Showing 350 items

matching trading vessel

-

Flagstaff Hill Maritime Museum and Village

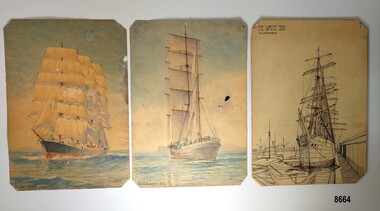

Flagstaff Hill Maritime Museum and VillagePainting - Paintings - set of three, Beni Carr Glyn Burnett, 1933

Beni Carr Glyn Burnett (also known as B. C. G. Burnett or Beni Burnett) was born in 1889 to missionary parents in Mongolia. When he was 15 years old he began training as an architect with a firm in Shanghai. He worked in Singapore, Japan and China before moving to Australia around 1933. In 1937 he was appointed as the Commonwealth principal architect in the Northern Territory. He went on to design a series of houses for senior public servants and military personnel which became very popular as they were specifically designed for the tropics - incorporating louvres, high ceilings and good ventilation. When Darwin was bombed in February 1942, he was evacuated to Alice Springs where he continued to work as an architect. He also became a Magistrate and Coroner in Alice Springs. In later life he was well known for sketching clientele in public bars. He died in 1955. Beni Burnett was living in Sydney in 1933 when he produced these three artworks. There were several photography firms operating in Sydney at this time who specialised in photographing ships and the shipping trade (e.g. Samuel J. Hood and William James Hall) and whose photographs were used by artists to produce ship portraits. Both of these photographers took photographs of the two ships in B. C. G. Burnett's watercolours. The "Magdalene Vinnen" was photographed by Samuel J Hood in a series of photos taken in March 1933. It was a 4 masted steel barque, built in 1921 in Kiel, Germany and for almost 80 years was the largest traditional sailing ship in operation. It was used extensively as a cargo ship. It sailed into Sydney Harbour on 27th Feb 1933, loaded with almost 16,000 bales of wool destined for Falmouth, England. In March 1933 (whilst in Sydney) the German Republic flag (on orders from Adolph Hitler) was lowered and replaced with the old monarchist flag which was then to be the official flag and beside it the Nazi flag was to be flown on all ceremonial occasions. It visited Australia again in 1935 with its cargo being wheat from Port Broughton, S. A. In 1936 it was renamed "Kommodore Johnsen" and in 1945 (after WW2) the ship was awarded to the Soviet Union as war compensation and renamed "STS Sedov". The "Winterhude" (originally called "Mabel Rickmers) was a three masted Finnish barque built in 1898 by Rickers - Werft Bremerhaven for use on the East India rice trade and later the South American nitrate trade. After WW1 it came under French control as war compensation. It was also sold several times and at one stage was called "Selma Hemsoth" but in 1925 it was bought by Gustaf Erikson who restored the name "Winterhude" and the vessel became a regular transport in the Australian wheat trade. In 1944 it was sold to the German navy before being taken over by the British at the end of WW2. It was photographed in Sydney by William James Hall in 1931 on its way to Port Lincoln, South Australia to load wheat for Europe. The third ship depicted by B. C. G. Burnett is a pen and wash sketch labelled "The White Ship" and exactly matches a photograph pasted into his personal scrapbook which is in the "Library and Archives N. T.". The name of the ship is unknown and B. C. G. Burnett may have taken some artistic licence with the colouring as in the original photograph, the ship had a dark hull.This set of three small artworks is significant as examples of shipping (particularly the use of sailing ships) that were still being used as late as the 1930's in Australia. They are also important because their creator (B. C. G. Burnett) went on to become a well-known public figure in the Northern Territory in the late 1930's due to his innovative approach to designing homes for the tropical climate.A set of three artworks by B. C. G. Burnett of sailing ships in Sydney Harbour. They are all on rectangular watercolour paper with small diagonal edges at each corner. Painting 1 is a watercolour painting of a sailing ship called "Magdalene Vinnen". It shows a 4 masted barque with a blue and red steel hull in full sail heading towards the viewer. The painter's name (B. C. G. Burnett) and date (1933) are written on the bottom left-hand corner of the painting. Painting 2 is a watercolour painting of a sailing ship called "Winterhude". It shows a 3-masted barque with a blue and red steel hull in full sail heading away from the viewer. A small figure can be seen at the wheel at the rear of the ship. The painter's name (B. C. G. Burnett) and date (1933) are written on the bottom left-hand corner of the painting. Sketch 3 is an ink sketch of an unknown sailing ship moored to a dock. There are several small boats tied up near the sailing ship and a large steel freighter can be seen in the background. There is a faint wash of colour on parts of the sketch - the bottom of the ship, the masts and booms and the water at the end of the pier. The title (The White Ship) and the artist's name (B. C. G. Burnett) are written in ink in the top left corner. 1 (front) - "B. C. G. BURNETT. 1933 2 (front) - "B. C. G. BURNETT. 1933" 3 (front) - "THE WHITE SHIP / B. C. G. BURNETT"flagstaff hill maritime museum and village, warrnambool, great ocean road, sailing ships, ships, barque, magdalene vinnen, winterhude, beni carr glyn burnett, b. c. g. burnett, beni burnett, painting, watercolour painting, sketch, ink sketch, sydney harbour, architect, darwin, burnett house, photography, samuel j. hood, william james hall, sedov, kommodore johnsen, mabel rickmers -

Flagstaff Hill Maritime Museum and Village

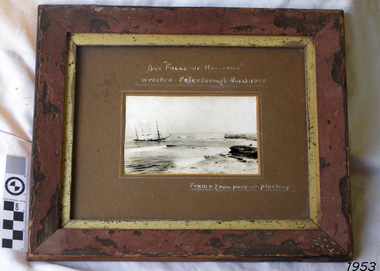

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Falls of Halladale 1886 - 1908, 1908

The photograph shows some of the hundreds of sightseers who visited the site of the wreced Falls of Halladale, watching the fully rigged ship slowly disintegrate over two months or more. The Falls of Halladale was a four-masted sailing ship built in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for the Pacific grain trade. The ship was sturdy. It could carry maximum cargo and maintain full sail in heavy gales. It was one of the last of the ‘windjammers’ that sailed the Trade Route, and one of the first vessels to include fore and aft lifting bridges, which kept the crew safe and dry as they moved around the decks in stormy conditions. It was one of several Falls Line ships named after the waterfalls of Glasgow by its owner, Wright, Breakenridge & Co of Glasgow. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000. It included 56,763 tiles of American slate roofing tiles, 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items (a list of items held at Flagstaff Hill Maritime Village is included below). The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m off-shore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). It was one of the last ships to sail the Trade Routes. The ship was one of the first vessels to have fore and aft lifting bridges. The wreck is an example of an International Cargo Ship and represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Photograph, behind glass in a timber frame. Image of a group of people seated on the ground with the stranded barque, the Falls of Halladale, in full sail nearby in the water. The photograph was taken at Peterborough, southwest Victoria, on November 13th 1908. A typed inscription is below the picture.Typed beneath photograph "Falls of Halladale 1886 - 1908"flagstaff hill, maritime museum, maritime village, flagstaff hill maritime museum and village, great ocean road, shipwreck, peterborough, falls of halladale, 1908, barque, scotish, 4-masted, sailing ship, 1886, glasgow, trade, grain trade, cargo, windjammer, fore and aft bridges, falls line, wright, breakenridge & co, american slate, roofing tiles, barbed wire, sewing machines, oil, benzene, port campbell rocket crew, sightseers, salvage, captain david wood thomson, captain thomson, navigational error, clyde-built, russell & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Falls of Halladale, After 13-11-1908

Falls of Halladale The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She was one of the first vessels to include fore and aft lifting bridges, which kept the crew safe and dry in as they moved around the decks in stormy conditions. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles, 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items (a list of items held at Flagstaff Hill Maritime Village is included below). The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Photograph of the wrecked ship, the Falls of Halladale, sails still flying. The ship was wrecked at Peterborough on Nov 13, 1908. The outer frame is made from a piece of planking. Handwritten inscriptions in white ink on the top of the matt board, and on the lower right.BQE "Falls of Halladale" "Wrecked. Peterborough. Nov 13. 1908" "Frame. from piece of planking."flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwreck, photograph, falls of halladale, planking frame -

Flagstaff Hill Maritime Museum and Village

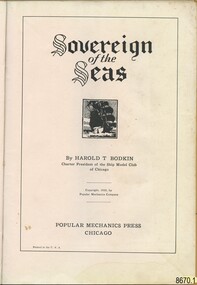

Flagstaff Hill Maritime Museum and VillageBook - "Sovereign of the Seas" book or manual for the ship model hobby enthusiast, Harold T. Bodkin, 1933, "Sovereign of the Seas", Popular Mechanics Press

Jim (James Bernard) Williams, who was the owner of this manual, was a long-time resident of Warrnambool having the opportunity to work at two notable historical businesses of the town. The first, Cramond & Dickson a drapier store established around 1852-1855 and which remained a store that traded under the same name for the longest in Victoria, before it closed its doors in 1974. The second business was Fletcher Jones a highly successful textile and clothing Australian business. Some of Jim’s spare time was devoted to the model ship making which would conjure up many fascinating stories of maritime history. In addition to Jim witnessing the tail end of ships at port in Warrnambool, his "father was as sea captain and operated his vessel in Bass Strait coastal trade between Tasmania and Victoria". The intricately detailed model made by Jim is full of precise detail. The manual and the blueprints held by Flagstaff Hill Maritime Village also reflect the intricate process and devotion to the task completed by Jim. The history of the shipwreck and maritime stories of the Victorian Southwest coast surrounding Warrnambool would have continued to inspire his passion. Three photos of the model and Jim, like the photo of Harold T. Bodkin in the manual, attest to the enthusiasm and enjoyment that was gained by him through this hobby. The manual opens to a photo of “Mr. Harold T. Bodkin adding finishing touches to model of the “Sovereign of the Seas”. The “Forward to Reader” which is on the next page is written by “E. R. HAAN, Technical Editor, Popular Mechanics Magazine. The forward explains the methodology used to achieve the fine detail that is part of the body of the model, by “applying imitation carvings”, and is cited as “a museum type of model”. The following page “Blueprints and Craftmats on the ‘Sovereign of the Seas’” discusses the availability of a set of blueprints to purchase separately. Followed by a description of the moulding process for the “miniature carvings”. “Historical Notes of Interest on the “Sovereign of the Seas (1637)” follow on the next page. The manual is divided into the following parts from pages 8 to 71: “Part I – Shaping the Hull/Part II – The Rudder, Quarter Galleries and Gunports/Part III Wales, Gunport Covers and Initial Ornamentation/Part V – Beakhead Decoration, Bulkhead and Rails, Etc./Part VI Carvings, Lanterns, Knights, Bitts and Painting/Part VII – Details of Mast Construction/Part VIII – Standing Rigging/Part IX – Running Rigging and Final Details. All of these instructions include photographs and detailed graphs. Then instructions on “How to Read and Use Ship-Model Drawings”, “The Shop-Model Maker’s Tools”, and “Simplified Ship-in-a-Bottle”. This is finished off with “Helpful Hints….” And numerous pages of advertising. Some adverts include aids for completing the “Sovereign of the Seas” model. Part I uses blue and black ink to illustrate a dramatic picture of the “Sovereign”, otherwise all print is in black ink on buff paper. This book in significant to the collection as it was donated along with other tools and blueprints which have been used by the donor of the "Sovereign of the Seas" model ship. It also connects with the wider community in that it is related to historical maritime interest and the donor, Jim Williams is also connected to other significant retail and manufacturing businesses of the past in Warrnambool. This manual has been covered with brown paper, including an extra strip for the spine. The front has a watermark at the top middle, some pencilled compass circles segmented into eight parts across the area and a small amount of script writing. The back also has the same type of compass circles and some other small shapes. There are also grease marks. The cover has a patina adding to variations of colour to the paper indicative of the book being handled often. The title page reads “Sovereign of the Seas” in an Old English font. This is followed by a lithograph print around 1 inch square of a ship at full sale. By HAROLD T. BODKIN/Charter President of the Ship Model Club of Chicago/Copyright, 1933, By Popular Mechanics Company/POPULAR MECHANICS PRESS/CHICAGO/Printed in the U.S.A. By HAROLD T. BODKIN/Charter President of the Ship Model Club of Chicago/Copyright, 1933, By Popular Mechanics Company/POPULAR MECHANICS PRESS/CHICAGO/Printed in the U.S.A.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, model ship, vessel sovereign of the seas, jim williams, james bernard williams, the forth tasmania, freda williams, heather williams, phyllis bowditch, fletcher jones staff 1936, 17th century sailing ship, cramond and dickson, sovereign of the seas, royal sovereign, sovereign, charles 1, fletcher jones, warrnambool breakwater -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Door, 1871 or earlier

The wooden door was salvaged from the wreck of the sailing ship Eric the Red, which was a wooden, three masted clipper ship. Eric the Red was the largest full-rigged ship built at Bath, Maine, USA in 1871, having had a 1,580 tons register. She was built and registered by Arthur Sewall, later to become the partnership E. & A. Sewall, the 51st ship built by this company. The annually-published List of Merchant Vessels of the U.S. shows Bath was still the home port of Eric the Red in 1880. The vessel was named after the Viking discoverer, Eric the Red, who was the first European to reach the shores of North America (in 980AD). The ship Eric the Red at first traded in coal between America and Britain, and later traded in guano nitrates from South America. In 1879 she was re-metalled and was in first class condition. On 10th June 1880 (some records say 12th June) Eric the Red departed New York for Melbourne and then Sydney. She had been commissioned by American trade representatives to carry a special cargo of 500 exhibits (1400 tons) – about a quarter to a third of America’s total exhibits - from America for the U.S.A. pavilion at Melbourne’s first International Exhibition. The exhibits included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, samples of corn and the choicest of leaf tobacco. Other general cargo included merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The Eric the Red left New York under the command of Captain Z. Allen (or some records say Captain Jacques Allen) and 24 other crew including the owner’s son third mate Ned Sewall. There were 2 saloon passengers also. The ship had been sailing for an uneventful 85 days and the voyage was almost at its end. On 4th September 1880 the Eric the Red approached Cape Otway with a moderate north-west wind and hazy and overcast atmosphere. Around 1:30am Captain Allen sighted the Cape Otway light and was keeping the ship 5-6 miles offshore to stay clear of the hazardous Otway Reef. However he had badly misjudged his position. The ship hit the Otway Reef about 2 miles out to sea, south west of the Cape Otway light station. He ordered the wheel to be put ‘hard up’ thinking that she might float off the reef. A heavy sea knocked the man away from the wheel, broke the wheel ropes and carried away the rudder. The sea swamped the lifeboats. The mizzenmast fell, with all of its rigging, then the mainmast also fell and the ship broke in two. Some said that the passenger Vaughan, who was travelling for his health and not very strong, was washed overboard and never seen again. The ship started breaking up. The forward house came adrift with three of the crew on it as well as a longboat, which the men succeeded in launching and keeping afloat by continually bailing with their sea boots. The captain, the third mate (the owner’s son) and others clung to the mizzenmast in the sea. Then the owner’s son was washed away off the mast. Within 10 minutes the rest of the ship was in pieces, completely wrecked, with cargo and wreckage floating in the sea. The captain encouraged the second mate to swim with him to the deckhouse where there were other crew but the second mate wouldn’t go with him. Eventually the Captain made it to the deckhouse and the men pulled him up. At about 4:30am the group of men on the deckhouse saw the lights of a steamer and called for help. At the same time they noticed the second mate and the other man had drifted nearby, still on the spur, and pulled them both onto the wreck. The coastal steamer Dawn was returning to Warrnambool from Melbourne, its sailing time different to its usual schedule. Captain Jones sent out two life boats, and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from Eric the Red. Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much needed clothing. Captain Allen was amongst the 23 battered and injured men who were rescued and later taken to Warrnambool for care. Warrnambool’s mayor and town clerk offered them all hospitality, the three badly injured men going to the hospital for care and others to the Olive Branch Hotel, then on to Melbourne. Captain Allen’s leg injury prevented him from going ashore so he and three other men travelled on the Dawn to Portland. They were met by the mayor who also treated them all with great kindness. Captain Allen took the train back to Melbourne then returned to America. Those saved were Captain Z. Allen (or Jacques Allen), J. Darcy chief mate, James F. Lawrence second mate, Ned Sewall third mate and owner’s son, John French the cook, C. Nelson sail maker, Clarence W. New passenger, and the able seamen Dickenson, J. Black, Denis White, C. Herbert, C. Thompson, A. Brooks, D. Wilson, J. Ellis, Q. Thompson, C. Newman, W. Paul, J. Davis, M. Horenleng, J. Ogduff, T. W. Drew, R. Richardson. Four men had lost their lives; three of them were crew (Gus Dahlgreen ship’s carpenter, H. Ackman steward, who drowned in his cabin, and George Silver seaman) and one a passenger (J. B. Vaughan). The body of one of them had been found washed up at Cape Otway and was later buried in the lighthouse cemetery; another body was seen on an inaccessible ledge. Twelve months later the second mate James F. Lawrence, from Nova Scotia, passed away in the Warrnambool district; an obituary was displayed in the local paper. The captain and crew of the Dawn were recognised by the United States Government in July 1881 for their humane efforts, being thanked and presented with substantial monetary rewards, medals and gifts. Neither the ship, nor its cargo, was insured. The ship was worth about £15,000 and the cargo was reportedly worth £40,000; only about £2,000 worth had been recovered. Cargo and wreckage washed up at Apollo Bay, Peterborough, Port Campbell, Western Port and according to some reports, even as far away as the beaches of New Zealand. The day after the wreck the government steam ship Pharos was sent from Queenscliff to clear the shipping lanes of debris that could be a danger to ships. The large midship deckhouse of the ship was found floating in a calm sea near Henty Reef. Items such as an American chair, a ladder and a nest of boxes were all on top of the deckhouse. As it was so large and could cause danger to passing ships, Captain Payne had the deckhouse towed towards the shore just beyond Apollo Bay. Between Apollo Bay and Blanket Bay the captain and crew of Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag-board bearing the words “Eric the Red” was found on the deckhouse; finally those on board the Pharos had the name of the wrecked vessel. During this operation Pharos came across the government steamer Victoria and also a steamer S.S. Otway, both of which were picking up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated on to Point Franklin. Some of the vessels yards and portions of her masts were on shore. The pieces of canvas attached to the yards and masts confirmed that the vessel had been under sail. The beach there was piled with debris several feet high. There were many cases of Diamond Oil kerosene, labelled R. W. Cameron and Company, New York. There were also many large planks of red pine, portions of a small white boat and a large, well-used oar. Other items found ashore included sewing machines (some consigned to ‘Long and Co.”) and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire (some branded “T.S” and Co, Melbourne”), kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts, croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a fly wheel, a cooking stove, timber, boxes, pianos, organs and a ladder. (Wooden clothes pegs drifted in for many years). There seemed to be no personal luggage or clothing. The Pharos encountered a long line, about one and a half miles, of floating wreckage about 10 miles off land, south east of Cape Otway, and in some places about 40 feet wide. It seemed that more than half of it was from Eric the Red. The ship’s crew rescued 3 cases that were for the Melbourne Exhibition and other items from amongst the debris. There were also chairs, doors, musical instruments, washing boards, nests of trunks and fly catchers floating in the sea. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. (There is a photograph of a life belt on the verandah of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. This is rather a mystery as the ship was registered in Bath, Maine, USA.) Parts of the ship are on display at Bimbi Park Caravan Park and at Apollo Bay Museum. Flagstaff Hill Maritime Village also has part of the helm (steering wheel), a carved wooden sword (said to be the only remaining portion of the ship’s figurehead; further research is currently being carried out), a door, a metal rod and samples of wood. Much of the wreckage was recovered by the local residents before police and other authorities arrived at the scene. Looters went to great effort to salvage goods, being lowered down the high cliff faces to areas with little or no beach to collect items from the wreckage, their mates above watching out for dangerous waves. A Tasmanian newspaper reports on a court case in Stawell, Victoria, noting a man who was caught 2 months later selling tobacco from the wreckage of Eric the Red. Some of the silverware is still treasured by descendants of Mr Mackenzie who was given these items by officials for his help in securing the cargo. The gifts included silver coffee and tea pots, half a dozen silver serviette rings and two sewing machines. The wreck and cargo were sold to a Melbourne man who salvaged a quantity of high quality tobacco and dental and surgical instruments. Timbers from the ship were salvaged and used in the construction of houses and sheds around Apollo Bay, including a guest house, Milford House (since burnt down in bushfires), which had furniture, fittings and timber on the dining room floor from the ship. A 39.7 foot long trading ketch, the Apollo, was also built from its timbers by Mr Burgess in 1883 and subsequently used in Tasmanian waters. It was the first attempt at ship building in Apollo bay. In 1881 a red light was installed about 300 feet above sea level at the base of the Cape Otway lighthouse to warn ships when they were too close to shore; It would not be visible unless a ship came within 3 miles from it. This has proved to be an effective warning. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn". “The Eric the Red is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA) Door from the wreck of the ship Eric the Red. The wooden singular rectangular door includes three insert panel sections. The top section is square shaped and is missing its panel or glass. The centre timber panel is about a third of the height of the top panel and the bottom timber panel is approximately equal in height to the total height of the two upper panels. The door fastenings include both a metal door latch and traditional door bolt. They are both attached to the front right hand side of the door. The bolt is just below the top panel, and the door latch is in approximately the centre of that side. The door latch has a round mark where a handle could have been attached. The wood of the door has scraping marks in a semi-circle around the door latch where the latch has swung around on its one remaining fastening and grazed the surface. There is a metal hinge at the top section of the door on the opposite side to the latch. The painted surface has been scraped back to expose the wood. The door is shorter than the average height of a person. On the reverse of the door there are lines on the panels, just inside their edges, is what appears to be pencil. The door is not aligned straight but is skew to centre.warrnambool, flagstaff hill, flagstaff hill maritime village, maritime museum, shipwreck coast, great ocean road, shipwreck artefact, eric the red, jaques allen, sewall, 1880, melbourne exhibition 1880, cape otway, otway reef, victorian shipwreck, bass strait, eric-the-red, door -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAward - Medal, Nelson Johnson, November 1880

This medal for bravery, for rescue of the crew from the shipwreck “Eric the Red” on 4th September 1880, was awarded to one of the crew of the steamer S.S. Dawn by the President of the United States in July 1881. The medal is engraved with the name “Nelson Johnson” (the anglicised version of his Swedish name Neils Frederick Yohnson). It was donated to Flagstaff Hill Maritime Village in 2013 by Nelson’s granddaughter. Nelson had migrated from Sweden to Sydney in 1879. The next year in 1880, aged 24, he was a seaman on the steamship Dawn and involved in the rescue of the survivors of the Eric the Red. Nelson Johnson was a crew member of the S.S. Dawn and was one of the rescue team in the dinghy in the early morning of September 4th 1880. Medals were awarded to the Captain and crew of the S.S. Dawn by the President of the United States, through the Consul-general (Mr Oliver M. Spencer), in July 1881 “ … in recognition of their humane efforts in rescuing the 23 survivors of the American built wooden sailing ship, the Eric the Red, on 4th September 1880.” The men were also presented with substantial monetary rewards and gifts. The city of Warrnambool’s care of the survivors was also mentioned by the President at the presentation, saying that “the city hosted and supported the crew ‘most graciously’. Previously, a week after the shipwreck, the Australian Government had also conveyed its thanks to the Captain and crew of the S.S. Dawn “Captain Griffith Jones, S.S. Dawn, The Hon. Mr Clark desires that the thanks of the Government should be conveyed to you for the prompt, persevering and seamanlike qualities displayed by you, your officers and crew in saving the number of lives you did on the occasion referred to. The hon. The Commissioner has also been pleased to award you a souvenir in commemoration of the occasion, and a sum of 65 pounds to be awarded to your officers and crew according to annexed scale. I am, &c, W Collins Rees, for and in the absence of the Chief Harbour Master.” The Awards are as follows: - Crew of DAWN'S lifeboat-Chief Officer, Mr G. Peat, 15 pounds; boat's crew-G. Sterge, A.B., 5 pounds; T. Hammond, A.B., 5 pounds; J. Black, A.B., 5 pounds; H. Edwards, A.B., 5 pounds. Dinghy's Crew-Second Officer, Mr Christie, 10 pounds; boat's crew -F. Lafer, A.B., 5 pounds; W. Johnstone, A.B., 5 pounds; Mr Lear, provedore, 5 pounds; Mr Dove, purser, 5 pounds. Captain Jones receives a piece of plate. (from “Wreck of the ship Eric the Red” by Jack Loney) The medal’s history, according to the Editor of ‘E-Sylum’ (the newsletter of The Numismatic Bibliomania Society “… appears to be an example of an 1880 State Department medal, catalogued as LS-3 (page 322 of R. W. Julian's book, Medals of the United States Mint: The First Century 1792-1892). The reverse is mostly blank for engraving, surrounded by a thin wreath. It was designed by George Morgan, chief engraver for the Philadelphia Mint, and struck in gold, silver and bronze. The one pictured here (in The Standard newspaper, 2nd July 2013) appears to be silver.” The following is an account of the events which led to the awarding of this medal. The American ship Eric the Red was a wooden, three-masted clipper ship. She had 1,580 tons register and was the largest full-rigged ship built at Bath, Maine, USA in 1871. She was built and registered by Arthur Sewall, later to become the partnership E. & A. Sewall, the 51st ship built by this company. The annually-published List of Merchant Vessels of the U.S. shows Bath was still the home port of Eric the Red in 1880. The vessel was named after the Viking discoverer, Eric ‘the Red-haired’ Thorvaldsson, who was the first European to reach the shores of North America (in 980AD). The ship Eric the Red at first traded in coal between America and Britain, and later traded in guano nitrates from South America. In 1879 she was re-metalled and was in first-class condition. On 10th June 1880 (some records say 12th June) Eric the Red departed New York for Melbourne and then Sydney. She had been commissioned by American trade representatives to carry a special cargo of 500 exhibits (1400 tons) – about a quarter to a third of America’s total exhibits - for the U.S.A. pavilion at Melbourne’s first International Exhibition. The exhibits included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, samples of corn and the choicest of leaf tobacco. Other general cargo included merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The Eric the Red left New York under the command of Captain Zaccheus Allen (or some records say Captain Jacques Allen) and 24 other crew including the owner’s son third mate Ned Sewall. There were also 2 saloon passengers on board. The ship had been sailing for an uneventful 85 days and the voyage was almost at its end. As Eric the Red approached Cape Otway there was a moderate north-west wind and a hazy and overcast atmosphere. On 4th September 1880 at about 1:30 am Captain Allen sighted the Cape Otway light and was keeping the ship 5-6 miles offshore to stay clear of the hazardous Otway Reef. However, he had badly misjudged his position. The ship hit the Otway Reef about 2 miles out to sea, southwest of the Cape Otway light station. Captain Allen ordered the wheel to be put ‘hard up’ thinking that she might float off the reef. The sea knocked the helmsman away from the wheel, broke the wheel ropes and carried away the rudder. The lifeboats were swamped, the mizzenmast fell, with all of its riggings, then the mainmast also fell and the ship broke in two. Some said that the passenger Vaughan, who was travelling for his health and not very strong, was washed overboard and never seen again. The ship started breaking up. The forward house came adrift with three of the crew on it as well as a longboat, which the men succeeded in launching and keeping afloat by continually bailing with their sea boots. The captain, the third mate (the owner’s son) and others clung to the mizzenmast in the sea. Then the owner’s son was washed away off the mast. Within 10 minutes the rest of the ship was in pieces, completely wrecked, with cargo and wreckage floating in the sea. The captain encouraged the second mate to swim with him to the deckhouse where there were other crew but the second mate wouldn’t go with him. Eventually, the Captain made it to the deckhouse and the men pulled him up. At about 4:30 am the group of men on the deckhouse saw the lights of a steamer and called for help. At the same time, they noticed the second mate and the other man had drifted nearby, still on the spur, and pulled them both onto the wreck. The coastal steamer SS Dawn was returning to Warrnambool from Melbourne, and its sailing time was different to its usual schedule. She was built in 1876 and bought by the Portland and Belfast Steam Navigation Co. in 1877. At the time of this journey, she was commanded by Captain Jones and was sailing between Melbourne and Portland via Warrnambool. The provedore the Dawn, Benjamin Lear, heard cries of distress coming through the portholes of the saloon. He gave the alarm and the engines were stopped. Cries could be heard clearly, coming from the land. Captain Jones sent out crew in two boats and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from Eric the Red. Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight, the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much-needed clothing. Captain Allen was amongst the 23 battered and injured men who were rescued and later taken to Warrnambool for care. Warrnambool’s mayor and town clerk offered them all hospitality, the three badly injured men going to the hospital for care and others to the Olive Branch Hotel, then on to Melbourne. Captain Allen’s leg injury prevented him from going ashore so he and three other men travelled on the Dawn to Portland. They were met by the mayor who also treated them all with great kindness. Captain Allen took the train back to Melbourne then returned to America. Those saved were Captain Zaccheus Allen (or Jacques Allen), J. Darcy chief mate, James F. Lawrence second mate, Ned Sewall third mate and owner’s son, John French the cook, C. Nelson sail maker, Clarence W. New passenger, and able seamen Dickenson, J. Black, Denis White, C. Herbert, C. Thompson, A. Brooks, D. Wilson, J. Ellis, Q. Thompson, C. Newman, W. Paul, J. Davis, M. Horenleng, J. Ogduff, T. W. Drew, R. Richardson. Four men had lost their lives; three of them were crew (Gus Dahlgreen ship’s carpenter, H. Ackman steward, who drowned in his cabin, and George Silver seaman) and one a passenger (J. B. Vaughan). The body of one of them had been found washed up at Cape Otway and was later buried in the lighthouse cemetery; another body was seen on an inaccessible ledge. Twelve months later the second mate James F. Lawrence, from Nova Scotia passed away in the Warrnambool district; an obituary was displayed in the local paper. Neither the ship nor its cargo was insured. The ship was worth about £15,000 and the cargo was reportedly worth £40,000; only about £2,000 worth had been recovered. Cargo and wreckage washed up at Apollo Bay, Peterborough, Port Campbell, Western Port and according to some reports, even as far away as the beaches of New Zealand. The day after the wreck the government steamship Pharos was sent from Queenscliff to clear the shipping lanes of debris that could be a danger to ships. The large midship deckhouse of the ship was found floating in a calm sea near Henty Reef. Items such as an American chair, a ladder and a nest of boxes were all on top of the deckhouse. As it was so large and could cause danger to passing ships, Captain Payne had the deckhouse towed towards the shore just beyond Apollo Bay. Between Apollo Bay and Blanket Bay, the captain and crew of Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag-board bearing the words “Eric the Red” was found on the deckhouse; finally, those on board the Pharos had the name of the wrecked vessel. During this operation, Pharos came across the government steamer Victoria and also a steamer S.S. Otway, both of which were picking up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated onto Point Franklin. Some of the vessels' yards and portions of her masts were on shore. The pieces of canvas attached to the yards and masts confirmed that the vessel had been under sail. The beach there was piled with debris several feet high. There were many cases of Diamond Oil kerosene, labelled R. W. Cameron and Company, New York. There were also many large planks of red pine, portions of a small white boat and a large, well-used oar. Other items found ashore included sewing machines (some consigned to ‘Long and Co.”) and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire (some branded “T.S” and Co, Melbourne”), kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts, croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a fly wheel, a cooking stove, timber, boxes, pianos, organs and a ladder. (Wooden clothes pegs drifted in for many years). There seemed to be no personal luggage or clothing. The Pharos encountered a long line, about one and a half miles, of f locating wreckage about 10 miles off land, southeast of Cape Otway, and in some places about 40 feet wide. It seemed that more than half of it was from Eric the Red. The ship’s crew rescued 3 cases that were for the Melbourne Exhibition and other items from amongst the debris. There were also chairs, doors, musical instruments, washing boards, nests of trunks and flycatchers floating in the sea. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with a chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. (There is a photograph of a life belt on the verandah of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. This is rather a mystery as the ship was registered in Bath, Maine, USA.) Parts of the ship are on display at Bimbi Park Caravan Park and at Apollo Bay Museum. Flagstaff Hill Maritime Village also has part of the helm (steering wheel), a carved wooden sword (said to be the only remaining portion of the ship’s figurehead; further research is currently being carried out), a door, a metal rod, samples of wood and this medal awarded for the rescue of the crew. Much of the wreckage was recovered by the local residents before police and other authorities arrived at the scene. Looters went to great effort to salvage goods, being lowered down the high cliff faces to areas with little or no beach to collect items from the wreckage, their mates above watching out for dangerous waves. A Tasmanian newspaper reports on a court case in Stawell, Victoria, noting a man who was caught 2 months later selling tobacco from the wreckage of Eric the Red. Some of the silverware is still treasured by descendants of Mr Mackenzie who was given these items by officials for his help in securing the cargo. The gifts included silver coffee and teapots, half a dozen silver serviette rings and two sewing machines. A Mr G.W. Black has in his possession a medal and a purse that was awarded to his father, another Dawn crew member who was part of the rescue team. The medal is similarly inscribed and named “To John Black ….” (from “Shipwrecks” by Margaret E. Mackenzie, 3rd edition, published 1964). The wreck and cargo were sold to a Melbourne man who salvaged a quantity of high-quality tobacco and dental and surgical instruments. Timbers from the ship were salvaged and used in the construction of houses and shed around Apollo Bay, including a guest house, Milford House (since burnt down in bushfires), which had furniture, fittings and timber on the dining room floor from the ship. A 39.7-foot-long trading ketch, the Apollo, was also built from its timbers by Mr Burgess in 1883 and subsequently used in Tasmanian waters. It was the first attempt at shipbuilding in Apollo Bay. In 1881 a red light was installed about 300 feet above sea level at the base of the Cape Otway lighthouse to warn ships when they were too close to shore; It would not be visible unless a ship came within 3 miles from it. This has proved to be an effective warning. Nelson Johnson married Elizabeth Howard in 1881 and they had 10 children, the father of the medal’s donor being the youngest. They lived in 13 Tichbourne Place, South Melbourne, Victoria. Nelson died in 1922 in Fitzroy Victoria, age 66. In 1895 the owners of the S.S. Dawn, the Portland and Belfast Steam Navigation Co., wound up and sold out to the Belfast Company who took over the Dawn for one year before selling her to Howard Smith. She was condemned and sunk in Suva in 1928. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn". The medal for bravery is associated with the ship the “The Eric the Red which is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA) This medal was awarded to Nelson Johnson by the U.S. President for bravery in the rescue of the Eric the Red crew. The obverse of the round, solid silver medal has an inscription around the rim. In the centre of the medal is the head of Liberty to the left, hair in a bun, with a sprig of leaves in the top left of a band around her head. There is a 6-pointed star below the portrait, between the start and end of the inscription. There are two raised areas on the rim, horizontally opposite each other, from the edge to just below the lettering and coinciding with the holes drilled in the edge. Slightly right of the top is a round indentation in the rim. The reverse has a wreath of leaves as a border, joined at the bottom by a ribbon bow. In the centre of the medal is an inscription, decorated with 3-pronged design and dots. The edge is plain with 2 small, rough and uneven holes horizontally opposite to each other, as though they had been used for mounting the medal at some stage. The medal has a matte finish on both sides and is slightly pitted and scratched.“PRESENTED BY THE PRESIDENT OF THE UNITED STATES” around the perimeter of the obverse of the medal. “TO / Nelson Johnson, / seaman of the British, / str “Dawn”, for bravery, / at risk of life, / in / rescuing the crew of / the American Ship / “Eric the Red.” “M” on obverse, truncation of the portraitwarrnambool, flagstaff hill, flagstaff hill maritime village, maritime museum, shipwreck coast, great ocean road, shipwreck artefact, eric the red, zaccheus allen, sewall, 1880, melbourne exhibition, cape otway, otway reef, victorian shipwreck, medal, nelson johnson, neils frederick yohnson, s.s. dawn, george morgan, hero -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Cutty Sark vessel and exhibition, Greenwich, England, wood carving, 06/11/2016

The Cutty Sark was launched on 22 November 1869. She was named by the wife of George Moodie, the ship's first master who had also supervised her construction. Cutty Sark left the Clyde on 13 January 1870. A month and two days later, she set sail from London for China. Cutty sark was designed and built by Scott & Linton of Dumbarton for 16,150 pounds. But much of the money was to be paid by Willis when the ship was launched. Just before they finished her, Scott & Linton ran out of money and went bankrupt. She was completed by William Denny & Brothers. The Cutty Sark was the first ship to reach London with a tea cargo in 1877. But she was one of only nine sailing ships that returned that year - in 1870 there had been 59. Steamships were now dominating the tea trade. In 1883 the Cutty Sark joined the booming trade in transporting Australian wool. Every year until 1895 she set out in the summer for Australia, to load a cargo of wool bales and return to England in time for the wool sales ini the first three months of the new year. Cutty Sark soon established herself as the fastest of the wool clippers. Under her last master, Richard Woodget she set record times of 70 days or less for the voyage which no other sailing ships could match.Wood carving from the Cutty Sark vessel and exhibition, Greenwich, England.cutty sark, exhibition, wool, australia, sailing, woodget, moodie, london, willis, dumbarton, scott & linton, william denny, tea, cargo, immigration, trade -

Flagstaff Hill Maritime Museum and Village

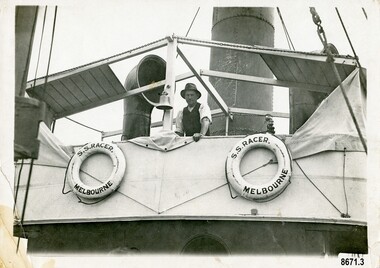

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Steam tug "Racer", circa 1920's

The ocean Steamtug "Racer" was built in 1886 in Sunderland by "Boolds, Sharer and Company" for the "Queenstown Tug and Shipping Company". It is mentioned in several newspapers that soon afterwards it sank in Queenstown Harbour, Ireland and remained submerged for six months before being raised. It was a steel screw boat with a sluice keel, was 185 tons and 420 feet long. It was purchased around 1889 by the "Melbourne Coal, Shipping and Engineering Company Ltd" as it had sufficient power to work with the huge iron clippers that the company were dealing with. It survived several dangerous incidents on its voyage out to Melbourne. On May 28th in the middle of the night in a heavy gale, the tug was swamped by heavy seas and then several hours later was almost run down by a very large ship (the clipper Loch Vennachar) in full sail. The "Racer" (later owned by the "Melbourne Steamship Company") became one of the fastest and best-known tugs in the Port of Melbourne - working in the port until 1935. The "Racer" was involved in many rescues and dangerous incidents during its 45 years including the attempted rescue of the "Craigburn" near Cape Schanck, the rescue of the "Edina" from a reef near Williamstown and the rescue of the "Netherby" from heavy seas near Inverloch. In March 1930 she was caught by a strong wind when turning in the Yarra River and crashed into the Spencer Street Bridge - resulting in some damage to the scaffolding on the bridge and slight damage to the tug. In 1906 the "Racer" created a record for the fastest tow when it towed the 900-ton barque "Elizabeth Graham" from Sydney to Melbourne in 73 hours. In 1934 it was withdrawn from commission with plans for it to be broken up for scrap metal but was bought by a Melbourne businessman to be converted into a three masted schooner trading between Tasmania and Melbourne. George (Joe) Cunningham was born in 1892 in Geelong. His father, Alexander Cunningham was a ship builder and carpenter. George worked on oceangoing ships as a young man but after his marriage, had a twenty-six year career on Tugboats. He worked as a deckhand on the "Racer" and then worked his way up as a mate and then master on the "Maitland" and "Tooronga". Later he was in charge of two larger boats - the "Alvina" and "Helen Moore" and was engaged in salvaging the Union Steamship vessel "Karkariki" near Gellibrand Pile Light at the entrance to Hobsons Bay. George Cunningham died in 1978. This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool.This item is significant as a reminder of the important role tugboats and their crews played in the maritime history of Melbourne and the surrounding seas. This is a close-up view of a tugboat showing a man leaning against the upper deck. Two lifebuoys (with the words S. S. Racer Melbourne) are attached to the side of the deck and a funnel and an airvent are in the background. A handwritten note in pencil saying "Geo Cunningham on board Racer "is on the back of the photograph.Back - "Geo Cunningham on board Racer" Front (on lifebuoys) - S. S. RACER MELBOURNEflagstaff hill maritime museum and village, great ocean road, tugboats, steamtug boats, racer, george cunningham, port of melbourne, melbourne steamship company, rescues, craigburn, steamtug, edina, elizabeth graham, netherby, yarra river, ships, historic maritime photographs, boolds sharer and company, queenstown tug and shipping company, melbourne coal shipping and engineering company limited -

Flagstaff Hill Maritime Museum and Village

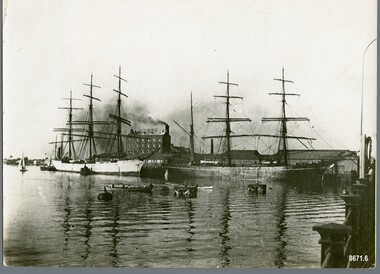

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels, Sailing Ships, Circa 1910 - 1913

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. There is some conflict re the identity of the ship in the foreground of this photograph. It has been identified as the "Dimsdale" by the original owner of this photograph and by the website "Photos of the Past" which have an identical copy of the photo, however the State Library of South Australia (who also have an identical copy of the photograph) have identified the date of the photograph as 1910 and the ship as the "Ainsdale". The "Dimsdale" and the "Lobo" were recorded several times in the local shipping news as being docked at the Port of Adelaide, at the same time, during the years 1912 and 1913, whereas the "Ainsdale" wasn't in Adelaide very often but was recorded as coming in and out of the Port of Adelaide in the years 1915 and 1916. On February 25th 1916, the two ships (the "Ainsdale" and "Lobo") were both in the Port of Adelaide at the same time, but the "Ainsdale" was loading at Outer Harbor and the "Lobo" was discharging timber at Corporation Wharf. The "Ainsdale" was owned by the same firm that had owned the "Dimsdale". The Dimsdale was a three masted steel ship built in 1890 by C. J. Bigger of Londonderry. It became notorious when it struck the Wonga Shoal lighthouse near Port Adelaide on the night of 17th November 1912, destroying the structure and killing two lighthouse keepers. The accident was investigated by the Marine Board, the Coroner, the Police Court, the Admiralty Court and by the Criminal Courts of South Australia where the Captain (John Jones) was charged with manslaughter and found "not guilty". The Dimsdale was sold to a Norwegian firm and its name was changed to "Kwango". It sank in 1915 near the Magdalen Islands in the Gulf of St. Lawrence. The "Lobo" was a well known "windjammer" trading from the Port of Adelaide to other parts of the world. For a number of years it was employed in the New Zealand and Tasmanian services, after which it made several voyages to North America. It was an iron barque of 945 tons, built at Sunderland in 1877 by Osbourne, Graham and Company. On October 18th 1916, the Lobo (owned by Walter and Morris, timber merchants) was on a voyage from Parapato (Mozambique) to New York with a cargo of mango bark and ebony, when it struck rocks and ran aground 30 miles east of the Angoche River in Portuguese East Africa. A detailed account of the incident, written by Mrs Murchison (the Captains wife who was on board with her two year old son) was published in the Adelaide newspaper "The Mail" on Saturday 9th December 1916. She, and several of the crew were put in a boat early in the morning and sent away from the wreck. Several hours later, they were joined by Captain Murchison and the remainder of the crew. They were in their small open boats for several hours before landing on a small uninhabited island where they remained for several days before being picked up by another vessel and taken back to Parapato. The captain was able to obtain a position on a steamer which took him and his wife and child back to England.This photograph is significant as a record of the world wide mercantile trade Australia was engaged in at the end of the nineteenth century and beginning of the twentieth century and as a record of the dangers faced by the crews of these ships.A black and white photograph showing two large sailing ships moored at a dock. There are industrial buildings in the background (one has smoke coming from its chimney) and several smaller craft (a rowing boat, two small boats that may be tugs and a little yacht) at the side of the ships. Pylons can be seen in the water and a metal fence is in the bottom right corner. On the back of the photo the words "Ship Dimsdale" and "Bk Lobo" are written diagonally across the top left corner in pencil. A beige paper label has been attached to the top right corner with the words "Dimsdale at Port Adelaide" and "Port Adelaide Historical Society may be interested" written in black ballpoint pen."Ship Dimsdale" / "Bk Lobo" ""Dimsdale" / at Port Adelaide" "- Port Adelaide Historical /Society may be / interested"warrnambool, dimsdale, lobo, barque lobo, port of adelaide, kwango, wonga shoal lighthouse, fred trewartha, ainsdale, frederick john fox trewartha, captain john jones, windjammer, iron barque, parapato -

Flagstaff Hill Maritime Museum and Village

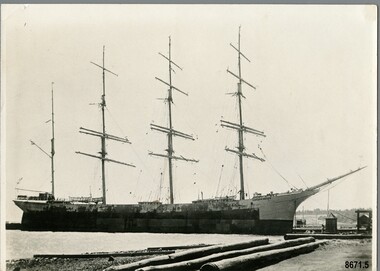

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel "Strathgryfe", late 19th or early 20th century

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. The "Strathgryfe" was a four masted steel barque built in 1890 by "Russell and Company", Port Glasgow and was owned by Duncan McGillivray (The Strathgryfe Ship Company Limited), Greenock. It arrived in Melbourne in December 1891 from New York. Between 1891 and 1910 it carried merchandise in and out of Australia to ports around the world - Melbourne to London (1892), Newcastle to San Francisco (1894), Capetown to Newcastle (1894), New York to Shanghai (1897), New York to Melbourne (1898), Frederickstadt to Melbourne (1899), Liverpool to Sydney (1900), San Francisco to Brisbane (1903), Newcastle to Pisagna, Chile (1905) and Rotterdam to Melbourne (1910). It carried breadstuffs from San Francisco, coal from Newcastle, wool from Sydney, saltpetre from Hamburg and wheat from Brisbane and Melbourne as well as a variety of general merchandise. In 1898, whilst on route between New York and Melbourne, it came across the Captain and crew of the missing barque "Glen Huntley" which had been reported as "lost" several months earlier. They had been marooned at Tristan D'Acunha (a remote group of volcanic islands in the South Atlantic ocean). Captain McIntyre, of the Strathgryfe, offered to bring Captain Shaw (of the Glen Huntly) on to Melbourne with them but the "old mariner" decided to stay on with his crew till arrangements could be made for rescuing the whole of them. In 1899, when in Melbourne, seven of its crew refused to go to sea in it due to its unsafe conditions. They said the vessel was unseaworthy and that the rigging was unsafe and the lifeboats, not watertight. The Captain (Donald McIntyre) denied the allegations and produced a marine surveyor's certificate as evidence of the condition of the vessel. The men were sentenced to three weeks imprisonment. In 1901 there was a fire on board the Strathgryfe just after it left Sydney for London which resulted in many bales of wool being destroyed. In 1902 it was beached at Shellback island (near Wilson's promontory) for several weeks and had to be considerably dismantled in order to lighten its load enough to allow tugs to pull it back into deep water. In 1910 it was sold to a German firm and renamed "Margretha". It continued to operate in Australian ports until 1914 when it left Sydney for the English Channel with 42,438 bags of wheat. However owing to W.W.1 breaking out, it made for the port of St Michael's where it remained for twenty-one months. Later it was seized by the Portuguese Government and renamed "Graciosa" and was leased back to the English Government. It was sunk by two German submarines in 1918.This photograph is significant as a record of the world wide mercantile trade Australia was engaged in at the end of the nineteenth century and beginning of the twentieth century.Black and white photograph of a four masted barque moored at a dock. The rigging and two lifeboats are clearly visible. Three large timber logs are in the foreground. On the back of the photograph, the donor's name and telephone number have been written in black ballpoint pen and the name of the ship has been handwritten (incorrectly) in pencil in cursive script.Back of Photo - donor's name and telephone number "Strarthgryfe" [Strathgryfe] / "late" / "Margurita" [Margretha]flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, strathgryfe, barque, steel barque, margretha, graciosa, frederick trewartha, mercantile trade, russell and company, merchandise, cargo ship, glen huntly, w. w. 1 -

Port of Echuca

Port of EchucaInstrument - Steering Wheel, PS Success, 1877

This steering wheel is from the PS Success. The PS Success was built in Moama in 1877 by GB Air for Westwood & Air. The Success towed barges of sawn red gum, wool & other cargo along the Darling and Murray Rivers as well as running as a passenger boat from Swan Hill to Mildura during 1915-16. The Success ended her working life in 1957 and was put up on the bank at Neds Corner, 80kms west of Mildura. The PS Success was donated to the Riverboat Historical and Preservation Society of Mildura with plans for full restoration but with funds becoming extremely difficult to secure, the Shire of Campaspe was approached to take ownership in 2009 to enable further restoration when possible. The Riverboat Preservation Society also donated this original steering wheel.The PS Success was an important vessel built in the Echuca area during the height of the Riverboat trade in the 1870s. She had a long, colourful history towing barges on the Murray River and in particular in the Mildura, Wentworth and Ned's Corner regions. Importantly, the Success was the last paddlesteamer to be working on the river system right up until the 1956 floods rescuing sheep and wool. The steering wheel is an important original element of the PS Success and her hopes for restoration one day. Red metal steering wheel with 10 spokes sitting on a heavy iron wheel stand. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Vessel, Couta boat, Viator, 1890-1920

The historic Victorian ‘couta boat “Viator” was built by renowned boat builder J.R. Jones of Williamstown in Melbourne, between 1890 and 1920. He was one of the early builders of this design. The features of Viator - carvel planked, open cockpit, vertical stem and straight keel, single mast and a pivoting centreboard - are all characteristics of an early Bass Strait ‘couta boat. This has been confirmed by experienced Victorian ‘couta boat restorer Tim Phillips. Viator served as a ‘couta fishing boat in the Warrnambool area until the mid-1930s, then some say she served as a mail ferry across to Portland. Later it was used as a fishing and recreation boat for local families. For years Viator sat in a paddock in East Warrnambool until purchased in 1975 and donated to Flagstaff Hill. ‘COUTA BOATS - The ‘couta design for vessels is believed to have originated at Port Phillip, Victoria, for the purpose of the Barracouta (‘couta) fishing industry, being both fast and seaworthy. , The 'couta fish was an important food fish in Australian waters, supplying Melbourne with plenty of inexpensive fish. VIATORY’S OWNERS - Some of Viator’s history is known: - 1940, registered Port Fairy and owned by G.J. Richards. - 1941-1945, registered in Port Fairy and owned by Jens “Peter” Petersen. - 1950’s “Brusher” Richards of Warrnambool and Port Fairy used it for fishing. - Peter Watson and his son also went fishing in Viator. - Frank Ferrier, boat builder, was an owner (son of ‘La Bella’ hero, William Ferrier) - Arthur Rogers owned Viator too, then sold it to Terry Pridmore and Wayne Moorefield - The Viator was stored in a paddock, unused, in Fairmont Avenue, Warrnambool, where it was gradually deteriorating. - 1975 Viator was purchase at a very reasonable price from Pridmore, then donated to Flagstaff Hill Maritime Village. RESTORATION - Shipwright Erik Mikkelsen soon started restoration on the Viator after it arrived at Flagstaff Hill in 1975. In 2006 the Maritime Museums of Australia awarded a grant to Flagstaff Hill Maritime Village to assist with the restoration and renovation of the Viator. Its restoration continues today in the care of Flagstaff Hill’s boat builder. J R. JONES - boat builder The photograph of the EVA MYRL shows the builder J R Jones with his team of workers. The other photograph shows a vessel built by J R Jones' son, J B Jones of Footscray, and his team of boat boulders. The photograph of the EVA MYRL was taken by E. A. Dond---. The other photograph is of the Sturrock Coot, taken a Albert Park Lake in St Kilda.The Viator is the most significant boat in the Flagstaff Hill's fleet, being the last remaining local 'couta boat and one of few existing examples of this craft. Viator received Heritage status with the Australian Maritime Museums Council and is listed on the Australian Register of Historical Vessels in 2006 (ARHV Number: HV000561). Viator was built in Victoria in the early days by renowned boat builder J.R. Jones, and sailed by fishermen for many years, both local and on the coastal waters of Victoria, and was possibly used for the mail service. It is significant for being used for the fishing trade, for government service, perhaps as a mail boat, and for recreation by local families.Vessel, the ‘Viator’, an historic Victorian ‘couta boat, handmade by renowned boat builder This J.R. Jones 'couta boat, the Viator, was built in Williamstown, c.1890-1920. The single mast vessel has a Caravel hull built from New Zealand Kauri, blackwood, with a red gum keel and a jarrah stem and stern. It has a pivoting centreboard. Two photographs are included; one of the builder with his team, the other is of his son J B Jones, with his team. Marked "Viator" Photograph 1759.2: "E. A. Dond---" (indecipherable". Handwritten on back "Grandfather / J R Jones / Built" Photograph 1759.3; sign within photograph "J B JONES / BUILDER / FOOTSCRAY", stamped in the card, bottom right " ----- / MELBOURNE" and handwritten on the back "I think this is Mr Abel Sturrock Coot Albert Park Lake"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, arhv hv000561, arthur rogers, bass strait ‘couta boat, “brusher” richards of warrnambool and port fairy, clinker hull boat, ‘couta crafted boat c 1890-1905, ‘couta fishing boat, erik mikkelsen shipwright, g.j. richards of port fairy, jens “peter” petersen, john lindsay, old mail boat, pivoting centerboard boat, peter watson, single-masted ketch, terry prodmore and wayne moorefield, vessel viator, viator a historical vessel, victorian ‘couta boat, victorian barracoota boat, warrnambool ‘couta boat, western victoria fishing boat, western victoria mail boat, hv000561, australian register of historical vessels, erik mikkelsen, j b jones, j b jones boat builder, footscray, sturrock coot, sturrock, j r jones, j r jones boat builder, williamstown, eva myrl -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDocument - Menu, Bill of Fare ship Schomberg, circa 1855 - May 12 1856