Showing 411 items matching "bracket"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Navigation Side Lamp, early 20th century

This pair of navigational lamps or lights was fitted to the vessel S.S. Rowitta when it was renovated to become a display passenger ferry at Flagstaff Hill Maritime Village from 1976-2015. Navigation lamps are used to indicate a vessel’s position and direction of travel to other vessels nearby. This system of coloured lamps is standardised throughout the world for all marine vessels, red is for port and green for starboard, (red is for the boats right hand side). These navigation lamps were not the original fittings for this vessel but had come from a similar vessel of the same era of the early 1900’s. The history of the lamp fittings at this time is unknown. SS ROWITTA: - The 1909 steam ferry, SS Rowitta, was installed as an exhibit at Flagstaff Hill in 1975 and was enjoyed by many visitors for 40 years. Rowitta was a timber steam ferry built in Hobart in 1909 using planks of Huon and Karri wood. She was a favourite of sightseeing passengers along Tasmania’s Tamar and Derwent rivers for 30 years. Rowitta was also known as Tarkarri and Sorrento and had worked as a coastal trading vessel between Devonport and Melbourne, and Melbourne Queenscliff and Sorrento. In 1974 Rowitta was purchased by Flagstaff Hilt to convert into a representation of the Speculant, a historic and locally significant sailing ship listed on the Victorian Heritage Database. (The Speculant was built in Scotland in 1895 and traded timber between the United Kingdom and Russia. Warrnambool’s P J McGennan & Co. then bought the vessel to trade pine timber from New Zealand to Victorian ports and cargo to Melbourne. She was the largest ship registered with Warrnambool as her home port, playing a key role in the early 1900s in the Port of Warrnambool. In 1911, on her way to Melbourne, she was wrecked near Cape Otway. None of the nine crew lost their lives.) The promised funds for converting Rowitta into the Speculant were no longer available, so she was restored back to her original configuration. She represented the importance of coastal traders to transport, trade and communication in Australia times before rail and motor vehicles. Sadly, in 2015 the time had come to demolish the Rowitta due to her excessive deterioration and the high cost of on-going repairs. She had given over 100 years of service and pleasure to those who knew her. These lamps are an historical example of navigational equipment used in the early 20th century, adhering to a navigational standard that is worldwide, and a design similar to what is still being used today. They were used on the display vessel at Flagstaff Hill Maritime Village as an aid to maritime education. The Rowitta represents the importance of coastal traders to transport, trade and communication along the coast of Victoria, between states, and in Australia before rail and motor vehicles. The vessel was an example of a ferry built in the early 20th century that served many different roles over its lifetime of over 100 years. Two side navigation ship's lamps, quarter circle shaped metal boxes with glass window and removable lid. The lid attaches to the box using four brackets, wingnuts and screws that swing down out of the way. The window of double-thickness glass is inserted on the curved side of the box and attached by screws around the frame. The inner glass panel is coloured according to the lamp’s use; port is red and starboard green. The port lamp has a round hole cut into each of the two straight sides and an electrical fitting inside. The starboard lamp also has a hole in each straight side (one with a threaded fitting). Its lid has an additional cross bar on top that has a circular space in the centre, nuts and screws fit through holes in the ends and a folding handle is attached across the centre space. The lamps were once fitted onto the vessel Rowitta. The starboard lamp has an inscription stamped into the metal. Impressed on 3689.2; “STARBOARD PATT 8025” flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, flagstaff hill maritime village, navigation lamp, navigation light, navigation equipment, starboard patt 8025, ship’s fitting, rowitta, tarkarri, speculant, purdon & featherstone of hobart, passenger ferry 1909, vessel, display rowitta, display passenger ferry, sorrento -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChest of drawers, early 20th century

