Showing 627 items matching "last day"

-

Federation University Historical Collection

Federation University Historical CollectionNewspaper, Ballarat 150 Years: Supplement to the Ballarat Courier, 1988, 17/03/1988

A supplement to celebrate 150 since the establishment of the Port Phillip Colony (Victoria).40 page newspaper published to celebrate the Sesquicentenary of Ballarat. Articles include: 1838-the pastoral period begins; First White Settlers arrive (Anderson, Winter, Yuille, Kirkland, Learmonth); Learmonths - Pioneer Settlers; The Rush to Ballarat; Last of the Aborigines; Eureka Affair Gains New Importance; Mining-After the rush; SMB - First Technical School; Clubs Play their Part; Ballarat Yuilles had Wealthy Ancestors; Town, Country Share a Close Relationship; Many Sides to Metals Industry; True Victorian City; Five Severe Recessions; Financiers to the Fore; Ready for War; City Rich in Sport Facilities; Visitors to most exciting place; No Place for a Nervous Lady; Theatres Provide Welcome Diversion for Mines; Might Achievers Among famous Citizens; Life Seemed Different After the War; Ballarat School of Mines Eastern Station Hotel; Memorial (Her Majesty's) Last of Many Theatres; Art Gallery at its Best; Pilgrimage to Yuille Cairn at Sebastopol Images include: Jelbart tractor; Sunshine Harvester; Bailey's Mansion; Pennyweight Hotel; Bridge Mall; Blue Riband Mine, Black Hill, Burrumbeet Shooting party; A wendouree rowing club; Motor Cycle Racing; Women bowlers, Queen Elizabeth; Gong Gong Methodist Church; Arbour day at Waterloo Farm, Smythes Rd; Gold panners (1890s); Ballarat Cricket Team (1902); William Peart; D'Angri's store; Sturt St Advertisements include: Rehfisch and Co.; UFS Dispensaries; Deutscher Mower Sales and Service; Haymes Paint; Cincotta's; Abraham's Sportscene; McK's; McKay Macleod; St John of God Hospital; Benjamins Real Estate; Ballarat Water Board; Cornell's Pharmacy; Laminex Industries; Coltman Mitre 10; Lal Lal Iron Mine; Heinz Bros; Crockers; Frank ford travel; S.J. Weir; Ludbrook Plumbing Service; Mars; Robert Sim Building Supplies, Frank Day; Sectrol Systems; Thornton Richardsballarat, anniversary, sydney abraham, cincotta, eureka, ballarat school of mines, mining, ballarat club, lal lal iron mine, ballarat rangers, victorian rifles, 3rd battalion victorian rifles, ballarat militia, white flat, celia scott, adelphi theatre, victoria theatre, montezuma theatre, charlie napier, juliamatthews, royal theatre, dick richards, henry sutton, eleanor lucus, martin hosking, newington estate, saleyards, g. gay & co, ballarat books, old benev' alleviated distress on goldfields -

Federation University Historical Collection

Federation University Historical CollectionPlan, Sulieman Pasha Co Plan Transverse Section

