; and others, in rows of half-a-dozen along the sides of muddy pools, working away at their puddling tubs with their shovels, chopping and stirring them about; other cradling; others washing out. (Continued) Markings: 34 994.LIF:4. Used as a teaching aid.hanimounteducation, tertiary, goldfields -

Melbourne Tram Museum

Melbourne Tram MuseumNewspaper, The Age, "Tram Man who halted city to save connies will punch out", 13/11/2010 12:00:00 AM

Newspaper clipping - from The Age, 13/11/2010 titled "Tram Man who halted city to save connies will punch out", about the retirement of the PTU by Lou Di Gregorio, about his working career starting at Essendon depot in 1965 and Secretary of the Union for 21 years. Notes the various issues, the tram blockade 1/1/1990, Moonee Ponds - Footscray Route, privatisation, Government. Notes Lou will retire in Feb. 2011. Has a photo of Lou at Essendon depot with a Z class in the background. Item by Clay Lucas, photo Vince Galigiuri.trams, tramways, unions, management, route 82, moonee ponds, footscray, privatisation -

Melbourne Tram Museum

Melbourne Tram MuseumNewspaper, The Age, "Propping up private operators won't help public transport", "Analysis & Debate - The Fine Print", 25/06/2008 12:00:00 AM

Newspaper clipping from The Age, dated 25-6-2008 1 - Editorial titled "Propping up private operators won't help public transport" - looks at the history of privatisation or franchising, the consolidation of operators, growth in transport demand the lack of oversight, public interest and the lack of penalties on poor performance. 2 - Article by Clay Lucas, Analysis & Debate - The Fine Print" about the issue of new tender documents that had been leaked, issues of over crowding, potential bidders, fines for poor performance, fare evasion. Quotes John Brumby, Lynne Kosky, Terry Mulder and Greg Barber.trams, tramways, franchising, yarra trams, tenders, public transport, railways, privatisation -

Churchill Island Heritage Farm

Churchill Island Heritage FarmWedding Photo of Mary Clay

Churchill Island Heritage Farm has a large photograph collection dating from the mid nineteenth century to the last decade. This photograph shows two members of Margaret Amess' household at Tynefield.Sepia photograph of a wedding portrait of a bride and groom standing in the apse of a cathedral.Catalogue number written in pencil on reverse. Written in pen on reverse: 'Mary Clay (nee Hennebery) was maid to Margaret Amess at "Tynefield" Elwood until she married the gardener./ Mary was auntie to the donor Joyce Hurle. The two oil paintings donated by Joyce had originally been given to Mary by M Amess as had the supper cloth embroidered by MA and damask dining table cloth used by her.'margaret amess, churchill island, photograph, wedding portrait -

Churchill Island Heritage Farm

Churchill Island Heritage FarmWedding Photo of Mary Clay

Churchill Island Heritage Farm has a large photograph collection dating from the mid nineteenth century to the last decade. This photograph shows two members of Margaret Amess' household at Tynefield.Sepia photograph of a wedding portrait of a bride and groom standing in the apse of a cathedral.Catalogue number written in pencil on reverse. Written in pen on reverse: 'Mary Clay (nee Hennebery) was maid to Margaret Amess at "Tynefield" Elwood until she married the gardener./ Mary was auntie to the donor Joyce Hurle. The two oil paintings donated by Joyce had originally been given to Mary by M Amess as had the supper cloth embroidered by MA and damask dining table cloth used by her.'margaret amess, churchill island, photograph, wedding portrait -

The Beechworth Burke Museum

The Beechworth Burke MuseumCeremonial object - Ushabti of Taweret-Khaiti, Circa 1292 BC

