Showing 418 items

matching pourer

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Watkins Polish, J. R. Watkins Co (USA), 20thC

The J. R. Watkins Co. opened its first overseas branch in Australia in 1935. The J. R. Watkins built a large factory at Highett on a six acres on the east side of Nepean Highway (no. 1123) in 1954. The J. R. Watkins company was founded in 1868 in Plainview, Minnesota USA, moving to Winona in 1885, by J. R. Watkins.Example of industry in the City of Moorabbin.Amber glass bottle with a metal screw on lid. A paper label is on the front of the bottle 'Watkins Polish" printed in yellow, black and white.PRINTED ON LABEL: 11 Fluid ounces - WATKINS POLISH - Gives a hard dry lustre excellent for Dusting For cleaning, dusting and polishing furniture, pianos, woodwork, linoleum, hardwood floors and all polished surfaces. Directions: If the article to be polished is dirty or gummy, clean it by washing with mild soap and warm water. Apply Watkins Polish with a damp, soft cloth (Dampened with water and wrung almost dry). The Polish may be poured on the damp cloth or on the surface to be polished. In either case rub it all with a dry cloth to obtain a high polish. When dusting, dampen the cloth with Watkins Polish - it keeps down the dust and gives a lustre which is neither greasy not gummy. The J. R. Watkins Co. Melbourne - Sydney - Adelaide - Kogarah EMBOSED ON BOTTLE: "The J.R.Watkins co. Made in Australia" the j. r. watkins co, highett, polish -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeMug, Shaving

A shaving scuttle and shaving mug were developed around the 19th century with the first patent for a shaving mug dating to 1867.[8] As hot water was not common in many households, one way to provide hot lather was to use a scuttle or mug. A traditional scuttle resembles a teapot with a wide spout where hot water is poured in, and this is where it differs from a shaving mug, which has no spout. Both shaving scuttles and mugs usually have a handle, but some have none. Shaving mugs often look like a standard mug, however, some also have a built in brush rest, so the brush does not sit in lather. Modern versions of the scuttle are in limited production, usually by independent potters working in small volumes.[9] At the top of the scuttle or mug is a soap holder. Traditionally, it was used with a hard block of shaving soap (rather than soft soap or cream) and therefore had drain holes at the bottom. Later scuttles and mugs do not include the holes, and thus can be used with creams and soft soaps. Some scuttles and mugs have concentric circles on the bottom, which retain some water thus helping to build lather.[9] In use, the shaving brush is dunked into the wide spout, allowing it to soak into the water and heat up. The soap is placed in the soap holder. When needed, one can take the brush and brush it against the soap, bringing up a layer of lather; excess water is drained back. This allows conservation of water and soap, whilst retaining enough heat to ensure a long shave. Source: www.wikipedia.org Local social historyOrnate white china mug with handle. Cup side to hold brush and saucer shaped top with 3 drainage holes. Gold painted decoration and flower garland of pink and yellow roses. Mother of pearl effect over sides.Made in Germanyshaving, item, china, mug, bathroom, men, personal, toiletry -

Melbourne Legacy

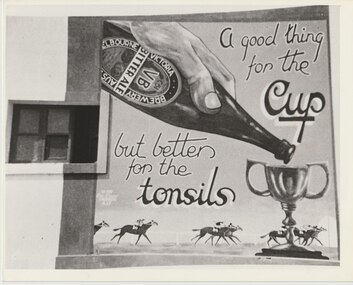

Melbourne LegacyPhotograph, A Mural West of Tobruk, 1941

A photo of a mural in Libya painted by a South Australian Sapper of a bottle of Victorian Bitter Ale being poured into the Melbourne Cup trophy and horses racing. The photo, and two others, were sent to Melbourne Legacy in 1979 by Legatee Syd Wilson of Yamba NSW. He thought Melbourne Legacy might be able to use them to generate money by selling them for advertising or publicity. He said they were enlargements of snapshots he had found in his old army trunk. The text says 'A good thing for the Cup but better for the tonsils'. Legatee Wilson's letter says the murals were: 'painted on three walls of a white concrete Italian block house (Police Check post I think), some 18/20 miles west of Tobruk, between Tobruk and Derna, and near a captured Italian airfield, somewhere about February 1941. Obviously they were painted by a Victorian Sapper. They were very well done, by a competent Sign-writer/artist, in correct and excellent colours (captured Itie paint no doubt - there was plenty in their Naval Stores at Tobruk).' (NB Itie was slang for Italian). 'The photos were there when we were coming back from Western Libya sometime in March 1941, prior to the 6th Division going to Greece.' From the AWM website the signs were painted by South Australian painter, SZ538 Sapper Leslie John “Doc” Dawes, 2/3rd Field Company, Royal Australian Engineers. There are several photos on the AWM site including the building the three murals were on.Photos taken by a Legatee when on active service in Libya in World War 2. They were donated to Legacy when it was thought they could be used for fundraising, which shows that Legatees were conscious of the way Legacy needs to generate funds to continue its work.Black and white enlargement of a photo taken in Libya of Victorian Bitter Ale for the Melbourne Cup mural.tobruk, beer, victorian bitter ale, ale, horse racing, murals, world war 2 -

National Vietnam Veterans Museum (NVVM)

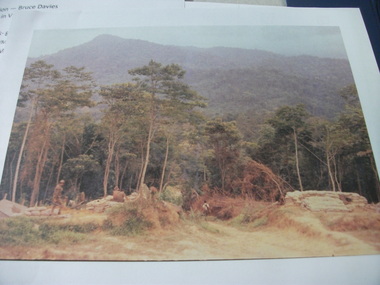

National Vietnam Veterans Museum (NVVM)Photograph, Gateway to Ngok Tavak, 1/05/1968 12:00:00 AM

In May 1968, in the western jungle of Vietnam near Laos, led by Australian Captain J White, 11th Mobile Strike Force Company (MSF) occupied an old French fort on a hill named Ngok Tavak tasked with improving allied intelligence-gathering capabilities in the area. However, with enemy activity increasing, on May 4th, 44 US Marines, 35 CIDG (Civilian Irregular Defence Group) and two 105mm Howitzer field guns arrived as reinforcement from the Special Forces base at Kham Duc. By May 9th, Captain White’s company numbered about 200 men. Although in a good defensive position, coming towards them was the Iron Brigade of the 2nd Division of the North Vietnamese Army (NVA). At 03:00 on May 10th, the attack on Ngok Tavak began. The NVA, led by Major Dang Ngoc Mai, poured through the entrance at the eastern wall quickly occupying most of the fort. By midday the next day, Captain White had lost 40 Nung soldiers and 11 Marines with over 70 others badly wounded. Realising he could not withstand another attack, Captain White decided to abandon Ngok Tavak. Once the wounded were evacuated, Captain White ordered strike aircraft to blast a ‘corridor’ through the surrounding enemy cordon using napalm. By early afternoon, what remained of the defenders escaped through the ‘corridor’ and helicopters eventually flew them to Kham Duc. Colour image of edge of Ngok Tavak fort with soldiers sitting on & walking around sand-bagged foxholes. Jungle & mountains in background.battle of ngok tavak, john white -

National Vietnam Veterans Museum (NVVM)

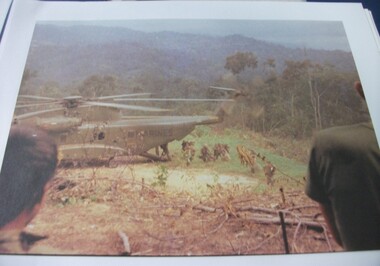

National Vietnam Veterans Museum (NVVM)Photograph, Marines arrive at Ngok Tavak 04/05/1968

In May 1968, in the western jungle of Vietnam near Laos, led by Australian Captain J White, 11th Mobile Strike Force Company (MSF) occupied an old French fort on a hill named Ngok Tavak tasked with improving allied intelligence-gathering capabilities in the area. However, with enemy activity increasing, on May 4th, 44 US Marines, 35 CIDG (Civilian Irregular Defence Group) and two 105mm Howitzer field guns arrived as reinforcement from the Special Forces base at Kham Duc. By May 9th, Captain White’s company numbered about 200 men. Although in a good defensive position, coming towards them was the Iron Brigade of the 2nd Division of the North Vietnamese Army (NVA). At 03:00 on May 10th, the attack on Ngok Tavak began. The NVA, led by Major Dang Ngoc Mai, poured through the entrance at the eastern wall quickly occupying most of the fort. By midday the next day, Captain White had lost 40 Nung soldiers and 11 Marines with over 70 others badly wounded. Realising he could not withstand another attack, Captain White decided to abandon Ngok Tavak. Once the wounded were evacuated, Captain White ordered strike aircraft to blast a ‘corridor’ through the surrounding enemy cordon using napalm. By early afternoon, what remained of the defenders escaped through the ‘corridor’ and helicopters eventually flew them to Kham Duc. Colour image of U.S. soldiers disembarking from a helicopter in a clearing in the jungle. Foreground is rear of two soldiers watching. Background is mountains.united states - marine corps, battle of ngok tavak, john white, ngok tavak -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Melbourne Tram Museum

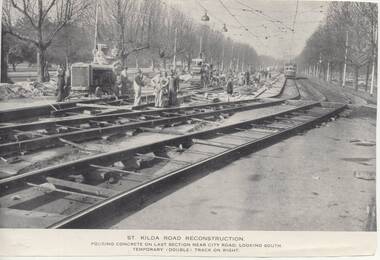

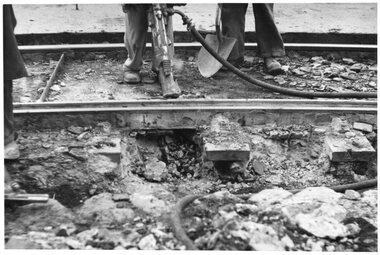

Melbourne Tram MuseumPhotograph - Illustration/s, Melbourne & Metropolitan Tramways Board (MMTB), 1950's?

Series of three Black and white Illustrations, reproduction of a MMTB report of photographs of the reconstruction of St Kilda Road, near City Road c1955. .1 Photo titled "St Kilda Road Reconstruction Pouring concrete on last section near City Road, looking south. Temporary (double) track on right. Shows a large group of men working, including some looking at the camera. Shows the construction of temporary track. Has a wide bodied W outbound. Has the Shrine of Remembrance in the far distance. .2 - showing "New Work and some temporary work" - shows the "shoo fly" temporary track link between the side temporary track and the new track. Has a tram in the far distance. Photograph taken near Victoria Barracks. .3 - "General view from just south of City Road, looking south - temporary (double) track in foreground. Similar to .l Originally reproduced in a possibly an MMTB report - not a mid 50's annual. Entry revised 7/7/2017 following addition of items .2 and .3trams, tramways, mmtb, st kilda rd, trackwork, reconstruction -

Frankston RSL Sub Branch

Frankston RSL Sub BranchStatuette, Mates

Small statuette depicting an Australian serviceman assisting a wounded comrade. The statuette depicts a scene from a famous moving film taken in New Guinea during World War 2 by Australian War Correspondent, Damien Peter Parer who was attached to the Australian Military Forces. The statuette is made from Pewter and is mounted on a stained wooden base. The following text statement is copied from the AWM website and describes the image in further detail: During the advance on Salamaua VX89711 Sergeant Gordon Raymond Charles Ayre MM, a 58/59th Battalion bandsman from Shepparton, Victoria, in pouring rain assists a wounded mate, VX132355 Private William Oswald Wallace Johnson, of the same unit, across Alan's (Allen's?) Creek to an advanced regimental aid post. Johnson had been wounded by a Japanese grenade on the 13th of July 1943 during an attack on the "coconuts" area. Sergeant Ayre was awarded the military medal for his performance during this action. This is one of the iconic images of the Second World War. (Still from AWM film F01866 "Assault on Salamaua", newsreel by Damien Parer)The wooden base has a label which is inscribed with the following: "MATES" Heritage Fine Arts, Limited Edition -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Video recordings: Promotional 1990-1994 NMCOT and NMIT, VHS video recordings: Promotional 1990-1994 NMCOT and NMIT

Promotional VHS Videos all produced during the 1990s. Listed alphabetically: An Introduction to NMIT 1996 Building & Construction Heidelberg 1992 Building & Construction Heidelberg 1992 1, 2, 3 (Umatic) Concrete pour - Heidelberg 1992 Foreign Fellowship Program 1996 Greensborough Music Promotional 1994 NMCOT College Promotion 1990 NMCOT College promotion 1992 NMCOT Corporate Video 1992 NMCOT Corporate video 1994 NMCOT Enrolment form 1991 (Umatic) NMCOT Enrolment Form 1992 NMCOT To Market to Market Promotional video 1993 NMCOT To Market to Market Promotional video 1994 NMIT Education TVCs To Market to Market 1997 NMIT To Market to Market Promotional video 1996 includes titles ‘General’, ‘Change’ and ‘Open Day’ Open Day (undated) Open Day 1992 Student Information Open day 1994, Commercial Course & College Information X 2 Open Day 1998 David Jones Promotional VHS Videos 1990s Recreation - Student Services 1994 X 2 TAFE College Group Marketing 1993 The TAFE Direction: smart options for young women (undated) northern metropolitan college of tafe, handbooks, nmit -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Floor Tile, circa 1878

This Minton floor tile is from the wreck of the Loch Ard and is currently on display in the Great Circle Gallery at Flagstaff Hill. The iron hulled clipper ship from the Loch Line was heading for Port Phillip from London, when it ran into the cliffs of Mutton Bird Island near Port Campbell. The Loch Ard was laden with a high value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well packed Minton porcelain peacock, a two meter high ceramic masterpiece of vivid glazed colours. (This is also on display in the Great Circle Gallery). The almost total loss of life and property from the Loch Ard registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. Wealth generated from Gold and Wool was increasingly being spent on grandiose private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton pottery at Stoke upon Trent, were their new range of colourfully patterned but very durable floor tiles ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These new floor tiles were “encaustic”, meaning that their designs and colours were encased “within” the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) were poured into a deep pre-molded casting. When fired, the resulting tile was colours-fast and design-fast. The Minton floor tile is significant for its hard-wearing yet attractive design. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections of objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history. A square Minton floor tile with a dark brown, beige and white pattern. The tile has a piece broken off along one side and some chipping along the edges. This ‘encaustic’ floor tile was recovered from the shipwreck of the LOCH ARD. Branded "... MINTON&CO Patent ..."flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, minton floor tile, encaustic tile, melbourne international exhibition, floor tile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Floor Tile, circa 1878

This Minton floor tile is from the wreck of the Loch Ard. The iron-hulled clipper ship from the Loch Line was heading for Port Phillip from London, when it ran into the cliffs of Mutton Bird Island near Port Campbell. The Loch Ard was laden with high-value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well-packed Minton porcelain peacock, a two-meter high ceramic masterpiece of vivid glazed colours. (This is also on display in the Great Circle Gallery). The almost total loss of life and property from the Loch Ard registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. The wealth generated from Gold and Wool was increasingly being spent on grandiose private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton Pottery at Stoke upon Trent, were their new range of colourfully patterned but very durable floor tiles ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These floor tiles were “encaustic”, meaning that their designs and colours were encased “within” the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) were poured into a deep pre-moulded casting. When fired, the resulting tile was colour-fast and design-fast. The Minton floor tile is significant for its hard-wearing yet attractive design. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections of objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history. A square Minton floor tile with a white background, and beige, dark blue, light blue and black geometric pattern as well as leaves in the design. The tile has corner broken off and some chipping along the edges. The reverse has five rows of five evenly spaced holes. The back of the tile has inscriptions. Made by Minton & Co. at Stoke upon Trent. This encaustic floor tile was recovered from the shipwreck of the LOCH ARD. Branded "... MINTON&CO / PATENT / STOKE UPON TRENT"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, minton floor tile, encaustic tile, melbourne international exhibition, floor tile, minton tile, minton & co., stoke upon trent -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncAlbum - Hume Reservoir Australia Album - Preparing a paddock for concrete. August 1927, 1927

This set of photos is from a leather bound album bearing the inscription "HUME RESERVOIR AUSTRALIA" plus 'The Rt. Hon. L. C. M. S. Amery, P. C., M .P.' all inscribed in gold. It was presented to The Rt. Hon. L. C. M. S. Amery, P. C., M. P, Secretary of State for Dominion Affairs on the occasion of his visit to the Hume Reservoir on 2nd November 1927. This album is of local and national significance as it documents the planning and development of the Hume Reservoir up to 1927. It was the largest water reservoir in the British Empire. The album records the pioneering engineering work that went into its construction.DEPARTMENT OF PUBLIC WORKS, N.S.W. RIVER MURRAY WATERS SCHEME. HUME RESERVOIR. 27. Preparing a Paddock for Concrete. Great care is taken in cleaning the surface of the concrete before placing the next layer. A hose applies a jet of water with a pressure of about 150 pounds to remove laitance and all dirt, which is swept off with brooms. (Laitance is the weak, milky or powdery layer of cement dust, lime and sand fines that appear on the surface of concrete. ) The square block of concrete in the foreground is poured at the same time as the concrete surrounding it and acts as a key for the next layer. Usually large granite “plums” or displacers weighing from 2 tons to 8 tons are used for this purpose and are placed in position by the cableway, but while the cableway is out of action the other method has been adopted. In this view may also be seen some of the timber piles and sheeting which form the inner side of the coffer dam. The outer side is formed of steel sheet piling. The space between the two lines of piles is 20 feet wide and is filled with earth after the steel and timber lines have been bound together by steel tie rods. New South Wales, August 1927.hume reservoir australia, river murray waters scheme, hume reservoir construction -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Tile, circa 1878

This Minton floor tile is from the wreck of the LOCH ARD. Other examples of this manufacture have been recovered from the wreck site and form part of the collection at Flagstaff Hill. The iron-hulled clipper ship from the Loch Line was heading for Port Phillip from London when it ran into the cliffs of Mutton Bird Island near Port Campbell and was wrecked on the early morning of June 1, 1878. The LOCH ARD was laden with high-value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well-packed Minton porcelain peacock, a two-metre-high ceramic masterpiece of vivid glazed colours. The almost total loss of life and property from the LOCH ARD registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. The wealth generated from gold and wool was increasingly being spent on magnificent private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton Pottery at Stoke upon Trent were their new range of colourfully patterned but very durable floor tiles – ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These new floor tiles were “encaustic”, meaning that their designs and colours were encased within the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) that were poured into a deep pre-moulded casting. When fired, the resulting tile was colour-fast and design-fast.The Minton encaustic floor tile is significant for its method of manufacture which makes it durable as well as decorative. The shipwreck of the LOCH ARD is of State significance. Victorian Heritage Register S417. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best-known shipwrecks in Victoria’s history.A square Minton floor tile with a black and beige pattern against a white base. This encaustic floor tile was recovered from the shipwreck of the LOCH ARD. On the back, or base, of the tile is inscribed the number “46” and the letters “Minton & Co Patent Stoke upon Trent”.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, mutton bird island, loch ard gorge, minton floor tile, encaustic tile, melbourne international exhibition, floor tile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeStrainer, Tea, 1920 (estimated); Approx. 1920

A tea strainer is a type of strainer that is placed over or in a teacup to catch tea leaves. When tea is brewed in the traditional manner in a teapot, the tea leaves are not contained in teabags, but rather are freely suspended in the water. As the leaves themselves may be distasteful, it is usual to filter them out with a tea strainer. Strainers usually fit into the top of the cup to catch the leaves as the tea is poured. Some deeper tea strainers can also be used to brew single cups of tea, much as teabags or brewing baskets are used - the strainer full of leaves is set in a cup to brew the tea, and then removed, along with the spent tea leaves, when the tea is ready to drink. By using a tea strainer in this way, the same leaves can be used to brew multiple cups. Tea strainer use declined in the 20th century with mass production of the tea bag, but is still preferred among connoisseurs who claim that keeping the leaves packed in a bag, rather than freely circulating, inhibits diffusion. Many assert that inferior ingredients, namely dust quality tea, are often used in tea bags. Tea strainers are usually either sterling silver, stainless steel, or china. Strainers often come in a set, with the strainer part and a small saucer for it to sit in between cups. Tea strainers in themselves have often been turned into artistic masterpieces of the silver- and goldsmith's craft, as well as rarer specimens of fine porcelain. Brewing baskets (or infusing baskets) resemble tea strainers, but are more typically put in the top of a teapot to contain the tea leaves during brewing. There is no definitive boundary between a brewing basket and a tea strainer, and the same tool might be used for both purposes. Tea strainers are also used by patients trying to pass a kidney stone. The patient urinates through the strainer, thereby ensuring that, if a stone is passed, it will be caught for evaluation and diagnosis. Source: www.wikipedia.net This item has historical significance in the evolution of Tea drinking.The Strainer being needed if a cup of tea was to be poured without tea leaves being present in the tea liquid.As Tea bags have been introduced into everyday life tea strainers are an item of the past. This particular tea strainer was an item for everyday useage.White enamel tea strainer, round in shape with flange edges, 7 small circle areas of perforations in the concave area of the utensil, a small perforated handle (same material) at one outer area of the item.domestic, kitchen, food, preparation, white, enamel, tea, strainer, beverage, perforated, utensil, round, flanges, leaves -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Lister Cream Separator, R.A. Lister & Co. Ltd, c1910

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. LISTER - A prominent make of separator which became very popular with the dairy farmer, was the "Lister" separator. The early separators sold by R. A. Lister in the 1880's, were made by "Koefoed & Hauberg", Copenhagen. Denmark, called the "Alexandria". Ashton Lister became the sole agent for Koefoed & Hauberg made separators in England and all the English Colonies, throughout the world. Being an enterprising salesman, Ashton, sent his son Edward on a three-year sales tour of Australia & New Zealand in 1890, (hence the strong presence of Lister in Australia.) Initially, the separator was totally manufactured in Denmark and assembled in Dursley, England. By 1892 Lister were making parts at their Victorian Iron Works, and around about the early 1900's, Lister began manufacturing separators in their own right, severing ties with Koefoed & Hauberg. The Lister firm is still going today, under the name of Lister Petter, England, but do not manufacture separators, as the manufacture of farm / domestic separators ceased in the early 1960's.This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is metal plated with blue enamel. The vat is made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A metal plate featuring the manufacturer information is attached to the side of the handle. Model CR 15 hand operated table version.On metal plate attached to handle" Lister/ MADE BY R. A. LISTER & Co.LTD. / AT DURSLEY ENGLAND / VICTORIAN AGENTS / GIPPSLAND & NORTHERN CO-OP/ CO. LTD. / MELBOURNE C.1"dairying industry, dairy machinery, milk separators, lister separators -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, Early 20th century

The basic balance scale has been around for thousands of years and its accuracy has improved dramatically over the last several centuries, the principle behind this tool remains unchanged. Its parts include a fulcrum, a beam that balances on it, a pan at the end of the beam to hold the materials to be weighed, and a flat platform at the other for the counter-balancing weights. Balance scales that require equal weights on each side of the fulcrum have been used by everyone from apothecaries and assayers to jewellers and postal workers. Known as an unequal arm balance scale, this variety builds the counterweight into the device. Counter scales used in dry-goods stores and domestic kitchens often featured Japanned or (blackened) cast iron with bronze trims. Made by companies such as Howe and Fairbanks, the footed tin pans of these scales were often oblong, some encircled at one end so bulk items could be easily poured into a bag. Seamless pans were typically stamped from brass and given style names like Snuff (the smallest) and Birmingham (the largest). Some counter scales were designed for measuring spices, others for weighing slices of cake. In the 18th century, spring scales began to appear and would use the resistance of spring to calculate weights, which are read automatically on the scale’s face. The ease of use of spring scales over balance scales. One of the most common types of spring scales was the kitchen scale also known as a family or dial scale. Designed for horizontal surfaces, these vintage kitchen scales used the weight of goods in a pan at the top of the scale to force the spring down rather than the balance system. Such scales were common in early 20th century households and were sold by many companies. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks were the most popular brands used. These scales are significant as they identify one of the basic preparation items for the weighing of foodstuff in the family kitchen to prepare everyday meals. This item is significant as it gives a snapshot into domestic life within the average home in Australia around the turn of the twentieth century and is, therefore, an item with social relevance. Black cast iron, medium weighing scales, with a fulcrum which the beam that balances on, there is as scoop at one end for the material to be weighted and a flat circular disc at the other end that holds the weights. Around the cast iron base is an embossed leaf pattern. All the weights have their weight embossed within the casting.There are 5 weights, marked 2 oz, 4 oz,8 oz,1 lb,2 lb, This scale does not have any visual markings on the arms to identify a maker or true balance. It is therefore assumed that these scales were made for domestic use only.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spring scale, scale -

Flagstaff Hill Maritime Museum and Village

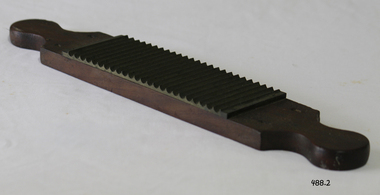

Flagstaff Hill Maritime Museum and VillageEquipment - Pill Maker Board

Before factory production became commonplace in medicine, dispensing was considered an art and pill machines such as these were a vital component of any chemist’s collection. This machine dates back to the days when your local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Pill machines such as these first appeared in the mid-1700s and quickly became a staple of the Victorian chemist’s shop. A ‘pill mass’ of medicinal powders mixed with a binding agent would be hand-rolled into a pipe on the tile at the back of the machine. This would then be placed across the grooved brass plate and cut into equal-sized pills using the corresponding side of the roller. Once all the necessary ingredients for the pills had been measured and ground with a pestle and mortar a final ingredient was poured in, syrup – this acted as a binding-agent. You could then roll it into a sausage shape. The largest part of the machine is the board. This is set at an angle and is comprised of the rolling surface, the cutting grooves, and the collection-tray. The large flat surface is for rolling out the pill-paste into the sausage shape. This is then rolled towards the brass cutting-grooves. The paddle (the second piece) is flipped over so that the grooves there line up with the grooves on the board. Rollers on the ends of the paddle roll against the brass edges of the board, and they guide the paddle straight across the grooves, taking the pill-mass with it. The grooves on the paddle and the board slice up the pill-mass and, after rolling the thing back and forth a couple of times like a rolling-pin, the circular pills roll off the grooves and into the tray at the bottom. https://galwaycitymuseum.ie/blog/collections-spotlight-victorian-pill-making-machine/?locale=en The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Pill making device including a grooved base board and grooved sliding board with two pill moulds.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pills, pill maker, medicine, health -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pill Rolling Pin