The Sulieman Pasha is possibly named after the most important Sultan of the Ottoman Empire, Suleiman One, or Suleiman the Magnificent, when the Ottoman Empire was at its peak. Or potentially a number of Ottoman governors, statesmen and military commanders with the same name after, however the spelling is slightly different to the mine name. No Turkish connection was found relating to the formation of the company, and remains unconfirmed. The mine operated from two shafts; No. 1 near the corner of Humffray and Mair streets, and also near where the Welcome Nugget (2217 ounces) was found years earlier; and the controversial No. 2 shaft several blocks south bordering the northern side of the main highway through Ballarat. The company produced 62 666 ounces of gold, the twelfth highest quartz reef gold production for any mine on the Ballarat goldfield. Some crushing figure examples are January-June 1881: 3674 tonnes 1085 ounces; January-June 1885: 2949 tonnes 1281 ounces; July-December 1885: 4459 tonnes 1119 ounces; January-June 1887: 1869 tonnes 730 ounces; July-December 1892: 1450 tonnes 771 ounces; July-December 1896: 4365 tonnes 1372 ounces. Like many mines in the area, gold grades were low. John Watson was noted as mine manager in the 1880s, and John Williams 1890s. The company was re-organised twice increasing the number of shares from 4000 to 24 000, and increasing the capital available. The Sulieman Pasha Company was formed in 1878. David Fitzpatrick was given the honour of turning the first sod of both the No.1 and later No. 2 shafts. The first dividend was given to shareholders in July 1881. The company obtained a prospecting vote (government grant) to start, and was very proud to be the first Victorian gold mining company to pay the funds back to the government. The event was marked by a lavish banquet laid out for ministers and government officials by the company. Leases were purchased to the south in 1885 to the Llanberris Mine boundary, after poor results began accumulating from the small No. 1 shaft. To take advantage of this new land the company planned to sink a second shaft. Initially this was to take place on government land, but the uproar from nearby residents caused the company to purchase land along the Main Road (now Western Highway), and the old Yarrowee Hotel which had occupied the site since the alluvial digger days of the 1850's was demolished. The area had since those days become heavily occupied with a number of shops, houses, a post office, church and two schools in the immediate area. The thought of an underground mine next door drew considerable opposition. The company (before the days of public relations departments) wrote 'most people would have thought that progress as vital as mining would be supported by tradesmen whose business rely on the mining industry. It seems when it comes to mining they are bereft of their senses, and considering the low ebb of mining in Ballarat East, the action of our opponents are unaccountable. (Sarcastically) There are certain engineering difficulties in moving the quartz reefs to a new location, but if we could to appease our opponents we would'. The company also wanted to take over 4 acres of the St Paul's school oval for machinery, but accused the St Paul's Church of wanting extortionate amounts of money upfront, and on a yearly basis for the privilege. It stated the church could not be opposed to mining when several years earlier it had formed its own company to mine the land, only for shareholders to lose their money. In 1886, the company approached the Minister for Mines, and attended heated public meetings on the matter. The local residents, shop owners, and church submitted a 60 person petition to the local council and government authorities. They stated the shaft contravened the mining statutes, which stating no mining could take place within 150 yards of a public building or church. A speech by a resident stated 'mining always comes with glorious pictures of the great benefits which would accrue all parties concerned if their request is granted, but if property is destroyed or depreciated in value, no-one then comes forward and compensates them'. The No. 2 shaft was approved including taking over part of the school oval. In 1888, workers at the company's No. 2 shaft went on strike to try and bring their wages in line with other mines in the district (the No. 1 shaft was operated by tributers). William Madden (26) was killed from a fall of earth underground the same year, while a year later his father John Madden (70) was similarly killed in the Madame Berry Mine elsewhere in the district. In 1897 as the amount of gold being found fell away, it came to light part of the deal to purchase the Yarrowee Hotel site was a 5% royalty on gold found. Shareholders could not understand why they were paying a royalty to the former owners of the property. The mine closed in 1898 due to a lack of gold. In 1902 a boy (age unknown) called Charles Lee was killed from a fractured skull while working to dismantle the Sulieman Pasha plant. The fuss over the No. 2 shaft had a sequel. On the company winding up, the land was purchased by J.S. Trethowan who built a house next to the shaft. In 1907, the shaft caved-in creating a sinkhole immediately at the back of the house. A Mr Chamberlain heard a deep rumbling sound at 5am, and looked out the window to see his fowl house and thirteen chickens disappear down an expanding hole. He then went back to bed, and called the police later in the day. The shaft was 1050 feet deep, and the hole at the surface that developed was 20 feet by 17 feet across, and 20 feet depth. In 1930 it is reported a syndicate had been formed to clean out the old shaft, and re-open the mine. It is assumed this was the No. 1 shaft but no more was found. (https://www.mindat.org/loc-304239.html, accessed 07/08/2019) A transverse section plan of the Sulieman Pasha Mine.sulieman pasha company, plan, mining, united black hill mine, victoria united mine, victoria street, britannia united mine, last chance mine, llanberris mine, ottoman empire, john watson, john williams, david fitzpatrick -

Federation University Historical Collection

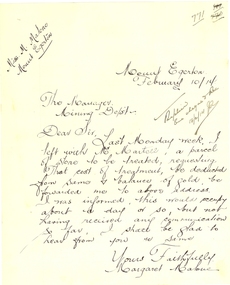

Federation University Historical CollectionLetter - Correspondence, Margaret Malone, Letter regarding gold assay from Mount Egerton Mine, 10/02/2014