Ushabti are tiny anthropoid (human-shaped) figures placed in the tombs of wealthy Egyptians. They were intended to do the work of the deceased in the afterlife. This purpose is implied through their name, which may have derived from the Egyptian word “to answer”. The Burke Museum in Beechworth is home to a particular ancient Egyptian Ushabti figure. This artefact was donated to the Museum in 1875. No details about how it left Egypt, arrived in Australia, and where it was located before this donation are known. The Nineteenth Century, when this artefact was donated, was a period when many museums acquired items of ancient Egyptian heritage. Many of these items were procured in less than desirable circumstances, having often been looted from ancient tombs and sold to tourists without documentation as to their original location and/or accompanying grave goods. These artefacts were also divested through partage (the trading of artefacts for funds); however, the latter is unlikely to have been the case for this artefact. Since the Ushabti was donated by an unknown donor, it is likely to have been in a private collection rather than an institution. Ushabti can be dated using iconographic analysis which is non-invasive and provides a comprehensive study of the artefact. The later period of the 18th Dynasty marked the beginning of an increase in both the inclusion of Ushabti as essential funerary items and the creation of Ushabti with tools. From this period, they are no longer depicted without tools. Depictions of tools including gardening hoes are frequently depicted grasped in the Ushabti’s hands whilst items like the seed-bag are depicted hanging on the back rather than in an alternative position. This Ushabti figure grasps a gardening hoe and a mattock and a small seed bag surrounded by a yoke bearing water jars are depicted on the upper back of the Ushabti. These features are essential in helping narrow this dating to the late 18th and before the early 20th Dynasty. The position of this seed bag also provides dating information. In the early 18th Dynasty this bag was consistently drawn on the front of the figurine; however, by the reign of Seti I, this feature moved to the back. Thus, since the seed bag is located on the back of this Ushabti, it cannot date to the early 18th Dynasty. By the 19th Dynasty, Ushabti’s were increasingly made from either faience or terracotta. The availability of these materials in Egypt resulted in the increase of Ushabti production with tombs containing many more figurines than previously seen. The Ushabti held by the Burke collections is made from terracotta. Terracotta was rarely used for Ushabti before and during the early 18th Dynasty with only the odd appearance until the late 18th Dynasty and becoming common through that period until the late Third Intermediate Period. Whilst the face has been damaged, there is no evidence for the Ushabti having been provided with an Osirian false beard. This omission rules out a dating of later than the 25th Dynasty when beards became prominent. The inscriptions also date the Ushabti to the New Kingdom. This is because of the use of sḥḏ (“to illuminate”) with Wsjr (“Osiris”) which only occurs in these periods. Therefore, considering all these elements, the Ushabti can be confidently be dated to between the late 18th to early 19th dynasty.Artefacts like this Ushabti are no longer exclusively representative of their origins in burial assemblages and significance in the mythology of the Egyptian afterlife but are also significant for the accumulated histories they have gained through travel. The movement of this artefact from Egypt to Australia allows insight into the collecting habits of the 19th century, and in particular, the reception of ancient Egyptian artefacts in small rural museums. The procurement of Egyptian artefacts was a social trend around the late 1800s to early 1900s. Egyptian artefacts were considered curiosities and recognised for their ability to attract public attention to museums. They were also utilised in Australian museums, like the Burke Museum, to connect the collection to one of the oldest civilisations known to man and since Australia was considered a “young” country by European settlers, this was vital and derived from an interest in Darwin’s “Origin of the Species” 1859. Furthermore, there was a culture of collecting in the 1800s amongst the affluent in English society which led to the appearance of many Egyptian artefacts in private collections. The acquisition of this Ushabti figure is not certain, but it was likely donated from a private collection rather than an institution. This particular artefact is significant as an example of a high-quality Ushabti representative of those produced during the late 18th or early 19th century. It provides insight into the individualism of an Ushabti and the mythology of ancient Egypt. It also provides an example of the types of items required in the tomb assemblages of this period and reinforces the importance of ensuring the successful afterlife of the deceased through art. This Ushabti belonged to a woman named Taweret-Khaiti, Chantress of Amun, in the late 18th Dynasty or early 19th Dynasty (c.1292 BC) of the Egyptian New Kingdom. It likely comes from an undetermined tomb in the locality of Thebes. This figure is made from Nile silt clay (a polyester terracotta; clay sourced from the banks of the Nile River) which was a popular material for Ushabti construction in the early 19th Dynasty. It is in a fair state of preservation (with the exception of a break through the centre) and originally made to a high quality. The face has been damaged but the eyes and eyebrows are clearly marked with black ink and the sclera painted white. The Ushabti is painted a light brown/yellow colour and features a vertical line of inscription down the lower front. The Ushabti wears a large wig and and a schematic collar. The arms are painted light brown and depicted crossed with bracelets around the wrists. It grasps a hoe and mattock. A yellow seed-basket is depicted on the Ushabti’s back. These features represent the likelihood that this particular Ushabti was intended to complete farm work for the deceased in the next life. There would have been additional Ushabti of similar design within the tomb who worked under the supervision of a foreman Ushabti. The foreman Ushabti would be depicted dressed in the clothing of the living. The inscriptions are painted freehand in black ink and written in a vertical column from the base of the collar to the foot pedestal on the front of the Ushabti. The owner of the Ushabti could elect to have the figures inscribed with their name, the Ushabti spell and any other details they deemed necessary. In the case of this example, the Ushabti is inscribed with the owner’s details and is an abbreviated version of the standard Ushabti formula. This formula ensured that the Ushabti would complete the desired task in the afterlife when called upon by the deceased. Ushabti which were not inscribed would represent their intended purpose through design; however, this Ushabti, like most made in the late 18th Dynasty, conveys its purpose both through both design and inscription. The inscription is as follows: sHD wsir nbt pr Smayt imn tA-wr(t)-xai(ti) mAa xrw which translates to: "The illuminated one, the Osiris (the deceased), the mistress of the household, Chantress of Amun, Taweret-Khaiti, true of voice (justified)"ancient egypt -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate