Showing 501 items matching "wax"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySki Skins - Pair

Ski skins and webbing were introduced into the Victorian Alps by European skiers. Enthusiasts travelled to enjoy the snow and to explore the Victorian Alps including the Bogong High Plains. This equipment enabled them to travel over snow without slipping when going up hills. They took the skins off when they wanted to slide down hills. In later years waxes were used for cross country skiing and then 'fish tail' markings on the back of skis to enable skiers to travel distances up and down mountains. Later developments also included motor transport (replacing horses to get to the snow line) and roads to take skiers to the ski fields and mechanised tows to take skiers up mountains so they could ski down (downhill skiing).Skiers visited the Bogong High Plains especially during the years of the State Electricity Commission of Victoria's construction of the Kiewa Hydro Electric Scheme from the 1930's onwards. Tourists to the area increased during this time and influenced the development of Falls Creek.Long cream strips with soft short 'fur' on one side and a type of strong hessian on the back with the length of the middle and sides stitched. At one end an adjustable strap is attached to a steel, hinged clasp and at the other end is a loop that fits over the ski. A quarter of the way from each end is a steel attachment for fastening over the ski - the 'toe' end with a rubber embossed flap and the other with a short and long strap each with a steel ring at the end.On the rubber attachment: 'vinersa/pat uno'ski skins; bogong high plains; falls creek -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Brass Plate, Warrnambool Chamber of Commerce

The Chamber of commerce was commenced in Warrnambool in March 1888 to consider firstly what could be done to assist the dairy industry which at the time was facing record low prices for its butter. Co-operatives had been started in Gippsland around that time and it was decided to start co-operative dairy factories at Woodford, Panmure and Framlingham, shortly followed by the Warrnambool Butter and cheese factory at Allansford. The Chamber over the next thirty years covered many business issues such as trading hours, transport, and public holidays but also put forward ideas which related to water and sewerage matters.ideas were even put forward in 1907 regarding utilising the Hopkins Falls to generate power As an organisation it has waxed and waned in Warrnambool with various names but all working towards improving trade and business opportunities in the town. A link to one of Warrnambool's organisations which over the decades has worked to improve the prosperity of the townRectangular brass plate with text stamped and infilled with black.Six screw holes. Fine bevelled edge.Warrnambool Chamber of Commerce. Regd Office.warrnambool, warrnambool chamber of commerce, commerce in warrnambool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Leisure object - Dolls, Celluloid baby early 20thC, 20thC

When celluloid was invented and first came to prominence in the 1870s, dolls were nearly all breakable and fragile--bisque and china dolls were easily shattered and papier mache and wax easily ruined. So doll companies started experimenting with celluloid to mould dolls. By the early 1900s, celluloid dolls were plentiful, since celluloid was easily moulded and generally inexpensive. Celluloid is one of the first synthetic plastics. It is a plastic created from wood products that includes cellulose nitrate and camphor. However Celluloid is flammable and deteriorates easily if exposed to moisture, and can be prone to cracking and yellowing with certain formulations. Celluloid dolls were produced as late as the 1950s, but the vast majority were produced from 1900 through the 1940s. This doll is dressed in baby clothes.A celluloid doll dressed in baby clothes.celluloid, dolls, cotton, moorabbin, ormond, cheltenham, clothing -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Leisure object - Doll, boy in blue knitted suit, 20thC

When celluloid was invented and first came to prominence in the 1870s, dolls were nearly all breakable and fragile--bisque and china dolls were easily shattered and papier mache and wax easily ruined. So doll companies started experimenting with celluloid to mould dolls. By the early 1900s, celluloid dolls were plentiful, since celluloid was easily moulded and generally inexpensive. Celluloid is one of the first synthetic plastics. It is a plastic created from wood products that includes cellulose nitrate and camphor. However Celluloid is flammable and deteriorates easily if exposed to moisture, and can be prone to cracking and yellowing with certain formulations. Celluloid dolls were produced as late as the 1950s, but the vast majority were produced from 1900 through the 1940s. The knitted outfit was made by an unrecorded home knitter probably as a present for a child. A very small celluloid doll dressed as a boy in fine hand -knitted hat, vest, jacket and pants.celluloid, dolls, knitting, wool, craftwork, moorabbin, bentleigh, cheltenham, toys -

National Wool Museum

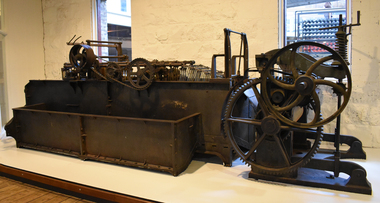

National Wool MuseumMachine - Scouring Bowl, J Dyson & Sons Pty Ltd, c.1890

Scouring is the process that removes wool wax and other unwanted products from wool. Wool is washed in a hot detergent solution. It moves through a series of scouring bowls and is then rinsed and dried. Careful handling and washing preserves the strength and softness of wool. If the wool contains lots of seeds and other vegetable matter, it must be cabonized. This means it is treated with a solution of sulpheric acid and then baked at high temperature to remove impurities. The disused scouring water left-over from this process was often let drain into rivers and watercourses causing pollution. Many of Geelong's wool scours along the Barwon River were closed due to environmental damage. The race system on this bowl is not the original it has been modified with a variation of the harrow system. Used at E.P. Robinson South Geelong from c.1890-1970.Scouring bowl.J. Dyson & Sons Pty Ltd, Geelongsouring bowl, j dyson & sons, geelong, wool processing, e. p. robinson, textile industry, factory, mill -

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

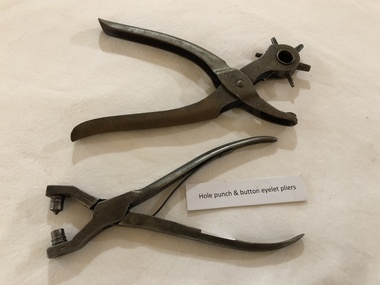

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

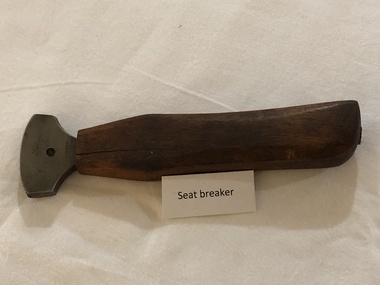

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Warrnambool and District Historical Society Inc.

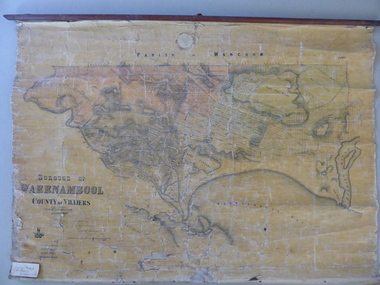

Warrnambool and District Historical Society Inc.Mao, Borough of Warrnambool, County of Villiers, 1873

This is an early map of the Borough of Warrnambool (1872/3) showing the central town area of Warrnambool and the surrounding district. Reserves, public buildings and some businesses are marked. The map was photolithographed by John Noone, a Melbourne artist and photographer who claimed in 1858 to have the oldest-existing photographic studio in Melbourne. Photolithography was a process first developed in Melbourne. For several years Noone was the official photographer for the Victorian Crown Lands Office and for the Victorian Public Library and Museum. The map has the stamp of the seller of the map – Charles Hider, the well-known stationer and bookseller in Timor Street, Warrnambool. The owner of the map, Henry George Marfell, (1883-1962) was the son of John and Mary Ann Marfell. The Marfells were well-known in Warrnambool as grain merchants and managers of the Warrnambool Co-Operative Milling Company. It is surmised from the writing on the Marfell label that this map was at some stage given by Henry Marfell to the old Warrnambool MuseumThis map of early Warrnambool is of considerable significance, firstly because its original state and early date (1873) make it of antiquarian and historical interest. Also the connection with the names, Charles Hider and Henry Marfell and the old Museum gives it added provenance and interest.This is a wax paper map mounted on cloth. At the top it is attached by nails to a piece of wood and at the top it has a cloth ring for hanging the map. The map is in black shadings on a yellow background. The map is badly creased and coming away from the cloth at the edges and at other various points. There is some red or pink marking or staining on the township area of the map (originally the sold lands on this map were coloured in brown and the reserves, buildings, etc in pink). On the left hand corner there is a piece of paper glued on with some handwriting in ink (Marfell). There is also the stamp of the seller of the map – Charles Hider, stationer and bookseller, of Timor Street Warrnambool‘Early Map of W’bool, H.G. Marfell’ history of warrnambool, charles hider, henry marfell -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomRifle Bucket

This type of rifle bucket was in use by the 4th Light Horse Regiment AIF in 1918. It was introduced into service following the Charge at Beersheba (Palestine, Oct. 31 1917) which lead to the introduction of the Cavalry sword to the Light Horse Brigades of the 1st AIF. The use of the cavalry sword required the riders arms to be free and this caused the relocation of the rifle from being slung on the rider's shoulder or carried in his right hand to being carried by the saddle. The Sword and the Rifle Bucket continued in use after WW1 by the 4th Corangamite Light Horse, the 17th Prince of Wales Light Horse Regiment and the 19th Yarrowee Light Horse Regiments in the 1920's and 1930's and possibly as late as 1941/42 prior to mechanisation and the demise of the use of the horse in combat. This item was designed to allow the rifle to be carried secured to the saddle and allow the right arm to be free to use the sword in combat. This Rifle bucket has had the mid strap replaced in service as evidenced by the use of 'black waxed, hand made thread', which was the type of stitching used by the Army on all saddlery and harness. On the rifle bucket, the makers name is usually stamped on this strap and the in service replacement of the strap explains why the maker's name is not present. The reinforcing leather at the lower edge of the bucket is unusual and judging by the colour of the leather it was added to the bucket by the regimental saddler as a repair probably at the same time as the mid section strap.None sightedrifle bucket, light horse, saddlery -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Roster, State Electricity Commission of Victoria (SECV), "Rotation Roster 3/70", Mar. 1970