Margaret Malone was associated with a kaolin mine at Mount Egerton. WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." (WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." (Adelaide Observer, 31 August 1929.)Hand written letter from Margaret Malone of the Mount Egerton Mine.Mount Egerton Mine February 10/14 The Manager Mining Dept Dear Sir, Last Monday week, I left with Mr Martell, a parcel of stone to be treated, requesting that cost of treatment, be deducted from some and balance of gold be forwarded me to above address. I was informed, this would occupy about a day or so, but not having received any communication so far, I shall be glad to hear from you are same. Yours faithfully Margaret Malonemargaret malone, female mine manager, kaolin, mount egerton, women -

Federation University Historical Collection

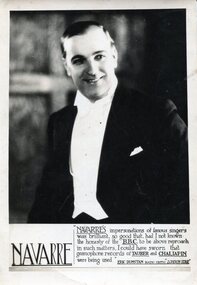

Federation University Historical CollectionPhotograph, Alexander Wright (Navarre)

Alexander Wright was born on 25 August, 1898 in Smeaton He was the brother of musician Frank Wright. Alex Wright was killed whilst performing at the Birmingham Empire as the result of a German air Attack in October 1940. The theatre had a direct hit. According to Frank Wright Alex was a great impersonator with a unique range Bass - tenor with many accents (not unlike Peter Dawson) "AUSTRALIAN CARUSO Smeaton Boy's Fame Andre Navarre, who left Australia about three years ago to study opera in Europe, bids fair to take a place among the world's great tenors. A few months ago Navarre sang for Melba for the first time, and she immediately acclaimed him to be a finished artist, describing his voice as the nearest approach to the immortal Caruso she had ever heard, writes the Ballarat "Courier." Andre Navarre is, however, only a stage name adopted by Alexander Wright, a son of Mr. and Mrs. William. Wright, of Armstrong street North, Ballarat, and brother of Mr. Frank Wright and Mrs. William Ritchie, of that city. Born at smeaton 31 years ago, in what may be termed a musical atmosphere; Alex. Wright showed a definite desire to sing at a very early age, and in his boyhood figured as soloist at school concerts, etc. His youth was spent around Smeaton, working at home and at various farms in the district until he was about 19 years of age, when he secured a position at the Dunlop rubber works, Melbourne. Up to this period Wright had no vocal training whatever, but being the possessor of a good resonant baritone voice, was persuaded by some of his friends to "have a go at the stage.'' Securing a position in the chorus of "Maid of the Mountains," which was at that time showing at the Theatre Royal, he soon made his voice heard to advantage, and also commenced to take lessons from Signor Robottaro. It was about this time that Wright was invited by a fellow musician to a musical evening at which a member of Rigo's grand opera company, then performing at " The Playhouse," was also present. Hearing Wright sing, the musician immediately said : ' You're a fool to waste your time in a chorus with that voice. Rigo is looking for a singer like you for the role of 'Figaro' in 'Barber of Seville'." Alex, however, did not take the remark seriously, and it was only after the numerous persuasions of friends who obviously knew the real value of his voice that the modest young man was eventually induced to meet Rigo. The Italian maestro was so delighted with the voice that without hesitation he was given the principle role of "The Barber" to study. Many singers having previously been tried and rejected for the part, Wright was astonished at his success in being chosen, and awakened suddenly to the fact by the maestro that a world voice, if properly trained, would surely develop in the young artist, Alex at once settled down to study, and all day long in his boarding house at St. Kilda could be heard rehearsing his new role. In less than a month he had completely mastered the part, and on the opening night, in the exacting role of "The Barber," he was an outstanding success. Later, he toured Australia with many leading artists, including Elsa Stralia and Harry Lauder, and spent his last two years in Sydney, where he was engaged as soloist in the biggest picture house. Realising that a training in Italy and on the Continent was essential for a successful operatic singer, the young artist decided to go overseas to continue his studies. He did not leave Australia, however, before he gratuitously gave a concert in his little home town to the obvious delight of all his old friends, who flocked from all parts of the district to hear him. The hall was packed to overflowing , and so pleased was Alex with the tumultuous reception he received that he sang fewer than 20 songs. Once in Italy, he lost no time in placing himself under the tuition of Cottone, and it was at the studio of this maestro that he met Toti dal Monte, a former protege of the same master. Two years were spent in Italy, when "Navarre" learned to speak the Italian language fluently, and acquired a wide knowledge of the operas. He sang in Milan about a year ago, and was paid some glowing tributes by the Italian Press critics, who likened his voice to that of Caruso. From Italy he went to Paris, where he met John Brownlee and many other famous singers. The critics on the Continent are unanimous that Andre Navarre-the unassuming Smeaton boy, whom his schoolmates still affectionately call "Hock"--is destined to become one of the luminaries in music history. It is interesting to recall some facts concerning the remarkable family from which this artist springs. Four other members have won championship honors in the musical world. Mr. Frank Wright has the Australasian cornet championship to his credit ; Mr. Norman Wright, of Sydney, has won a tenor championship of New Zealand, and has recorded for the Columbia Gramophone Company ; Mrs. Wm. Ritchie ( formerly Miss Laura Wright) won the A.N.A. contralto championship in Melbourne; whilst the oldest member, Lydia (Mrs. C. Cane, now in N.Z.) won the violin championship at South Street when 17 years of age. Last year Mrs. and Mr. Wright celebrated their golden wedding. Both of the old folk are intensely musical, and it has been said that the voice of the mother, although entirely untrained, showed in her earlier days glimpses of the beautiful quality which made Melba famous. Andre Navarre does not propose leaving the Continent for some time. Recently he was offered a 12 months' contract to sing in London for £2500 but on the advice of Melba and his coach, it was refused on the grounds that yet another 12 months' French study was necessary to ensure absolute perfection. That "Alex " has lost none of his school-boy wit is evinced by his own jocular remark that he has "a top C sharp that will crack every window in the Sydney Town Hall!" (Horsham Times, 20 February 1931) "AUSTRALIAN KILLED An Australian, Alexander Wright, radio variety star, who toured Europe and Australia under the pseudonym of Navarre, was killed during a recent air raid in a Midland . town. His broth-er, Frank Wright, is musical director for the London County council."(Border Morning Mail, 22 Oct 1940) Black and white image of Smeaton born Alexander Wright whose professional name was Navarre "Prince of Mimics". alexander wright, alec wright, navarre -

Federation University Historical Collection

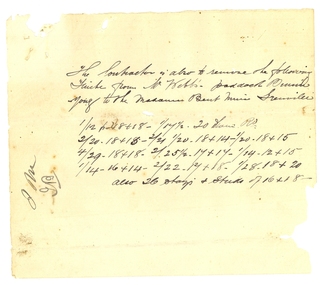

Federation University Historical CollectionDocument, Contract for the Madame Bent Gold Mining Company, 1886, 1886

Handwritten on foolscap paper, with red seal on last page.1) The Subcontractor is also to remove the following [ ? ] from Mr Webb's paddock ... to the Madame Bent Mine Grenville ... .2) Specification for the taking doan, removal and reerection 2 Engines 2 boilers pumping gear, Bob, Poppett heads and Capstone etc, for teh Mdame Bent G.M.Cy Grenville. The company will provide ... .3) Morey's Coys yard, together with holding down bolts, and the following ... .4) to the extent of Bed ... Carpentry Work - To carefully take down the poppet heads and co... and erect the same on the claim complete ... .5) Engine Framing as shown for the winding engines and pumping engines. Properly fitted to get ... .6) The boilers to be fed in front. The contractor to cut and drill all necessary holes in the boilers and pipes - to fire blow ... The contractor to make good any damage or breakage or loss to machinery or any part hereof that may occur to it during the removal of the reerection of same. The loss or damage, if any, not being made good by the contractor, or in the event of the works not being proceeded with to the satisfaction of the Company;s Engineer, The company's Engineer hereby ... .7) of the whole of the works, and in default thereof the COntractor shall forfeit the sum of two pounds ... Signed James Malcolm Witness L. Menz The Common seal of the company was affixed this thirteenth day of December:/86 by its manager James Burrell in the presence of [illegible] managers Seal - Madame Bent Gold Mining Company Durham Lead Buninyongmadame bent gold mining company, richard squire, james malcolm, james burrell -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour, Memorial to Francis Davis in the grounds of Federation University, SMB Campus, 2012, 20/09/2012