This medical bureau / cabinet shows several signs of being used for a different purpose before being a medical bureau. It once had the words "GENUINE PURE QUALITY" lettered across the top of the front, as can been still seen from the impression left behind in the stained timber. On each drawer above the handle is a faint impression of something long and rectangular, as though there had been a label attached. The front panel of the drawers is made of the same wood as the rest of the outer cabinet, most probably blackwood. The handles on the drawers are not the original handles either. There are 3 filled-in holes that would form the corners of a triangle, apex at the top, around the perimeter of the current handles. The sides of the drawers are made from plywood and the base made from alternating lengthwise strips of oak and beech wood pressed together, rounded corners at the back and joined to the front panel with metal brackets. The backs of the base of the drawers have four round impressions in them. Along the back edge of the base, in the centre, is a rectangular hole. Between the front pair of round holes is a faint black rounded marking, like the impression made by rubber. The cabinet may have once been a filing cabinet, with the drawers used as document drawers, each with a spring-loaded clamp attached to the back of them to secure documents within. The original handles could have been the half-cup type used for filing cabinets. The construction and use of plywood could place this cabinet in about 1950's.Chest of drawers (or Medical Bureau, or Apothecary Chest, or Filing Cabinet) wooden, dark stained, with 30 small drawers (10 rows, 3 columns). The outer wood of cabinet is possibly blackwood and the edges of top and sides have carved wood decoration. Drawer fronts have bevelled edges and round silver-coloured metal knobs. Drawers have plywood sides, and oak and beech wood bases/, Each drawer has four round depressions (in a square-shaped arrangement) at the back plus a small rectangular hole cut in the centre back of base. A faint impression from previous lettering is evident in the wood stain across top front of cabinet.Impression of previous lettering across top front of cabinet "GENUINE PURE QUALITY". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, drawers, bureau, cabinet, chest of drawers, furniture, bedroom furniture, household storage, medical bureau, apothecary cabinet, document drawers, filing cabinet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPolisher Floor, Hoover Appliances, Meadowbank

This appliance was a time saving method of cleaning floors. It appeared at a time (after World War II) when the domestic pressures faced by mothers and domestic staff was on the increase. The necessary "working parents" was through necessity becoming part of the "typical" family environment. It was the start of the ever increasing demand, from an economical reason, for both parents to work outside their property. Historically the period of the 1950s was one of extreme changes. It was an era where established role models were under pressure from an ever increasing demand for new and advancing consumerism. Communication levels via radio, newspapers and television was expanding at an ever increasing rate. Relatively isolated rural areas were opening up (post war) to foreign ideologies of consumerism. The basic restraints of "this will be alright mate, she'll do" was under a slow but effective take over. "I can get this done faster by this new whiz bang gadget that I saw on the TV last night!" was the new way to live by.This item is very significant in that it demonstrates the new consumerism at its infant stage of the social changes occurring due to greater communication levels between the rural Australian communities and other advancing communities world wide. The Kiewa Valley residents (mainly from the intermingling of rural and post World War II refugees working at the construction of the Victorian Hydro electricity installations, resulted in this rural area becoming integrated to new ways of living (both socially and economically). Once the attitude of "we have always done it this way mate!" was challenged and overcome, the acceptance of new time saving "gadgets" which started to pour in from foreign markets, the relative isolation of the Kiewa Valley (being mainly psychological entrenched), was over.This hoover electric floor scrubber and polisher has a main base containing two brushes (can be replaced with polishing pads). The two brushes/pads are fastened or removed from the base unit by pulling/pushing the heads from the small hexagonal shaft on the bottom of the machine motor. A pressure sensitive wire is inlaid at the brush/pad end to hold the brush/pad unit onto the shaft. The discs body and main body covering the electric motor are made from sturdy plastic. The rest of the appliance materials i.e. upright handle and the u framed attaching arm are made from lightweight powder coated steel. A small (350mm) red coloured foot switch protrudes from the back of the motor to release the the upright handle from the storage position to the action position.There are two fork shaped brackets on the rear of the handle, for securing the 6.5 metre long electrical cord and plug. There is no on/off switch on the appliance. A small stainless steel "u" framed clip (for hanging the appliance in the vertical position) for cupboard storage. Within the circle of the cleaning brush is stamped "1 above S.A.B.351" and on the opposite side P/No: 5023792". On the main plastic head of the brush discs are "TO CLEAN" and under this "USE ONLY WARM(underlined) WATER AND SOAP" on the opposite side, and within a circle is the Hoover Trademark. On the front of the blue coloured plastic dome covering the electric motor is (on a raised domed shaped plaque (on a red background) Hoover in slanted print from left to right(in a diagonal level)domestic appliances, floor cleaning, electric floor scrubbers and polishers -

Ballarat Tramway Museum

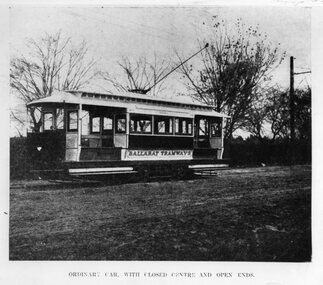

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s - set of 2, 1905

B&W photograph of the one of the ESCo California Combination tramcars at the time of the opening of the service, photographed most likely in Wendouree Parade, near the dept. Shows bracket arm in background, trolley pole and head. Also shows the nature of the road surface at the time, c1905. The print for this photograph made from a copy negative of page 454 of the Australasian, August 19, 1905 in 1993. Print includes caption "ORDINARY CAR, WITH CLOSED CENTRE AND OPEN ENDS" See Reg. Item No. 763. Photo has been mounted onto a styrene card with card sides and Velcro strips on the top edge for display purposes. Mounted Oct. 1993 for the CHHA Exhibition, theme "Made in Australia". 762.1 - added 6/12/2004. Same print with details of source written on the rear. ARHS Vic. Div. Photo Number 771/23, ex Latrobe Library. Not as good as print as above. Cropped at base - does not have caption. See Alan Bradley, draft Chapter 3 of the history of Ballarat Tramwaystrams, tramways, esco, tramcars, ballarat -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown Coal

Brown Coal is typically found as rocks. During formation the Brown Coal starts as peats, which is an acidic brown deposit resembling soil, and over time when subjected to pressure and heat these peats form the Coal. Brown Coal is the lowest rank of coal as it has a low carbon (energy) content, and a high moisture content. This high moisture content makes Brown Coal unsuitable for overseas exports. This particular specimen was recovered from the Yallourn Mine in Latrobe Valley, Victoria as part of the geological survey of Victoria being carried out by Alfred Selwyn. Otherwise known as the 'Yallourn Power Station', the Yallourn Mine is Australia's second largest mine. Yallourn Mine was first built in 1920, and since then it has been providing over 1 billion tonnes of Brown Coal to Australia every year. The Yallourn Mine is responsible for 22% of Victoria's electricity and 8% of Australia's electricity. As of 2021 the mine employs around 500 people. Due to ongoing maintenance issues and Australia's move to cleaner energy, the Yallourn Mine intends to shut down permanently as of 2028. Soon after gold was discovered in 1851, Victoria’s Governor La Trobe wrote to the Colonial Office in London, urging ‘the propriety of selecting and appointing as Mineral Surveyor for this Colony a gentleman possessed of the requisite qualifications and acquaintance with geological science and phenomena’. Alfred Selwyn was appointed geological surveyor in Australia in 1852 which began the Geological Survey of Victoria. In 1853-69 the Geological Survey issued under Selwyn's direction sixty-one geological maps and numerous reports; they were of such high standard that a writer in the Quarterly Journal of the Geological Society of London bracketed the survey with that of the United States of America as the best in the world. During his years spent in Australia, Selwyn collected numerous significant geological specimens, examples of which are held in collections such as the Burke Museum.Brown coal is considered to be an essential rock to Australia's energy consumption. Although plentiful in sources, Brown Coal is not able to be exported overseas due to its high moisture content. As Australia moves towards cleaner energy, Brown Coal is going become less used. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A solid hand-sized sedimentary rock that is a dark shade of brown.13 / BROWN COAL / Showing Woody structure / Locality: Yallourn, Vic. | Label probably / correct but / can't find reference / no. 13 to match in / registers. / C Willman / 15/4/21burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, yallourn, yallourn mine, victoria, coal, brown coal, brown coal specimen, alfred selwyn, geological survey of victoria, geological survey, yallourn power station -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Clare Gervasoni, Ballarat School of Mines Technical Art School, c2008, 29/07/2020

The former Ballarat Circuit Court Building, later the first building of the Ballarat School of Mines, was demolished to make way for a new custom built Art School building. Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above.Colour photograph of a sandstone detail on a double storey, red brick building - the Ballarat Technical Art School, a division of the Ballarat School of Minesballarat school of mines, ballarat technical art school, architecture, art, gribble building -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Clare Gervasoni, Ballarat School of Mines Technical Art School, c2008, c2008

The former Ballarat Circuit Court Building, later the first building of the Ballarat School of Mines, was demolished to make way for a new custom built Art School building. Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above.Colour photographs of a double storey, red brick building built - the Ballarat Technical Art School, a division of the Ballarat School of Minesballarat school of mines, ballarat technical art school, architecture, art, gribble building -

Federation University Historical Collection

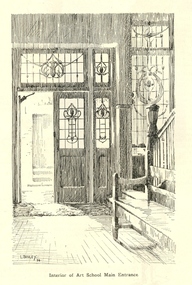

Federation University Historical CollectionArtwork, other - Artwork, Artwork from the Ballarat School of Mines Students' Magazine, 1934, 1934

Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above. This building is now the Gribble Building on the Federation University Australia SMB Campus.Artwork by students of the Ballarat Technical Art School from the 1934 Ballarat School of Mines Students' Magazine .1) Stairs to the Ballarat Junior Technical School from Grant Street .2) Caricatures by Nornie Gude .3) work by Colin S. Hunt .4) A girl and a rooster by Gilda Gude .5) Self Portrait .6) Main entrance to the Ballarat Technical Art School by Lorna Bailey .7) Artwork from the magazineballarat technical art school, gribble building, gribble, stained glass, white flat, hopwood, bailey, gude, ballarat junior technical school, visual arts -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationWeights

A small number of heavy cast iron weights and two rods remain at the Point Hicks. The weights and rods were part of the original clockwork mechanism that was fitted beneath the lens to keep the kerosene-fuelled light turning. They were attached to a cable or chains and moved vertically in similar fashion to the way weights move on grandfather clocks. As the weight fell, the optic clock was driven and the lens was turned. To keep the clock turning, the weight needed to be wound back up to the top of its travel. The cables and weights in this lighthouse were visible as they moved through the length of the tower up to the lantern room. It was usual for systems to move inside a tube extending up to the top, but in this case the tower’s cast iron spiral staircase, which is supported on cantilever cast iron brackets set into the concrete wall, spiralled around the space in which they moved. Lighthouse keepers had the arduous job of having to constantly wind the clock to keep the light active, and at least two keepers needed to observe a strict roster of hours. When electric motors were invented, all of this became redundant and the motors were able to turn the optic for as long as there was power to drive them. In December 1964, the original 1890 Chance Bros kerosene-fuelled light and clockwork mechanism were replaced by small electric motor, and the number of keepers reduced to two. The six circular weights and rods originate from the obsolete system and may have been part of a larger set. Wilsons Promontory retains seven of its original set of ten weights, all of which are detached from the tower’s weight tube. Cape Schanck has a set of fourteen weights remaining in situ as well as another four detached weights, which have inscriptions . One weight is displayed in the lantern room at Cape Otway. The Point Hicks weights have first level contributory significance for the insights they provide into the superseded technology and operations of a late nineteenth century lighthouse. They are well provenanced and are significant for their historic value as part of the lightstation’s Chance Brothers optical system installed in 1890.PHLS0005.1 Round cast iron weight with flat base used for lens clock-work mechanism attached to a bent metal rod. PHLS0005.2 Removable round cast iron weight with flat base used for lens clock-work mechanism stored above the other weight. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Mixed media - DONEY COLLECTION: DARKROOM EQUIPMENT

Alan Doney darkroom collection: 40a dartk room equipment collection 40b four film devreloping cannisters, adapts to adjustable film sizes (35mm, 120mm etc) 40c spool winder in two parts, stored in scotch tape tin 40d developer lens holder and fil/negative constraint for enlarging photos 40e darkroom light shade with electricity chord 40f red darkroom safety light for developing film with the darkroom 40g three developing items - two lens caps, thremometer caps/containers, & photo developing tongs 40h leather pouch for protection of flat ground glass panes 40i steel slide cover & bracket 40j two sets of steel film weights to hold/hang developed photograph films 40k rubber tubes and syphons 40l two plastic measuring beakers & two (yellow & blue) plastic spoons for developing process 40m KODAK film flow solution (Keogh's Camera Store $1.02) & KODAK plus-X pan film tin container 40n three darkroom miscellaneous items (includes Uniprint eqipment knob) -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Folder, William Pollock, "The Melbourne Cable Tramway System", c1940

Folder - heavy red covers with two screw sets containing a photocopy of a report by William Pollock, prepared after the closure of the cable tram system titled ""The Melbourne Cable Tramway System". Image numbers listed: Folder – htd4715i1 Inside of folder – htd4715i2.jpg Report –Photocopy of a 14 foolscap sheets, paper titled “The Melbourne Cable Tramway System” by William Pollock, describing the system in detail, listing 26 appendices. Has notes on each Power Station, including a table of opening, closing, power produced and cables, fuel, permanent way (track), cables, underground gear, tunnels, flooding and the grip. Image – htd4714i3.pdf Appendix 1 – Handwritten table “Cost the Melbourne Tramway System” – photocopied special size sheet folded. See image htd4715i4.jpg 2 – Drawing – Typical Power House layout - image htd4715i5.jpg 3 – Drawing – Head of Cable Driver – htd4715i6.jpg 4 – Drawing – Rope Drive – htd4715i7.jpg 5 – Photocopy of a Fuel and Water test sheet for the Esplanade Power House – two sheets – 14/5/1918 – htd4715i8.jpg and htd4715i9.jpg 6 – Section of Cable Tram track – htd4715i10.jpg 7 – Tar Burner used by MTOC 1893 – 1900 - htd4715i11.jpg 8 – Yoke Bracket for line drums – A1 Pulley – htd4715i12.jpg 9 – Tunnel Yoke – htd4715i13.jpg 10 – Elevating Wheel or Pulley with shield plate – htd4715i14.jpg 11 – Curve Pulleys, curve drum and rubbing bar – 2 sheets – htd4715i15.jpg and htd4715i16.jpg 12 – Curve or Conical drum – htd4715i17.jpg 13 – Cable Separating pulley or cone line drum – htd4715i18.jpg 14 – Yoke Pulley or General Pulley – htd4715i19.jpg 15 – Yoke Bracket for Drums – htd4715i20.jpg 16 – Automatic Switch Gear – htd4715i21.jpg 17 – Hand operated switch gear – htd4715i22.jpg 18 – Hand pickup – htd4715i23.jpg 19 & 20 – Photo of bunched strands and damaged cable – htd4715i24 21 – Diagram of Rope – Clarendon St Rope No. 41 – htd4715i25.jpg 22 – Strand Alarm – htd4715i26.jpg 23 – Rope History – two sheets – htd4715i27 and htd4715i28.jpg 24 – Rope Splice – htd4715i29.jpg 25 – Cable Grip – htd4715i30.jpg 26 – Crown Pulley – two sheets – htd4715i30 and htd4715i31trams, tramways, drawings, tramcars, cable trams, trackwork, mto co, reports -

Bendigo Military Museum

Bendigo Military MuseumUniform - MESS DRESS, ARMY, 1987

Uniform issued to S/SGT "Brian Thompson". Years of service 1973 - 1993. 316221.1. Jacket - white colour polyester/cotton fabric, rolled collar jacket, shoulder epaulettes, top of sleeves, black colour rank badge with gold colour crown and three stripes = Staff Sergeant. Manufacturers label back below collar. 2. Trousers - black colour cotton/polyester fabric with fob pocket and two side pockets. Metal and nylon zipper fly. Red colour wool fabric twin 2 cm stripe down each side seam. Manufacturers label back below waistband. Black colour polyester fabric lining waistband and pockets. Black plastic button inside waistband. 3. Cummerbund - Red colour polyester fabric, broad waist sash with three pleats, metal hook and bracket buckle and hook and loop fastener to adjust lengthy. Black colour polyester fabric lining. Manufacturers label. 4. Bowtie - black colour polyester fabric, pre-tied bow tie with metal clasp. Manufacturers label. 5. Braces - set of white colour cotton elastic braces with metal clips to attach to trousers. Metal slide clips to adjust length and plastic strap joiner.Manufacturers information. 1. Jacket - black fabric label - TETOROM/ 65% POLYESTER/ 35% COTTON/ WIMBLEDON WEAR/ MELBOURNE". White fabric label "97R/ WARM MACHINE WASH/ D NOT BLEACH/ MACHINE TUMBLE DRY/ WARM. WARM IRON." 2. "A.G.C.F./ VICTORIA/ 1987/ ^/ ARMY NO/ NAME" 3. "POLYESTER/ DRY/ CLEAN/ (50c) ONLY" 4. POLYESTER/ DRY/CLEAN/ (50c) ONLY"uniform, army, mess dress, brian thompson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Machine - BABY DAISY: HAND OPERATED BELLOWS VACUUM CLEANE

Hand operated Bellows vacuum cleaner. Previously #27 The “Baby Daisy” Vacuum Cleaner is constructed from timber, steel and leather bellows. It has a carry handle fixed to the top. The base is approx. 500mm x 250mm. The height is approx 400mm. On one side is a bracket for a handle (missing) used to operate the bellows. The device is mounted on a foot plate that is split. On one side of the bellows is a circular metal detachable hatch, fixed by wing-nuts. This has a central hole for a tube (missing). Attached internally to this hatch is a cloth dust collection bag. The metal hatch has the following moulded words arranged in a circular fashion. 'DAISY Vacuum Cleaner). There are two brass plates fixed to the side of the cleaner above the hatch. These plates are stamped with 'Rd. No. 518080 and Rd. No. 530353' Gold printed Labels on the side say the following. BABY DAISER Vacuum Cleaner. Registered England. No. 518080/7 No. 530353/08 Trade Mark No.294851 /07 Designs France No. 25469/08 Germany No. 330219 / 08 Further Patents applied for. In the centre of the label is a picture of a Daisy Flower. With the words Iles Patent. This is surrounded by a ribbon with the words. 'The Daisy Registered Trade Mark'. On one side near the base of the cleaner the number '7749' is stamped into the metal.fBaby Daisydomestic equipment, cleaning, vacuum cleaner -

Flagstaff Hill Maritime Museum and Village

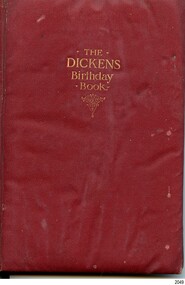

Flagstaff Hill Maritime Museum and VillageBook - Birthday Book, Raphael Tuck & Sons et al, The Dickens Birthday Book, 1901-1911

