Showing 2220 items

matching cast

-

Clunes Museum

Clunes MuseumDomestic object - FLAT IRON - DOMESTIC

Example of domestic items used prior to the invention of electricityCAST METAL FLAT IRON FOR PRESSING CLOTHES"METTERS K P B VIC" RAISED ON BODY THE NUMBER "5" IS RAISED ON BODYflat iron, domestic item -

Clunes Museum

Clunes MuseumDomestic object - POT - CAST IRON

POT - CAST IRON BOILER WITH HANDLE AND LIDCLARK & CO. 5 / Glocal history, cooking, domestic items (kitchen) -

Stawell Historical Society Inc

Stawell Historical Society IncEquipment - Realia, Morter & Pestle, 1930'3

Used at Stawell Technical or Stawell High SchoolCast Iron Morter & Pestle rusty colourscience, education -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchAmmunition, Projectile

Cast iron projectile possible 18 pounder232 A 89 -

Melbourne Legacy

Melbourne LegacyMemorabilia - Object, Legacy Torch, c.1980s

Unknown. Assume produced for display or commemoration purposes. One has been used on the Centenary of ANZAC Street Art Mural on the back of Legacy House, Melbourne. The badge of Legacy is the Torch and Wreath of Laurel. The Torch signifies the undying flame of service and sacrifice of those who gave their lives for their country. The Wreath of Laurel is the symbol of our remembrance of them.The Legacy Torch created in metal. 'Logo' of Legacy ClubCast metal Legacy torch (two copies)torch, logos -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

Cast iron Glue Pot used in Carpentrystawell -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 1940's

2 Hole Punch Black Cast Iron stawell -

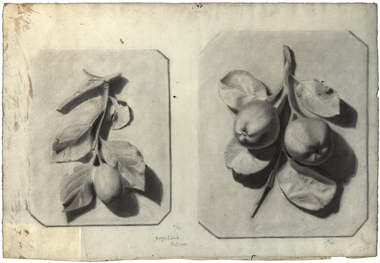

Federation University Art Collection

Federation University Art CollectionDrawing, Drawing From Plaster Casts 'Fruit' by Evelyn Lamb, 10/1901

Evelyn LAMB Evelyn Lamb was a student of an early Ballarat Art School. This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Two drawing of plaster casts depicting fruit. art, artwork, evelyn lamb, plaster cast, fruit, alumni, ballarat technical art school, unframed -

Mont De Lancey

Mont De LanceyBall and Ring Bunion Stretcher

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron ball and ring bunion stretcher.boot stretchers -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

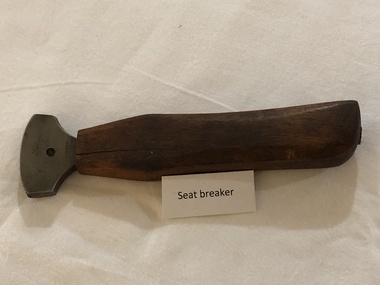

Mont De Lancey

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

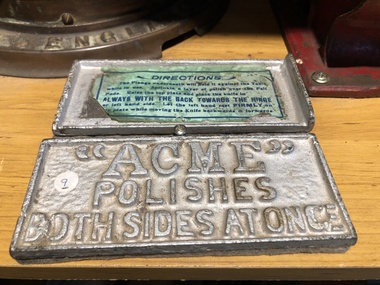

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1910

Cast iron static type knife cleaner'"Acme" Polishes Both Sides At Once'knife cleaners -

Mont De Lancey

Mont De LanceyLemon Squeezer, Circa 1910

Enamelled blue, cast iron lemon squeezer.juicers -

Mont De Lancey

Mont De LanceyLemon Squeezer, McMillan & Co, Circa 1912

Cast iron, screw type lemon squeezer'Victor'juicers -

Mont De Lancey

Mont De LanceyLemon Squeezer, McMillan & Co, Circa 1911

Cast iron lemon squeezer, with metal strainer'Success'juicers -

Bass Coast Shire Council - Art Collection

Bass Coast Shire Council - Art CollectionArtwork, other - Today and Future, Victoria Nelson

AustraliaCast Bronze, Granite blocks and weathered patina Plaque -

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - foot last

Used by cobblers for the repair of footwear ca1910we believe this was retailed by HOLDEN ca 1910Iron cast three shaped shoe lastAJK TITANshoe last, cobblers, civilian, ca1910 -

Working Heritage Crown Land Collection

Working Heritage Crown Land CollectionDecorative object - Finial

Cast iron finial spike for a fence post -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Weight, Unknown