Francis Gordon Davis was born in Ballarat on 09 August 1899. He is the only former student of the Ballarat Junior Technical School who was killed on service during World War One. Davis enlisted into the Australian Flying Corps, Laverton, on 12 April 1918 at which time he was 18 and 8 months and served as a second class Air Mechanic. His service number was 3310. He died accidentally from shock resulting from an accident resulting from skidding a Leyland Motor Lorry at Leighterton, Tetbury, Gloucester, England on 28 January 1919 and is buried in Grave 6 in the Soldiers Corner of the Leighterton Cemetery. Francis Davis was accorded a full military funeral, firing party, bugler and pallbearers. The coffin was draped in the Union Jack and surmounted in several beautiful wreathes sent from his brother 2/A.M. E.H. Davis (A.F.C Leighterton), officer of the A.F.C. Leighterton, Gloucester, Cadets of A.F.C. and many other personal friends of the deceased. The "Last Post" was sounded at the graveside, and the Rev. Major K.D. Norman C. of E. A.I.F. officiated. The grave was to be turfed and an oak cross erected by the A.I.F. London. Administrative Headquarters A.I.F. London were represented at the funeral. (http://bih/index.php/Francis_G._Davis) In June 1922 Alfred Davis, the father of Francis Davis, planted a tree in the grounds of the Ballarat Junior Technical School in honour of hos son. It was the first tree of six planted in the grounds of the Ballarat School of Mines on Arbor Day 1922. Speaking of the planting of the tree by Mr Davis the Chief Secretary (Mr M. Baird M.L.A.), said he trusted the memory would ever remain green at the school. Had he and others not given their lives nothing that we could have done to-day could have retrieved the time. Australians had indeed done splendidly, but they should take a wider outlook than Australia, and reading the history of the Genoa Conference he had been struck by what had been done ... We should honor such men as he in whose memory that tree was planted, and the schools that sent them out to fight for us. He hoped the empire would always be able to produce such men, so that the Empire would always be able to lead the World's struggle for the benefit of humanity. The last post was then sounded by Mr. H. Green. ... (Ballarat Courier, 19 June 1922)A number of photographs of a tree and marble plaque in the grounds of the Ballarat School of Mines. It was a memorial to Francis Davis, a former student of the Ballarat Junior Technical School, who died on active service during World War One.ballarat school of mines, ballarat junior secondary school, world war one, memorial, marble plaque, marble memorial, tree, memorial tree, davis, francis davis -

Flagstaff Hill Maritime Museum and Village

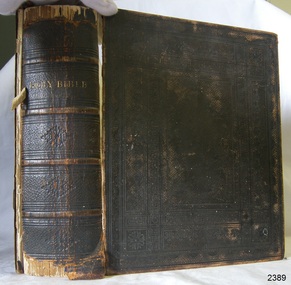

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Holy Bible, 1866

This King James version of the Holy Bible, with Old and New Testaments, was published in 1866 in London. The large Bible contains family records of Joseph Bell (born 9-5-1829) and Elizabeth Bell (born 22-101833). Joseph and Elizabeth Bell were married on 12-09-1854 in St Paul's church, in Bristol, England. The loose endpaper within the Bible is headed 'Singleton, 2nd day of 1st month 1869" It records their marriage and the birth of their ten children. between 1856 and 1878. It appears that the entries up until their 8th child were written at the same time, 2nd January 1869, with the last two entries for children number 9 and 10, written at a later date. This fits with the Bible being published in 1866. The children were Thomas, Mary, James, John, Ruth, Andrew, Joseph, Elizabeth, Lewis and Hannah. Further research is being carried out to connect this branch of the Bell family with local history.The Holy Bible is significant for being published over 150 years ago when printed books were very expensive. The book contains handwritten records of the Bell family of Bristol and is a significant source of the Bell family history. Book, black hard cover with embossed pattern and gold test, metal locking clasp. King James Version of the Holy Bible, containing the Old and New Testaments. It was published by Oxford University Press in 1866. Inscriptions on the loose endpaper list the marriage of Joseph and Elizabeth Bell in 1854 at St Paul's, Bristol, England, and their ten children born from 1856 to 1878.Spine: "HOLY BIBLE" Fly: "THE HOLY BIBLE CONTAINING THE OLD AND NEW TESTAMENTS: TRANSLATED OUT OF THE ORIGINAL TONGUES:: AND WITH THE FORMER TRANSLATIONS DILIGENTLY COMPARED AND REVISED, BY HIS MAJESTY'S SPECIAL COMMAND" "APPOINTED TO BE READ IN CHURCHES" "OXFORD: PRINTED AT THE UNIVERSITY PRESS FOR THE BRITISH AND FOREIGN BIBLE SOCIETY, INSTITUTED IN LONDON IN THE YEAR 1804." "SOLD TO SUBSCRIBERS AT THE SOCIETY'S HOUSE, EARL STREET, BLACKFRIARS, LONDON." "MDCCCLXVI" (converts from Roman Numerals to the number 1866) LOGO with a motto: [shield with scroll, three crowns and test] "dominus illuminatio mea" (Latin, translates to "The Lord is My Light") On endpapers: Heading in script: "Singleton 2nd day of 1st month 1869" and listed below " Joseph Bell, born 9/5/1829 married Elizabeth Bell, born 22/10/1833 on 12/9/1854 at St Pauls, Bristol, England." (Numbered 1 to 10, their children and their birth dates, from 1856 to 1878, are also listed. The children were Thomas, Mary, James, John, Ruth, Andrew, Joseph, Elizabeth, Lewis and Hannah.) flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, holy bible, book, religious book, bell family, bell family bible, elizabeth bell, joseph bell, 1826, 1833, 1854, st paul's bristol -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Loch Torridon, Early 20th century