Significant in being a roster rotation sheet that was issued following the reduction in services on the Ballarat system. Shows how the crews were organised and how the system worked for a whole year.Single sheet of off white duplicating paper titled "Rotation Roster 3/70". Printed by wax cut stencil or Gestetner method. Details the run number that an employee would do for a particular week and day of the week and the total hours mins worked that week. Has "LJD / 3/70", showing that Les Denmead authorised the roster. Was part of D. J. Everett papers. See also Reg. Item 2294 for 14/9/70 version of this document. 2293.1 - As above, but complete copy, no piece missing. Stored with a piece of archival photo backing board to aid use. Use with care.trams, tramways, ballarat, rosters, employees, shifts -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - List, Tramway Museum Society of Victoria (TMSV), "Notes on the disposal of Rolling Stock - Ballarat Tramways", 1972

Sheet prepared by the TMSV showing the details of the disposal or disposition of the tramcars from the Ballarat depot following closure of the system.Single page - foolscap size white coloured paper, printed using the Gestetner wax stencil process; titled "Notes on the disposal of Rolling Stock - Ballarat Tramways", published by the TMSV c1972 following closure of the system. Details the tramcar, who to, date left the depot and gives notes on the disposal etc. Prepared by Keith Kings. Second copy added 11/6/2016 with upgraded image - from the collection of Charles Craig. Note for the move of tram 18, the Courier has a photograph of the event published on 1/10/1971, was moved the previous day. See also Reg items 5444 and 6664 for other lists. ballarat, closure, tramcars, disposal -

Ballarat Tramway Museum

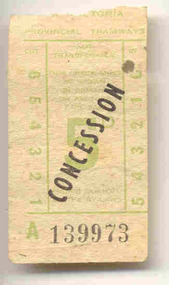

Ballarat Tramway MuseumEphemera - Ticket, State Electricity Commission of Victoria (SECV), Set of SEC predecimal tickets - Wal Jack Collection, 1963 - 1966

Yields information about the style and printing of tickets used in Ballarat tramways and how they were presented at the various times during the SEC control.One number - 1 No. - Paper SEC ticket - 5d in value, over stamped in black "Concession", (five pence) - green ink on off white paper, numbered A139973. The ticket price is in green ink while the ticket number itself is in black ink. On rear in green ink is a diagonal criss cross or tartan pattern. All tickets have been used. Not numbered on rear. All tickets and Reg Item 4006, 4007, 4009 to 4018 were received originally in a folded cloth wrapper - wax canvas? - see Reg item 4009. See Alan Bradley notes on SEC tickets. trams, tramways, secv, ticket, transfer tickets -

Ballarat Tramway Museum

Ballarat Tramway MuseumEphemera - Ticket, State Electricity Commission of Victoria (SECV), Set of SEC predecimal tickets - Wal Jack Collection, 1966

Yields information about the style and printing of tickets used in Ballarat tramways and how they were presented at the commencement of the SEC fare system. Generally issued c1966 following decimal currency, not formally used.Two number - 2 No. - Paper SEC ticket - 12c in value, (Twelve cents) - orange ink on off white paper, numbered A198304 and 305. The ticket price is in brown ink while the ticket number itself is in black ink. On rear in brown ink is a diagonal criss cross or tartan pattern. Tickets have not been used, torn complete from block. Have not been numbered on rear. All tickets and Reg Item 4006, 4007, 4009 to 4018 were received originally in a folded cloth wrapper - wax canvas? - see Reg item 4009. See Alan Bradley notes on SEC tickets. trams, tramways, secv, ticket, transfer tickets -

Ballarat Tramway Museum

Ballarat Tramway MuseumEphemera - Ticket, State Electricity Commission of Victoria (SECV), Set of SEC predecimal tickets - Wal Jack Collection, 1966

Yields information about the style and printing of tickets used in Ballarat tramways and how they were presented at the commencement of the SEC fare system. Generally issued c1966 following decimal currency, not formally used.Three number - 3 No. - Paper SEC ticket - 8c in value, (Eight cents) - green ink on off white paper, numbered B157289, 290 and 291. The ticket price is in green ink while the ticket number itself is in black ink. On rear in green ink is a diagonal criss cross or tartan pattern. Tickets have not been used, torn complete from block. Have not been numbered on rear. All tickets and Reg Item 4006, 4007, 4009 to 4018 were received originally in a folded cloth wrapper - wax canvas? - see Reg item 4009. See Alan Bradley notes on SEC tickets. trams, tramways, secv, ticket, transfer tickets