None available for this item an early disc weight it's maker date of manufacture is not knownNone availableWeight cast iron disc on-black colourNumber 2 marked on upper surfaceflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumMicrotome/W... (H.A. Waters)

Microtome for cutting resin embedded tissues for electron microscopy. In 1957 a modified hodge microtome redesigned and built by H.A. Waters of the Melbourne University Department of Physics was acquired. The Waters microtome is of thermal expansion type - the rod “A” is heated and by expansion pushes the resin block forward by a fraction. It is mounted on a long cast iron base. The movement of the block is eccentric drawing the specimen away from the knife after cutting, The glass knife ‘B’ is adjustable by means of a modified microscope column screws ‘C’. The microtrome is driven by a continuous action electric motor mounted on the common base. Hand cutting can also be done. The cutting was controlled by viewing through a Leitz Binocular microscope mounted on the same base. The original microscope was subjected to nine modifications by Dr S Weiner from whose PhD Thesis (1962) ‘Electron Microscopical Studies of the Liver’ this information was obtained. (text provided by Professor H Attwood) Microtome made of metal and enamelled in light blue. Components are identified by the use of stick on labels. The microtome is mounted on a long cast iron rectangular base and has an electrical cord for connection to a power point.Plaque on back: “Pathology Department, University of Melbourne Serial No. 0091. Date: 7/7/1968” -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLead Shot Mould

Bullets for early firearms were made as lead balls in iron scissor moulds. The moulds had scissor action, with ends shaped as a hollow half-sphere that formed a ball when the handles closed. Melted lead was poured into a small filling hole in the top of the closed mould. When the lead was set the handles were opened and the ball was released from the mould. Excess lead was trimmed using the cutting edge of the mould. The task of pouring the melted lead into the mould had to be performed slowly so that air pockets didn’t form. The shot would have a join line around it, which would make it inaccurate; the join needed to be carefully filed to make the ball into a smooth sphere. Larger quantities of lead shot were often cast in a multi-bullet mould that was used in a similar way. Lead shot mould; cast iron, scissor type metal object with sphere shaped mould at end used to make lead shot balls for a shotgun. Mould has a cutting edge to trim off excess lead.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, firearms, bullet, cast bullet, lead ball, lead shot, scissor mould -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLead Shot Mould

Bullets for early firearms were made as lead balls in iron scissor moulds. The moulds had scissor action, with ends shaped as a hollow half-sphere that formed a ball when the handles closed. Melted lead was poured into a small filling hole in the top of the closed mould. When the lead was set the handles were opened and the ball was released from the mould. Excess lead was trimmed using the cutting edge of the mould. The task of pouring the melted lead into the mould had to be performed slowly so that air pockets didn’t form. The shot would have a join line around it, which would make it inaccurate; the join needed to be carefully filed to make the ball into a smooth sphere. Larger quantities of lead shot were often cast in a multi-bullet mould that was used in a similar way. Lead shot mould; cast iron, scissor type metal object with sphere shaped mould at end used to make lead shot balls for a shotgun. Mould has a cutting edge to trim off excess lead.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, firearms, bullet, cast bullet, lead ball, lead shot, scissor mould -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1880

Cast iron and wood static knife cleaner. Cast iron base, two circular wooden discs with cork pads between. Brass screw tightener."Our Own"knife cleaners -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1910

Hand cranked, cast iron knife cleaner. Cast iron circular barrel, with iron and wood handle. Cork/chamois ?, within barrel for cleaning knives."Beatrice Knife Cleaner" on the front. "Rd. No 686261" on the back.knife cleaners -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationLid, ship tank

The heavy cast iron, round lid was originally fastened into a large, riveted metal box, known as a ship tank. It has the name ‘John Bellamy London’ cast in capitals in a continuous circle on the outer edge of the lid face, and the words ‘Byng St Millwall’ on the inner circle. , of Millwall, London, manufactured boilers and ship tanks from the 1860s to the 1930s and came from a family of tank makers who began manufacturing tanks some time before 1856. Ship tanks were invented in 1808 by notable engineer, Richard Trevithick and his associate John Dickinson. Their patent obtained the same year described the tank’s superior cubic shape that allowed it to fit squarely as a container in vessels and thus use space efficiently, while its metal fabric preserved and secured its liquid or solid contents from damage. The containers revolutionised the movement of goods by ship and made wooden casks redundant. Research by Michael Pearson has determined that they were carried on passages to Australia from at least the 1830s conveying ships’ victuals and water storage, as well as general goods heading for the colonies. Pearson found photographic evidence of their use in the 1860s, and by the 1870s they appeared to be in common use. lids surviving from containers indicate that nearly all the tanks transported to Australia came from London manufacturers. It was usual for the brand name to also feature as a stencil on the tank but in most cases this eventually wore off. A tank without its original stencil survives at Wilsons Promontory. Tanks transporting ‘drinking water or perishable dry goods were hermetically sealed by the use of the tightly fitting lid with a rubber sealing ring ‘which was screwed tight with the aid of lugs cast into the lid and wedges cast into the rim of the loading hole’. The raised iron rod welded across the outer face of many lids such as the Bellamy example, allowed for screwing the lid tight. Once in the colonies, the ship tanks were often recycled and adapted for many resourceful uses such as packing cases, dog kennels, water tanks, oil containers and food stores and this invariably led to the separation of the lid and tank. The Bellamy lid could have been salvaged from a shipwreck but is more likely to have to have originated from a recycled tank that was brought to the lightstation for water storage purposes. Pearson writes that: Ship tanks show up at a wide range of sites, many of them isolated like lighthouses. They were, I think, usually taken there for the purposes they filled, usually water storage, as they were readily available, relatively light to transport, and probably very cheap to buy as second-hand goods containers. In rural areas they may have been scavenged for their new uses from local stores, to whom goods were delivered in them. Parks Victoria has identified five tank lids in the lightstation collections covered by this project. In addition to the Bellamy lid at Point Hicks, they include a Bow brand lid at Point Hicks and another at Cape Otway, unidentified lids at Cape Otway and Wilsons Promontory. Pearson and Miles Lewis have each recorded two versions of the Bellamy trade name on the lids; one being ‘John Bellamy Byng St. London’; the other, ‘John Bellamy Byng St. Millwall London’. The Point Hicks lid has the second version of the name, as do other examples in Victoria that Lewis has identified at Illawarra, Toorak; Warrock homestead, Casterton; Eeyeuk homestead, Terang; Ward’s Mill, Kyneton; and Boisdale homestead near Maffra, and in NSW at Ayrdale Park, Wolumla; and Bishop’s Lodge, Hay. Pearson’s list includes the same lids in NSW at Tumbarumba; the Quarantine Station, Sydney; Willandra Station; Bedervale, Braidwood; Gunnedah Museum; Walla Walla and Macquarie Island. The Point Hicks lid is currently stored in the lighthouse although it is unlikely that its use had any association with this building. The lid is in good condition and retains the central bung. Pearson notes that ‘surviving lids are far less numerous than the tanks themselves, presumably because the uses to which the tanks were put did not require the lid to be retained’.347 The Bellamy ship tank lid has first level contributory significance for its historic values. Circular cast-iron disc with raised outer ridge with inscription. It also has an inner depression with inscription. Two metal sections form handles over inner depression. Hole in middle of disc.Around perimeter of outer edge "JOHN BELLAMY LONDON" Around inner area "BYNG ST MILLWALL" -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Orbost & District Historical Society

Orbost & District Historical Societybilliard table iron

This item was used at The Men's Club Orbost in Livingstone Street, Orbost.This item is representative of the leisure activities of people during the nineteenth century and early 20th century. The Orbost Men's Club no longer exists. It is also significant as being associated with the history of Australia's leading manufacturer of billiard tables, Alcock of Melbourne who were established in 1854 and are still in business today.Billiard table iron; a heavy iron of cast metal. This has a large, rectangular face with attached, cast metal handle. This was used for pressing the cloth of a billiards table. Engraved/embossed on handle is ALCOCK THOMSON & TAYLOR PTY LTDrecreation billiards billiards-table-iron men's-club-orbost -

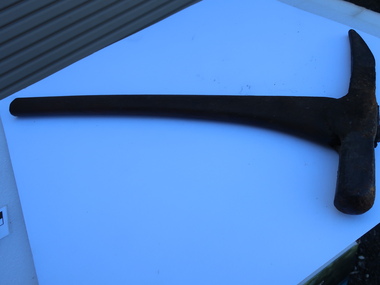

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMiners Pick - short

Formerly KV 071. It was used to break up rock and ore, making it easier to extract valuable minerals. The pointed end of the pick axe was used to chip away rock, while the flat end was used to strike the rock for breaking it apart. This one has a short handle. Miners picks were commonly used in the the 19th and early 20th centuries for extracting gold from underground mine tunnels.Used in the Kiewa Valley where prospecting for gold occurred.Formerly KV 071. Cast iron symmetrical pick tool on cast iron with a wooden handle. It has a pointed end and a flat end. It is 12 inches long.gold mining, miners' pick axe, hand tool