The Loch Torridon was built in response to the need for a large cargo-carrying ship in the 1870s becoming famous for being one of the most per4fect four-masted barques ever built. She was built for the Loch Line in 1880 by Messrs. Barclay, Curle, and Co. Her measurements were 287 feet in length and 42 feet in beam, and 24 feet depth of hold. She was well sparred and her sail plan was so perfectly balanced that she was a very handy ship, easy on her helm, which was not a common virtue amongst large four-masted ships of her day. Her sails were interchangeable on all three masts, which was common in the last days of sail for both economical and practical purposes. The Loch Torridon was considered one of the most graceful and elegant ships ever launched from the Glasgow shipyards. The first master was Captain Pinder, the first cargo was bound for Melbourne Australia, after which she went on to Calcutta with a cargo of horses. On August the 22nd 1882 with a cargo of Jute onboard loaded in Calcutta the Loch Torridon ran into a storm. Sailing in heavy seas the captain, the second mate also the man at the wheel, and a boy was washed overboard with the first mate just escaping the same fate. Captain Pinder and the crew members could not be rescued and were never seen again with the first mate having to bring the ship home. The next Captain was Robert Pattman who was regarded as a fine navigator and seaman who sailed the Loch Torridon for the next twenty-six years and nine months. He had made 25 voyages around the world during this time without any serious mishap. In 1909 Captain Pattman resigned his command of the ship to switch to a steam vessel but unfortunately was injured on his first voyage and had to be landed at Falmouth, he dies of his injuries shortly afterwards. The Loch Torridon kept on sailing until 1915 after having been sold to a Russian company two years earlier. Near the end of January 1915, the ship sprang a leak of the west coast of Ireland and was abandoned sinking shortly afterwards. For further information regards possible maker of the model see Provenance sec this document: The item is of significance as an item made possibly by a man who served on the original ship making the item of historical significance given that the original craft was a well-known and respected trade vessel making voyages between England and Australia as well as the near East. Ship model Loch Torridon 4 masted, hull is black, grey and white. Ship in full sail with 4 lifeboats on deck. Ship sits on textured base. Has plain blue background. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Net Floats, 20th century

These net floats are handmade from lightweight cork wood and are used for suspending fishing nets in the water. Newspaper articles dated from 1848 to 1916 mention net fishing in Warrnambool's Hopkins and Merri rivers and Lady Bay. The Melbourne Argus dated January 11, 1848, published a quote from Captain Theobald of the vessels ELLEN and ELIZABETH, made on his first visit to Warrnambool "“…Fish are very plentiful here; on Christmas day a net was thrown into the Hopkins, and, after two or three draws, a boat load of beautiful fish was obtained…” The Argus, Melbourne, Sat. 29 May 1858, forwarded from The Examiner newspaper; "Extraordinary Fish. We have been presented with a very singular fish, caught by Mr. Meek in the Hopkins [Hopkins River, Warrnambool] last week. It is about three inches long, with a slate-coloured body, and a beautiful wing on each side. It was caught with other fish at night, in a net, and its eyes shone as bright as diamonds." A method for making cork net floats mentioned, in a 15th-century book, advised cutting the corks and then burning a hole through the centre of each one with a hot iron. The prepared corks were then joined together with a horsehair line. The cork's size and the line's thickness depended on the net's weight.The net floats are an example of fishing equipment used for many centuries and still in use today. In Warrnambool net fishing was a common practice from 1848 and became a livelihood for many fishermen. Net floats; cylindrical blocks of 16 corks threaded onto string with a hook-holding device at the end. warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, net floats, cork net floats, fishing, fisheries, fishing equipment, handmade, net fishing, fisheries act, andrew ferrier, william flett, warrnambool breakwater, merri river, hopkins river, captain theobald, ellen, elizabeth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Net Floats, 20th century

These net floats are handmade from lightweight cork wood and are used for suspending fishing nets in the water. Newspaper articles dated from 1848 to 1916 mention net fishing in Warrnambool's Hopkins and Merri rivers and Lady Bay. The Melbourne Argus dated January 11, 1848, published a quote from Captain Theobald of the vessels ELLEN and ELIZABETH, made on his first visit to Warrnambool "“…Fish are very plentiful here; on Christmas day a net was thrown into the Hopkins, and, after two or three draws, a boat load of beautiful fish was obtained…” The Argus, Melbourne, Sat. 29 May 1858, forwarded from The Examiner newspaper; "Extraordinary Fish. We have been presented with a very singular fish, caught by Mr. Meek in the Hopkins [Hopkins River, Warrnambool] last week. It is about three inches long, with a slate-coloured body, and a beautiful wing on each side. It was caught with other fish at night, in a net, and its eyes shone as bright as diamonds." A method for making cork net floats mentioned, in a 15th-century book, advised cutting the corks and then burning a hole through the centre of each one with a hot iron. The prepared corks were then joined together with a horsehair line. The cork's size and the line's thickness depended on the net's weight.The net floats are an example of fishing equipment used for many centuries and still in use today. In Warrnambool net fishing was a common practice from 1848 and became a livelihood for many fishermen.Net floats; cylindrical blocks of 18 corks of various sizes threaded onto string.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, net floats, cork net floats, fishing, fisheries, fishing equipment, handmade, net fishing, fisheries act, andrew ferrier, william flett, warrnambool breakwater, merri river, hopkins river, captain theobald, ellen, elizabeth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales, Thaddeus Fairbanks, 1880-1910

Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example circa 1900 of the first type of platform scales used in a grocery store. This design for accurately measuring goods that were sold over the counter revolutionised the weighing of goods throughout the world. Platform scale metal black with removable tray & pan. Has horizontal brass arm with a brass slide weight black removable weight hook and 2 x 2 lb. weights. Fairbanksflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGun, Mid 19th Century

Hollis Brothers were first recorded trading from 11 Weaman Row in 1840 but appear to have started trading a little earlier. The firm later became Isaac Hollis & Sons and claimed establishment from 1814. Richard & William Hollis were recorded trading in Bath Street Birmingham from 1814 to 1818 so it may be that the Hollis brothers were descended from them. The brothers were Isaac Hollis (b.1815) and Frederick Hollis (birth date unknown), but Frederick died 20 December 1839. Isaac was recorded in the 1841 census living in Weaman Row. He was a 25-year-old gun and pistol maker, married to Emma 1821. They had two children, Isaac (1837), and Henry (1839). After Frederick died, Isaac carried on trading under the name of Hollis Brothers until 1845 when he re-named the business Hollis Brothers & Co who traded up to 1848. In 1844 Isaac entered into a short term partnership with William Tranter at 10 & 11 Weaman Row, presumably to complete a particular contract or supply certain parts. This partnership lasted until 1849. In 1848 Isaac took in Isaac Brentnall Sheath as a partner, and the firm of Hollis & Sheath was established, expanding into 10 Weaman Row. Hollis & Sheath were licenced makers of percussion breech-loading guns. In 1861 the firm changed its name to Isaac Hollis & Sons on the departure of Isaac Brentnall Sheath. Isaac Sheath died in July 1875. By about 1870 Isaac Hollis and Henry Hollis had taken over the day to day running of the business. Isaac Hollis was responsible for the overall management and the marketing of the firm's products. Henry was responsible for manufacturing. The firm became volume producers of inexpensive trade guns and sporting guns for the South African and the British colonies. In 1870 the firm opened a shop at 44a Cannon Street in London; in 1871 this moved to 83 Cheapside. Isaac Hollis Jnr died October 1875 in Birmingham aged 37. He was never married and in 1876/1877 Henry registered a limited liability company, Isaac Hollis & Sons Ltd, but by 1879 they were again trading as Isaac Hollis & Sons. From 1879 the London shop was at 6 Great Winchester Street. From 1932 to 1933 the London business traded as Hollis, Bentley & Playfair Hollis, Bentley & Playfair finally closed in Birmingham in 1953. This gun is a typical example of the type of firearm issued to the colony's military in 1861. Specifically made by Isaac Hollis and Sons for the military market of the time and sold through contractors Hebbert & Sons, military suppliers, in London. The gun was probably issued from the Hythe Armory to British troops (a training facility) or police prior to coming to Tasmania Australia around 1861.Gun; Percussion Carbine, .577 Cal. Colonial Tasmanian issue Artillery carbine, Pattern 1861. Muzzle loading "Cap and Ball" musket. Wood stock and ram rod. Inscriptions are on the stock and breech. Gun was made for Herbert & Co. London by Isaac Hollis & Sons, Birmingham.Stamped on stock "SOLD 95", " ISAAC HOLLIS & SONS" "GUN & PISTOL MANUFACTURES" "BIRMINGHAM" "LASTON ARMOURER HYTHE" "MANUFACTURED EXPRESSLY FOR HEBBERT & CO LONDON". Stamped on breech "25", and "25C ---05"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, firearms, gun, muzzle loading musket, isaac hollis and son, hebbert & sons, military supplies, lee enfield -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTile, c 1914