Birthday Books are personal record books for names and birth dates of friends and relatives. This book includes a quote from Charles Dickens for each day of the year. The books were published in many editions, with different publishers, illustrators, covers and designs. This Dickens Birthday book was presented as a gift to fifteen-year-old Clara Skirrow on January 19th 1911, by Mr and Mrs B Watson, perhaps the 'Benji Watson' in the book, whose birthday was July 1st, 1887. The entries in the book include several with the surnames Watson and Skirrow. Interestingly, names are entered in various writing styles, perhaps because each entry was written by the person of that name, similar to an autograph book. Curiously, there are two entries for Connie Watson, one in brackets on March 16th, the other on March 23rd, without brackets. The artist, Pilford Fletcher Watson (1892-1907), was born in London. He moved to Sydney, where he became a prominent and well-established artist and a founding member of the Academy of Arts, Australia, established in 1891. His works included local scenery, architecture, and the interiors of historic buildings. Many of his pieces were bequeathed to the State Library of New South Wales. The firm, Raphael Tuck & Sons Ltd, was a printer and publisher that operated in London from 1866 to 1960. Its logo was the artist's easel, palette and brush. The firm that specialised in greeting cards and produced puzzles. It also became the world’s largest postcard publisher. In 1960, the firm amalgamated with others to become the British Printing Corporation. The fly page states that Ralph Tuck & Sons, Ltd. was the publisher to Their Majesties, the King and Queen, and Their Royal Highnesses, the Prince and Princess of Wales. This would suggest that this book was published from 1901 to 1910, when King Edward VII and Queen Alexandra, and Prince George and his wife Princess Mary were permitted to use these titles. NAMES LISTED IN THE BIRTHDAY BOOK (the museum has photographs of every entry in the book, which are available on enquiry): - January 1 Mrs J (or S) Watson January 11 Wilfred Skirrow, 1904 January 16 Elsie Watson, 1897 January 17 Elsie Hartley, 23/06/2012 [error?] January 21 Frances Victoria Haieck January 29 Annie Skirrow, 1884 February 14 Willie Illingworth February 17 Bessie Watson February 19 Mrs Butterfield, 22 Apperley Rd, Idle [UK] February 27 William Ernest Futter ? March 13 Carrie Barker March 16 Connie Watson March 19 Hilda Graham March 20 Mrs W. Illingworth March 23 Connie Watson April 5 Mrs Ruth Ann Skirrow April 6 William Dickinson Goldsbrough April 11 Norman Goldsbrough April 16 May Jessen April 19 Mrs A Dixon April 20 Mrs S Watson April 23 John Fred Stansfield, 1912 April 24 Reginald Goldsbrough May 12 Bertha Ellis May 18 Gladys McInnes May 28 Mrs Arthur Watson June 3 Jack Watson, 1910 June 10 Mr James Watmough June 18 Miss Hilda Hodgson, 1895 June 26 Sarah Atkinson, 1894 June 30 Mary A Bannister, 1896 July 1 Benji Watson, 1887 July 1 Ester Watmough, 1896 July 2 Clara Skirrow, 1896 July 2 Aunt Jinni July 2 Aunt Hannah July 10 Ellen Gertrude Connolly July 11 Violet Mathieson July 23 Hady Rogers July 26 Sarah Atkinson August 2 Allan Watson August 3 George Skirrow August 6 Thomas Skirrow August 6 Gladys Patten August 8 John Waite, 1909 August 21 Lilian Pattison, 1909 August 25 Ethel Watson, 1889 August 25 Evellyn Goldsbrough September 4 Miss Frances Barker September 12 Ernest Hartley, 1888 September 14 Harry Stansfield, 1895 September 20 Harry Padgett September 25 Leslie Watson September 26 Florrie Wise, 1896 September 27 Dorothy Watson, 1909 October 1 Madge Ferrier October 3 Elizabeth Padgett, 1896 October 5 Violet Altridge, 1895 October 13 Elsie Hodgson, 1893 October 18 Arthur Watson October 21 Emily Bradshaw November 14 Mr A Dixon December 27 Laura Hartley, 1890 December 29 Arther Skirrow, 1894 December 29 Dolly GrahamThis early 20th-century Birthday Book is significant for containing quotes by the famous writer Charles Dickens. It is also connected to the popular and prolific publisher and printer, Raphael Tuck & Sons Ltd, and the renowned illustrator and artist, Pilford Fletcher Watson. Ownership of a rare and beautifully presented book like this indicates the value placed on keeping records of family and friends, and remembering their birthdays, in the early 1900s. The book is highly significant for the entries of local family names, some with birth dates. Book: small book with padded maroon leather hard cover and embossed with gold text on cover and spine; cover also has a gold motif. The pages include coloured illustrations, sketches, and lines for personal entries. The first pages are about Charles Dickens. Title: The Dickens Birthday Book, with six illustrations in Colour by P. Fletcher-Watson Publisher: Raphael Tuck & Sons Ltd, Britain Printed in England 1901-1910 Artist: P. Fletcher-Watson This padded red leather hardcover book has embossed gold text on the front cover and spine. The six colour illustrations throughout the book were by artist P. Fletcher-Watson; one is a portrait of Dickens. Each day has a quote from Charles Dickens' works and blank lines below. The drawing on the fly page depicts a stone building with side pillars and a logo in the centre of the horizontal beam. It has a gift inscription for Clara Skirrow on January 19th, 1911. There are handwritten entries under many of the dates, some include years that range from 1884 to 1912, and one includes an address in the U.K.. Embossed on cover and spine: “The DICKENS Birthday Book” Handwritten in black ink: "From Mr & Mrs B. Watson / To Clara Skirrow / With Best wishes / January 19th 1911" Illustration on fly page: Logo [artist's palette, brush and easel] Publisher information: “Raphael Tuck & Sons Ltd, London, Paris, Berlin, New York, Montreal,” “Publishers to their Majesties the King and Queen, and T.R.H. the Prince and Princess of Wales” “Printed in England” Handwritten entries with names, some dates, and one address. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, birthday book, p. fletcher-watson, raphael tuck & sons ltd, 1901-1910, illustrated, 19-01-1911, mr & mrs b. watson, clara skirrow, red cover, british printing corporation, king and queen and trh prince and princess, king edward vii and queen alexandra, antique book, rare book, atkinson, bannister, barker, bradshaw, butterfield, connolly, dixon, ellis, ferrier, futter, goldsbrough, graham, hartley, hodgson, illingworth, jessen, mathieson, mcinnes, padgett, patten, pattison, rogers, stansfield, waite, watmough, watson, wise, dickens birthday book, charles dickens, dickens quotes, skirrow -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationWeights

A small number of heavy cast iron weights and two rods remain at the Point Hicks Lightstation. These weights comprise one rod with a forked top and four circular weights attached to the bottom of the shaft. The weights and rods were part of the original clockwork mechanism that was fitted beneath the lens to keep the kerosene‐fuelled light turning. They were attached to a cable or chains and moved vertically in similar fashion to the way weights move on grandfather clocks. As the weight fell, the optic clock was driven and the lens was turned. To keep the clock turning, the weight needed to be wound back up to the top of its travel. The cables and weights in this lighthouse were visible as they moved through the length of the tower up to the lantern room. It was usual for systems to move inside a tube extending up to the top, but in this case the tower’s cast iron spiral staircase, which is supported on cantilever cast iron brackets set into the concrete wall, spiralled around the space in which they moved. Lighthouse keepers had the arduous job of having to constantly wind the clock to keep the light active, and at least two keepers needed to observe a strict roster of hours. When electric motors were invented, all of this became redundant and the motors were able to turn the optic for as long as there was power to drive them. In December 1964, the original 1890 Chance Bros kerosene‐fuelled light and clockwork mechanism were replaced by small electric motor, and the number of keepers reduced to two. The six circular weights and rods originate from the obsolete system and may have been part of a larger set. Wilsons Promontory retains seven of its original set of ten weights, all of which are detached from the tower’s weight tube. Cape Schanck has a set of fourteen weights remaining in situ as well as another four detached weights, which have inscriptions. One weight is displayed in the lantern room at Cape Otway. The image shows four of the clockwork weights attached to a rod with a forked top. They were part of the original clockwork mechanism that was fitted beneath the lens to keep the kerosene‐fuelled light turning. The Aldis lamp in its case sits on the floor next to the weights. Source: Parks Victoria.The Point Hicks weights have first level contributory significance for the insights they provide into the superseded technology and operations of a late nineteenth century lighthouse. They are well provenanced and are significant for their historic value as part of the lightstation’s Chance Brothers optical system installed in 1890. Four circular metal weights are stored on a metal rod with a forked section at the top. The weights have a cut out section which allows the weights to be removed easily. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEngine Dynamometer, c.1890’s