This clay roof tile was part of the ANTARES cargo, a large consignment of tiles on its way to Melbourne. THE ANTARES In mid-November 1914, after the beginning of the First World War, a young local man went one evening to fish near the Bay of Islands, west of Peterborough. He later arrived home hurriedly and in an agitated state declaring: "The Germans are coming!" His family laughed and disbelieved him, as this young fellow was prone to telling fictional tales. About a month later, on December 13th 1914, local farmers Phillip Le Couteur and Peter Mathieson were riding in the vicinity, checking on cattle. Phillip Le Couteur saw what he “thought was the hull of a ship below the cliffs.” He rode to Allansford and contacted police. The next day, two Constables and Phillip Le Couteur returned to the site, where they dug a trench near the top of the cliff and sank a log in it. To this they attached a rope, which they threw down the cliff face. Constable Stainsbury and Phillip Le Couteur then made the dangerous descent down the rope on the sheer cliff face. They found wreckage strewn around a small cove and a portion of a man's body under the cliffs. The hull of the ship could be seen about 300 metres out to sea. Some of the wreckage revealed the name Antares and the remains of the ship's dinghy bore the name Sutlej. During the next two weeks and with the help of the Warrnambool lifeboat and crew, two more bodies were found. Later investigations proved that the tragic wreck was indeed that of the Antares, reported overdue on the 207th day of her voyage from Marseilles, France, to Melbourne. She was a three masted, 1749 ton iron clipper, built in Glasgow in 1888 and originally named and launched as the Sutlej. Bought in 1907 by Semider Bros. from Genoa, Italy, she was refitted and renamed Antares. It was later realised that the local lad who a month earlier had declared he had seen German guns being fired, had probably seen distress flares fired from the deck of the Antares the night she was wrecked. She was last sailed under Captain Gazedo and wrecked at what is now known as Antares Rock, near the Bay of Islands. She had been carrying a large cargo of roof tiles from France to Melbourne, consigned to Mullaly & Byrne. Many of them are now to be seen amongst the battered and scattered remains of the wreck. Some of the timbers were found to be blackened by fire. An Information Board has been erected on the cliff top near to the site of the Antares wreck, at the end of Radfords Rd, west of Peterborough. (Ref: Flagstaff Hill Maritime Village’s “Antares” fact sheet, Victorian Heritage Database, Information Board at Peterborough, Flagstaff Hill Significance Assessment 2010) The Antares was one of the last of the 'tall ships' to be lost along the south west coast of Victoria, and is the only wreck that took the lives of all people on board. She is listed on the Victorian Heritage Register VHS S34. The Antares is significant as a sail trader carrying an international inbound cargo. It is part of the Great Ocean Road Historic Shipwreck Trail. Piece of a clay roof tile recovered from the wreck of the Antares. Has a relief of a horse on back. Artefact Reg No A/7.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, antares, tall ship, peterborough, 1914 shipwreck, phillip le couteur, peter mathieson, constable stainsbury, sutlej, antares rock., bay of islands, clay tile, roofing tile, roof tile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin